Sumake CS-32C User manual

Other Sumake Power Tools manuals

Sumake

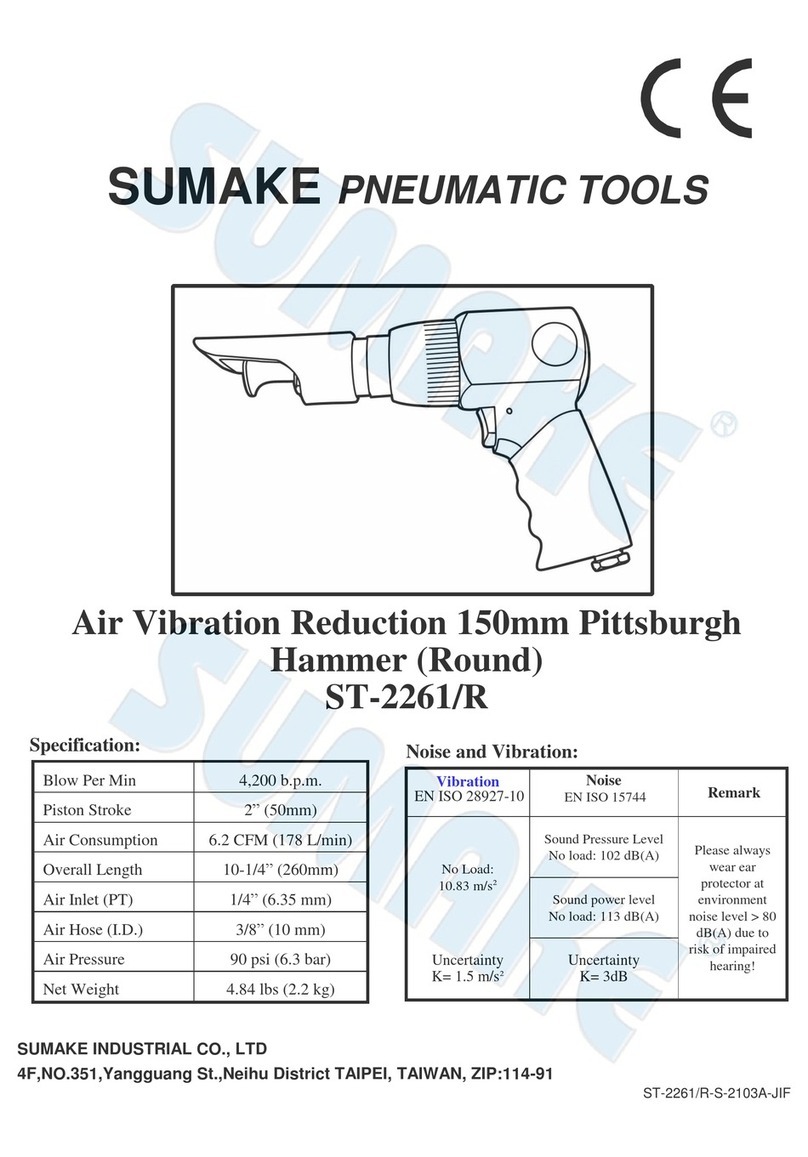

Sumake ST-2261 User manual

Sumake

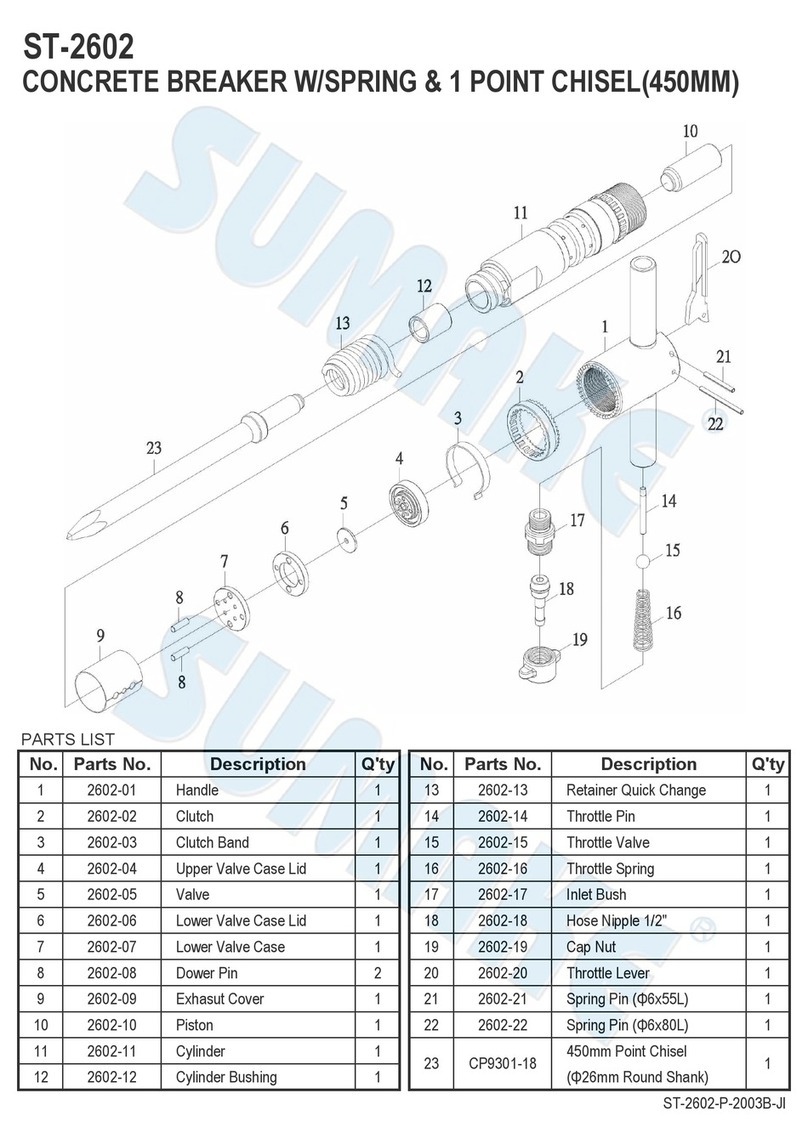

Sumake ST-2602 User manual

Sumake

Sumake ST-6676 User manual

Sumake

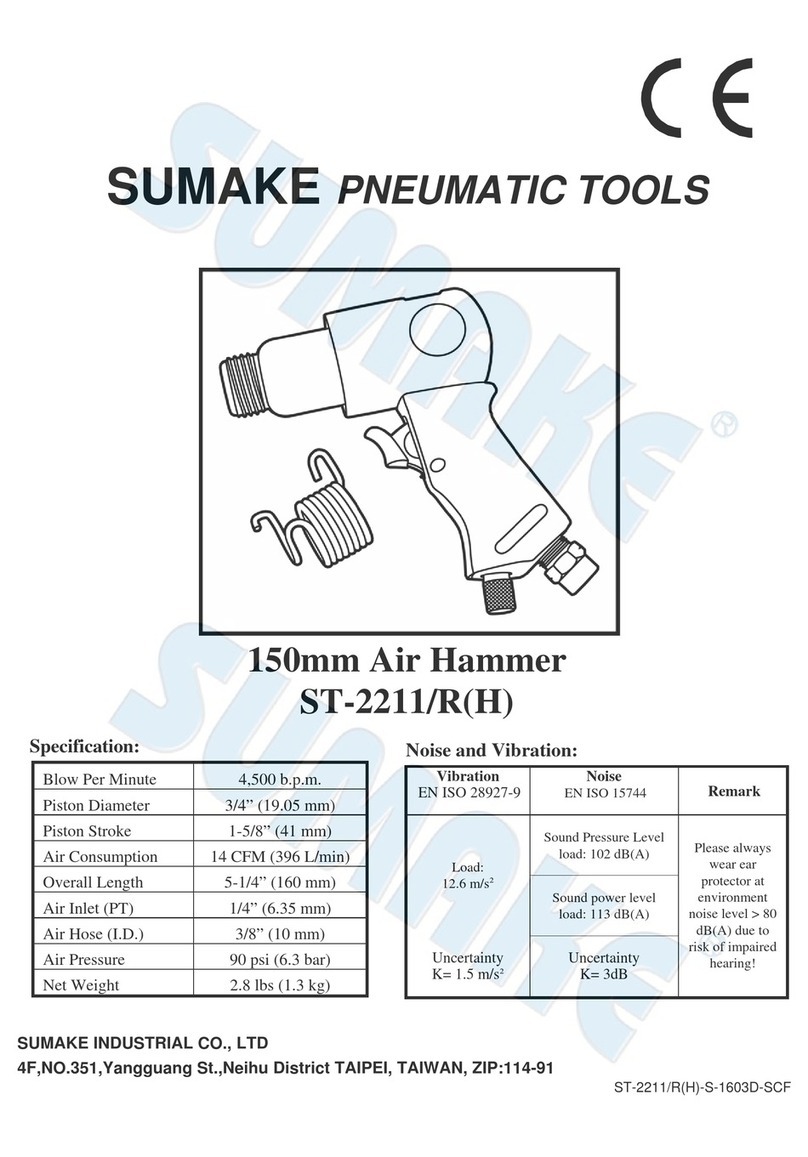

Sumake ST-2211 User manual

Sumake

Sumake FAW060 User manual

Sumake

Sumake ST-2210 User manual

Sumake

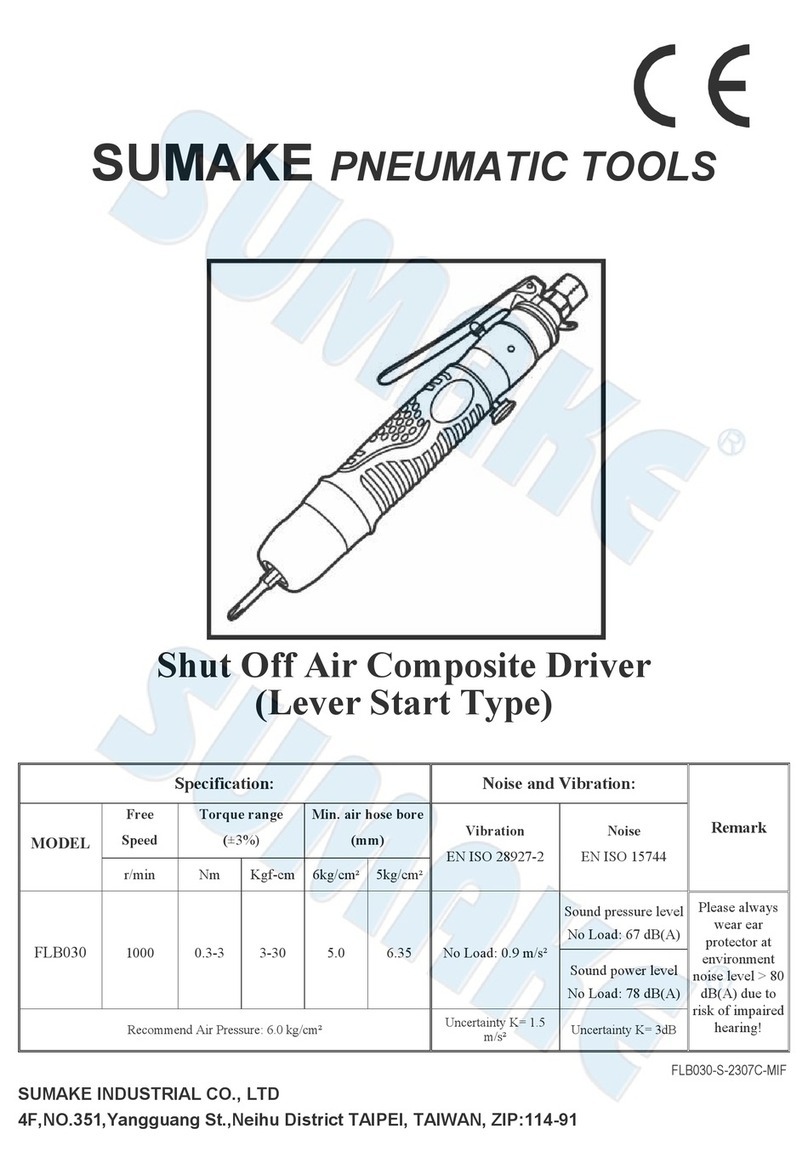

Sumake FLB030 User manual

Sumake

Sumake S Series User manual

Sumake

Sumake ST-M5032H User manual

Sumake

Sumake EMS-B1450 User manual

Sumake

Sumake ST-2310 User manual

Sumake

Sumake ST-2248SR User manual

Sumake

Sumake ST-5555C User manual

Sumake

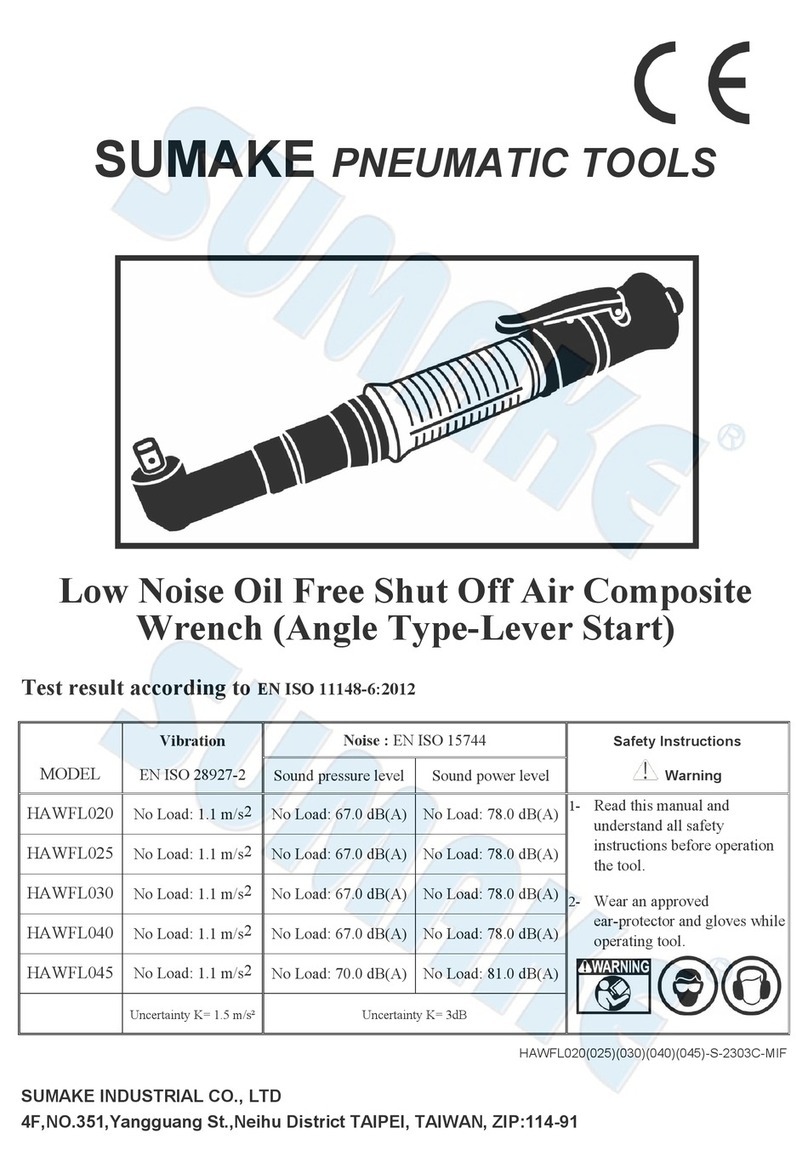

Sumake 020 User manual

Sumake

Sumake ST-3310PF User manual

Sumake

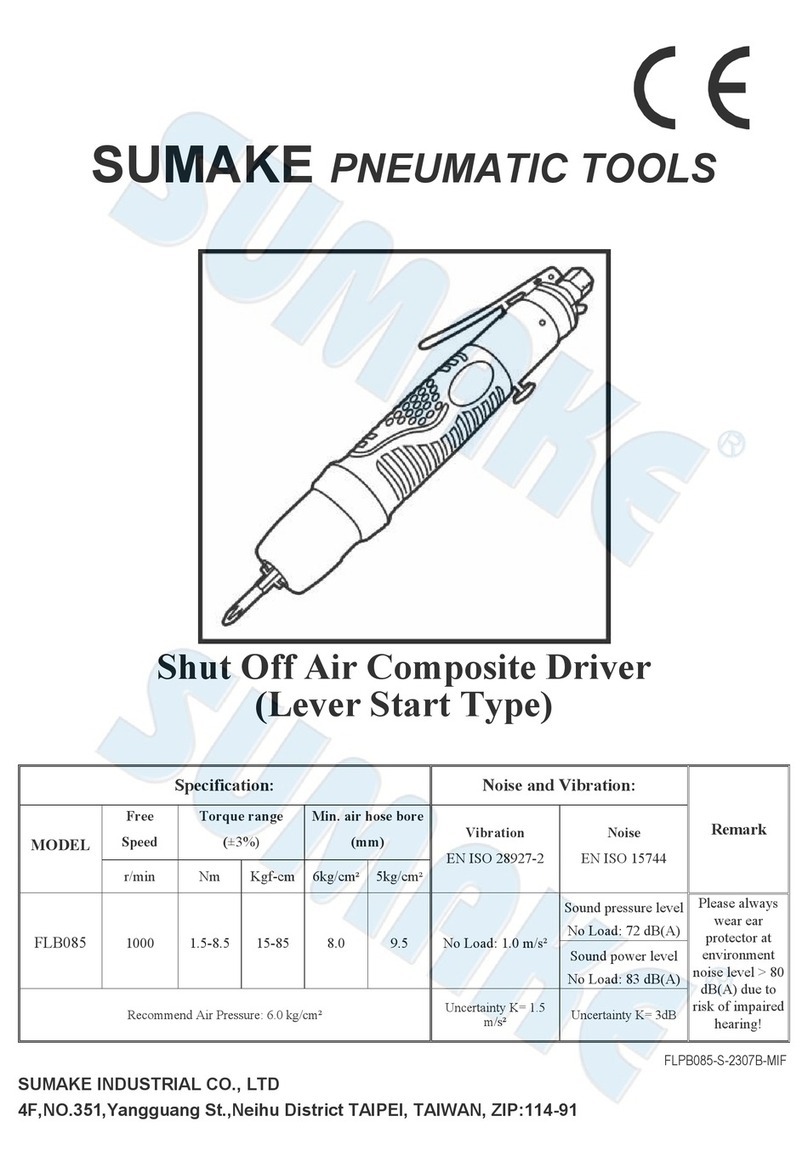

Sumake FLB085 User manual

Sumake

Sumake 97/25K User manual

Sumake

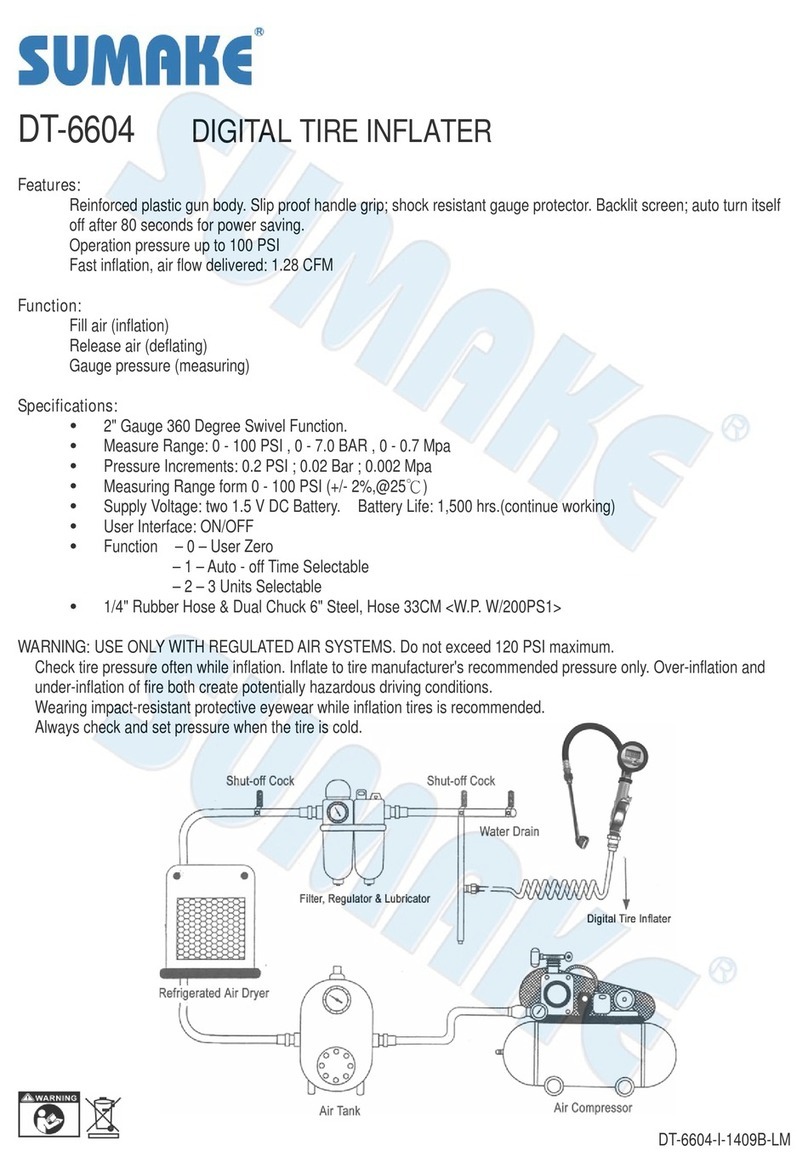

Sumake DT-6604 User manual

Sumake

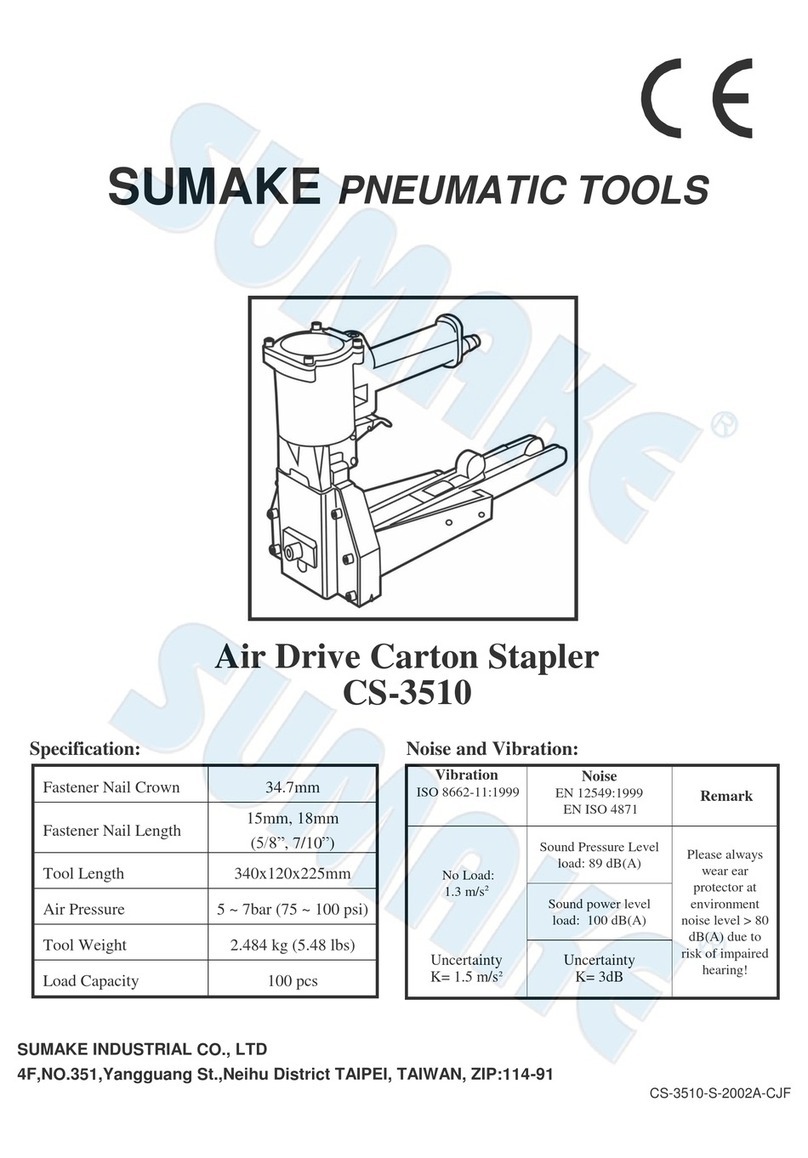

Sumake CS-3510 User manual

Sumake

Sumake ST-66154 User manual