2

PELICAN Ceiling

We reserve the right to alter specifications. 20080315 www.swegon.com

Technical Description

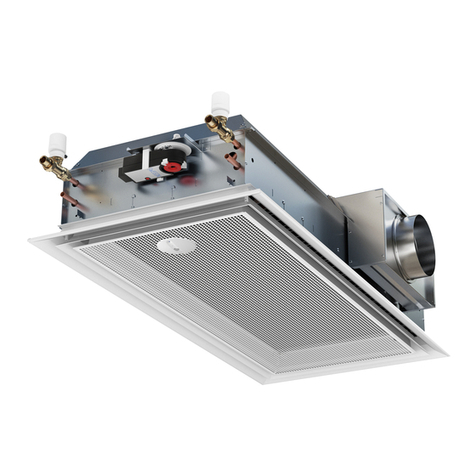

Design

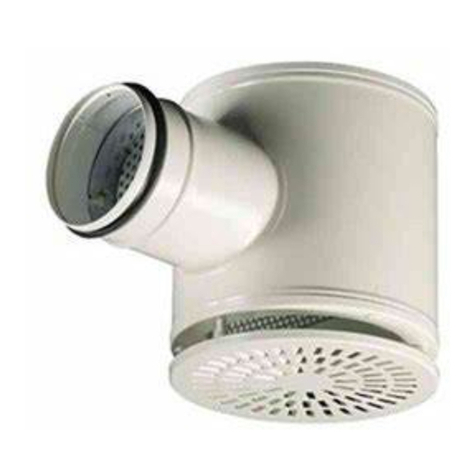

The square, perforated supply air diffuser consists of a

diffuser backing box and a diffuser face. The air diffuser's

perforated face plate is equipped with an adjustable air

flow director for simple variation of the distribution pattern.

The diffuser face is easy to install and remove. This enables

quick and uncomplicated installation, commissioning and

cleaning.

The air diffuser is also available in a low version if the

space inside the ceiling void is restricted. The air diffuser is

then supplied without sleeve coupling.

Materials and finish

The diffuser backing box and the diffuser face are made

of sheet steel. The commissioning box is made of galva-

nized sheet steel. The interior and exterior surfaces of the

air diffuser are painted in our standard white colour: RAL

9010. Air diffuser is also available painted in alternative

standard colours: dusty grey RAL 7037, white aluminium

RAL 9006, jet black RAL 9005, grey aluminium RAL 9007

and signal white RAL 9003 (NCS 0500).

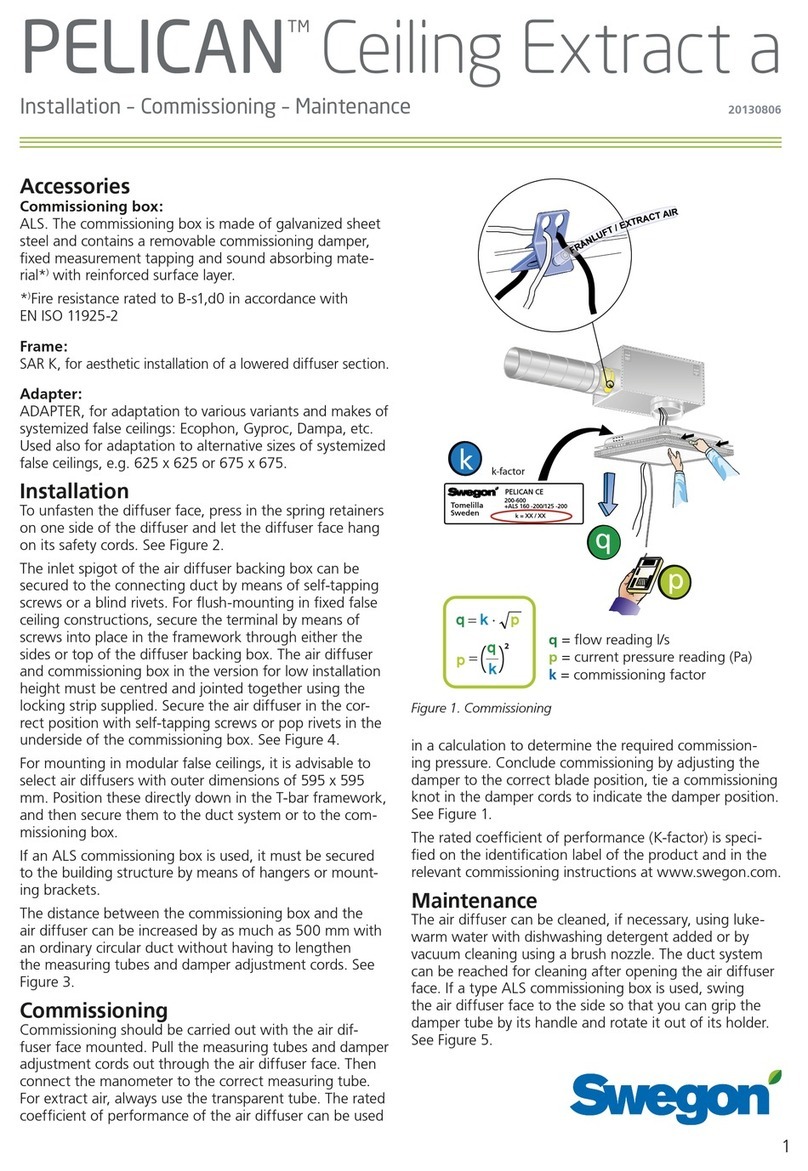

Accessories:

Commissioning box:

ALS commissioning box made of galvanized sheet steel.

The commissioning box contains a removable commis-

sioning damper, fixed measurement tappings and sound

absorbing material with a reinforced surface layer.

A combination for low design is also available, if instal-

lation in an extra low ceiling void is required. The air dif-

fuser as well as the commissioning box are then supplied

without any insertion joint and branch.

The commissioning box is available with 1 or 2 changes in

dimension between the inlet and the outlet.

Frame:

SAR K, for aesthetic installation of a lowered diffuser section.

Adapter:

ADAPTER L, for matching the diffuser to suspended ceil-

ing systems.

Project Design

PELICAN Ceiling is available in two connection sizes with

square dimensions of 395 x 395 and 595 x 595 mm

respectively. This makes the air diffusers very easy to

install in suspended modular ceilings with size 600 x 600

mm insertion dimensions for modules. Position the air

diffuser on the surface of the T-bar framework and then

secure it to the duct system. PELICAN Ceiling is also

available in a low version for installation in a ceiling void

where the installation height of components must be

minimized.

The air flow director can be accessed after you remove

the air diffuser face from its spring retainers. It consists of

a number of adjustable air deflectors and by turning these

you can easily set the distribution pattern desired. See

Figures 1 and 2.

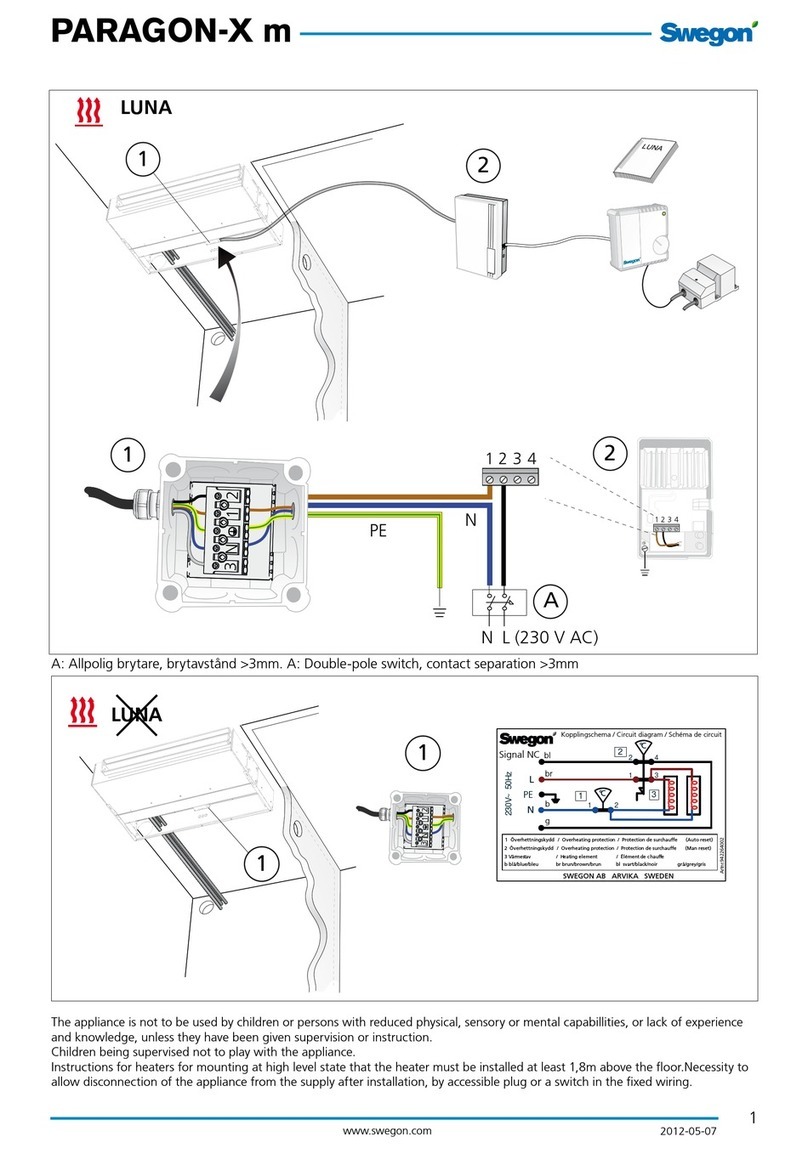

Installation

To unfasten the diffuser face, press in the spring retainers

on one side of the diffuser and let the diffuser face hang

on its safety cords. The inlet spigot of the diffuser backing

box can be secured to the connecting ducting by means

of self-tapping screws or a blind rivets. For flush-mount-

ing in fixed ceiling constructions, secure the air diffuser by

means of self-tapping sheet metal screws in the underside

of the commissioning box.

For installation in modular suspended ceilings, position

the air diffuser directly down in the T-bar framework, and

then secure it to the building structure with hangers or

mounting brackets. The distance between the commis-

sioning box and the air diffuser can be increased by as

much as 500 mm using an ordinary circular duct without

having to lengthen the measuring hoses and damper

adjustment cords. When the air diffuser is used for

exhaust air, remove the perforated plate in order to

reduce the risk of clogging. See Figures 1 and 2.

Commissioning

Commissioning for supply air must be carried out with

both the diffuser section and the perforated diffuser face

mounted. Pull out the white and red (or blue for a two-

step box) measuring hoses and the damper adjustment

cords through the diffuser face perforations and connect

the measuring hoses to a manometer. The required com-

missioning pressure can be calculated using the K-factor

of the air diffuser. When you have set the damper blade

to the correct position, tie a commissioning knot in the

damper cords to indicate the damper position. To com-

mission for extract air, move the commissioning box’s

measuring hose to the measuring nipple on the damper

handle. See Figure 4.

The K-factor is specified on the identification label of the

product and in the relevant commissioning instructions at

www.swegon.com.

Maintenance

The air diffuser can be cleaned, if necessary, using luke-

warm water with dishwashing detergent added. The duct

system can be accessed after you have opened the air

diffuser face and removed the perforated plate. If an ALS

commissioning box is used, pull the distributor plate aside

to enable you to grip and twist the damper unit from of

its mounting.

Environment

The Declaration of construction materials is available from

at www.swegon.com.