Sure Flame IX405 User manual

Other Sure Flame Heater manuals

Sure Flame

Sure Flame SL11E User manual

Sure Flame

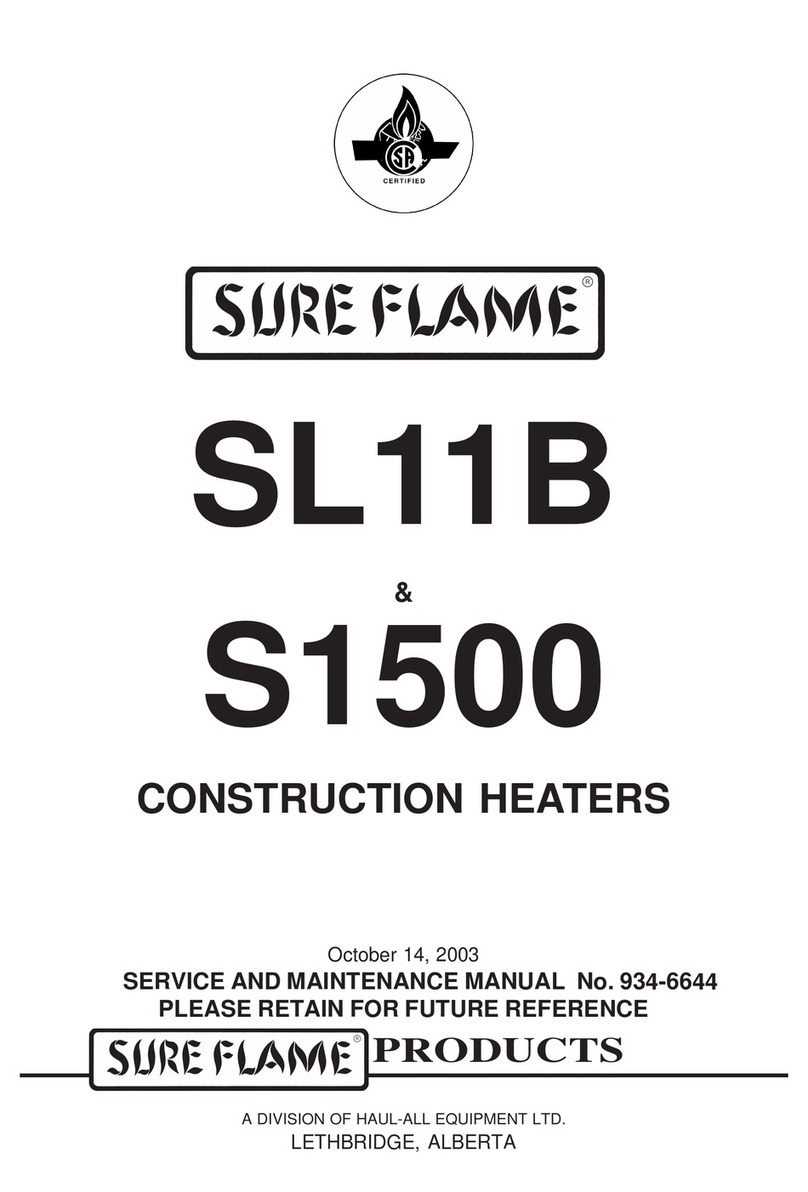

Sure Flame SL11B Installation and user guide

Sure Flame

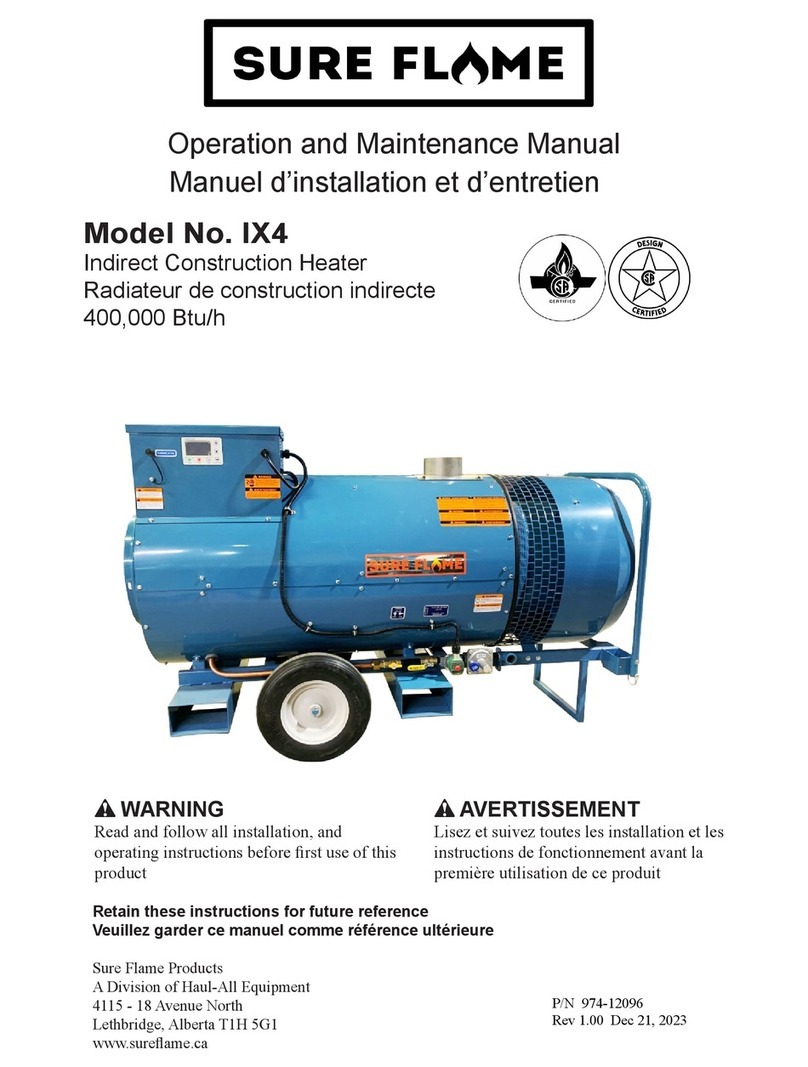

Sure Flame IX4 User manual

Sure Flame

Sure Flame SE405 Installation and user guide

Sure Flame

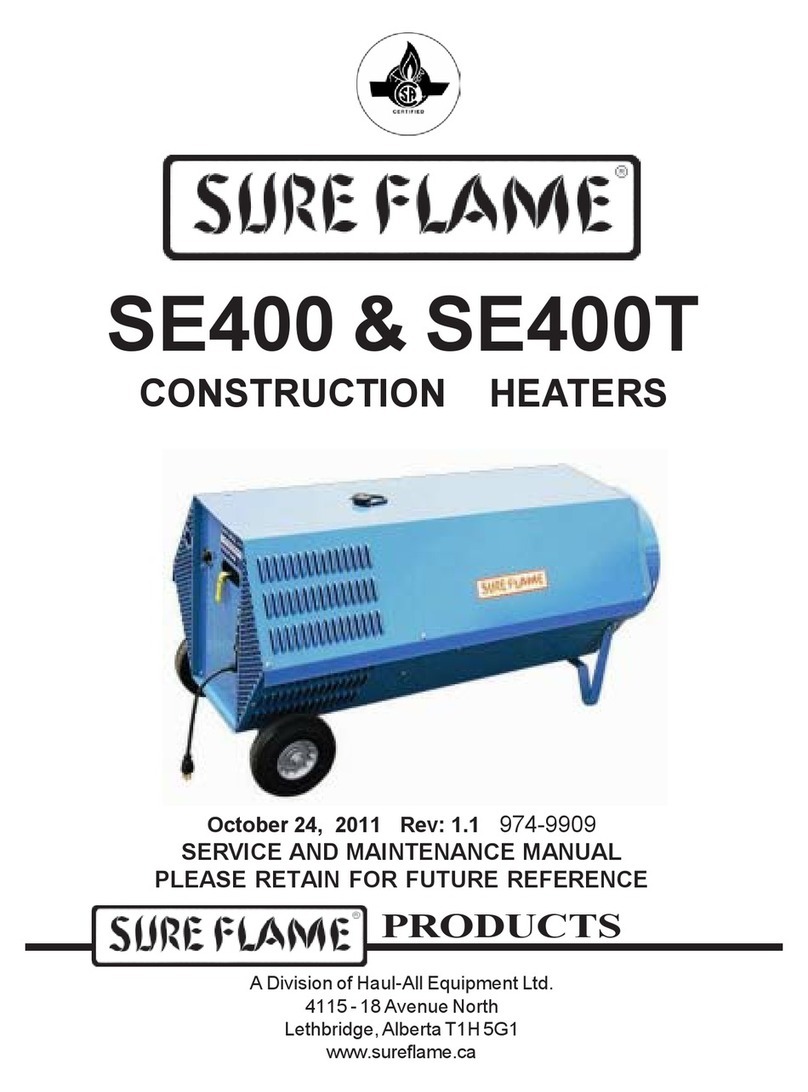

Sure Flame SE400 User manual

Sure Flame

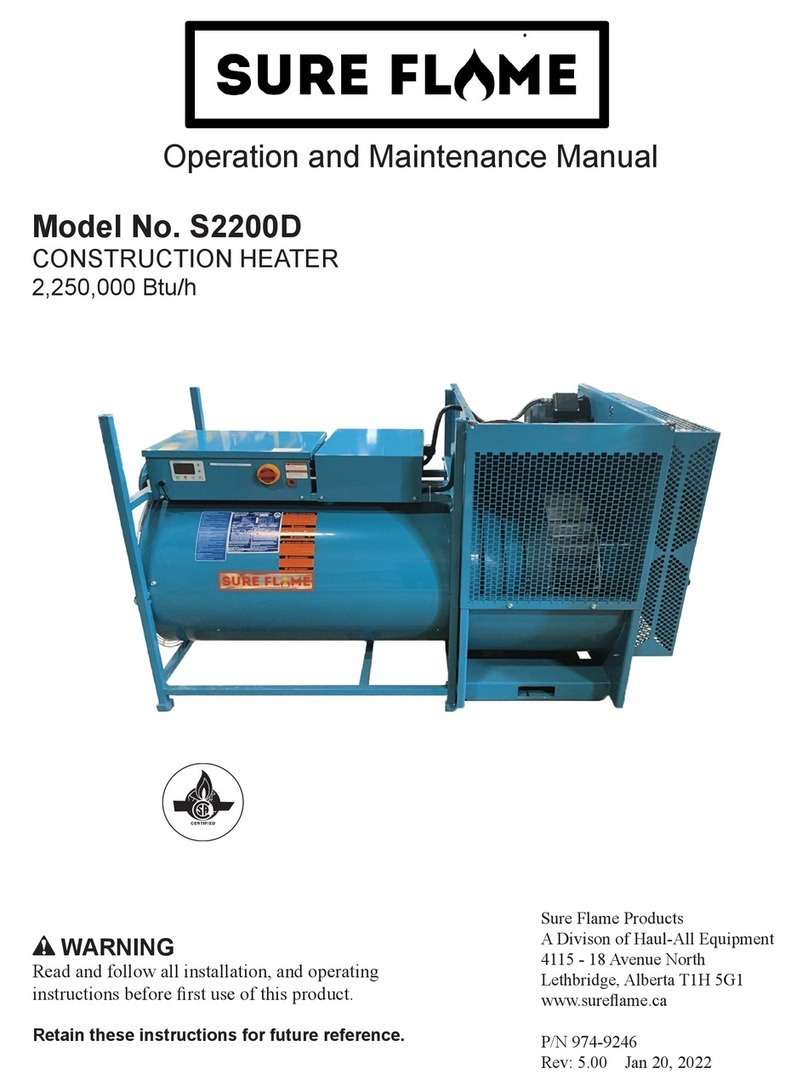

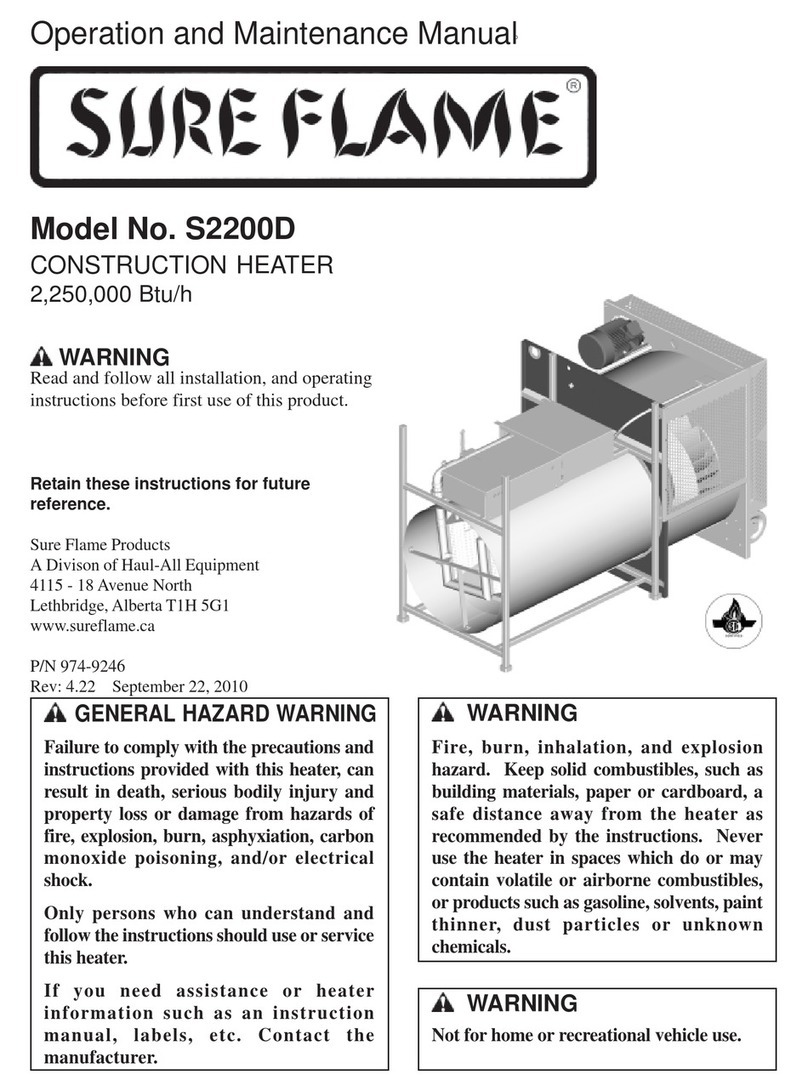

Sure Flame S2200D User manual

Sure Flame

Sure Flame ID 100 User manual

Sure Flame

Sure Flame IX800 User manual

Sure Flame

Sure Flame S400 Installation and user guide

Sure Flame

Sure Flame S1505B User manual

Popular Heater manuals by other brands

Trox Technik

Trox Technik WL Fitting instructions

Alpina

Alpina HP-12AR instruction manual

Dantherm

Dantherm Master BC 121 User and Maintenance Book

S&P

S&P CAF-900 M PD manual

Frost Fighter

Frost Fighter IDHQR Series Installation - Operation/Maintenance Instructions and Parts List

Hyundai

Hyundai H-HV3-10-UI568 Instruction manual & warranty card