PARAMAX SFC Operating Manual

e-mail: marktind@sce-cyclo.com

www.sumitomodriveeurope.com

Tel. +49 (0) 8136 66 0

Cyclostraße 92

85229 Markt Indersdorf 29

PX_SFC_DEU_ENG_11_09_991131

The drive unit is to be set up so that inspection, maintenance, and other operations such as lubricant

top-ups, can be carried out easily.

In order to prevent overheating and risk of re, ventilation of the PARAMAX SFC gearbox should not be

obstructed.

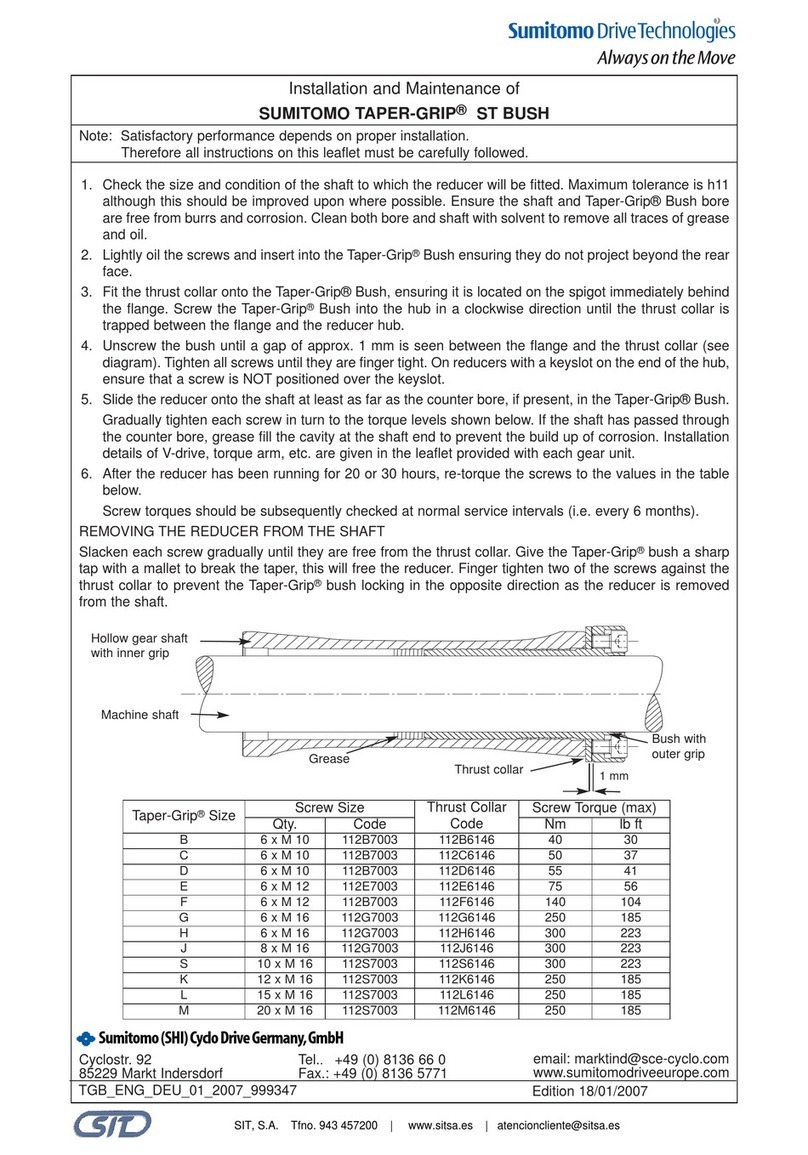

Tighten the mounting bolts to the specied torque only after carefully establishing perfect evenness

over the entire surface of the mounting base, which should provide torsional stiness and vibration

damping, and after aligning the drive. After about 4 weeks, all mounting bolts should be checked again

to ensure the correct tightening torque.

We recommend using mounting bolts of DIN quality 10.9.

If the drive is to be loaded up to maximum output torque or maximum transverse force, positive-t con-

nections (e.g. DIN 6325 cylinder pins) should be provided in addition to the foot mounting bolts.

5.2 Installation

Table 1 Mounting screw torques

* Screw class ISO 898-1/8.8

Mos2 paste is recommended for preventing electrochemical corrosion between the PARAMAX SFC gear

and the work machine when dierent metals are connected together, for example cast iron and stainless

steel.

The housing should also be grounded, using the grounding screws on the motor.

If the drive is to be painted over or partially re-nished, rst ensure that the vent valve and shaft seals

are carefully masked o. Remove the masking tape after the painting work is completed.

PARAMAX SFC gear units should not be used for any purposes other than those indicated on the model

plate or in the manufacturer’s documentation; otherwise there is a risk of electric shocks, injuries, or

damage to the equipment.

Do not place any inammable objects near the unit, otherwise there is a risk of re.

Do not place near the PARAMAX SFC gear unit any objects that obstruct the ventilation. Insucient ven-

tilation can lead to overheating, and therefore a risk of burning or re.

Do not step on or hold onto the PARAMAX SFC gear unit, as this may cause injuries.

Installation size SFC045 SFC055 SFC060 SFC065 SFC070 SFC075

Screw size * M24 M30 M30 M30 M36 M36

Torque Nm 706 1400 1400 1400 2430 2430

in lbs 6250 12390 12390 12390 21510 21510

Instrucciones de instalación y mantenimiento Reductores PARAMAX SFC para Torres de Refrigeración