-2- R3C

IMPORTANT SAFETY RECOMMENDATIONS

FAILURE TO COMPLYWITH THE FOLLOWING SAFETY RECOMMENDATIONS MAY

RESULT IN SERIOUS PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

1. READ AND FOLLOW ALL SAFETY AND INSTALLATION INSTRUCTIONS

CAREFULLY.

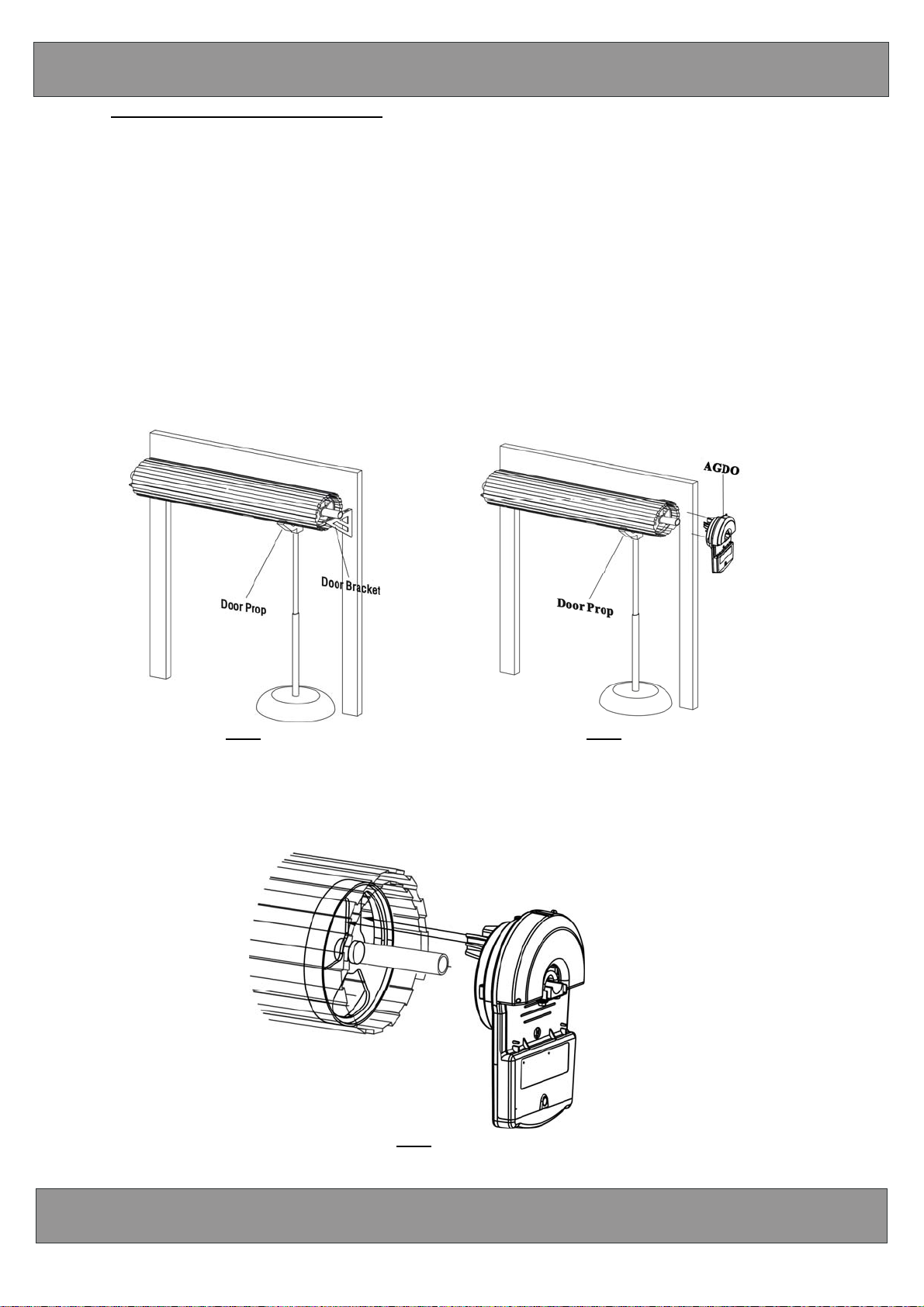

2. The installation of the Automatic Garage Door Opener (hereinafter referred to as AGDO)

must be carried out by a technically qualified or licensed person. Attempting to install the

AGDO without suitable technical qualification may result in severe personal injury, death

and/or property damage.

3. Only install the AGDO on a well functioning, properly balanced and aligned garage door. An

improperly balanced or malfunctioning garage door could cause serious injury. Have a qualified

person check and if required, make repairs to the garage door before installing the AGDO. As a

general rule a garage door is deemed to be well balanced and aligned if it;

a. requires an equivalent amount of applied force to manually open or close and,

b. requires no more than 150N (15kg) of applied force to either manually open or close and,

c. does not rise or fall more than 100mm when stopped at any position between fully open or

fully closed positions and,

d. Does not rub on or make contact with any supporting or surrounding structures.

4. Repairs to garage doors must only be carried out by technically qualified persons. Attempting to

repair the garage door without suitable technical qualification may result in severe personal injury,

death and/or property damage.

5. Remove or render inoperative all existing locks and ropes prior to installation of theAGDO.

6. If possible, install the AGDO at least 2 meters or more above the ground. Adjust the manual

release cord so that it hangs approximately 1.8 meters from the ground.

7. Do not connect the AGDO to the power source until this manual instructs you to do so.

8. The AGDO must be connected to a properly earthed general purpose 240V outlet.

9. Where fitted, locate the wall control panel/push button;

a. within site of the garage door and,

b. at a minimum height of 1.5 meters above the ground so that it remains out of the reach of

small children and,

c. away from all moving parts of the door.

10. Affix the entrapment warning label in a prominent position adjacent to the garage door & AGDO.

11. The manual release instruction tag must remain attached to the manual release cord.

12. After installing and correctly adjusting the AGDO, the garage door must stop and reverse

direction when it comes into contact with a 40 mm high solid object placed on the floor under the

garage door.

13. The correct function of the safety obstruction reversing system should be checked on a monthly

basis. Make sure that the garage door reverses easily when it makes contact with an obstruction.

14. Never use the AGDO unless the garage door is in full view and free from objects such as cars,

children and/or adults.

15. Never allow children to operate the AGDO.

16. Never operate the AGDO when children/persons are under or near the path of the door. Children

must be supervised at all times when near the garage door and when theAGDO is in use.

17. Never attempt to disengage the AGDO to manual operation when there are children/persons or

and other objects including motor vehicles under or near the path of the garage door.

18. Never attempt to make any repairs or remove any of the screw-on covers from the AGDO without

first disconnecting the power supply cord from main power supply.