PARASOL VAV

10 Swegon reserves the right to alter specifications. 20160301

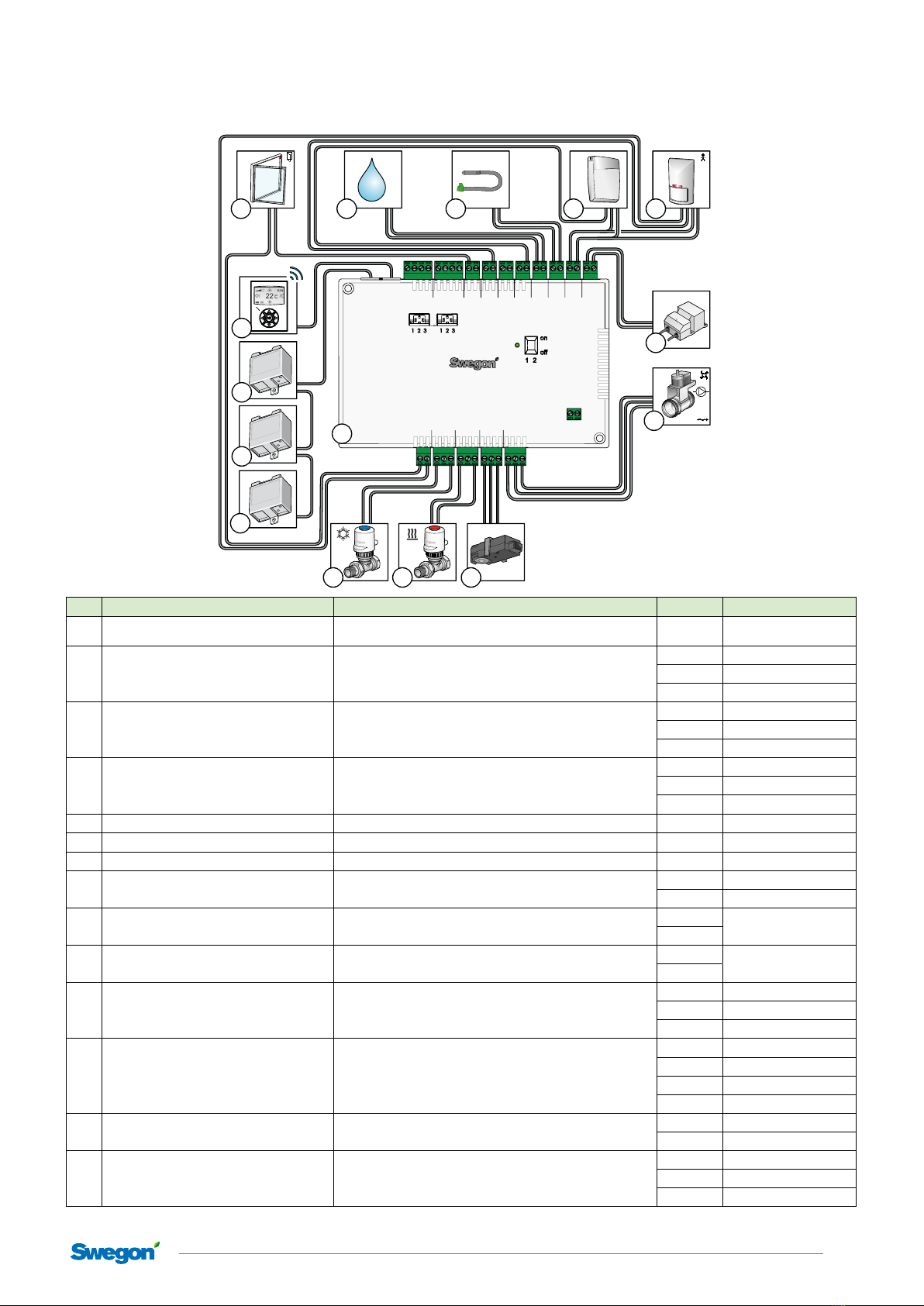

Conductor W4.1 VAV,

Commissioning/Checking the airflows

This information is a summary of the most important

points in connection with commissioning, checking the

airflows and adjustments.

For more detailed information see also Conductor

Technical Manual and Parasol VAV Product Datasheet at

swegon.com.

• Use CONTROL Zone dampers or equivalent dampers for

the best operation and constant pressurisation in the

zone.

• Check that all the products/constituent units are ener-

gised.

• Check that Conductor W4.1 VAV is set to Parasol VAV.

- Appl. parameter

- P_1964

- Value = 3

• Check that the Modbus address is correct if Super WISE

or another BMS is used.

- The Modbus address is unique for each room.

• For a correct Modbus addressing in the SuperWISE, the

room numbering is done in steps of 4.

Example

The master product in room no 1 shall have Modbus ID 4

The master product in room no 2 shall have Modbus ID 8

The master product in room no 3 shall have Modbus ID 12

• Check the pressure sensor's address

- SA1 = 3

- SA2 = 6

-EA = 4 (optional: extra pressure sensor if the extract

air damper is controlled from Conductor)

To set the C-factors and airflows

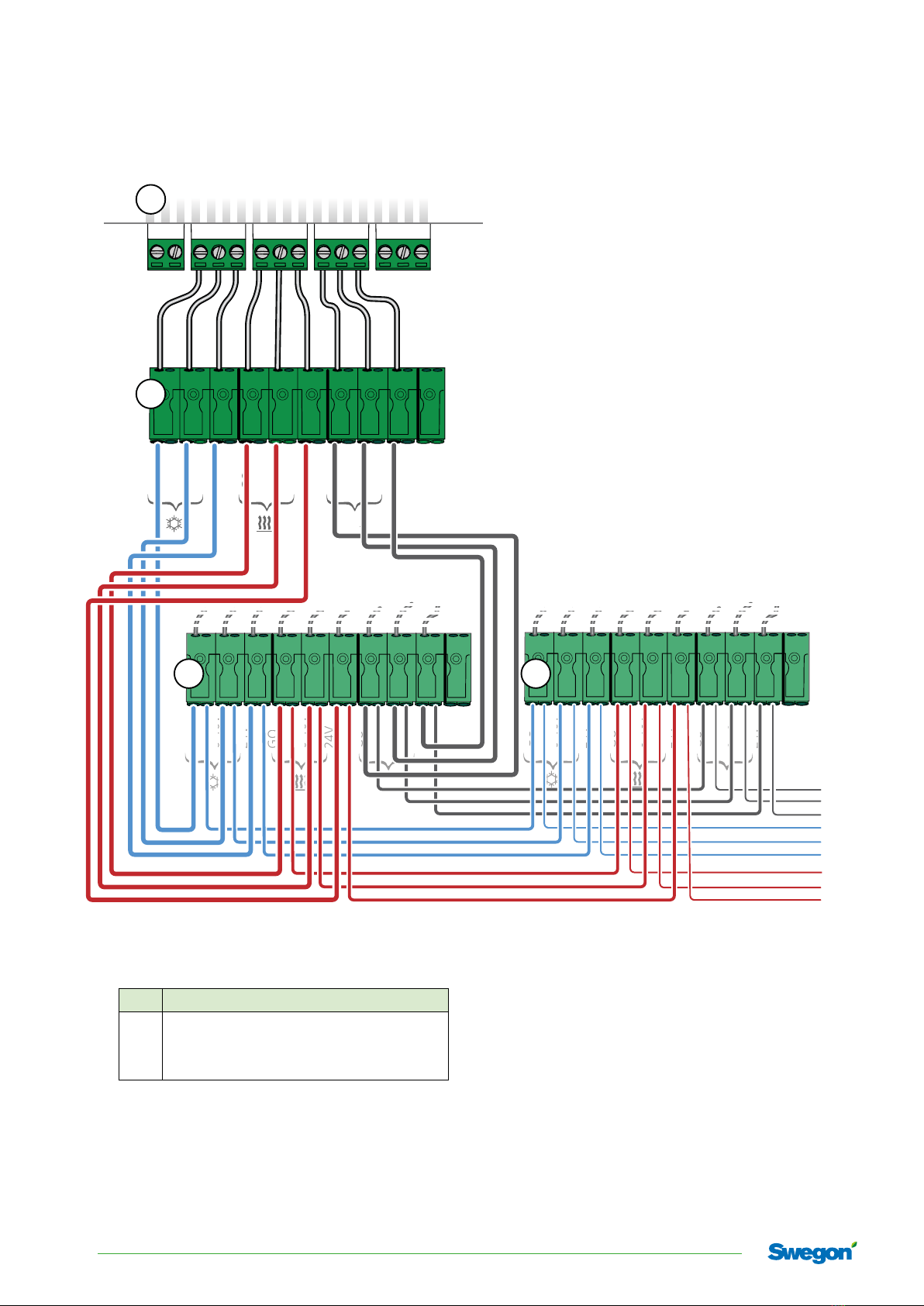

The Conductor W4.1 VAV calculates how the air damper

should either open or close in order to obtain the required

airflow. The Conductor W4.1 VAV calculates the airflow

in the air duct on the basis of the C-factor (resistance) and

the pressure in each air duct.

The C-factor SA1 and SA2 respectively are the sum of

C-factor of SA1: long sides (side 2 + 4) and SA2: short

sides (side 1 + 3) for all the modules (Master and slave

modules) connected to a Conductor W4.1 VAV.

• Check and adjust, if required, the C-factors and airflows

• Ensure that the C-factors of the SA1 and SA2 and the

required airflows are correct:

- RE Settings

- C-factor SA1 = Enter the total C-factor for the long

sides.

- Norm SA1 = Enter room's required airflow for occu-

pancy.

- Boost SA1 = Enter the maximum airflow for the

room.

- C-factor SA2 = Enter the total C-factor for the short

sides.

- Boost, SA2, does not have to be changed since the

setting for SA1 is used even here.

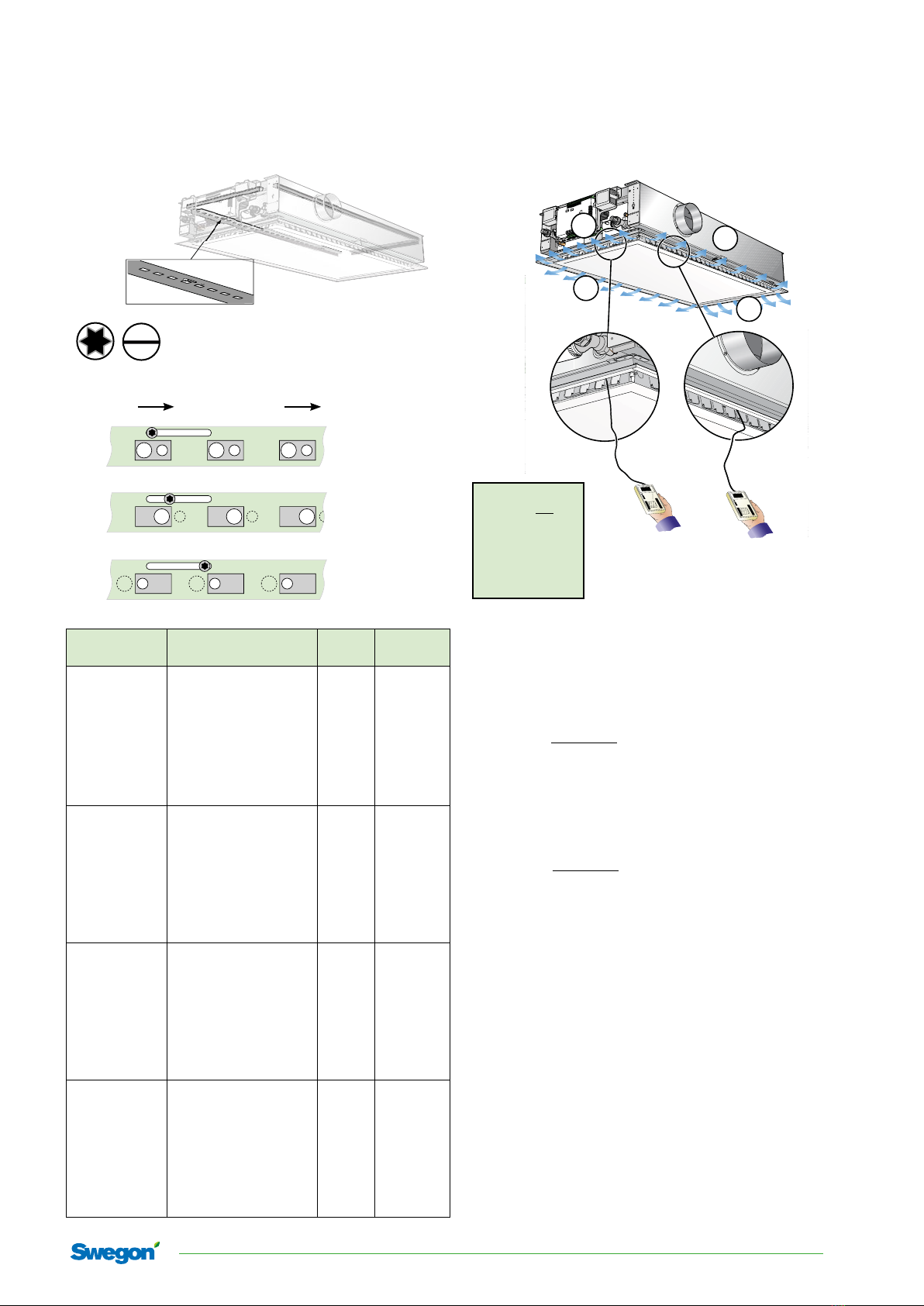

+40°

-40°

0°

-40º +40º

0º

-40º 0º

0º

Vacancy flow

Conductor W4.1 VAV can also manage extract airflows.

Enter the vacancy flow as a percentage of the occupancy

flow (Norm SA1).

• Check and adjust the vacancy flow in menu P_1938.

To check the performance of the actuators

• Check that the valve actuators for chilled water and

heated water are operating correctly.

- Settings - Commissioning – Water

- Activate and open the valve actuators with Cool

valve - Open or Heat valve – Open.

- Check after 2 - 3 minutes the actuator's indicator

which should now be in the raised position above

the enclosure which indicates that the actuator is in

the open position.

Commissioning and checking the airflows

Before you begin commissioning, ensure the following:

• The air handling unit has been started up

• The fire dampers, if required, are fully open

• The zone damper is in full operation

• Open the air damper of all the modules:

- Settings - Commissioning – Water

-Air – Max.Occ – On

The modules will now adjust themselves to product the

airflow that has been entered in Boost SA1.

• Check that the max. flow has been reached.

- Adjust the pressure setpoint of the zone dampers

upwards using the TUNE Control hand-held termi-

nal until the correct airflow has been obtained. If

the max. flow has still not been obtained, you can

close another/other zone damper(s).

The module (reference module) with the greatest devia-

tion from the design max. flow can be found by measur-

ing the max. flow of all the modules in the zone.