SUNPOWER CORPORATION

Safety and Installation Instructions - Document 001-14158 Rev **

©May 2007 SunPower Corporation. All rights reserved. Specifications included in this manual are subject to change without notice.

Safety and Installation Instructions

(United States and Canada)

1.0 Introduction

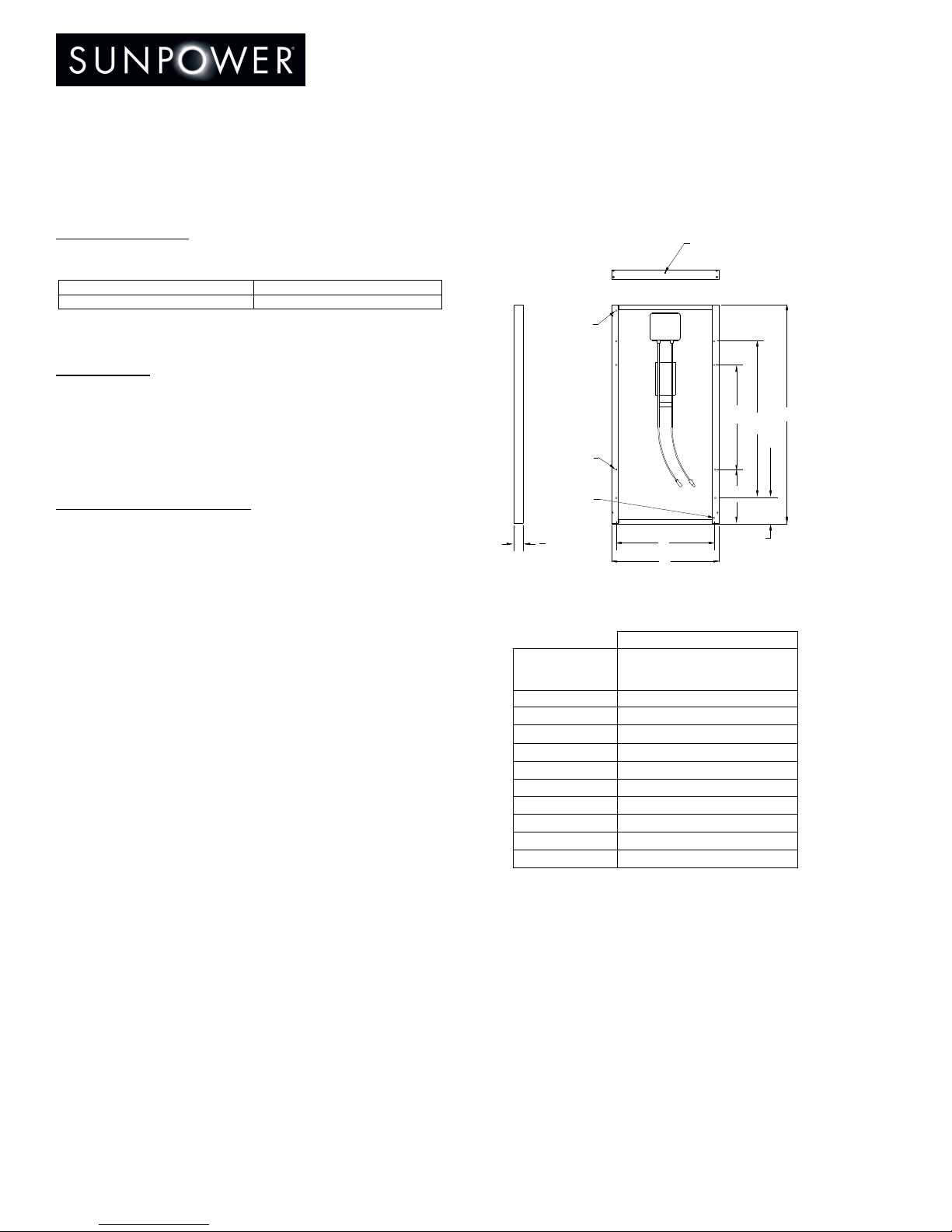

This manual provides safety and installation instructions for UL-listed

SunPower photovoltaic (PV) modules carrying the UL logo on the product label

(Figure 1).

Figure 1

1.1 Disclaimer of Liability

The installation techniques, handling and use of this product are beyond

company control. Therefore, SunPower does not assume responsibility for

loss, damage or expense resulting from improper installation, handling or use.

1.2 Underwriters Laboratories (UL) Listing Information

This product meets or exceeds the requirements set forth by UL1703 for PV

Modules. This UL Standard covers flat-plate PV modules and panels intended

for installation on buildings or those intended to be freestanding. To satisfy the

listing for this product the modules must be mounted with a rack or standoff

structure. The UL listing does not include integration into a building surface

because additional requirements may apply. This product is not intended for

use where artificially concentrated sunlight is applied to the module.

1.3 Limited Warranty

Module limited warranties are described in the SunPower warranty certificates

obtainable at www.sunpowercorp.com.

2.0

Safety Precautions

Before installing this device, read all safety instructions in this document.

•Cover all modules in the PV array with an opaque cloth or material before

making or breaking electrical connections.

•All installations must be performed in compliance with the National

Electrical Code (NEC) and any applicable local codes.

•There are no user serviceable parts within the module. Do not attempt to

repair any part of the module.

•Installation should be performed only by authorized personnel.

•Remove all metallic jewelry prior to installing this product to reduce the

chance of accidental exposure to live circuits.

•Use insulated tools to reduce your risk of electric shock.

•Do not stand on, drop, scratch, or allow objects to fall on modules.

•If the front glass is broken, or the back sheet is torn, contact with any

module surface or module frame can cause electric shock.

•Do not install or handle the modules when they are wet or during periods of

high wind.

•Contact your module supplier if maintenance is necessary.

•Save these instructions!

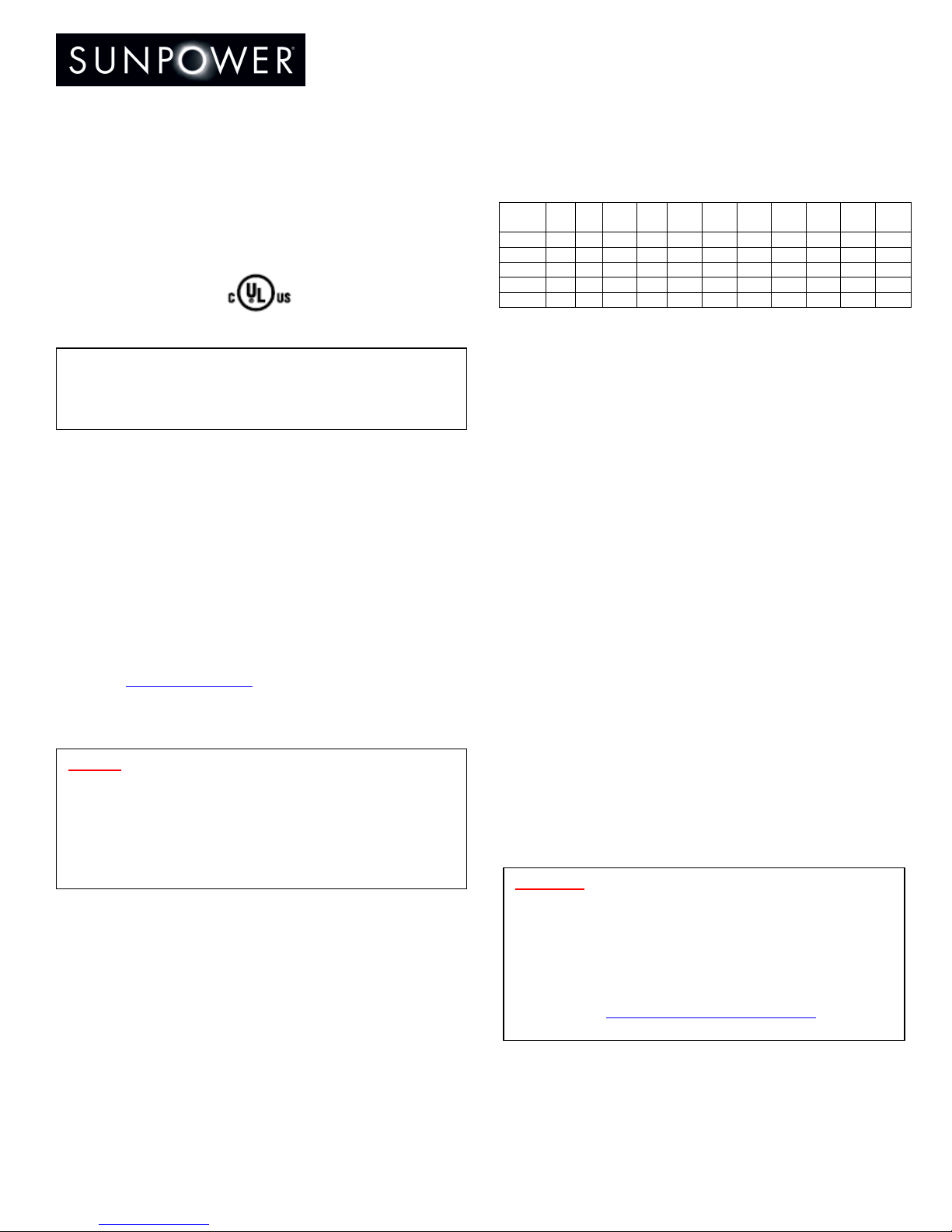

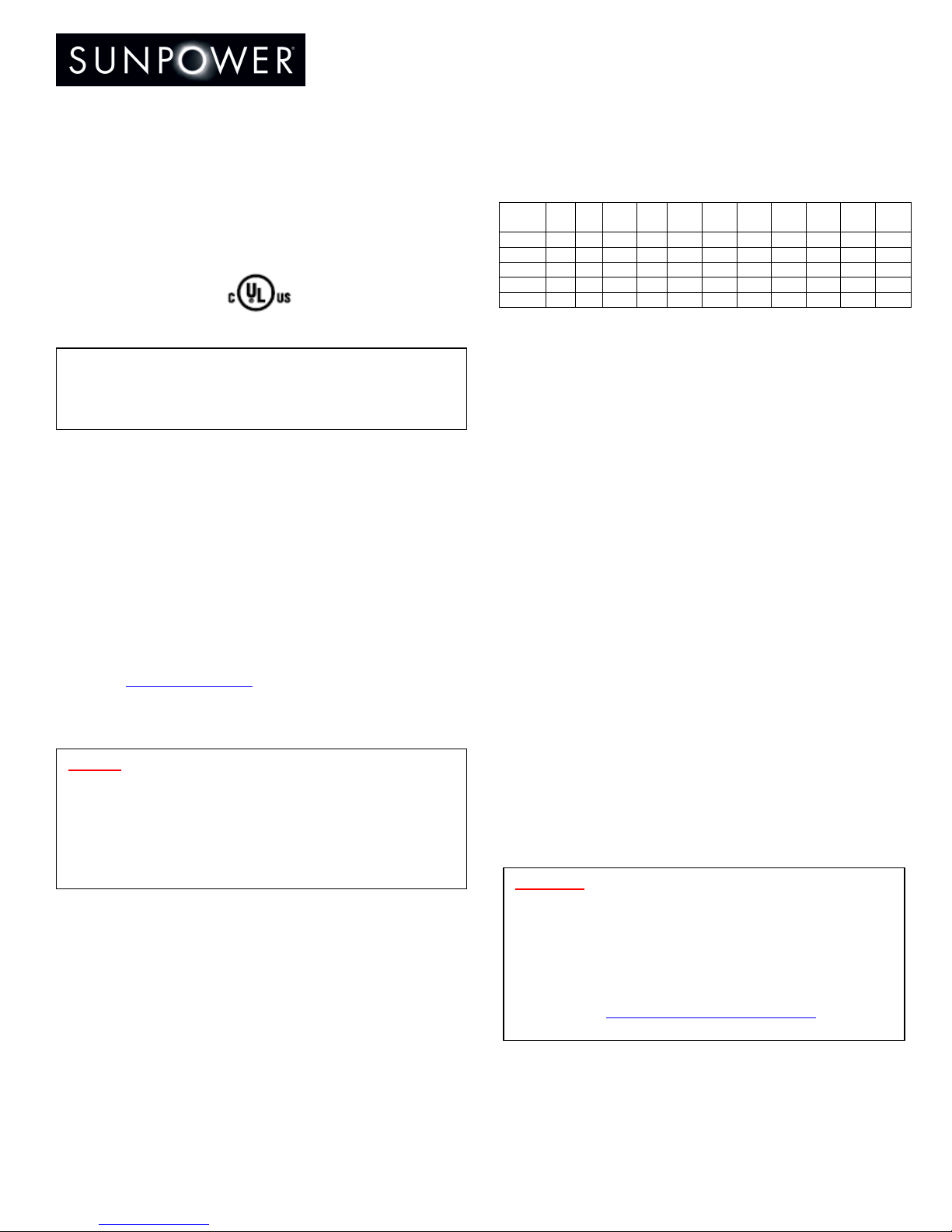

3.0 Electrical Characteristics

The module electrical ratings are measured under Standard Test Conditions

(STC) of 1 kW/m² irradiance with AM 1.5G spectrum and a cell temperature of

25º C. SunPower modules deliver specific electrical characteristics (Figure 2).

Electrical Characteristics at STC

Module Rated

Power

(W)

Power

Tol

(%)

Voltage

at Rated

Power

(V)

Curr at

Rated

Power

(A)

Open

Circuit

Voltage

(V)

Short

Circuit

Current

(A)

Max

Series

Fuse (A)

Max Sys

Voltage

(V)

Current

Temp

Coeff

(mA/°C)

Voltage

Temp

Coeff

(mV/°C)

Power

Temp

Coeff

(%/°C)C)

SPR-220-

WHT 220 +/- 8 39.8 5.53 48.3 5.95 15 600 3.5 -136.8 -0.38

SPR-215-

BLK 215 +/- 8 39.8 5.40 48.3 5.80 15 600 3.5 -136.8 -0.38

SPR-210-

WHT 210 +/- 5 40.0 5.25 47.7 5.75 15 600 3.5 -136.8 -0.38

SPR-205-

BLK 205 +/- 5 40.0 5.13 47.8 5.53 15 600 3.5 -136.8 -0.38

SPR-200-

WHT 200 +/- 5 40.0 5.0 47.8 5.4 15 600 3.5 -136.8 -0.38

Figure 2

A photovoltaic module may produce more current and/or voltage than reported

at STC. Sunny, cool weather and reflection from snow or water can increase

current and power output. Therefore, the values of Isc and Voc marked on the

module should be multiplied by a factor of 1.25 when determining component

voltage ratings, conductor ampacities, fuse sizes, and size of controls

connected to PV output. An additional 1.25 multiplier may be required by the

NEC for sizing fuses and conductors as described in the NEC Section 690-8.

3.1 Fire Rating

The module is Class C fire rated.

4.0 Electrical Connections

Modules may be connected in series and/or parallel to achieve the desired

electrical output as long as certain conditions are met. Please use only the

same type of modules in a combined source circuit.

4.1 Equipment Grounding

To avoid electrical shock, ground the frame of the module or array before

wiring the circuit using a grounding method that meets NEC requirements for

grounding solar electrical systems. SunPower recommends the following two

methods of grounding the module frame.

1) Attach an equipment ground conductor with stainless steel hardware at one

of the four designated 0.17grounding holes on the module frame. If an

equipment ground conductor larger in diameter than #10 AWG is necessary, a

grounding lay-in lug is required. A thread-forming 10-32 stainless steel screw

is required when using a self-drilling type screw to make the frame ground

connection. Please refer to NEC Article 690 on grounding PV arrays for

specific requirements.

2) SunPower modules can be grounded using third-party grounding washer or

clip systems provided they have been tested and certified to meet UL 467

requirements for bonding/grounding systems and are installed according to the

manufacturer’s specified instructions.

4.2 System Grounding

4.3 Series Connection

The modules may be wired in series to produce the desired voltage output. Do

not exceed the maximum system voltage indicated in Figure 2.

4.4 Parallel Connection

The modules may be combined in parallel to produce the desired current

output. Each series string or module may be required to be fused prior to

combining with other strings. Figure 2 describes the maximum fuse size

allowed. Please refer to the NEC Article 690 for additional fusing requirements.

Important! Read this instruction sheet in its entirety

before installing, wiring, or using this product in any way.

Failure to comply with these instructions will invalidate

the SunPower Limited Warranty for PV Module.

Danger! Module interconnects pass direct current (DC) and

are sources of voltage when the module is under load and

when it is exposed to light. Direct current can arc across

gaps and may cause injury or death if improper

connection or disconnection is made, or if contact is

made with module leads that are frayed or torn. Do not

connect or disconnect modules when current from the

modules or an external source is present.

Important! For optimal performance, SunPower PV modules

must only be used in configurations where the positive

polarity of the PV array is connected to ground. Failure to

comply with this requirement will reduce the

performance of the system and invalidate SunPower’s

Limited Power Warranty for PV Modules.

For more information on grounding the system correctly, visit

our website at www.sunpowercorp.com/inverters or contact

SunPower technical support at 1