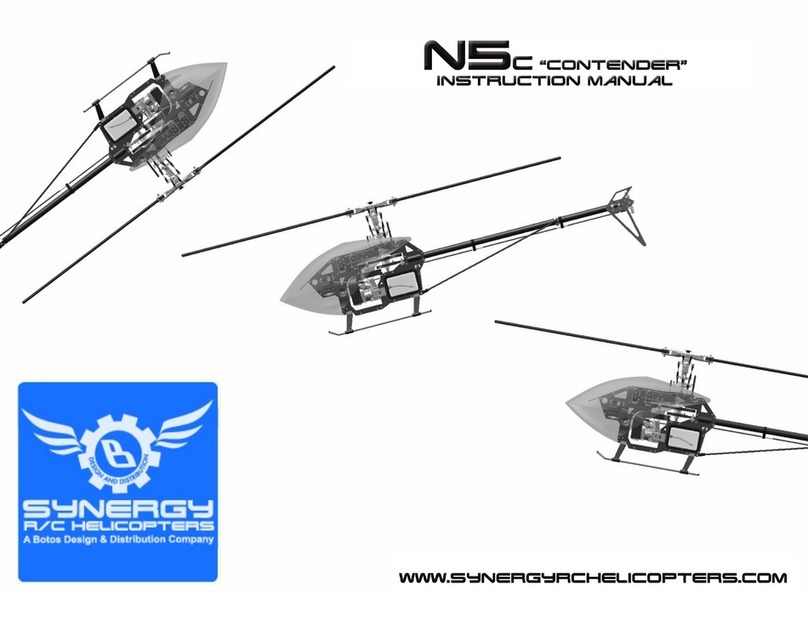

Congratulations on your purchase of the Synergy N5c radio controlled helicopter kit. The Synergy N5c was

designed and developed by Botos Design & Distribution Inc.. The design of the Synergy N5c emerged from

many years of experience in the hobby including design, research & development, and last but not least

as a world class pilot who truly enjoys this wonderful hobby.

This radio controlled helicopter is NOT A TOY. It is a sophisticated piece of equipment and was designed

and intended for hobby use only. If not properly assembled, maintained or operated, it is capable of

causing property damage and bodily harm to both the operator and/or spectators. Botos Design &

Distribution Inc., its affiliates and its authorized distributors assume no liability for damage that could occur

from the assembly or use/misuse of this product. If you are new to the hobby we strongly recommend

seeking the help and advice from an experienced modeler.

Operating a model helicopter requires a high degree of diligence and skill. If you are new to the hobby, it

is best to seek help and guidance from experienced radio controlled helicopter pilots. This will both greatly

speed up the learning process and make it much safer for you.

For those pilots who will be operating their Synergy N5c in the United States, we strongly recommend

joining the AMA. The AMA is a non-profit organization that provides services to the model aircraft pilots. As

an AMA member, you will receive a monthly magazine entitled Model Aviation and most importantly a

liability insurance plan to cover against possible accident or injury. All AMA charter aircraft clubs require

individuals to hold a current AMA sporting license prior to operation of their models

For further information, you can contact the AMA at

Academy if Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256