SAFETY INSTRUCTIONS

delta10 - dl/01-2005

1

1

1 SAFETY INSTRUCTIONS

1.1 General Information

Prior to installation, starting and operation of the

system relevant safety instructions should be read

carefully and considered accordingly.

Persons charged with transport, storing, installa-

tion, starting, operation, maintenance and service

have to know the content of this manual.

This manual contains information and warnings to

be followed by the user to ensure safe operation

and to maintain the system in secure condition. It

should be located in a suitable place close to the

system.

In addition to this manual all valid, legal and other

local regulations concerning prevention of acci-

dents as well as protection of the environment are

applicable.

Please consider all instructions, in particular safety

instructions, in order to achieve safe operation of

the system.

Possible hazards harming the user or resulting in

damage to the system are clearly stated within ap-

propriate chapters of this manual.

Safety instructions plus important information are

marked in the following way:

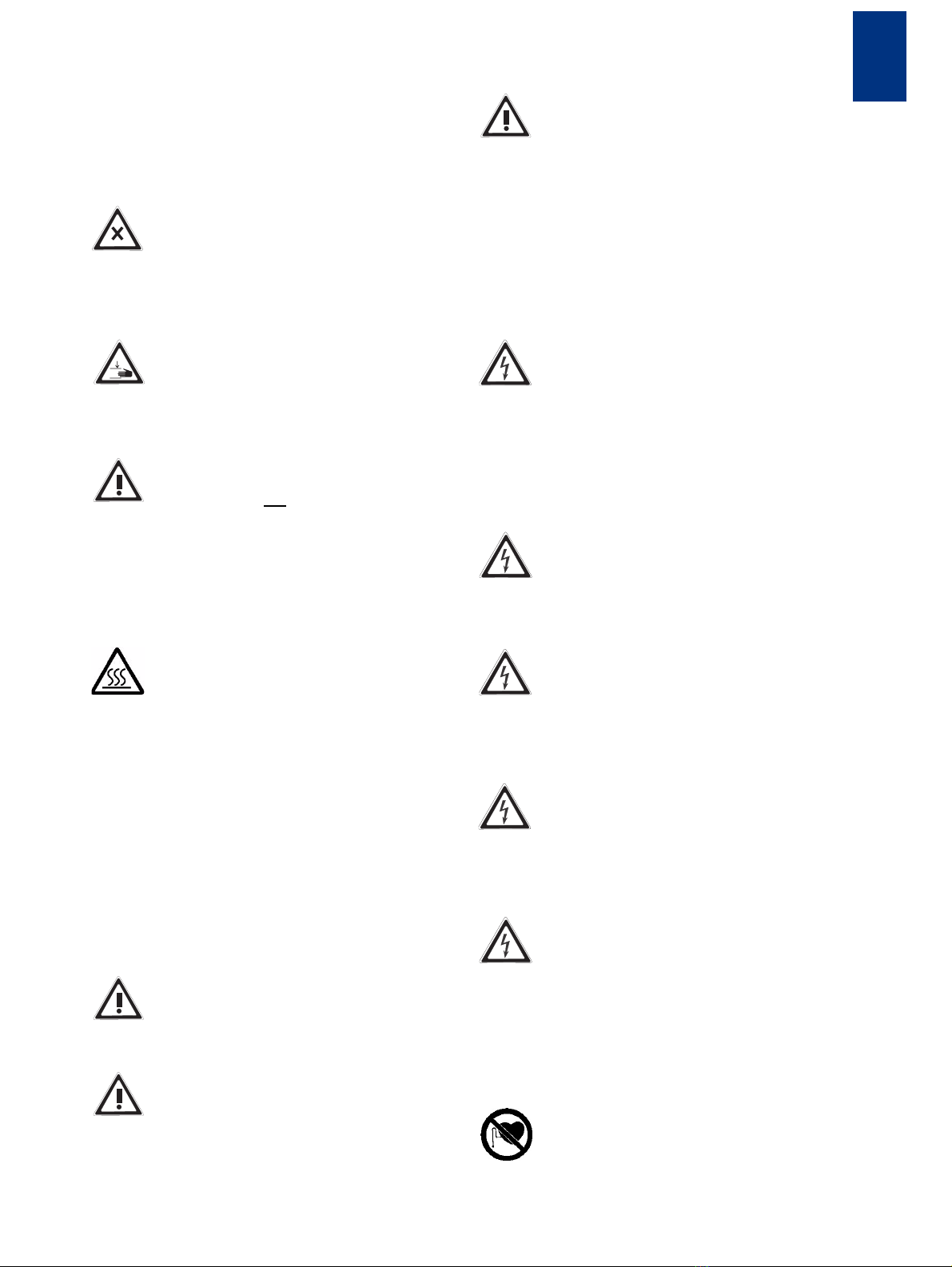

Danger!

The word ”Danger!” combined with this or

a more specific symbol indicates an im-

mediate hazard while using the system.

Neglecting of instructions given in this

documentation or on the system itself can

result in severe personal injury or death of

the operator or of persons being close by.

The system, other equipment or the envi-

ronment can be seriously damaged as

well.

Warning!

The word ”Warning!” combined with this

or a more specific symbol indicates an im-

pending hazard while using the system.

Neglecting of instructions given in this

documentation or on the system itself can

result in severe personal injury of the op-

erator or of persons being close by.

The system, other equipment or the envi-

ronment can be damaged as well.

Caution!

The word ”Caution!” combined with this or

a more specific symbol indicates a pos-

sible hazard while using the system.

Neglecting of instructions given in this

documentation or on the system itself can

result in personal injury of the operator or

of persons being close by.

The system, other equipment or the envi-

ronment can be damaged as well.

Please consider all instructions, in particular safety

instructions, in order to achieve safe operation of

the system.

Advice contained in this chapter is intended to sup-

plement, not to supersede, the safety advice given

in other chapters of this manual and the general

safety code of behavior prevailing in the user’s

country.

1.2 Operating Personnel

This technical device may only be operated by qual-

ified and trained personnel.

No pacemakers!

No access for persons with pacemakers!

Emission levels way impact cardiac pace-

makers!

Please verify the following conditions:

• Minimum age of operator:

Observe the national regulations of your coun-

try.

• Transport and mounting:

Transport and mounting work requires person-

nel specially trained for such tasks.

• Connecting and handling of process media:

The handling of process media, hazardous

chemicals etc. requires appropriately trained

and informed personnel. Hazards for each

chemicalhave to be wellknown and precautions

strictly observed.E

• Electrical installations:

Electrical installations and repair work requires

appropriately trained and informed personnel.