2

content

Safety Precautions................................................................................................................3

Preface..................................................................................................................................4

1Introduction .....................................................................................................................4

1.1 Brief Introduction.....................................................................................................4

1.2 Product Properties ..................................................................................................4

1.3 Product identity definition........................................................................................5

2 Product Specification .......................................................................................................6

2.1 Size and Weight......................................................................................................6

2.2 Performance Parameter .........................................................................................6

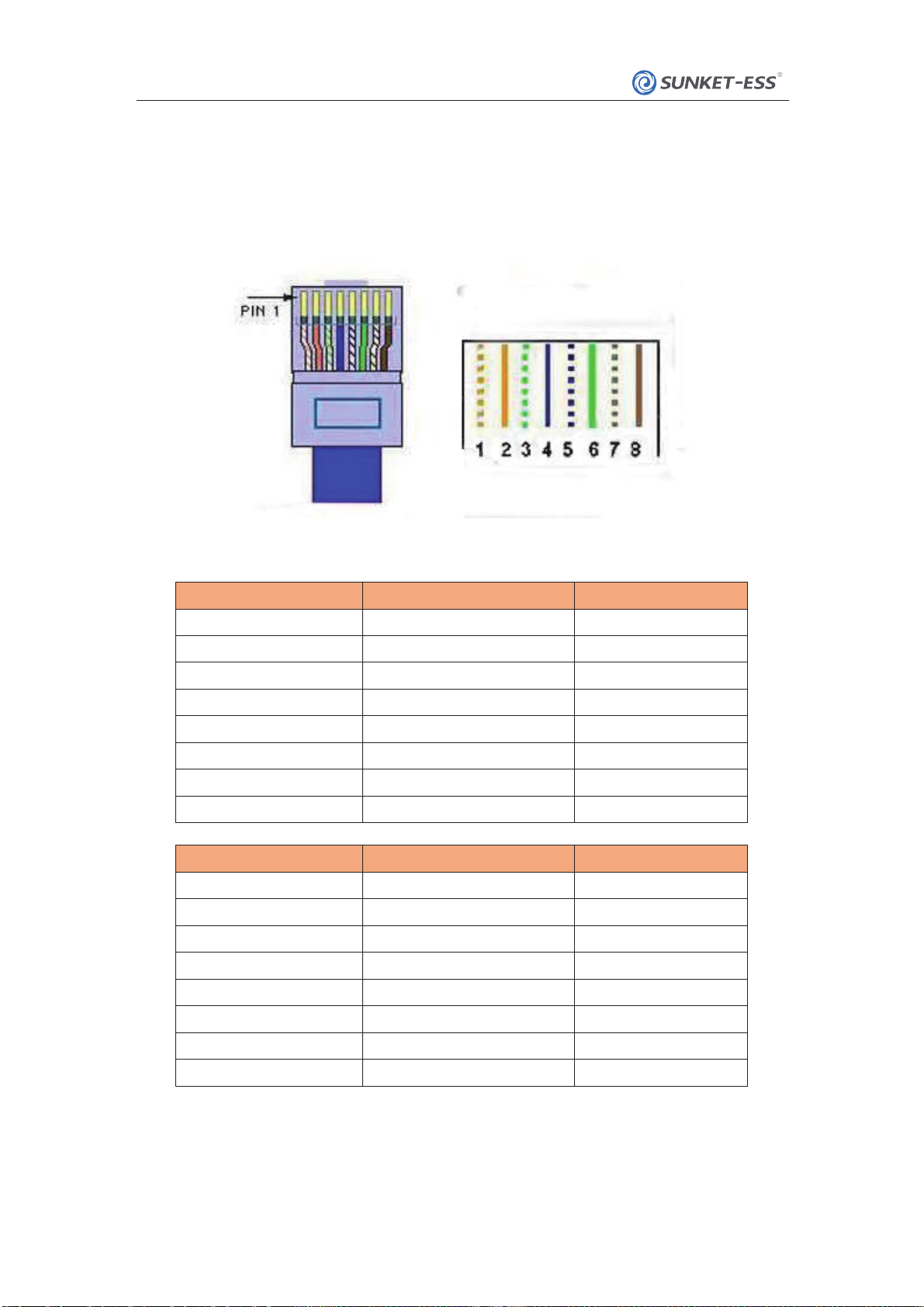

2.3 Interface Definition...................................................................................................6

2.4 Battery Management System(BMS).....................................................................

9

2.4.1 Voltage Protection .....................................................................................

9

2.4.2 Current Protection .....................................................................................

9

2.4.3 Temperature Protection ...........................................................................

10

2.4.4 Other Protection ........................................................................................

10

3 Installation and Configuration ........................................................................................

10

3.1 Preparation for installation....................................................................................

10

3.1.1 Environmental requirements ......................................................................

11

3. 1.2 Tools and data...........................................................................................

11

3.1.3 Technical preparation..................................................................................

11

3. 1.4 Unpacking inspection................................................................................

12

3. 1.5 Engineering coordination ..........................................................................

13

3.2 Equipment installation...........................................................................................

13

3.2.1 Installation preparation...............................................................................

14

3.2.2 M echanical installation ............................................................................

14

3.2.3 Electrical installation .................................................................................

14

3.2.4 Battery parameter settings on the inverter.................................................

16

4 Use, maintenance and troubleshooting.........................................................................

16

4.1 Battery system usage and operation instructions ..............................................

16

4.2 Alarm description and processing ........................................................................

17

4.3 Analysis and treatment of common faults ............................................................

18

LFP5000

..

..

..