Sure Flame Products

Maintenance and Opertation Manual

P/N 974-9246 Rev 4.22. September 2010

5

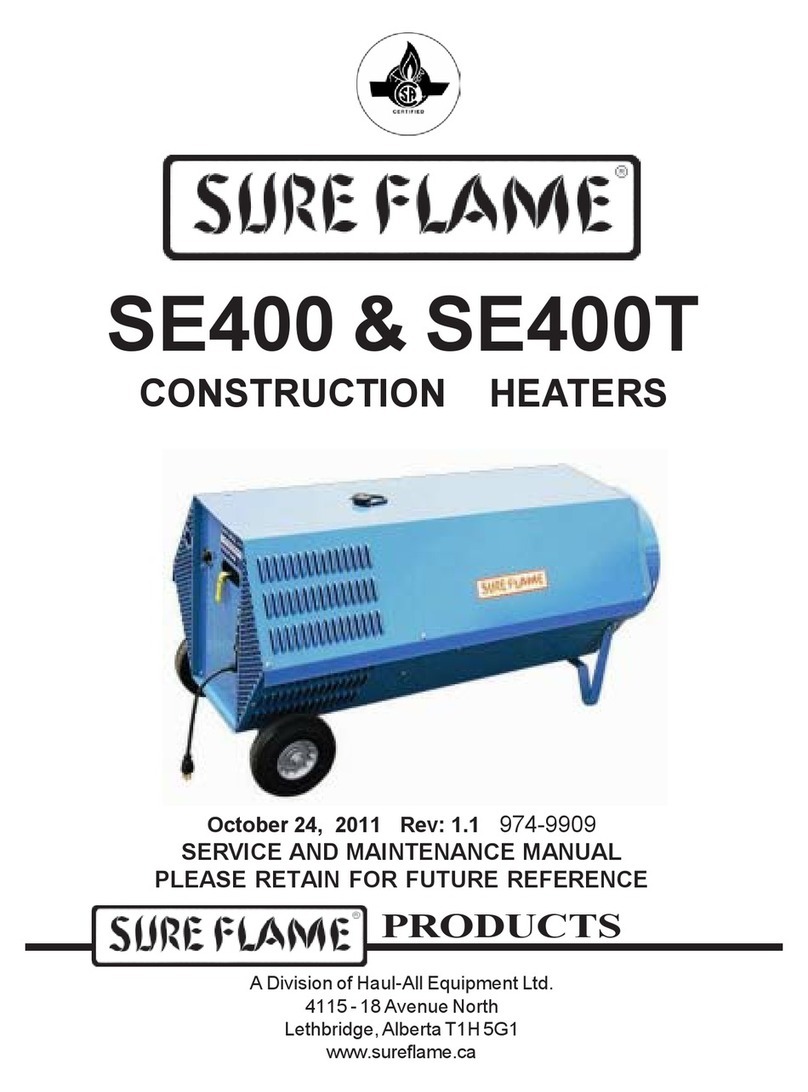

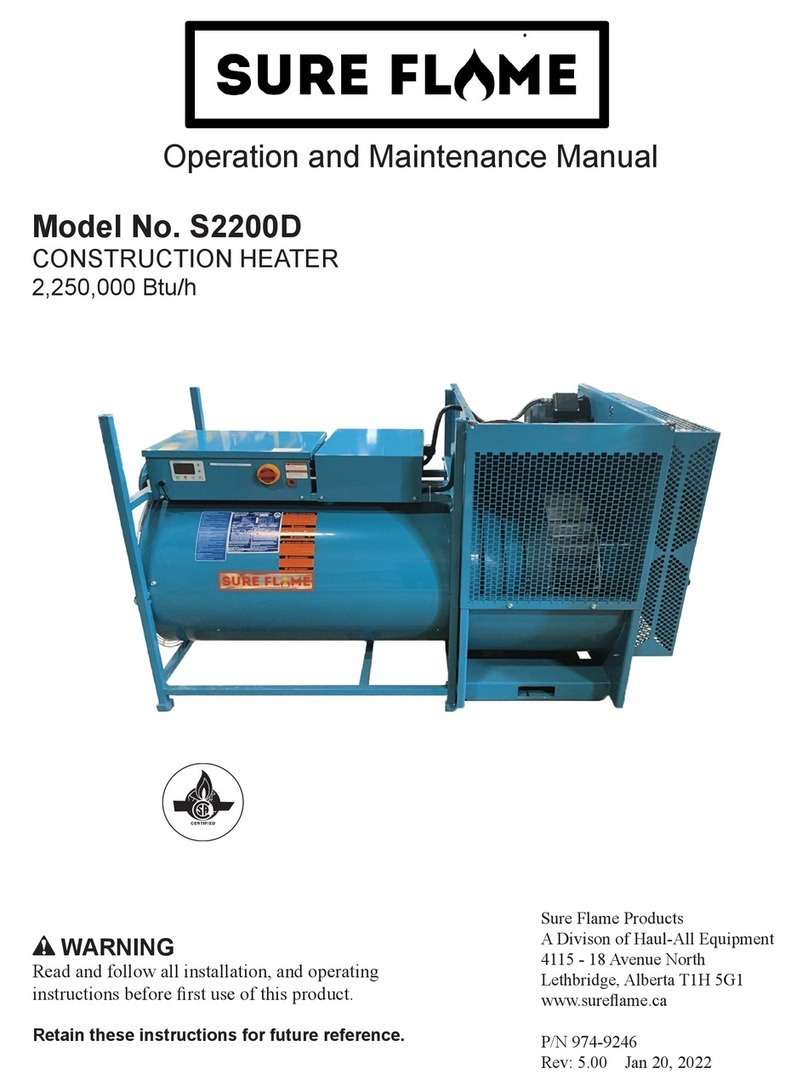

The Sure Flame Model S2200 is a direct fired

gas heater intended to be used primarily for the

temporary heating of buildings under construc-

tion, alteration, or repair. Since all the products

of combustion are released into the area being

heated, it is imperative that adequate ventilation

is provided. The flow of supply air must not be

obstructed in any way.

1. Install the heater in a horizontal position at

least 10 feet (3 m) from any LP-gas

container. The front outlet must be at least

20 feet (6 m) from any LP-gas container.

Allow the following clearances from any

combustible material or fuel containers:

Outlet: 25 feet (7.6 m)

Sides: 3 feet (0.9 m)

Intake: 3 feet (0.9m)

Top: 4 feet (1.2 m)

Duct: 1 foot (0.3 m)

Floor: Noncombustible

Also make sure that no flammable vapours

are present in the space where the heater is

being used.

2. When connecting the heater to a natural gas

or propane supply line ensure that the

pressure at the heater inlet is within the

specified range. Excessive pressure (over 5

psig or 34 kPa) will damage the controls and

void the warranty.

3. Visually inspect the supply hose assembly

and ensure that it is protected from traffic,

building materials, and contact with hot

surfaces. If it is evident that there is

excessive abrasion or wear, or the hose is

cut, it must be replaced.

4. After installation, check the hose assembly

for gas leaks by applying a water and soap

solution to each connection.

5. Connect the heater to an adequate electric

power supply as specified on the Heater

Specification label and the Electric Motor

plate.

6. For protection against shock hazard the

supply cord should be plugged directly into

a properly grounded receptacle in compli-

ance with the

Canadian Electrical Code,

CSA C22.1, Part 1.

The appliance area should be kept clear and free

from combustible materials, gasoline, and other

flammable vapours and liquids.

Ensure that the flow of supply air is not

obstructed.

The installation and operation of the heater shall

comply with the code requirements specified by

the authorities having jurisdiction.

General criteria for the installation and use of

construction heaters may be found in the

applicable sections of the

Natural Gas and Propane Installation

Code,CSA B149.1

The installation and maintenance of the heater

must be accomplished by a qualified service

person.

This heater is approved for use without

ductwork, or with up to 40 feet of 24” square

ductwork. Only ductwork supplied by the

manufacturer should be used with this heater.

When using the heater without ductwork,

securely fasten the outlet screen in the down

position.

Heater Installation