6613A — OPERATING MANUAL AND PARTS LIST 1 rev. 07/15/04

OWNER/USER RESPONSIBILITY

The owner and/or user must have a thorough understanding of

the manufacturer’s operating instructions and warnings before

using this jack. Personnel involved in the use and operation of

equipment shall be careful, competent, trained, and qualified

in the safe operation of the equipment and its proper use

when servicing motor vehicles and their components. Warning

information should be emphasized and understood.

If the operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed with the

operator in the operator’s native language by the purchaser/owner,

making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturer’s instructions. Owner and/or user is

responsible for keeping all warning labels and instruction

manuals legible and intact. Replacement labels and literature

are available from the manufacturer.

IMPORTANT! BEFORE USING THIS JACK:

1. Remove the threaded oil fill screw from the service jack.

2. Replace with threaded breather before use.

BEFORE USE

Replace oil fill screw with breather as illustrated on page 1.

Air may become trapped in the hydraulic system during transit.

To purge air:

1. Open release valve by turning handle counterclockwise.

2. Pump handle rapidly 4 full strokes. This will expel air that

may have entered hydraulic fluid passages during transit.

3. Close release valve by rotating handle clockwise and

pump handle.

4. If lift arm raised, jack is ready for use. If not, repeat

this procedure.

INSPECTION

Visual inspection should be made before each use of the service

jack, checking for leaking hydraulic fluid and damaged, loose or

missing parts. Each jack must be inspected by a manufacturer’s

repair facility immediately, if accidentally subjected to an

abnormal load or shock. Any jack which appears to be damaged

in any way, found to be badly worn, or operates abnormally

MUST BE REMOVED FROM SERVICE until necessary repairs

are made by a manufacturer’s authorized repair facility. It is

recommended that an annual inspection of the jack be made

by a manufacturer’s authorized repair facility and that any

defective parts, decals or warning labels be replaced with

manufacturer’s specified parts.

A list of authorized repair facilities is available from the

manufacturer.

MAINTENANCE

IMPORTANT: When adding or replacing hydraulic fluid, always

use a quality hydraulic fluid. DO NOT use brake fluid, alcohol,

glycerine, detergent motor oil, or dirty oil as improper fluid can

cause serious internal damage to jack.

To add hydraulic fluid: With saddle fully lowered and jack on

level ground, remove filler screw. Hydraulic fluid should be

filled to level of hydraulic fluid filler screw hole. If low, add

hydraulic fluid as needed.

Maintenance and Inspection: The owner and/or user must

maintain and inspect the jack in accordance with the

manufacturer’s instructions.

6613A

2 Ton Capacity Low Profile Jack with Quick Lift System

THIS OPERATING MANUAL CONTAINS IMPORTANT SAFETY INFORMATION.

READ CAREFULLY AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING TOOL. SAVE THIS MANUAL FOR FUTURE USE.

USE ONLY ON HARD LEVEL SURFACES.

DO NOT GET UNDER A VEHICLE THAT IS ONLY SUPPORTED BY A TROLLEY/SERVICE

JACK–USE VEHICLE SUPPORT STANDS.

THIS IS A LIFTING DEVICE ONLY. DO NOT MOVE OR DOLLY THE VEHICLE WHILE ON

THE JACK. IMMEDIATELY AFTER LIFTING SUPPORT THE VEHICLE WITH APPROPRIATE

MEANS.

DO NOT OVERLOAD. OVERLOADING CAN CAUSE DAMAGE TO OR FAILURE

OF THE JACK.

LIFT ONLY ON AREAS OF THE VEHICLE AS SPECIFIED BY THE VEHICLE MANUFACTURER.

CENTER LOAD ON SADDLE PRIOR TO LIFTING. OFF-CENTER LOADS MAY CAUSE DAMAGE

TO JACK, LOSS OF LOAD, PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

NO ALTERATIONS TO THE JACK SHALL BE MADE.

READ, STUDY AND UNDERSTAND THE OPERATING MANUAL PACKED WITH THIS JACK

BEFORE OPERATING.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN LOSS OF LOAD, DAMAGE TO JACK,

AND/OR FAILURE RESULTING IN PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

FOR YOUR SAFETY AND TO PREVENT INJURY:

Use Service Jack for

lifting purposes ONLY.

Always support

vehicle with

jack stands.

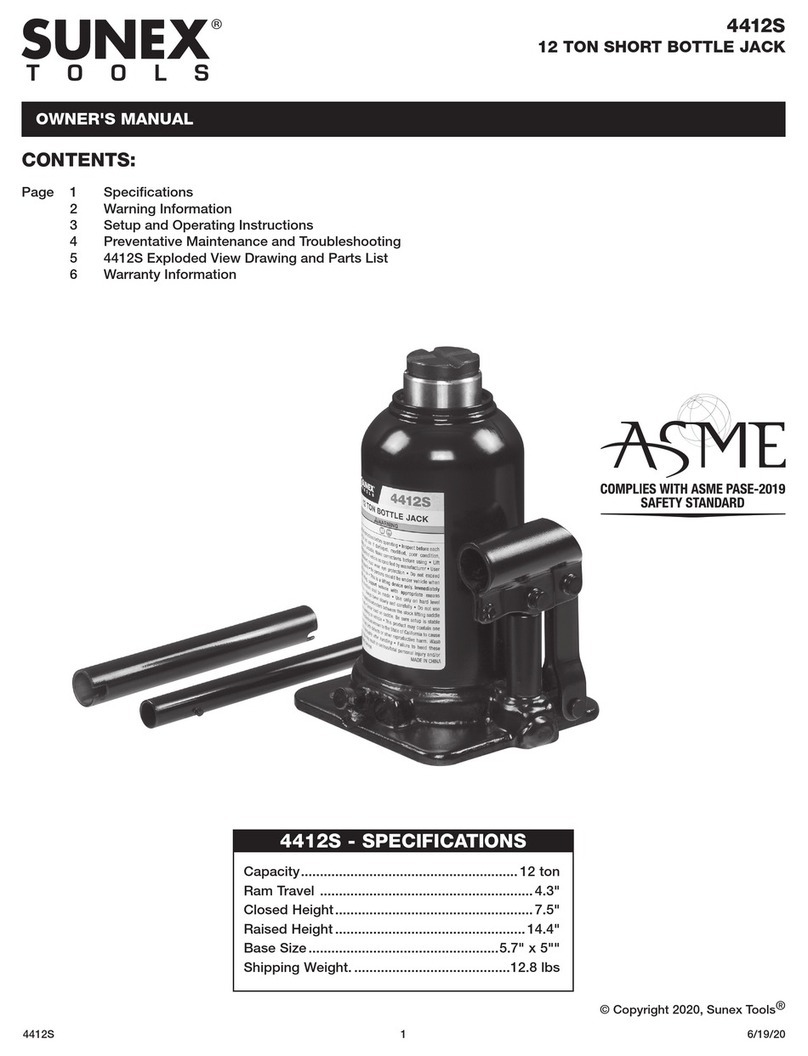

Oil fill screw to

be removed

Oil fill hole Breather installed