TOPP K200T User manual

K200T

K280T

COD.0P5521

EN

VER 0.0

REV 08.19

INSTRUCTIONS FOR INSTALLATION AND USE

installer's manual/original instructions

LINEAR TELESCOPIC DOORS WITH TWO OR FOUR WINGS

ELECTROMECHANICAL AUTOMATION FOR SLIDING

IT

2K200T-K280T

EN INDEX

EN

INSTRUCTIONS FOR INSTALLATION AND USE

6.1- Maintenance ......................................................................................................................................pag. 58

5.10- Self restore management after anti panic alarm ..................................................................pag. 56

5.9- Self restore management of errors F-G-H-I-J .........................................................................pag. 56

7- EC DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY ............................pag. 60

EU DECLARATION OF CONFORMITY ......................................................................................................pag. 60

5.4- Reset phase: learning .....................................................................................................................pag. 52

5.6- Programming parameters ...............................................................................................................pag. 53

5.8- Self restore management of errors C-D-E-K-N-P-Q ........................................................................pag. 55

5.5- restart in case of power failure:zero (near).......................................................................................pag. 52

5.11- self restore management after ........................pag. 56 opening fire or an opening of emergency

6.2- Spare parts and accessories available on request.............................................................................pag. 58

6- APPENDICES

6.3- Demolition...........................................................................................................................................pag. 59

5.12- Digital switch .................................................................................................................................pag. 57

5.7- List of errors and warning ................................................................................................................pag. 54

6.4- Troubleshooting ..................................................................................................................................pag. 59

1.5- Techinical assistance..........................................................................................................................pag. 04

3.7- Assembling drive bracket and belt block bracket on slow wing..........................................................pag. 18

4.3- Electronic control unit .........................................................................................................................pag. 29

2.3- Technical data ....................................................................................................................................pag. 05

3.6- Assembly and adjustment of fast and slow sliding wings ...................................................................pag. 16

4.2- Electrical connection...........................................................................................................................pag. 28

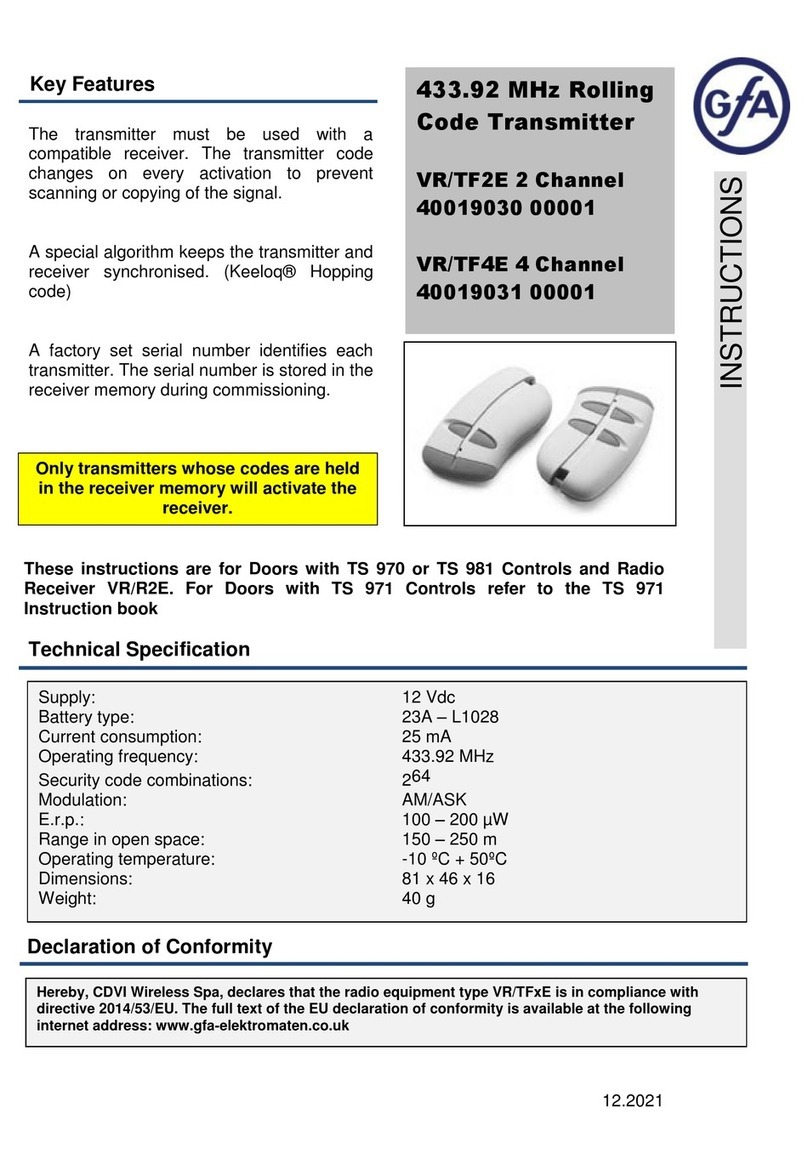

4.9- Connection of key device.................................................................................................................pag. 49

3.12- Assembling raceway fastening brackets for closure of the slow wing .............................................pag. 27

3.8- Assembling motor module, belt transmission,belt on fast wings and logline.....................................pag. 20

2.6- Types of sliding doors with two wings ................................................................................................pag. 07

3.9- Fastening drive brackets on fast wings .............................................................................................pag. 23

3.11- Assembling casing cover .................................................................................................................pag. 26

1- GENERAL INFORMATION

4- ELECTRICAL CONNECTION

2.1- Rating place and “CE” marking .........................................................................................................pag. 04

1.2- General safety rules ...........................................................................................................................pag. 03

3.2- Assembling the crossbar.....................................................................................................................pag. 11

1.1- General recommendations .................................................................................................................pag. 03

1.3- Installation...........................................................................................................................................pag. 03

1.4- User ....................................................................................................................................................pag. 04

2- TECHNICAL DESCRIPTION

2.2- Intended use ......................................................................................................................................pag. 04

2.5- Models................................................................................................................................................pag. 06

3- INSTALLATION

2.7- Description of parts and dimensions .................................................................................................pag. 08

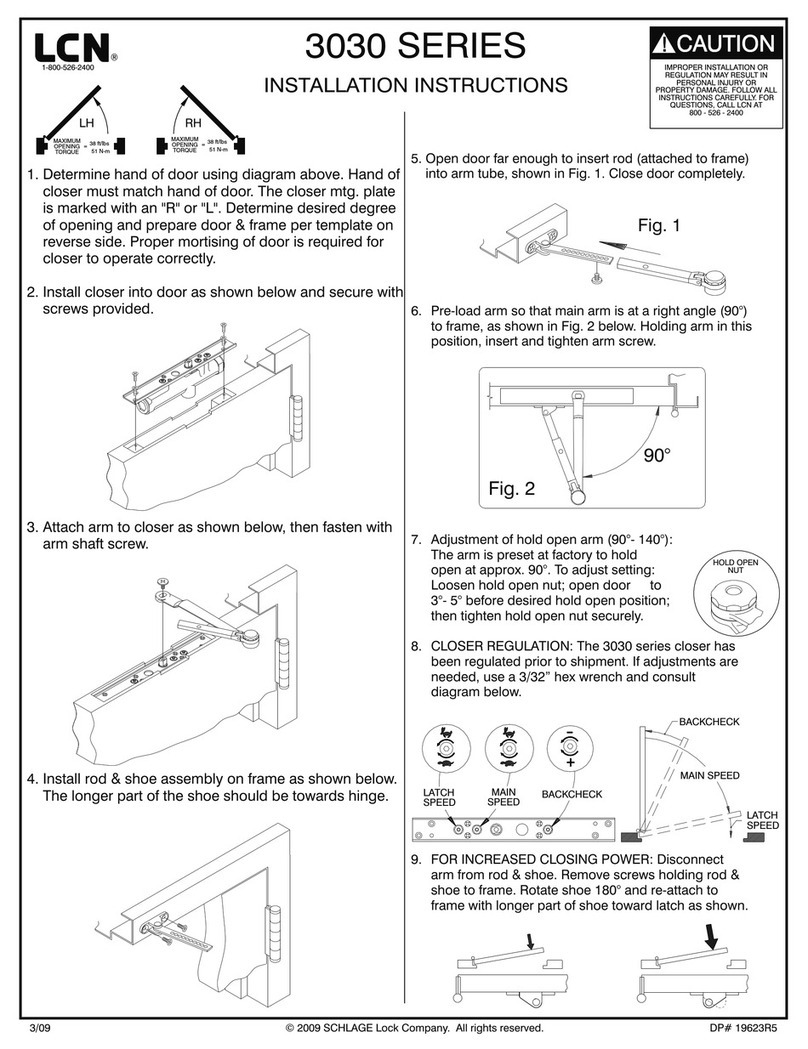

3.1- General recommendations .................................................................................................................pag. 11

3.3- Assembling the adaptor and track ......................................................................................................pag. 12

2.4- Package..............................................................................................................................................pag. 05

3.5- Adjustment of trolleys and assembly of belt on slow wing..................................................................pag. 15

3.4- Assembling trolleys on wings .............................................................................................................pag. 13

3.10- Assembling wing block ....................................................................................................................pag. 25

4.1- General recommendations .................................................................................................................pag. 28

4.4- Pre-wired electrical connections.........................................................................................................pag. 30

4.5- Electrical wiring diagram (flow chart)..............................................................................................pag. 32

4.7- Program selection with MS1 knob ..............................................................................................pag. 48

4.8- DS2 digital connection ....................................................................................................................pag. 48

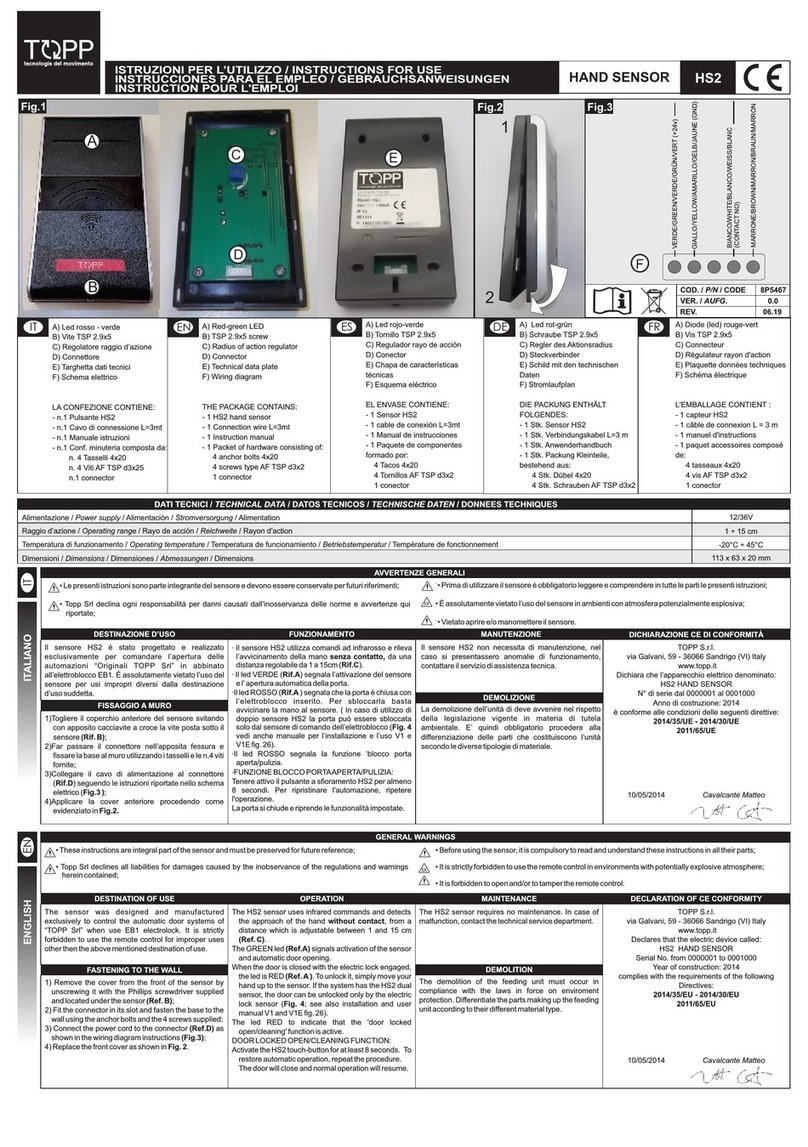

4.6- Connection of detection sensors ...................................................................................................pag. 33

4.10- Antipanic connection .....................................................................................................................pag. 49

4.11- Connetion of door block and pharmacy function .............................................................................pag. 50

5- USE AND OPERATION

5.1- 51 Technical description .......................................................................................................................pag.

5.2- Emergency battery ..........................................................................................................................pag. 51

5.3- First card start-up .............................................................................................................................pag. 51

IT

1

1.1

1.3

1.2

3

K200T

-K280T

GENERAL INFORMATION

GENERAL RECOMMENDATIONS

GENERAL SAFETY RULES

&TOPP srl reserves the right to amend or improve the manual and the products described therein at any time without

notice.

Before installing the automation the installer must read and understand all parts of this manual.

&This manual is an integral part of the automation unit and must be kept by the installer, with all the enclosed

documentation, for future reference.

&This manual provides all instructions necessary to ensure correct installation and maintenance of the automation:

TOPP srl is not liable for any damage to persons, animals and property caused by failure to follow these instructions.

&This manual was written by TOPP srl, which holds the copyright. No part of this manual may be reproduced or

published without the manufacturer's written authorization.

&The data contained in this manual were written and checked with the maximum care; TOPP srl is not liable for possible

errors due to omissions or printing errors, or errors in transcription.

&Do not remove or alter the plates and labels applied by the manufacturer on the automation and its accessories.

&Any tampering with or unauthorized replacement of parts or components of the automation mechanisms and any use

of accessories or consumables other than the originals may represent a hazard and relieves the manufacturer of any civil

and penal liability.

&In order for the automation unit to operate correctly, shall be carried out a periodical maintenance on it, as indicated in

par. 6.1 of this manual. Maintenance operations that require the automation unit to be even partially disassembled should

be carried out exclusively after the power supply to the same has been cut off.

&Never try to oppose the movement of the door and work near the hinges or other mechanical moving parts in motion

(such as belts, carriages, etc.). The manufacturer is not liable for any damages caused by improper or unreasonable use

of the automation.

&IMPORTANT! – During handling and installation of the parts, the personnel shall be equipped with suitable personal

protection equipment (PPE) so as to perform the works required under safe conditions.

&IMPORTANT! –The personnel must be informed of the risks of accident, about the safety devices for the operators

and about the general rules for accident prevention foreseen by the international directives and laws in force in the country

in which the automation is installed. In any case, the personnel must comply scrupulously with the safety regulations for

prevention of accidents in force in the country in which the automation is installed.

&IMPORTANT! – To prevent injury and risks for the health of the workers, the maximum limits shall be applied for

manual handling of loads, as provided in standard ISO 11228-1.

&When handling electric parts always wear grounded antistatic conductive bracelets as electrostatic charges can

damage the electronic parts on the circuits.

&The automation contains mobile mechanical parts, electrical connections and electronic circuits for control of door

movement; the automation must therefore be protected, along its entire length, by an aluminum casing.

&This device may be used by children no younger than 8 years of age, by people with reduced physical, sensory or

mental capacities and by inexperienced users, as long as they are supervised or as long as they have received

instructions on the safe use of the device.

&Children must not play with the device.

INSTALLER

&Installation of the automation must be done exclusively by qualified technical personnel in possession of the

professional requisites foreseen by the laws in the country of installation.

&The installer must be able to install the automation, start it and operate it with the power on in electrical cabinets or

shunt boxes, and must be qualified to perform all actions of an electrical and mechanical nature and any kind of

adjustment.

&After installing the automation, the installer must analyze the system for risks and verify that the sliding door

installation does not present risks of crushing or shearing, adopting adequate corrective measures, if necessary, and

applying the warning signs foreseen by the laws in force to identify hazardous zones.

&The installer must verify compliance with the current directives and regulations on the safe use of motorized doors.

&Every installer must provide visible annotation of the data identifying the drive system.

INSTRUCTIONS FOR INSTALLATION AND USE

EN

IT

2

2.1

4K200T-K280T

1.5

SERVICING

1.4

USER

The user must not open the casing or perform any operations restricted to maintenance personnel or specialized experts.

In case of breakdown or malfunction of the door, the user should simply switch off the circuit breaker and abstain from any

attempt to repair the system.

The user must be able to operate the automation under normal conditions and perform simple operations or startup or

resetting the automation following any forced interruptions, using the devices provided (digital switch, analogue switch,

etc.).

Use of the automation must be exclusively permitted to users who comply with the instructions in this manual and in the

manuals of the TOPP devices connected to it.

Contact the installation technician or retailer for assistance.

TECHNICAL DESCRIPTION

RATING PLATE AND “CE” MARKING

The “CE” marking certifies the conformity of the machine to the essential health and safety requisites foreseen by the

European product directives.

It is formed of an adhesive plate made from polyester, screen-printed black, with the following dimensions: W=50mm -

H=36mm.

It should be applied by the installation technician in a clearly visible position on the outside of the automation unit.

INSTRUCTIONS FOR INSTALLATION AND USE

EN

&The installation technician shall accept full responsibility for any installation errors and for any failure to adhere to the

instructions provided in this manual. The installation technician shall therefore be exclusively liable for any damages

caused to users and/or third parties that may arise as a result of incorrect installation.

&The installer must also supply the owner with all information regarding automatic, manual and emergency function of

the automation.

2.2

PROPER USE

The recovery action must be taken into account in applications where there are features that provide access

control with inputs different from those of the radar (example reader bedge) for which automation could not

ensure the operating mode set.

It is strictly forbidden to use the automation for purposes other than those described herein, in order to guarantee at all

times the safety of the installer and user and the correct function of the automation.

The automation in order to perform the above, if set in a mode other than "Closed", perform a reset called "Near"

that provides for the complete opening and closing of the doors at a low speed, before returning in the set state the

function selector.

The K200T/280T automation mechanism was designed and produced exclusively to operate (open and close) linear

sliding doors in residential, public and industrial buildings.

events as described in chapters 5.8-5.10.

The door may be used in escape routes only if equipped with anti-panic break-through systems. It must be possible to

break through in the direction of escape no matter what the position of the door.

In case you want to exclude the auto recovery please contact support Topp Srl.

The automation software is designed to perform automatic recovery in the instance where anomalous

2.4

2.3

2 PANELS 4 PANELS

K200T

Tab. 1

K280T

900÷4200 mm

230V ~ 50Hz 230V ~ 50Hz

24V 500mA max 24V 500mA max

0,32A 0,41 A

70W 90W

5 x 20 - T 800 delayed

IP X0 IP X0

1800÷4200 mm

2 x 100 kg 4 x 50 kg 2 x 140 kg 4 x 70 kg

900÷4200 mm

1800÷4200 mm

5

K200T

-K280T

TECHNICAL DATA

Tab. 1 lists the technical data that characterize the automation.

MODEL

POWER SUPPLY

PERIPHERAL POWER OUTPUT

ABSORPTION

POWER ABSORBED

TYPE OF USE Continuous Continuous

OPENING/CLOSING SPEED Adjustable 10 ÷ 80cm/s Adjustable 10 ÷ 80 cm/s

Adjustable 1 ÷ 5 cm/s Adjustable 1 ÷ 5 cm/s

OPENING/CLOSING APPROACH SPEED

OPENING/CLOSING ACCELERATION Adjustable 1 ÷ 12 Adjustable 1 ÷ 12

AUTOMATIC CLOSING TIME Adjustable 0 ÷ 60 s Adjustable 0 ÷ 60 s

MAINS VOLTAGE FUSE 230V 5 x 20 - T 800 delayed

PROTECTION OF ELECTRIC DEVICES

WORKING TEMPERATURE

NUMBER OF DOOR PANELS

MAXIMUM CAPACITY

SIZE OF OPENING

4 PANELS

2 PANELS

PACKING

INSTRUCTIONS FOR INSTALLATION AND USE

EN

Every standard package of the product (cardboard carton) contains:

-N.1 kit of transmission brackets and slow door driver;

-N.2 trolley units with relative hardware for fastening to the adapter for fast wing plus 2 for slow wing;

.-Make sure the parts described above are in the package and check that the automation has not undergone any

damage during shipment. If anything is wrong, do not install the automation; you must request technical assistance

from your retailer or the manufacturer.

If you need more parts, contact the manufacturer.

-N.2 brackets for support of the crossbar;

@The quantity of some parts may vary depending on the type of configuration used (e.g. number of wings).

-N.1 automatic door (complete with motor module and belt transmission preassembled on the crossbar, lateral plugs,

automation casing, wing stop stroke limit, cable sleeves, emergency battery, raceway, 1 ferrite, 1 ferrite holder, 4

rubber cable sleeves);

-N.4 floor runners with relative hardware for assembly of the wings;

-N.2 labels to signal movement of the wings, which must be applied at the center of the mobile wings (Ref. A)

-20°C

+50°C

-20°C

+50°C

Warning labels

for moving wings

Ref. A

2.5

VPA

VL

LT/LC

25 25

S

S

LT/LC

LT/LC

PC

BP

PC

Fig. 2

Fig. 3

Fig. 4

VL = gross opening

VPA = net doorway width

PC = electric wire raceway

F = side fixed

BP = rail + runner on the floor

LT/LC =automation length / casing length

S = thickness profile

2 Wings with opening toward the right

4 Wings

2525

LT/LC

PC

BP

BP

BPBP

PC

F

F

F F

25

25 F

SS

VPA

VL

25

S

25 F

25

25 F

S

BP

F

LT/LC

VPA

VL

S

25

25

FS

PC

LT/LC

PC

BP

F

BP

6K200T-K280T

VPA = net doorway width

BP = rail + runner on the floor

S = thickness profile

VL = gross opening

PC = electric wire raceway

LT/LC =automation length / casing length

F = side fixed

VPA = net doorway width

F = side fixed

LT/LC =automation length / casing length

S = thickness profile

BP = rail + runner on the floor

VL = gross opening

PC = electric wire raceway

INSTRUCTIONS FOR INSTALLATION AND USE

MODELS

EN

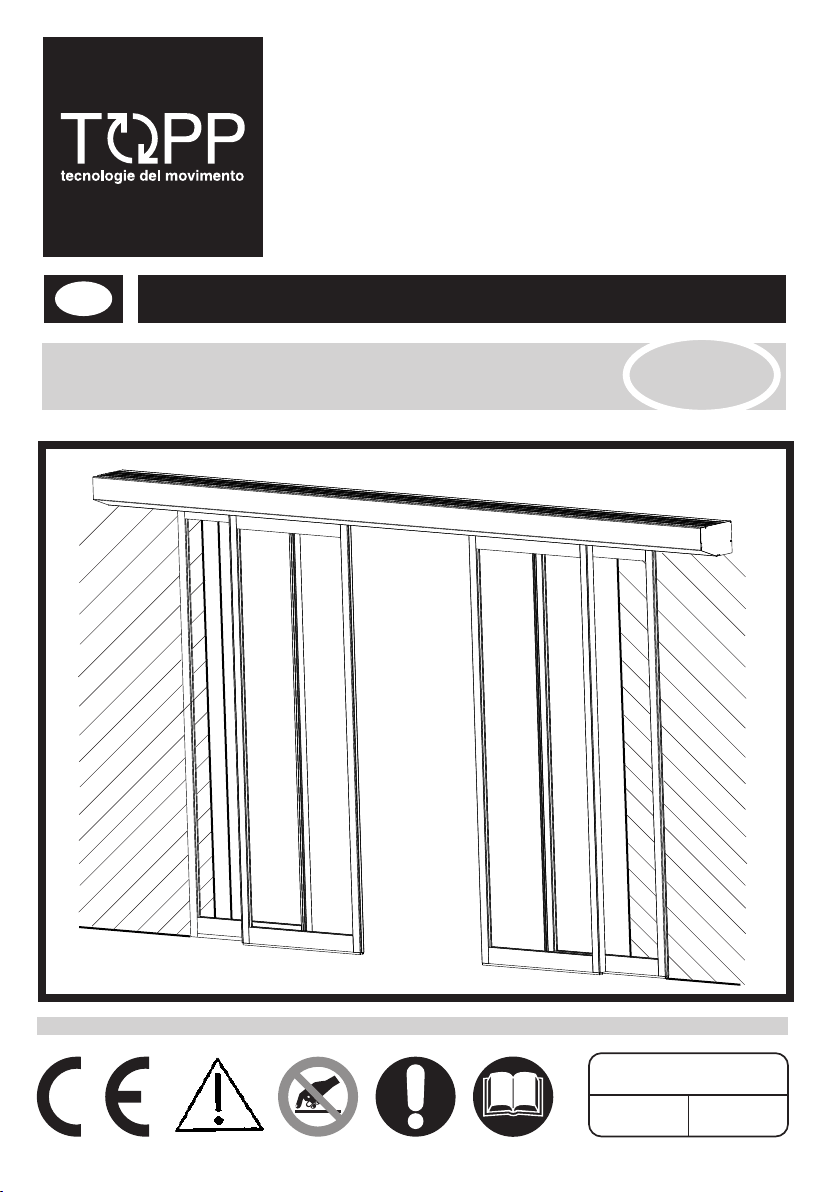

Three automation models are available:

- Automation for 4 wings version 2 right and 2 left (Fig.2) which allows the wings to slide simultaneously toward

the right and toward the left;

- Automation for 2 wings version right (Fig.3) which allows the wings to slide in one direction only. The figure

shows an application with the direction of opening toward the right (seen from the front of the automation);

- Automation for 2 wings version left (Fig.4) which allows the wings to slide in one direction only. The figure shows

an application with the direction of opening toward the left (seen from the front of the automation).

At the time of ordering a two-wing application, always specify the direction of opening using the front view of the

automation as your reference.

To comply with the safety regulations, the size of the passage VPA must be smaller than the size of opening

VL. The size of the passage VPA may be the same as the opening VL when the door upright does not have any

rounding and/or protrusions that could cause a shearing effect in relation to the top section of the door frame.

2 Wings with opening toward the left

2.6

Sliding door panel

Automation

Fig. 5a

Fig. 5b

Fig. 6

Fixed door panel

Wall end

7

K200T

-K280T

EN

TYPES OF SLIDING DOORS WITH TWO PANEL

To reduce the hazard of getting the fingers caught, we recommend the assembly type as shown in Fig.5a and Fig.5b,

where the wall and/or tubular frame act as a jamb and stop the door panel.

Alternatively, proceed as shown in Fig.6 overlapping the end of the wall (and/or closing upright) with the profile of the

sliding panel and moderating the closing speed and speed of approach of the door.

@In some countries the laws forbid this type of assembly as there is a possible risk of getting the fingers caught.

Sliding door panel

Sliding door panel

Fixed door panel

Automation

Tubular jamb

Wall end Fixed door panel

Sliding door panel

Automation

Tubular jamb

Overlap

Sliding door panel

INSTRUCTIONS FOR INSTALLATION AND USE

2.7

1 -

2 -

3 -

4 -

5 -

6 -

7 -

18 -

12 -

13 -

14 -

15 -

16 - Fast wing plastic runner

17 -

8 -

9 -

10 -

19 -

11 -

Belt transmission rear bracket (RCP)20 -

Belt transmission front bracket (RCA) with tension adjustment device

21 -

Slow wing plastic runner with thickness22 -

23 -

24 -

Logline

Ferrite

8K200T-K280T

EN

Main crossbar

Carriage with double wheel

Lateral case fastener

Adapter for door panel suspension

Casing

Fast door panel drive bracket

Toothed transmission belt

Belt transmission with pulley

Low voltage transformer

Electronic control circuit

Door lock with manual release

Emergency battery

Photocell control unit

Gearmotor K200T

Rail for door guide

Wire raceway

Door stop

Metal motor module

INSTRUCTIONS FOR INSTALLATION AND USE

DESCRIPTION OF PARTS AND DIMENSIONS

Fig. 7a

77

Crossbar supporting hooks

2 2

20 20

21 21

Slow wing Slow wing

Anta Veloce

5

15 15

16

13

44

9

67

63

19

3

218

18 12 11

10

14

1

AL AV AV AL

2222 16

17

17 23

24

K200T

8

Fast wing Fast wing

9

K200T

-K280T

EN

INSTRUCTIONS FOR INSTALLATION AND USE

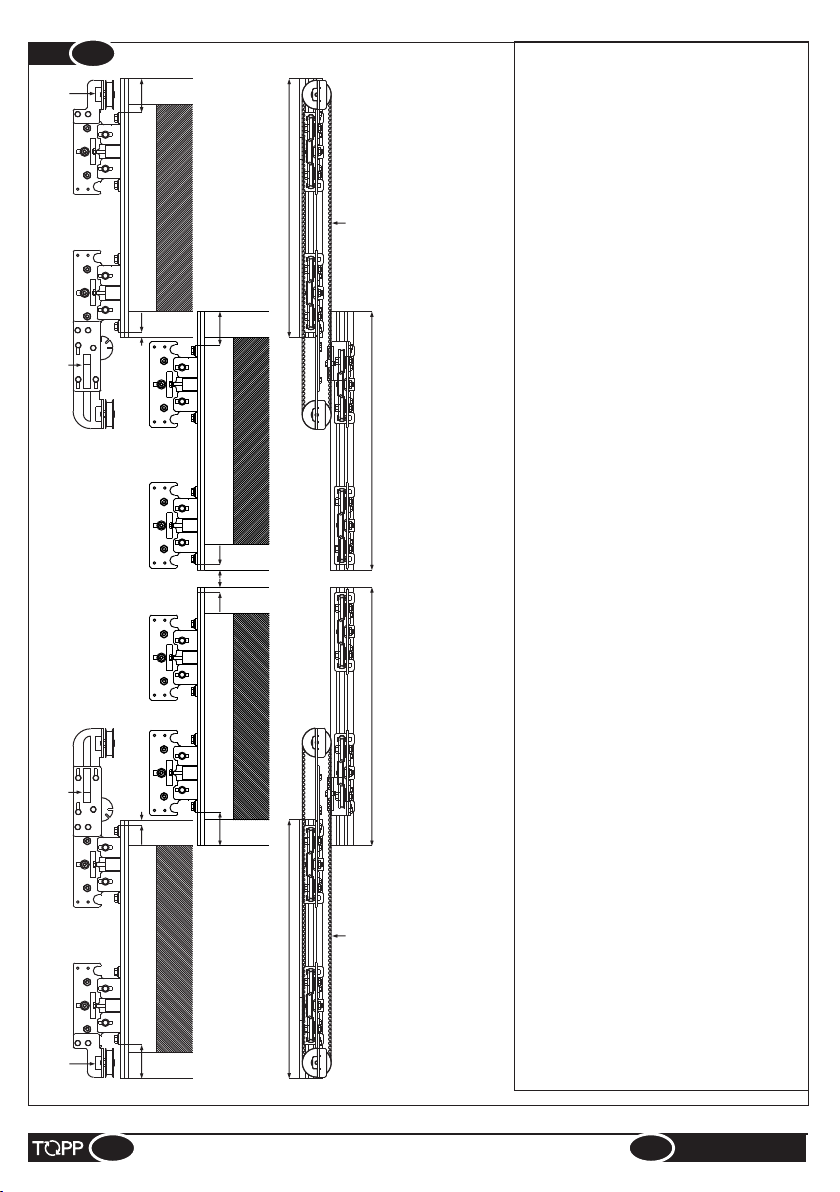

1 -

2 -

3 -

4 -

5 -

6 -

7 -

18 -

12 -

13 -

14 -

15 -

16 -

17 -

8 -

9 -

10 -

19 -

11 -

20 -

21 -

22 -

23 -

24 -

Logline

Ferrite

Main crossbar

Carriage with double wheel

Lateral case fastener

Adapter for door panel suspension

Casing

Fast door panel drive bracket

Toothed transmission belt

Belt transmission with pulley

Low voltage transformer

Electronic control circuit

Door lock with manual release

Emergency battery

Photocell control unit

Gearmotor K280T

Rail for door guide

Wire raceway

Door stop

Metal motor module

Fast wing plastic runner

Slow wing plastic runner with thickness

Belt transmission rear bracket (RCP)

Belt transmission front bracket (RCA) with tension adjustment device

Fig. 7b

77

Crossbar supporting hooks

2 2

20 20

21 21

Slow wing

Anta Veloce

Slow wing

Anta Veloce

5

15 15

16

13

44

9

67

63

19

3

218

18 12 11

10

14

1

AL AV AV AL

2222 16

17

17 23

24

K280T

8

Fast wing Fast wing

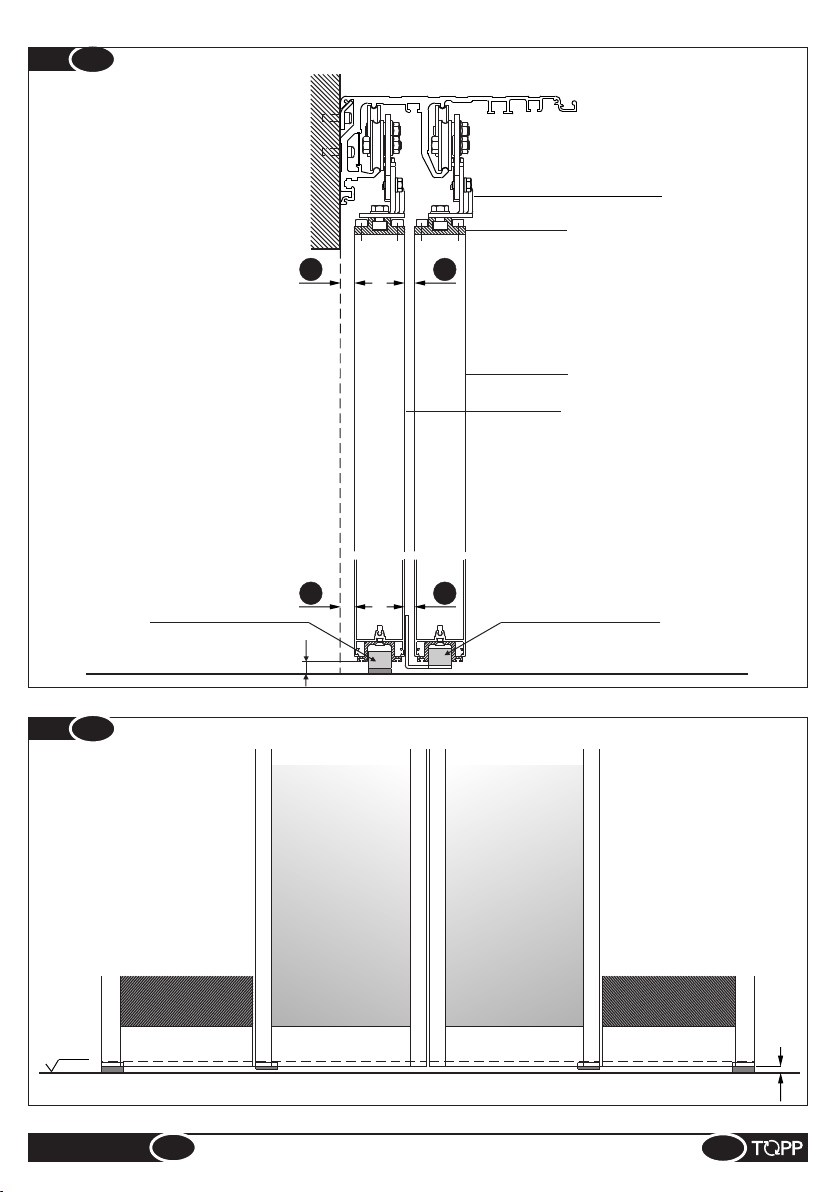

320

16

Fig. 9

10 K200T-K280T

EN

INSTRUCTIONS FOR INSTALLATION AND USE

Crossbar supporting bracket

Fig. 8

Ceiling height

Opening door height

Fig. 8

Ceiling height

Opening door height

10 MIN

227

122

29

46

12±10

10

5

9

14±10

IT

3

3.1

3.2

11

K200T

-K280T

INSTALLATION

GENERAL RECOMMENDATIONS

The automation must be installed exclusively by competent, qualified technical personnel in possession of the

technical requisites foreseen by the legislation in force in the country of installation.

&The glass for door panels shall comply with the provisions of the Standard (EN 16005 4.4.2 - Materials: tempered

glass in accordance with EN 12150_1; stratified glass in accordance with EN ISO 12543-1 and EN ISO 12543-2).

&Do not use the automation in environments with a potentially explosive atmosphere.

&The forces developed by the complete system during operation must respect the regulations in force in the country of

installation; if this is not possible, protect and signal by means of electronic safety devices the zones affected by those

forces.

&During installation of the door, take care to avoid any risks during the movement of closure and/or opening the door,

and to protect against risks in accordance with the provisions of standard EN 16005 at item 4.6.2.1 for the door opening

movement and item 4.6.2.2 for door closure. Protection of the primary closing edge should take account of the types of

users of the door (see EN 16005, 4.6.2.2).

&Before installing the automation, verify that the structure to be automated is stable, sturdy and able to withstand the

weight of the automation and, if necessary, take steps to ensure that it is. Topp srl is not liable for failure to comply with the

rules of good workmanship in the construction of the door panels to motorize, or for any distortions that may develop with

use of the device.

&Do not install the automation on the external wall of the building, subject to atmospheric agents (rain, snow, etc.).

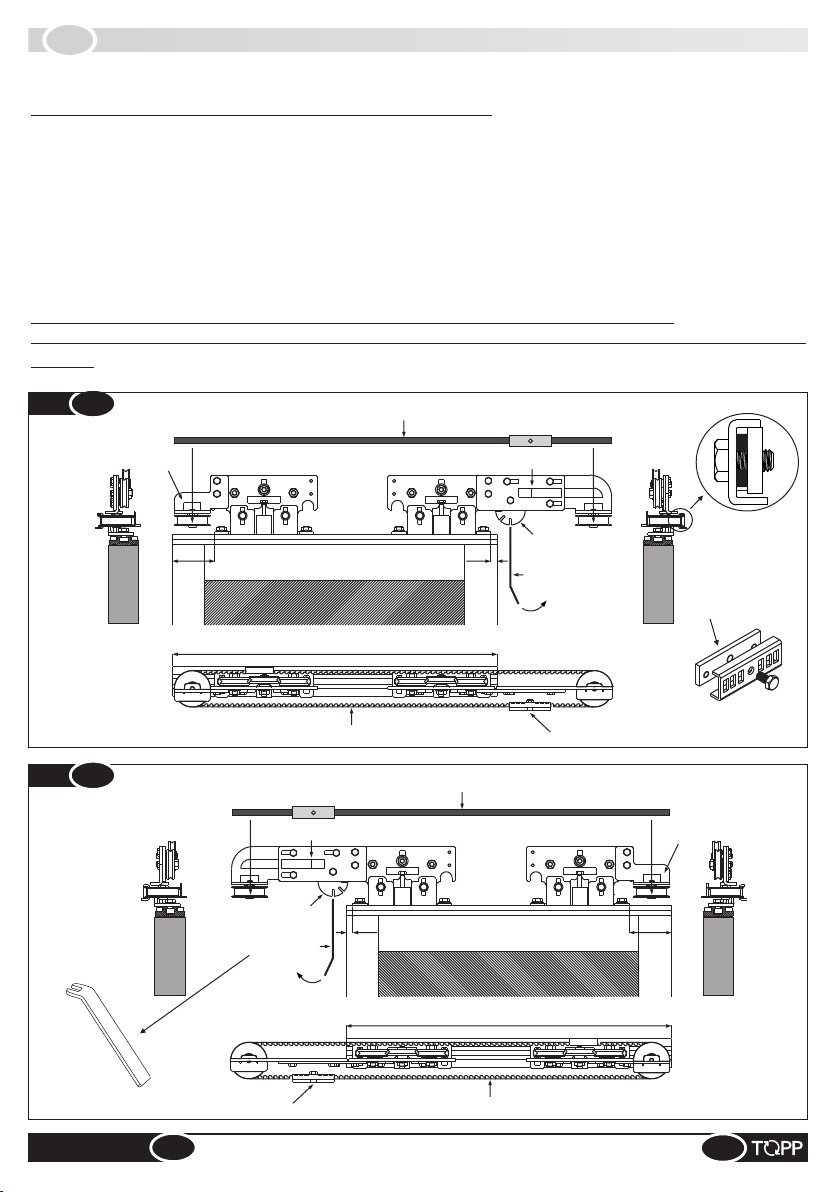

INSTALLING THE CROSSBAR

INSTRUCTIONS FOR INSTALLATION AND USE

EN

-Remove the automation casing cover.

-Fasten the crossbar to the wall, positioning 3 self-tapping screws type d.5.5 or d.6.3 for every meter of crossbar,

-Fasten the supporting brackets to the wall using self-perforating/self-tapping screws type d5.5 or 6.3.

@If the floor is not perfectly flat, decide the position of the supporting brackets using the highest point of the floor

as your reference.

-Install the crossbar and check the alignment.

(Model with 4 wings) Proceed as follows to assemble the crossbar:

-Mark the center of the opening VL on the wall or surface for fastening, corresponding to the center of the crossbar;

-Fasten the supporting brackets to the wall using self-perforating/self-tapping screws type d5.5 or 6.3.

-Remove the automation casing cover.

-Install the crossbar and check the alignment and horizontal leveling.

-Fasten the crossbar to the wall, positioning 3 self-tapping screws type d.5.5 or d.6.3 for every meter of crossbar,

taking care not to damage the sliding base of the trolleys with the drill chuck. In case of damage, it is necessary to

replace the entire crossbar.

(Model with 2 wings) - Proceed as follows to assemble the crossbar:

-Mark the starting point of the crossbar on the wall or surface for fastening, corresponding to:

ŸThe right edge of the opening wall for application of 2 wings with the opening on the left;

-After fastening the crossbar, clean the sliding zone carefully to remove any drilling residues.

-Decide the position in which to fasten the supporting brackets of the crossbar, referring to the measurements shown

in Fig.8.

@If the floor is not perfectly flat, decide the position of the supporting brackets using the highest point of the floor

as your reference.

ŸThe left edge of the opening wall for application of 2 wings with the opening on the right;

-Decide the position in which to fasten the supporting brackets of the crossbar, referring to the measurements shown

in Fig.8.

100 mm

50 mm

3.3

70÷80 40

Door panel

40

45

Adapter

20

31

Rail

Fig. 10

70÷80

40 40

Adapter

20

31

70÷80 70÷80100÷150 100÷150

rail

Flaring

12 K200T-K280T

Materials of the fastening surface Minimum thickness

IRON

ALUMINUM

REINFORCED CONCRETE

SOLID WOOD

PERFORATED CONCRETE

2 mm (with lesser thickness use threaded rivets)

3 mm (with lesser thickness use threaded rivets)

110 mm (with lesser thickness use chemical bolts)

INSTALLING THE ADAPTER AND RAIL

-Drill the door at the bottom and fasten the rail using flared self-tapping cylindrical screws diam. 4.8.

-Make sure the upper part of the panel crossbar is reinforced at the base (minimum thickness 3 mm);

@The number of fastening holes will depend on the size and weight of the door.

-Mark the fastening points on the door using the adapter and rail as a templat;

-Drill the adapter and rail starting at about 70/80 mm from the end;

-Drill the door panel at the top and fasten the adapter using cylindrical M6 screws or cylindrical self-tapping d5.5 screws

depending on the type of material;

-Cut the adapter and rail to the measurement of the finished door width, removing another 2 mm from the jamb sider;

INSTRUCTIONS FOR INSTALLATION AND USE

EN

taking care not to damage the sliding base of the trolleys with the drill chuck. In case of damage, it is necessary to

replace the entire crossbar.

3.4

MONTAGGIO DEI CARRELLI SULLE ANTE

3.4

Fig. 12

10

65

65

RCP RCA

LAL

LAV

Fig. 13

65

10 65

LAL

LAV

RCP

RCA

Fig. 11

CAL

CAL

13

K200T

-K280T

INSTALLING THE CARRIAGES ON THE DOORS

Installation by insertion

Fastening nut

Carriage

Standard adapter

2 doors panel, opening toward the left

Slower wing back

Fast wing front

2 doors panel, opening toward the right

INSTRUCTIONS FOR INSTALLATION AND USE

EN

@Position the trolleys on the fast wing, make an approximate adjustment and partially tighten the screws.

Assemble the trolleys on the wing adapter as shown in the figures.

@Position the trolleys on the rear of the slow door before assembling it, and make an approximate adjustment,

after which you can assemble the transmission brackets RCP and RCA, the transmission belt on the trolleys, and

partially tighten the screws.

Fast wing front

Slower wing back

65÷70

65÷70

Fig. 14

10

65

65

RCP RCA

LAL

LAV

65

10 65

LAL

LAV

RCP

RCA

1010

DOUBLE WINGS, OPENING THE RIGHT OR THE LEFT

WIDTH OF WINGS AND SLOW WING BELT

VPA LAL LAV CAL

900 500 500 1392

1000 550 550 1496

1100 600 600 1592

1200 650 650 1696

1300 700 700 1792

1400 750 750 1896

1500 800 800 1992

1600 850 850 2096

1700 900 900 2192

1800 950 950 2296

1900 1000 1000 2392

2000 1050 1050 2496

2100 1100 1100 2592

2200 1150 1150 2696

2300 1200 1200 2792

2400 1250 1250 2896

2500 1300 1300 2992

2600 1350 1350 3096

2700 1400 1400 3192

2800 1450 1450 3296

2900 1500 1500 3392

3000 1550 1550 3496

3100 1600 1600 3592

3200 1650 1650 3696

3300 1700 1700 3792

3400 1750 1750 3896

3500 1800 1800 3992

3600 1850 1850 4096

3700 1900 1900 4192

3800 1950 1950 4296

3900 2000 2000 4392

4000 2050 2050 4496

4100 2100 2100 4592

4200 2150 2150 4696

4 WINGS SIMULTANEOUS OPENING THE RIGHT OR

THE LEFT

VPA LAL LAV CAL

1800 500 500 1392

1900 525 525 1444

2000 550 550 1496

2100 575 575 1544

2200 600 600 1592

2300 625 625 1644

2400 650 650 1696

2500 675 675 1744

2600 700 700 1792

2700 725 725 1844

2800 750 750 1896

2900 775 775 1944

3000 800 800 1992

3100 825 825 2044

3200 850 850 2096

3300 875 875 2144

3400 900 900 2192

3500 925 925 2244

3600 950 950 2296

3700 975 975 2344

3800 1000 1000 2392

3900 1025 1025 2344

4000 1050 1050 2496

4100 1075 1075 2544

4200 1100 1100 2592

CAL CAL

14 K200T-K280T

4 wings, simultaneous opening toward the right and left

Slower wing back Slower wing back

Fast wing front Fast wing front

INSTRUCTIONS FOR INSTALLATION AND USE

EN

Fig. 15

Slow wing,opening toward the left

3.5

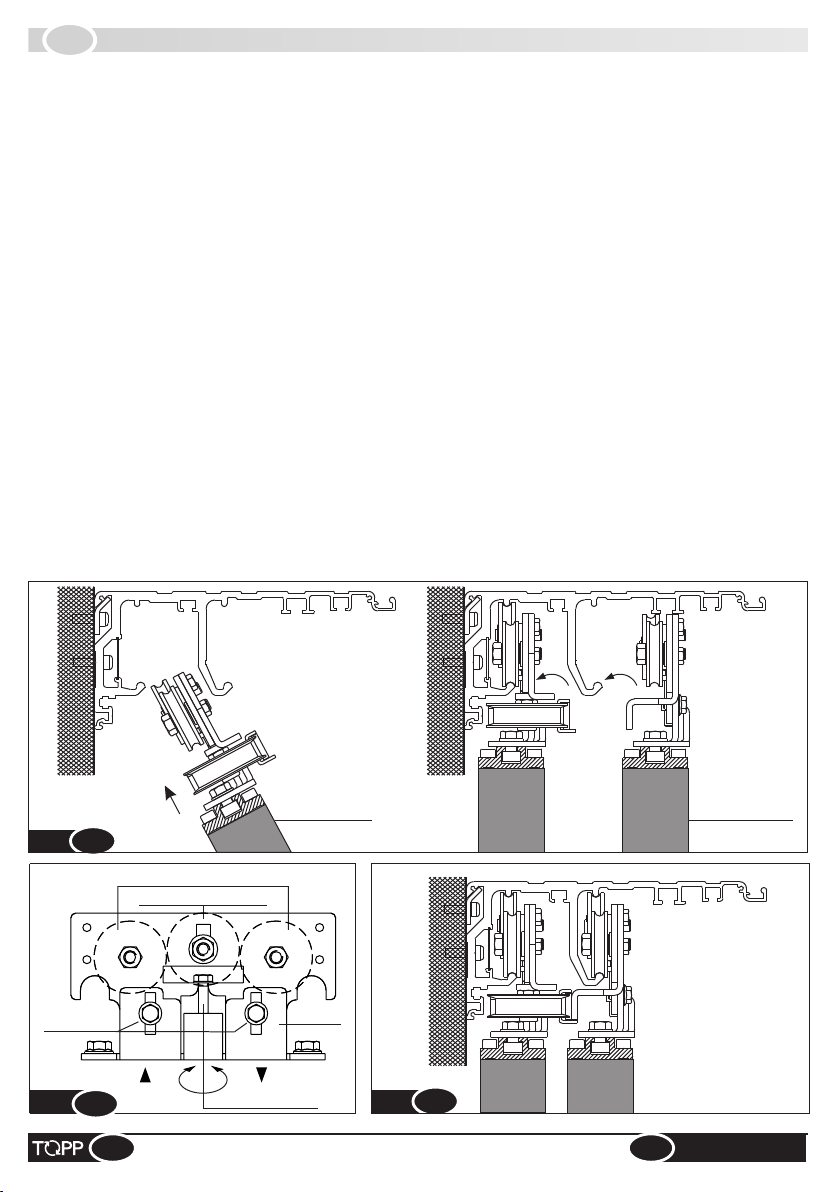

ADJUSTMENT OF TROLLEYS AND ASSEMBLY OF BELT ON SLOW WING

10

65

RCP RCA

Slow wing back

LAL

CAL

Fig. 16

10 65

LAL

RCP

RCA

CAL

RGC

Wrench supplied

RGC

Belt joint plate

Internal

side

Internal

side

CAL

CAL

15

K200T

-K280T INSTRUCTIONS FOR INSTALLATION AND USE

EN

Slow wing, opening toward the left (Fig.15):

Note! Tightening should not be excessive as it functions as a driver for the slow wing and not as drive traction like the

fast wing.

@To tighten the belt CAL turn the adjustment wheel RGC counterclockwise with the special wrench supplied to

obtain a minimum provisional tightening, then partially tighten the screws on bracket RCA .

Note! Final tightening will be done only after assembling and adjusting the wings on the crossbar.

After assembling and adjusting the trolleys on the wing, loosen the screws of the bracket RCA and assemble the belt

CAL on the pulleys of the transmission brackets RCP and RCA.

Note! The belt joint plate must be facing toward the inside of the door.

Slow wing, opening toward the left (Fig.16):

@To tighten the belt CAL turn the adjustment wheel RGC clockwise with the special wrench supplied to obtain a

minimum provisional tightening, then partially tighten the screws on bracket RCA .

Slow wing,opening toward the right

Internal

side Wrench supplied Internal

side

Slow wing back

Belt joint plate

Note the direction

of installation

3.6

ASSEMBLY AND ADJUSTMENT OF FAST AND SLOW SLIDING WINGS

Fig. 17

Slow wing Fast wing

Antiderailment wheel

SX

Bearing wheels

Trolley

screw

Adjustment screw

Trolley

DX

Fig. 18 Fig. 19

16 K200T-K280T

EN

INSTRUCTIONS FOR INSTALLATION AND USE

-Fasten the slow wing on the sliding base of the crossbar by tilting and inserting it while lifting it slightly upward, while

the fast wing is fastened straight (Fig.17);

To fasten the sliding wings to the crossbar proceed as follows:

@ If an air seal brush is foreseen between the fast wing, the slow wing and the upright or fixed wall, adjust the wing

so that there is a space of about 1 mm on the entire length between the brush and the wing;

Adjust the wing height using the special adjustment screws on the trolleys (Fig.18 and 21). After performing this

operation, tighten the screws on the load-bearing wheels and raise the antiderailment wheel;

-Bring the wings up to the crossbar and make sure the sliding base of the trolleys is clean and free of any scraps;

@ Make sure the slow wing is raised off the floor by at least 12 mm and the fast wing is raise of the floor by at least

5mm.

-Before tightening the screws make sure the trolleys are aligned with the crossbar and with each other;

@ Use the height adjustment screws on the trolleys to raise or lower the wing by ±10mm (with the crossbar correctly

installed in respect of the measurements and dimensions shown in Fig.8).

-Lower the antiderailment wheels of the trolleys (Fig. 18);

-Fasten the runner of the slow wing in accordance with measurement “A1” on the floor using the d.8 blocks and self-

tapping screws type d.5x60 found in the hardware package (fig. 22); then fasten the runner of the fast wing on the

front vertical upright of the slow wing, based on measurement “A2”, using the self-tapping screws type d.4.8x20 found

in the hardware package (Fig.23);

-Loosen the trolley fastening wheels and fit the no. 10 wrench supplied into the special adjustment screw to adjust the

height of the trolley. Turn it to the right or left so as to raise the wing off the flow by about 12 mm (measurement of the

standard runner);

-Adjust the space “A1” and “A2” (Fig.22 and 23) by loosening the screws that fasten the lower brackets of the trolley

to the adapter. There are slots on the base of the brackets that can be used to move the wing by about 18 mm;

-Decide distance “A1” and “A2” for adjustment of the wing (Fig. 20);

A1

Fig. 20

Trolley bottom bracket

Fast wing

Adapter

Fast wing runner

A2

Slow wing

A1 A2

Slow wing runner

12 mm

Fig. 21

LPF

12

17

K200T

-K280T INSTRUCTIONS FOR INSTALLATION AND USE

EN

Slow wing Slow wing

Fast wing Fast wing

Fig. 23

Slow wing plastic runner

WALL

Fig. 22

Fast wing plastic runner

Fast wing back part

Slow wing

LPF

12

5

Fast wing

SLOW WING FAST WING

Two self-drilling screws

3.7

ASSEMBLING DRIVE BRACKET AND BELT BLOCK BRACKET ON SLOW WING

18 K200T-K280T

EN

INSTRUCTIONS FOR INSTALLATION AND USE

Slow wing back part

-Align the front upright of the slow wing with the rear upright of the fast wing in the closed position, fasten the drive

bracket on the belt, then fasten it to the rear trolley of the fast wing (Fig.25 and 26).

Assemble the drive bracket and belt block bracket on slow wing as shown in the figures:

(Use the same assembly procedure for all models, 2-wing and 4-wing, but with different right and left brackets).

NOTE: Insert the threaded plate on the crossbar.

-Make sure the belt CAL of the slow wing is tightened correctly and the trolleys have been fastened and adjusted

permanently;

-Stack and align the slow wing with the fast wing in the open position, fasten the FCT bracket (crossbar belt block) on

the crossbar with the specific M5x12 screws (Fig. 27). It permits adjustment by ± 20mm.

Fig. 25

RCP RCA

Slow wing

Fast wing

Fig. 26

RCP

RCA

CAL

CAL

Drive bracket slow wing

Rear trolley fast wing

M5x8

M6x10

M5x8

M6x10

Fig. 27

25 (+/-20)

Belt block bracket

Side fixing

trolleys

A

DETAIL A

N° 2 screws M5x12

Threaded plate

19

K200T

-K280T INSTRUCTIONS FOR INSTALLATION AND USE

EN

2 wings,opening toward the left

2 wings,opening toward the right

Side fixing

trolleys

Slow wing

Fast wing

Drive bracket slow wing

Rear trolley fast wing

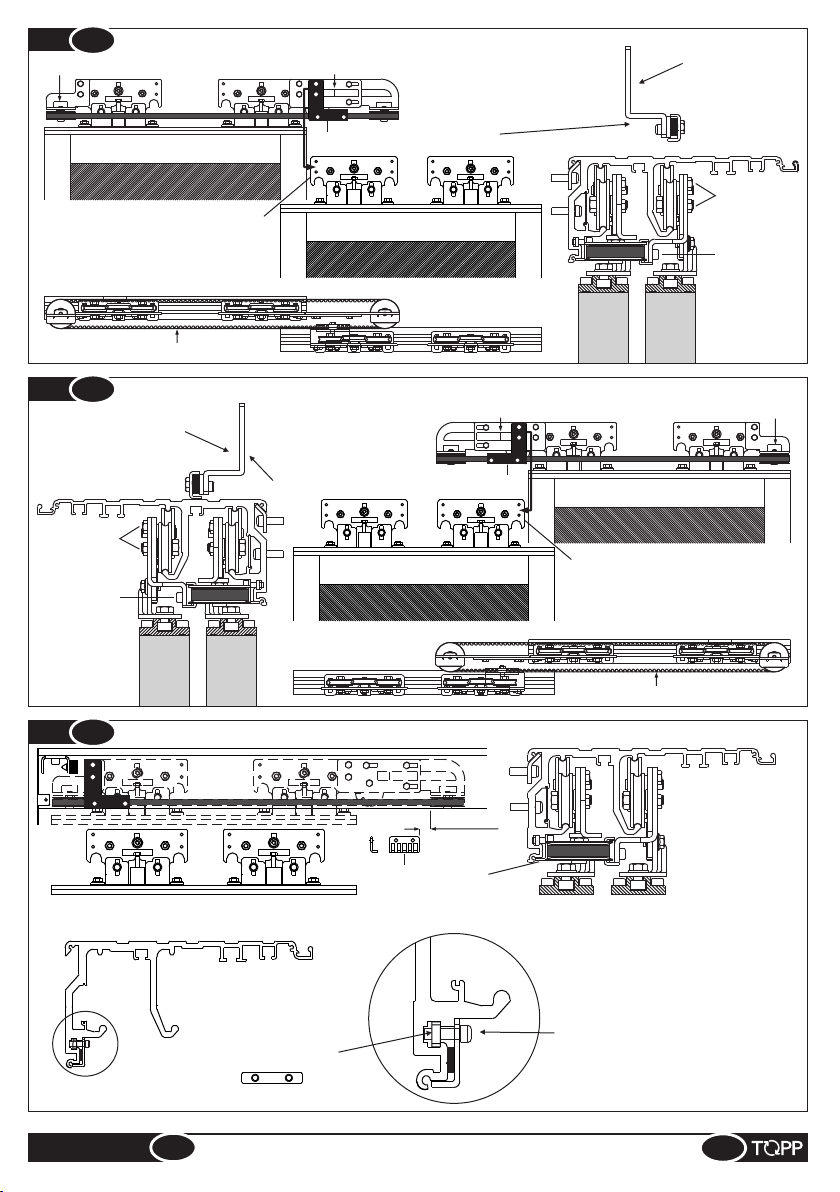

3.8

ASSEMBLING MOTOR MODULE, BELT TRANSMISSION,BELT IN FAST WINGS AND LOGLINE

K200T - 2 WINGS (Fig.28a)

VPA A B L Belt L Logline

900 120 1162 1x2312 352

1000 120 1266 1x2520 456

1100 120 1370 1x2728 560

1200 120 1474 1x2936 664

1300 120 1578 1x3144 768

1400 120 1682 1x3352 872

1500 120 1786 1x3560 976

1600 120 1890 1x3768 1080

1700 120 1994 1x3976 1184

1800 120 2098 1x4184 1288

1900 120 2202 1x4392 1392

2000 120 2306 1x4600 1496

2100 120 2410 1x4808 1600

2200 120 2514 1x5016 1704

2300 120 2618 1x5224 1808

2400 120 2722 1x5432 1912

2500 120 2826 1x5640 2016

2600 120 2930 1x5848 2120

2700 120 3034 1x6056 2224

2800 120 3138 1x6264 2328

2900 120 3242 1x6472 2432

3000 120 3346 1x6680 2536

3100 120 3450 1x6888 2640

3200 120 3554 1x7096 2744

3300 120 3658 1x7304 2848

3400 120 3762 1x7512 2952

3500 120 3866 1x7720 3056

3600 120 3970 1x7928 3160

3700 120 4074 1x8136 3264

3800 120 4178 1x8344 3368

3900 120 4282 1x8552 3472

4000 120 4386 1x8760 3576

4100 120 4490 1x8968 3680

4200 120 4594 1x9176 3784

K200T - 4 WINGS (Fig.28b)

VPA A B L Belt L Logline

1800 1292 1292 2x2568 1774

1900 1344 1344 2x2672 1878

2000 1396 1396 2x2776 1982

2100 1448 1448 2x2880 2086

2200 1500 1500 2x2984 2190

2300 1552 1552 2x3088 2294

2400 1604 1604 2x3192 2398

2500 1656 1656 2x3296 2502

2600 1708 1708 2x3400 2606

2700 1760 1760 2x3504 2710

2800 1812 1812 2x3608 2814

2900 1864 1864 2x3712 2918

3000 1916 1916 2x3816 3022

3100 1968 1968 2x3920 3126

3200 2020 2020 2x4024 3230

3300 2072 2072 2x4128 3334

3400 2124 2124 2x4232 3438

3500 2176 2176 2x4336 3542

3600 2228 2228 2x4440 3646

3700 2280 2280 2x4544 3750

3800 2332 2332 2x4648 3854

3900 2384 2384 2x4752 3958

4000 2436 2436 2x4856 4062

4100 2488 2488 2x4960 4166

4200 2540 2540 2x5064 4270

20 K200T-K280T

EN

INSTRUCTIONS FOR INSTALLATION AND USE

Lower belt bracket – front carriage – wing opens to the right

Upper belt bracket – front carriage – wing opens to the left

Fig. 28a

BBELT TENSION ADJUSTEMENT

A

BELT TRANSMISSION

MOTOR MODULE

BELT TRANSMISSION

MOTOR MODULE

AB BELT TENSION ADJUSTEMENT

2 WINGS LEFT: 1 SLOW WING LEFT + 1 FAST WING LEFT

2 WINGS RIGHT: 1 SLOW WING RIGHT+ 1 FAST WING RIGHT

4 WINGS: 1 SLOW WING LEFT + 1 FAST WING LEFT / 1 SLOW WING RIGHT + 1 FAST WING RIGHT

C

LB

BELT TRANSMISSION

BELT TENSION ADJUSTEMENT

Fig. 28b

A

Lower bel bracket- front carriage – wing opens to the right

Upper belt bracket – front carriage – wing opens to the left

MOTOR MODULE

This manual suits for next models

1

Table of contents

Other TOPP Door Opening System manuals