6. EQUIPPING THE WINCH WITH A

ROLLER FAIRLEAD will substantially

reduce wear on the wire rope

during angle pulls (Figure 11).

The rollers eliminate heavy rubbing

and abrasion to the wire rope.

Periodically check tightness of

mounting bolts and electrical con-

nections. Remove any dirt or corro-

sion that may have accumulated on

the electrical connections.

Repairs should be done by

Authorized Superwinch Repair

Centers ONLY. Do not attempt to

disassemble the gearbox.

Disassembly will void warranty.

LUBRICATION

The gearbox and drum bearing are

permanently lubricated with a high

performance gear lube.

REPLACING THE WIRE ROPE

Never substitute a heavier or lighter

wire rope. Never use rope made of

any other material other than wire.

Always replace damaged wire

rope with manufacturer’s

identical replacement part (see

Replacement Parts list). Pass attaching

end of wire rope through the fairlead (if

equipped) and attach it to the drum.

When inserting the wire rope into

the drum, insert it into the correct

end of the hole provided (Figure

12). Tighten the set screw securely.

It is important that the wire rope

be wound tightly onto the drum.

A good way to do this is to attach

the wire rope hook to a fixed object

at the top of a slight incline, then

winch the vehicle up the incline.

When wire rope is removed from

the drum, as in bringing the hook

to the load, the freewheel feature

of the winch should be used.

BRAKE ADJUSTMENT

Over time, the load-holding brake

in your winch will wear. Should you

find the load beginning to slip,

adjustments can be made to the

brake mechanism as follows:

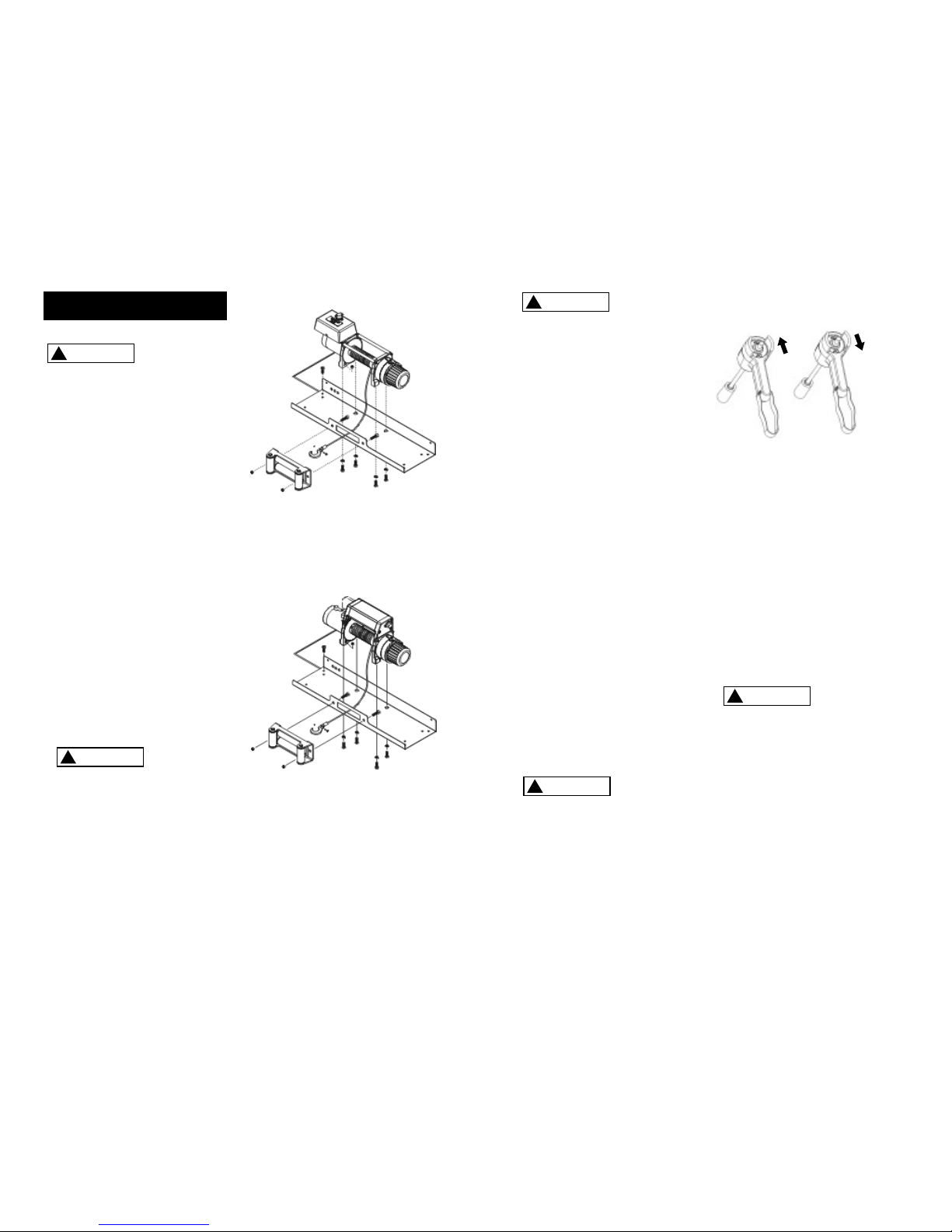

1) Loosen the 3 retaining bolts and

remove the brake cover. (Ref.#25

Figs. 13, 14)

2) Remove the two retaining C-rings.

(Ref.#35 Figs. 13, 14)

3) Insert washers to maintain a spacing

of .090" +/- .010" between the C-ring

grooves and the brake actuating cam.

(Ref.#21 Figs. 13, 14)

4) Re-install the two C-rings and

brake cover.

PULLING OUT THE WIRE ROPE

The wire rope has been installed on

your winch under minimal load at

the factory. The wire rope must be

respooled onto the drum under

load so that the outer layers will

not draw down into the inner ones

thereby damaging the wire rope.

Rotate the clutch lever to the “Free

position as shown in Figure 8. If

there is a load on the wire rope, the

clutch lever may not turn easily. DO

NOT FORCE THE CLUTCH LEVER.

Release tension on the wire rope by

jogging out some of the wire rope,

then try releasing the clutch. Pull

out the wire rope and secure to

anchor or load. Check that there

are at least five (5) turns of wire

rope left on the drum. Re-engage

the drum by rotating the clutch

lever to the “Engaged”position

(see Figure 8).

Lever must be in

the engaged

position and locked before winching.

TIPS FOR EXTENDING THE LIFE OF

THE WINCH

1. KEEP A TIGHTLY WOUND WIRE

ROPE DRUM. Do not allow the

wire rope to become loosely

wound. A loosely-wound drum

allows a wire rope under load to

work its way down into the layers

of wire rope on the drum. When

this happens, the wire rope may

become wedged within the body

of the windings damaging the

wire rope. To prevent this prob-

lem, keep the wire rope tightly

and evenly wound on the drum

at all times. A good practice is to

rewind the wire rope under ten-

sion after each use. One way to

do this is to attach the hook to a

stationary object at the top of a

gradual incline and winch your

vehicle up the incline.

2. DO NOT ALLOW WINCH MOTOR

TO OVERHEAT. Remember, the

winch is for intermittent use only.

During long or heavy pulls the

motor will get hot. The internal

parts will be hotter than the case.

To check the motor temperature,

stop winching and carefully touch

the motor case, if the motor is

uncomfortable to touch, allow

the motor to cool before continu-

ing. KEEP THE ENGINE RUNNING

TO RECHARGE THE BATTERY dur-

ing this break.

3. To maximize winch and wire rope

life, use a pulley block to double

line heavier loads (Figure 9).

4. The pull required to start a

load moving is often much

greater than the pull required

to keep it moving. AVOID

FREQUENT STOPPING AND

STARTING during pull.

5. PREVENT KINKS BEFORE THEY

OCCUR.