• All-metal and 2mm carbon fiber construction

• CNC machined 6061-T6 aluminum and Delrin components

• 140mm full head width for optimal disk loading

• Extra wide head block for quick cyclic response and high stability

• Capable of 2800+ RPM head speed for maximum performance

• Machined Delrin helical main drive for quiet, efficient power transfer

• 6mm width belt-driven tail with spring tension system

• 10mm main shaft with triple support bearings

• 8mm head axle with pivot rocker and solid dampers

• 6mm tail shaft with HD tail hub and HD grips

• 24mm self-supporting boom (no boom supports needed)

• Turnbuckle linkages for quick/precise adjustments

• Adjustable C.G. battery tray with quick locking system

Motor: 4020 class with 5mm shaft (1350-1400kV recommended)

ESC: 6S 90A or greater

Main Blades: 500-520mm (516 Rail Blades recommended)

Tail Blades: 80mm (80.6 Rail Blades recommended)

Battery: 6S 3850-4500 mAh

Cyclic Servos: Mini Required

Tail Servo: Full Size (760us tail servo recommended)

Main Ratio: 11.31-8.62:1 (18T included; 10.06:1)

Tail Ratio: 5.0-4.1:1 (20T included; 4.5:1)

Main Rotor Diameter: 1172mm (with Rail 516mm)

Tail Rotor Diameter: 228mm (with Rail 80.6mm)

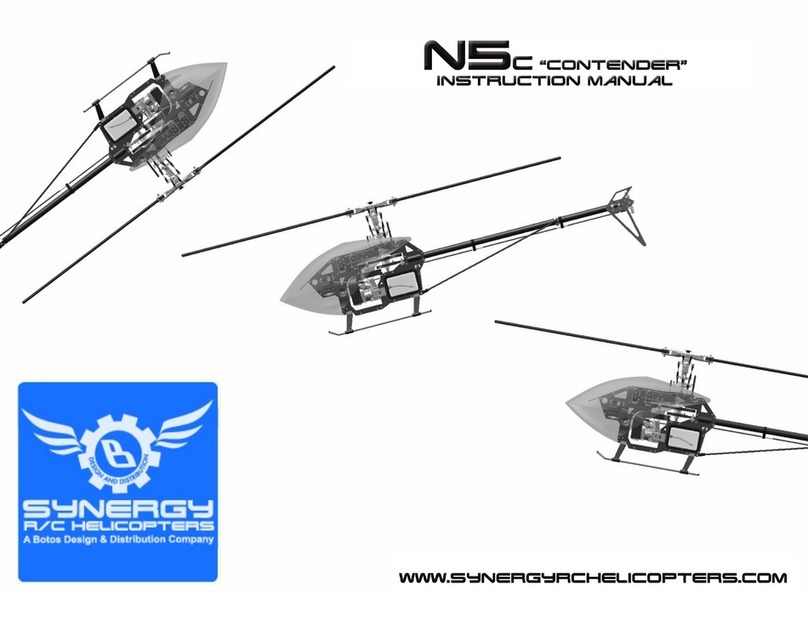

Congratulations on your purchase of the Synergy 516 radio controlled helicopter kit!

The Synergy 516 was designed and developed by Botos Design & Distribution Inc.. The design of the Synergy 516 emerged from many years of

experience in the hobby including design, research & development, and last but not least as a world class pilot who truly enjoys this wonderful

hobby.

This radio controlled helicopter is NOT A TOY. It is a sophisticated piece of equipment; it was designed and intended for hobby use only. If not

properly assembled, maintained, and operated, it is capable of causing property damage and bodily harm to both the operator and/or spectators.

Botos Design & Distribution Inc., its affiliates, and its authorized distributors assume no liability for damage that could occur from the assembly or

use/misuse of this product. If you are new to the hobby we strongly recommend seeking the help and advice from an experienced modeler.

Operating a model helicopter requires a high degree of diligence and skill. If you are new to the hobby, it is best to seek help and guidance from

experienced radio controlled helicopter pilots. This will both greatly speed up the learning process and make it much safer for you. For those pilots

who will be operating their Synergy 516 in the United States, we strongly recommend joining the AMA. The AMA is a non-profit organization

that provides services to the model aircraft pilots. As an AMA member, you will receive a monthly magazine entitled Model Aviation and most

importantly a liability insurance plan to cover against a possible accident or injury. All AMA charter aircraft clubs require individuals to hold a

current AMA sporting license prior to operation of their models.

For further information, you can contact the AMA at:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256

Features: Specifications:

01 | INTRODUCTION

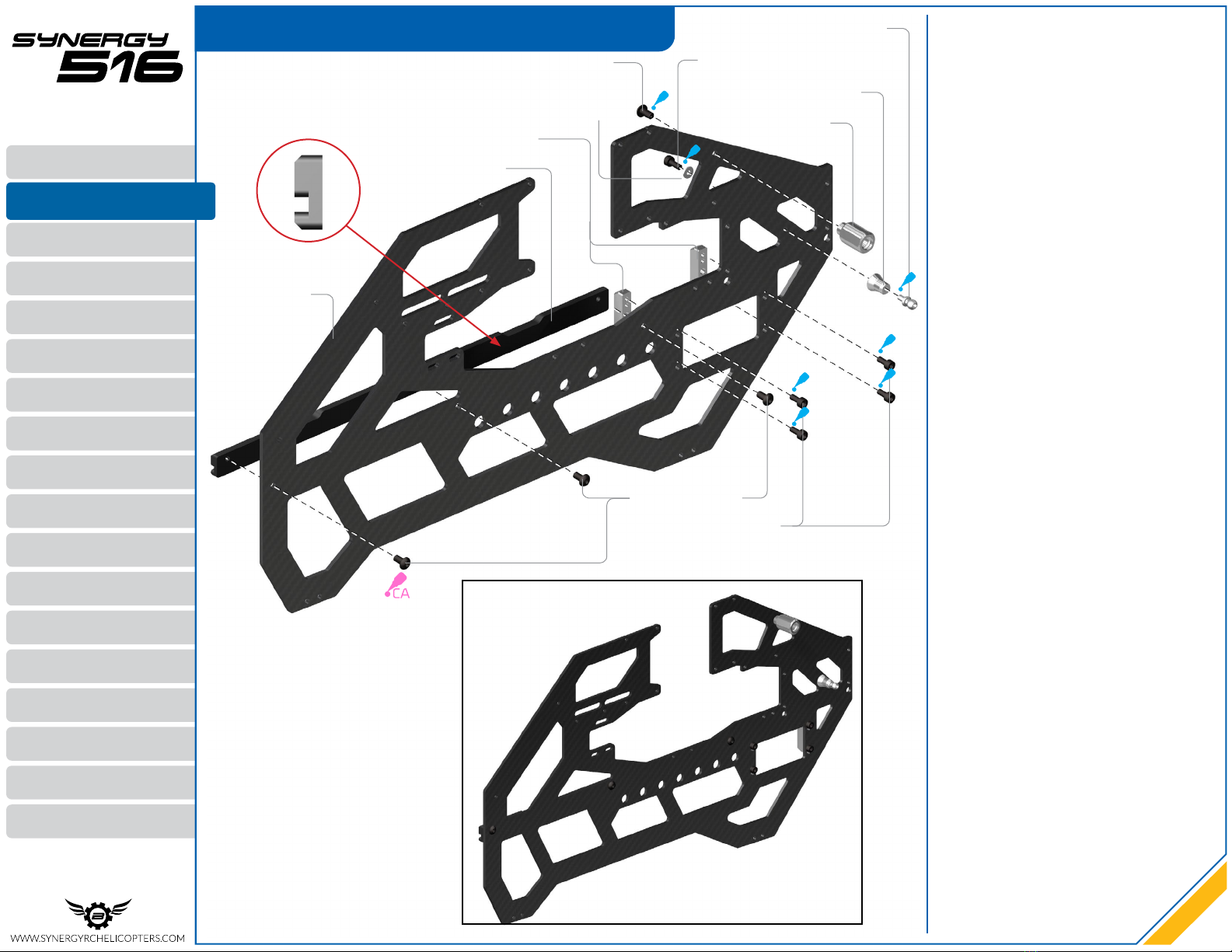

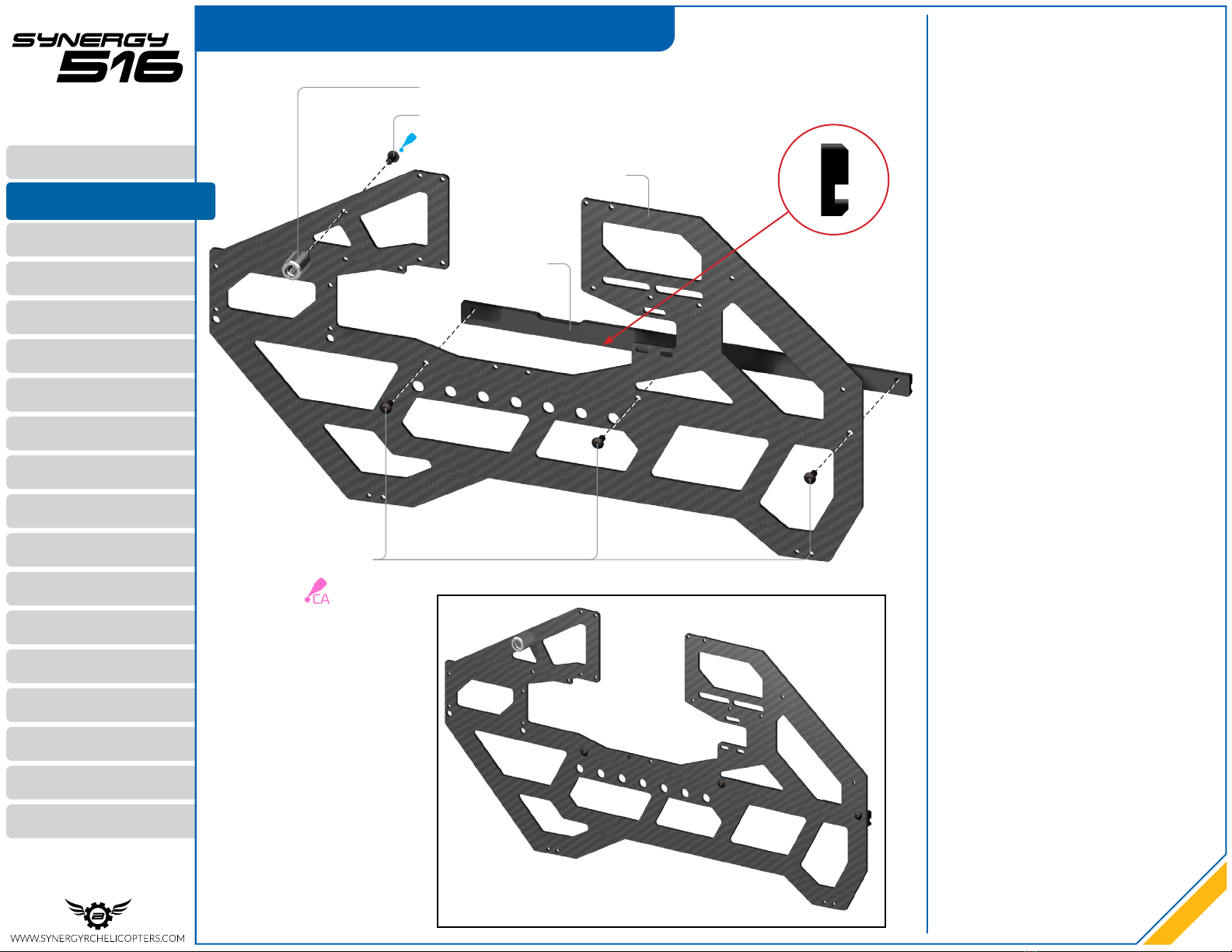

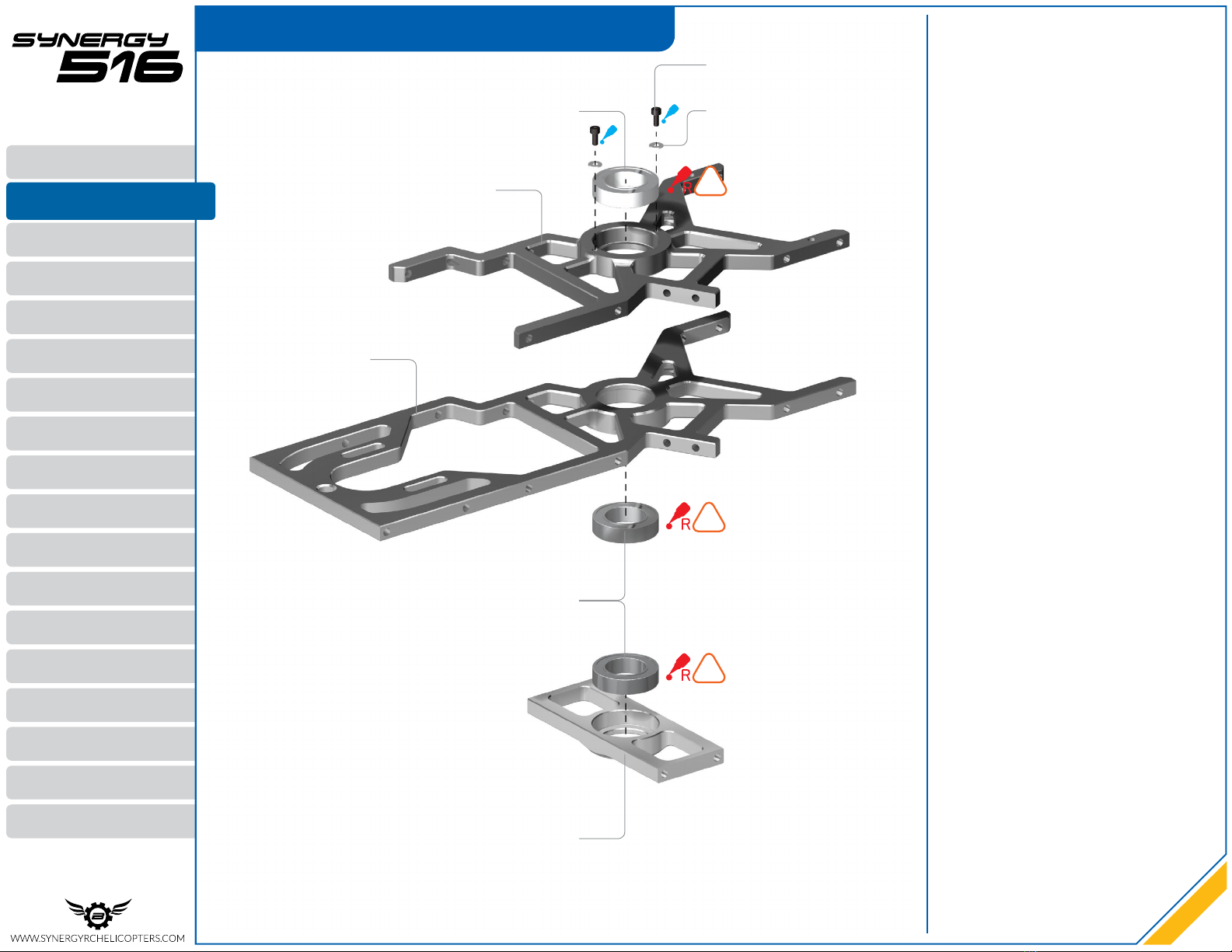

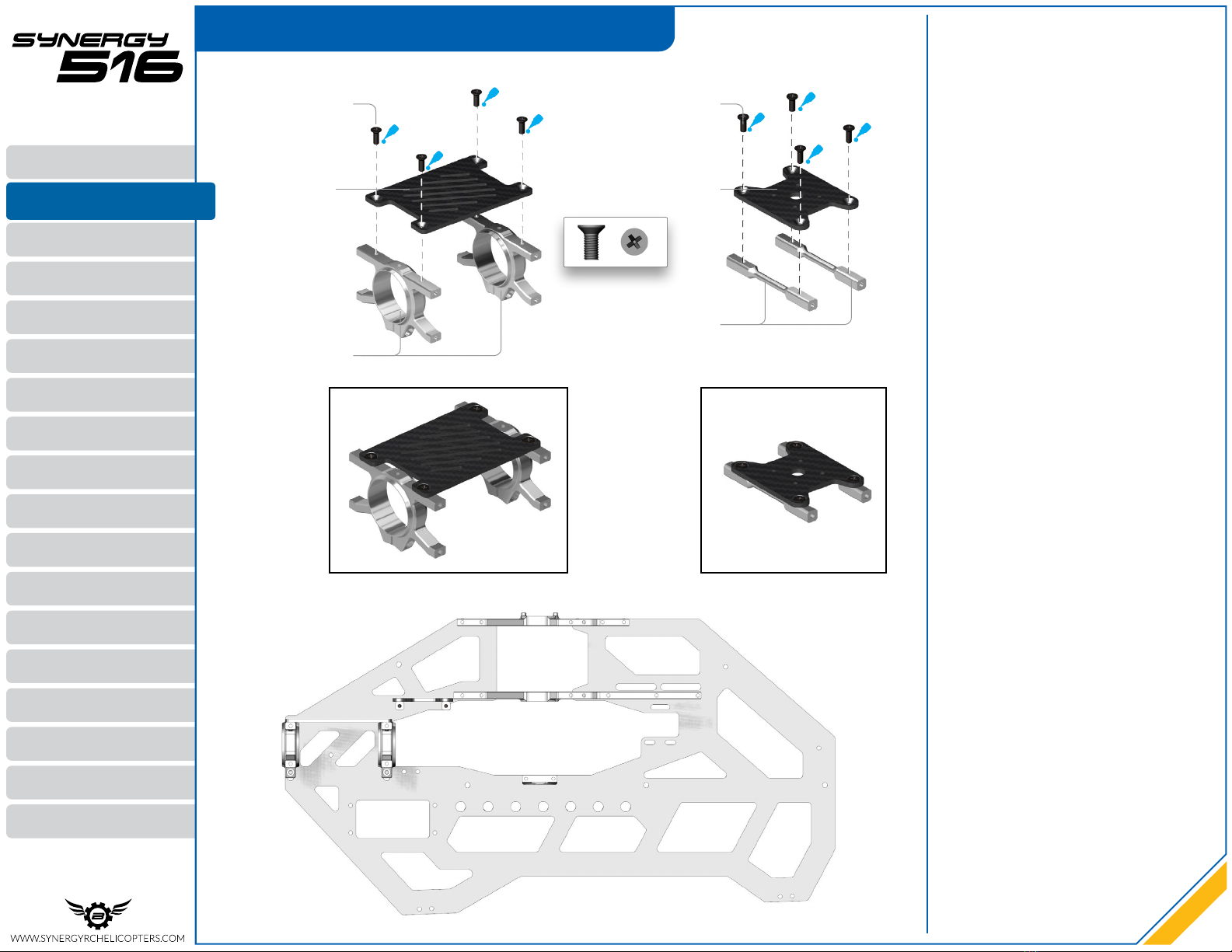

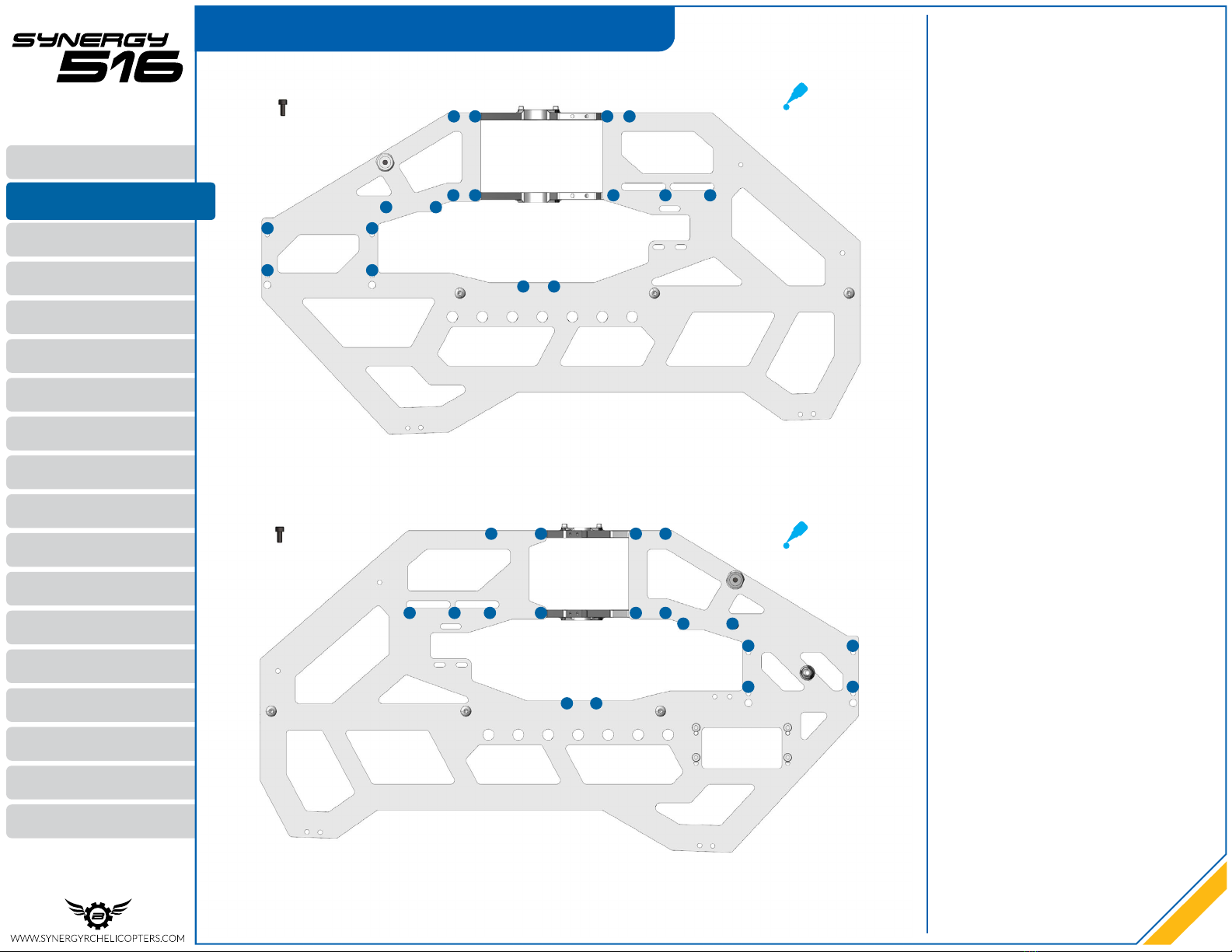

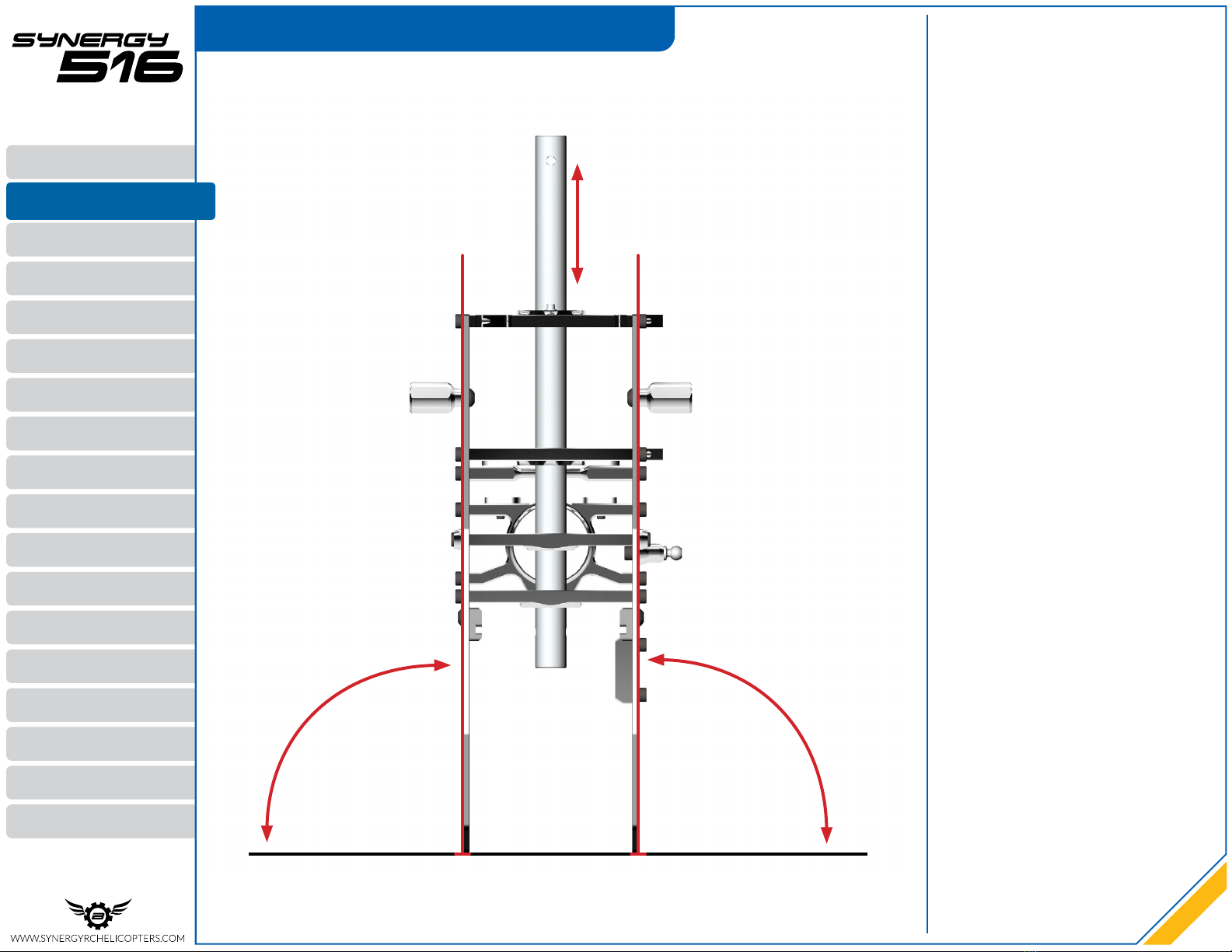

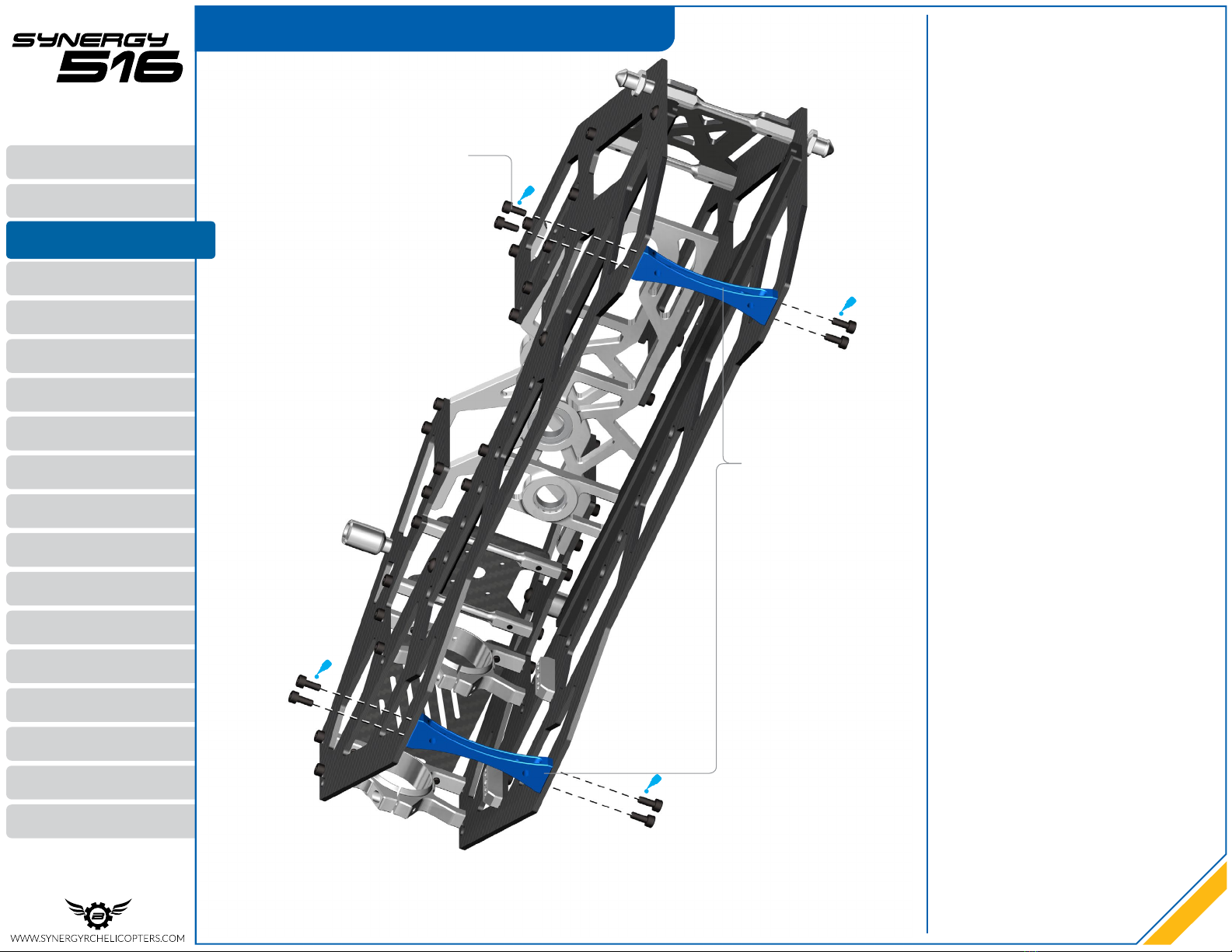

02 | FRAME

03 | LANDING GEAR

04 | BELT TENSION ARM

05 | MAIN DRIVE

06 | BOOM INSTALLATION

07 | TAIL ASSEMBLY

08 | SETTING BELT TENSION

09 | SWASH PLATE

10 | CYCLIC SERVOS

11 | ANTI-ROTATION GUIDE

12 | TAIL SERVO

13 | MAIN HEAD

14 | PITCH LINKAGES

15 | MOTOR INSTALLATION

16 | BATTERY TRAY & CANOPY

17 | BLADE INSTALLATION

18 | COMPLETE MODEL

01 | INTRODUCTION

2

Rev 1.0M

INTRODUCTION