19

SR 580 Helmet with Visor

1. General information

SR 580 together with the fan unit SR 500/SR 500 EX/SR 700

and approved filters is included in the Sundström fan-assisted

respiratory protective device system conforming to EN 12941/

EN 12942:1998 (fig. 2). SR 580 can be used together with fan

unit SR 500 EX in explosive atmospheres.

The breathing hose must be connected to the fan unit equipped

with filters. The above atmospheric pressure generated in the

head-top prevents particles and other pollutants from being

admitted into the breathing zone.

SR 580 can also be used together with compressed air

attachment SR 507 (fig. 1). This combination forms a breathing

apparatus designed for continuous air flow, for connection to

a compressed air supply in accordance with EN 14594:2005.

If you have any questions regarding the selection and mainte-

nance of equipment, consult your work supervisor or get in touch

with the sales outlet. You can also contact the Sundström Safety

AB’s Technical Support department. Respiratory protection

must always be part of a respiratory protection programme.

Forinformationandguidance,seeEN529:2005.

This standard provides information about the important aspects

of a respiratory protection programme, but does not replace

national or local regulations.

1.1 Applications

The SR 580 together with fan SR 500/SR 500 EX/SR 700

or SR 507 compressed air attachment can be used as an

alternative to filter respirators in all situations in which these are

recommended. This applies particularly to work that is hard,

warm or of long duration. When selecting the head top, some

of the factors that must be taken in to account are as follows:

• Typeofpollutants

• Concentrations

• Workintensity

• Protectionrequirementsinadditiontorespiratoryprotective

device.

The helmet must only be used when carrying out work it is

intended for. It provides limited protection by reducing the

force of falling objects that strike or penetrate the top of the

helmet shell.

The risk analysis should be carried by a person who has

suitable training and experience in the area.

1.2 Warnings/limitations

Warnings

The equipment must not be used

• ifthesurroundingairdoesnothavenormaloxygen

content,

• ifthepollutantsareunknown,

• inenvironmentsthatareimmediatelydangeroustolifeand

health(IDLH),

• withoxygenoroxygen-enrichedair,

• ifyoufinditdifficulttobreathe,

• ifyousmellortastepollutants,

• ifyouexperiencedizziness,nauseaorotherdiscomfort.

Materials that come into contact with the skin of sensitive

people may cause allergic reactions.

Damaged or scratched occulars must immediately be replaced.

Eye-protectors against high-speed particles worn over stan-

dard ophthalmic spectacles may transmit impacts, thus

creating a hazard to the wearer.

Limitations

• Thehead-topsmustnotbeusedtogetherwithpeel-offsin

potentially explosive atmosphere.

• Iftheface seal isnotfirmly in contactwiththeface, the

pressure necessary for maintaining the correct protection

factor will not be established.

• Iftheuserisexposedtoveryhighworkintensity,apartial

vacuum may occur in the device during the inhalation phase,

which may involve the risk of leakage into the head-top.

• Theprotectionfactormaybereducediftheequipmentis

used in surroundings in which high wind speeds occur.

• Thesealofthehead-topagainstthefacemustbeassured.

This may be difficult to achieve if the user has a beard or

sideboards.

• Beawarethatthebreathinghosemightmakealoopand

get caught up by something in your surrounding.

• Neverliftorcarrytheequipmentbythebreathinghose.

• Thehelmetisnotdesignedtowithstandpenetrativeimpacts

from the front, sides or back, but can provide protection

against less severe impacts against those surfaces.

• Avoidcontactwithelectricalwiringwhenusingthehelmet.

• When gluingitems tothehelmet,only rubber or acrylic-

based adhesives may be used. The helmet must not be

painted.

2. Use

2.1 Unpacking

Check that the equipment is complete as shown on the packing

list and that it has not been damaged during transit.

2.2 Packing list

• Helmet

• Lowervisorframe

• Visor

• Faceseal

• Breathinghose

• Userinstructions

• Cleaningtissue

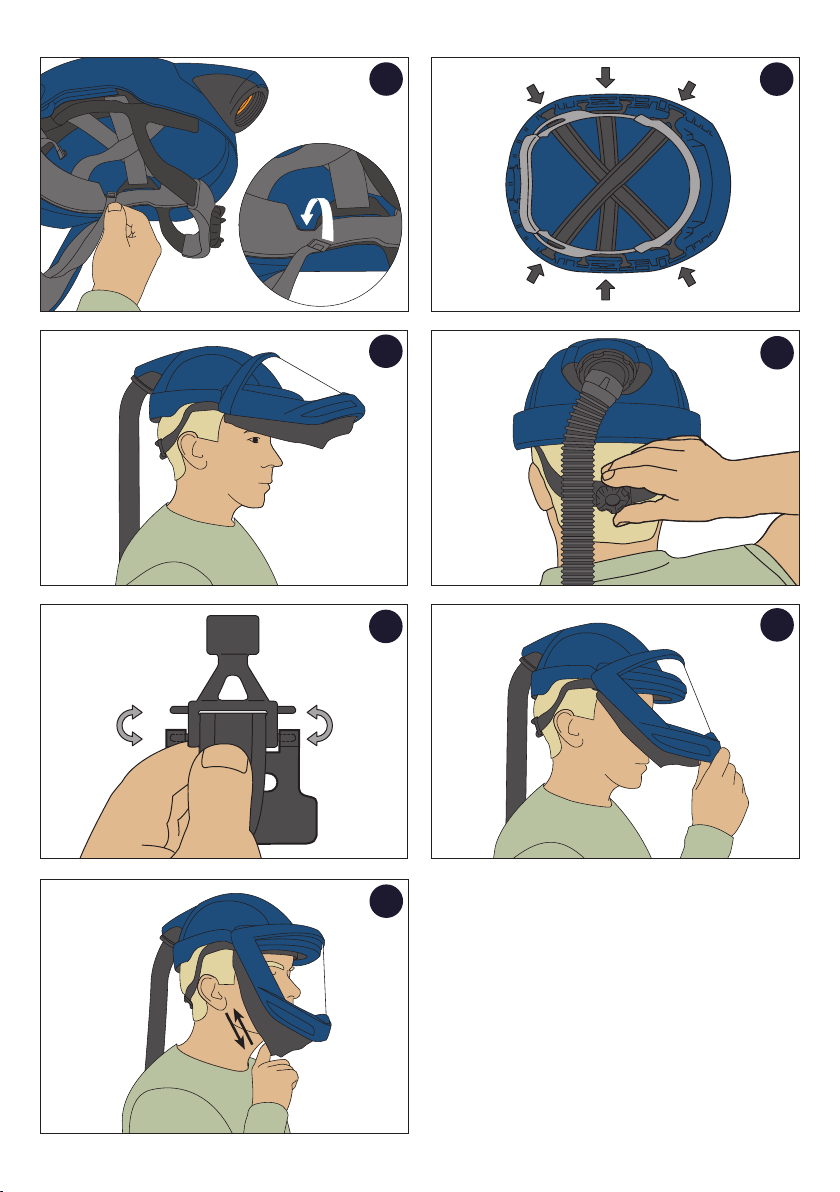

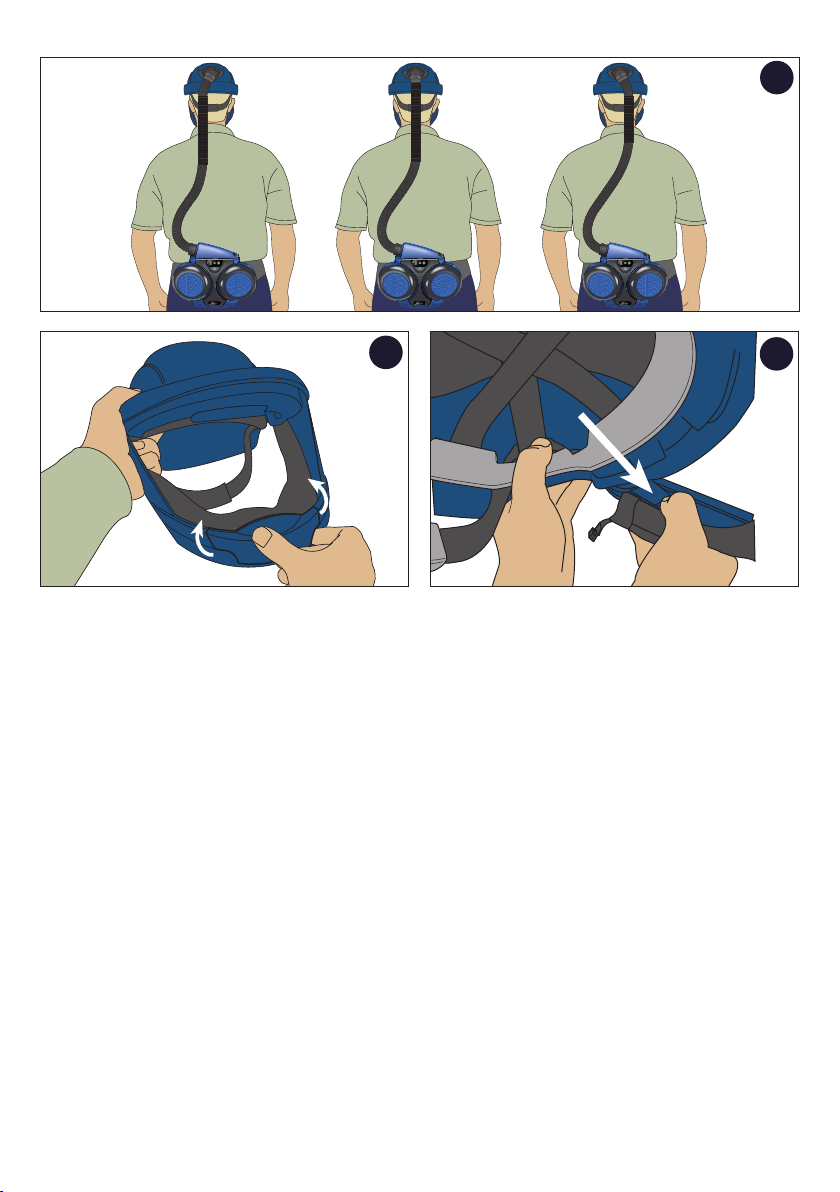

2.3 Assembly

Also see the user manual for the SR 500/SR 500 EX/SR 700 fan

and the SR 507 compressed air attachment, whichever is used.

Face seal and visor

Assembly of the face seal and visor does not require any tools.

Do the following:

• Fitthefacesealontheinnerflangeinthelowervisorframe

(fig. 3). Start at one side, push the pin upwards and control

that the lip is fastened in the lower visor frame (fig. 4).

• Pushalongthefacesealframesoitissecurelyfastenedon

the lower visor frame (fig. 5). Control that the pin and lip is

fastened on both sides (fig. 4).

• Fitthevisorintothelowervisorframe.Applyingalittlewater

to the seal will make fitting easier (fig. 6).

• Fitthelowervisorframetothehelmetbyslidingitintoposi-

tion. A ‘click’ indicates that the frame is locked in position

(fig. 7a-7d).

• Checkthatthevisorhasachievedafullsealaroundtheentire

visor frame.

• Attachthehooksintheheadharness(fig.8).

EN