Visual inspection should be made before each use of the jack, checking for leaking hydraulic fl uid and dam-

aged, loose or missing parts. Each jack must be inspected by a manufacturer’s repair facility immediately,

to an abnormal load or shock. Any jack which appears

to be damaged in any way, is found to be badly worn,

or operates abnormally MUST BE REMOVED FROM

SERVICE until necessary repairs are made by a manu-

facturer’s authorized repair facility. It is recommended

that an annual inspection of the jack be made by a

manufacturer’s authorized repair facility and that any

defective parts, decals or warning labels be replaced

with manufacturer’s specifi ed parts.

A list of authorized repair facilities is available from

Model 6603 service jack is a self-contained device designed for lifting, but not sustaining, a partial vehicular

load. It consists of a frame with wheels and swivel casters supporting a mechanism that actuates a pivoting

lift arm equipped with a saddle. It is designed for use by professional auto mechanics.

Air may become trapped in the hydraulic system during transit. To purge air:

1. Open release valve by turning handle counterclockwise.

2. Pump handle rapidly 4 full strokes. This will expel air that may have entered oil passages during transit.

3. Close release valve by rotating handle clockwise and pump handle.

4. If lift arm raises to full height, jack is ready for use. If not, repeat this procedure or follow the

troubleshooting instructions provided.

SERVICE JACK SERVICE JACK

THIS IS A LIFTING DEVICE ONLY. DO NOT MOVE OR

DOLLY THE VEHICLE WHILE ON THE JACK. IMMEDIATELY

AFTER LIFTING SUPPORT THE VEHICLE WITH AP PRO PRI ATE

DO NOT OVERLOAD. OVERLOADING CAN CAUSE DAM AGE

TO OR FAILURE OF THE JACK.

LIFT ONLY ON AREAS OF THE VE HI CLE AS SPEC I FIED BY THE

VEHICLE MAN U FAC TUR ER.

CENTER LOAD ON SADDLE PRI OR TO LIFT ING. OFF-CENTER

LOADS MAY CAUSE DAM AGE TO JACK, LOSS OF LOAD,

PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

THIS JACK IS DESIGNED FOR USE ONLY ON HARD LEVEL SUR-

FAC ES CAPABLE OF SUS TAIN ING THE LOAD. USE ON OTHER

THAN HARD LEVEL SUR FAC ES CAN RE SULT IN JACK IN STA BIL-

I TY AND POSSIBLE LOSS OF LOAD.

NO ALTERATIONS TO THE JACK SHALL BE MADE.

READ, STUDY AND UN DER STAND THE OP ER AT ING MAN U AL

PACKED WITH THIS JACK BEFORE OP ER AT ING.

FAILURE TO HEED THESE WARNINGS MAY RE SULT IN LOSS

OF LOAD, DAMAGE TO JACK, AND/OR FAIL URE RE SULT ING

IN PROP ER TY DAMAGE, PERSONAL OR FATAL INJURY.

!

Always Support Vehicle with

!

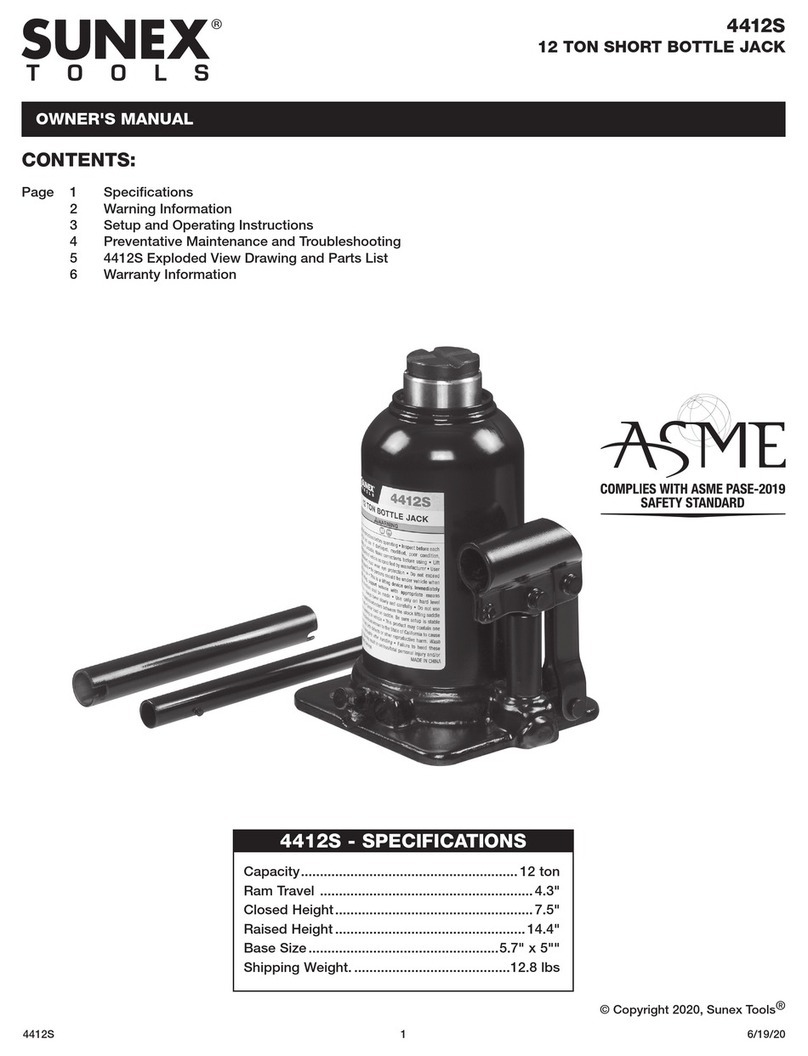

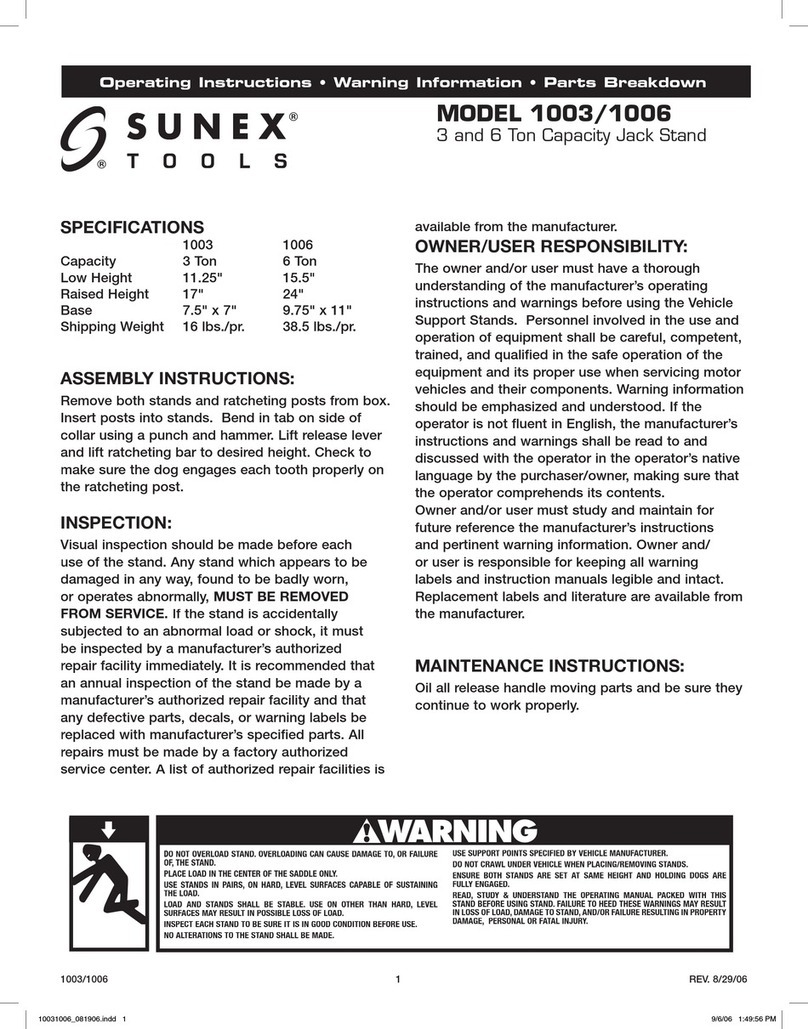

Model 1003

3 TON

CAPACITY

RATCHETING

JACK STAND

▲ WARNING

!

ENSURE BOTH STANDS ARE SET AT SAME HEIGHT & HOLDING DOGS ARE FULLY ENGAGED.

USE STANDS IN PAIRS, ON HARD, LEVEL SURFACES CAPABLE OF SUSTAINING THE LOAD.

LOAD & STANDS SHALL BE STABLE. USE ON OTHER THAN HARD, LEVEL SURFACES MAY

RESULT IN POSSIBLE LOSS OF LOAD.

READ, STUDY & UNDERSTAND THE INSTRUCTION MANUAL PACKED WITH THIS STAND

BEFORE USING STAND.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN LOSS OF LOAD, DAMAGE TO STAND,

AND/OR FAILURE RESULTING IN PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

DO NOT OVERLOAD STAND. OVERLOADING CAN CAUSE DAMAGE TO, OR FAILURE OF,

THE STAND.

INSPECT EACH STAND TO BE SURE IT IS IN GOOD CONDITION.

NO ALTERATIONS TO THE STAND SHALL BE MADE.

PLACE LOAD IN THE CENTER OF THE SADDLE ONLY.

USE SUPPORT POINTS SPECIFIED BY VEHICLE MANUFACTURER.

DO NOT CRAWL UNDER VEHICLE WHEN PLACING OR REMOVING STANDS.

Model 1003

3 TON

CAPACITY

RATCHETING

JACK STAND

▲ WARNING

!

ENSURE BOTH STANDS ARE SET AT SAME HEIGHT & HOLDING DOGS ARE FULLY ENGAGED.

USE STANDS IN PAIRS, ON HARD, LEVEL SURFACES CAPABLE OF SUSTAINING THE LOAD.

LOAD & STANDS SHALL BE STABLE. USE ON OTHER THAN HARD, LEVEL SURFACES MAY

RESULT IN POSSIBLE LOSS OF LOAD.

READ, STUDY & UNDERSTAND THE INSTRUCTION MANUAL PACKED WITH THIS STAND

BEFORE USING STAND.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN LOSS OF LOAD, DAMAGE TO STAND,

AND/OR FAILURE RESULTING IN PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

DO NOT OVERLOAD STAND. OVERLOADING CAN CAUSE DAMAGE TO, OR FAILURE OF,

THE STAND.

INSPECT EACH STAND TO BE SURE IT IS IN GOOD CONDITION.

NO ALTERATIONS TO THE STAND SHALL BE MADE.

PLACE LOAD IN THE CENTER OF THE SADDLE ONLY.

USE SUPPORT POINTS SPECIFIED BY VEHICLE MANUFACTURER.

DO NOT CRAWL UNDER VEHICLE WHEN PLACING OR REMOVING STANDS.

6603_OpMan_101905.indd 1 10/31/05 2:43:42 PM