TABLE OF CONTENTS

A1

Fuel Tank Assembly

A2

Landing Gear Assembly

A3

Engine / Clutch Assembly

A4

Clutch Bell & Start Shaft Assembly

A5

Servo Tray Assembly

A6

Right Frame Support Assembly

A7

Bearing Block Assembly & Installation

A8

Servo Tray Installation

A9

Clutch Stack & Belt Idler Installation

A10

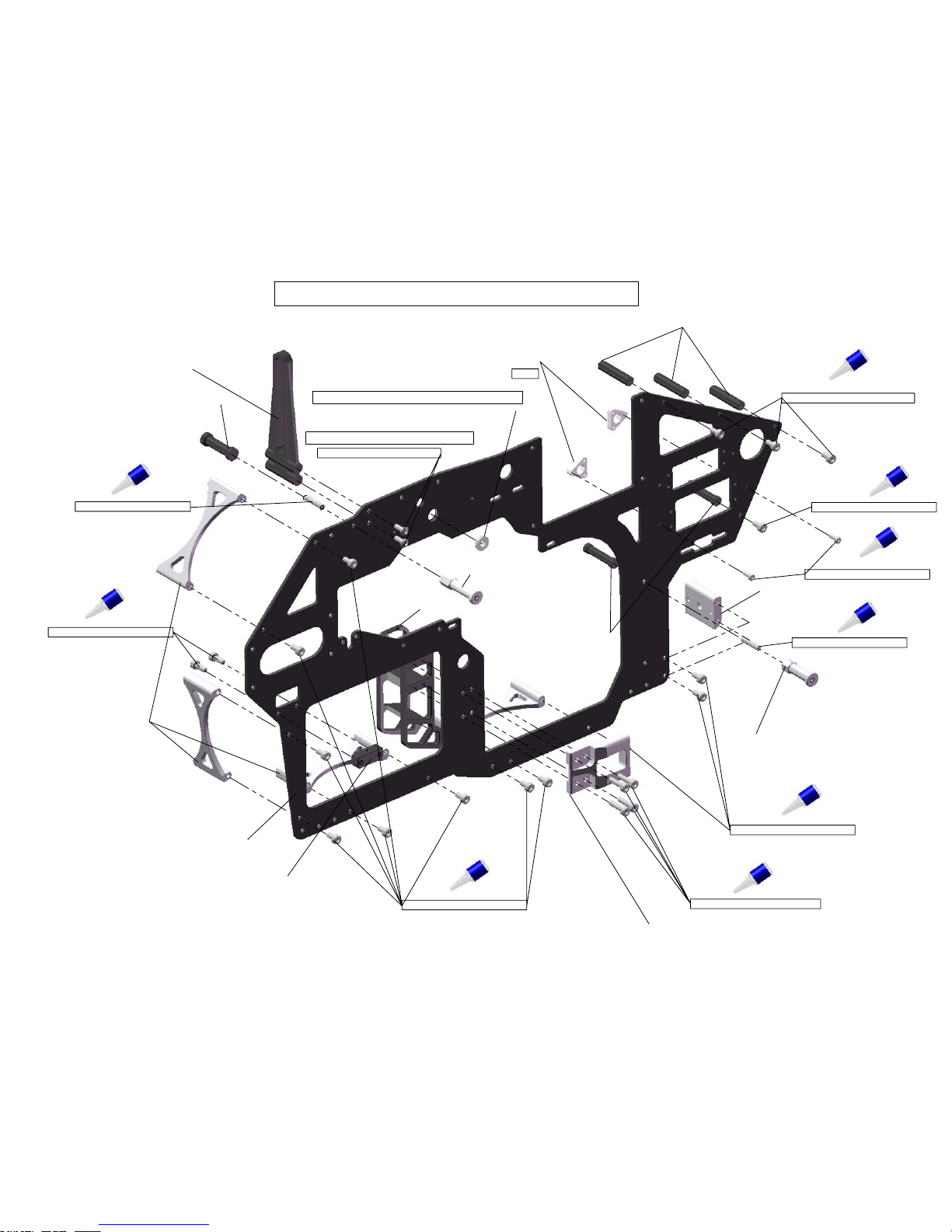

Left Frame Assembly Step 1

A11

Left Frame Assembly Step 2

A12

Frame Alignment

A13

Landing Gear & Fuel Tank Install

A14

Engine Installation

A15

Fan Shroud Installation

A16

Cyclic Control Assembly

A17

Cyclic Bell Crank Installation

A18

Belt Drive Tail Box Assembly 1-2

A19

Belt Drive Tail Box Assembly 3

A20

Tail Rotor Hub Assembly

A21

Pitch Slider Assembly

A22

Tail Pitch Slider & Tail Rotor Hub Install

A23

Belt Drive Tail Pushrod & Guides

A24

Belt Drive Tail Boom Installtion

A25

Boom Support Assembly

A26

Tail Box Assembly for Torque Tube

A27

Tail Bell Crank Assembly

A28

Tail Rotor Hub & Pitch Slider Installation for Torque Tube

A29

Torque Tube Assembly

A30

Tail Boom to Torque Tube Assembly

A31

Torque Tube Tail Section Completion

A32

Torque Tube Input Transmission Assembly

A33

Input Transmission Installation

A34

Tail Boom Install

A35

Main Gear and Main Pulley Assembly

A36

Main Belt Pulley & Main Gear Installation

A37

Belt Drive Train Install Step 2

A38

Crown Gear Assembly

A39

Crown Gear & Main Gear Install

A40

Auto Hub Bolt Install

A41

Crown Gear Hub Pin Install

A42

Crown Gear Mesh Adjustment

A43

Tail Servo & Linkage Assembly

A44

Flybar Head Block Assembly

A45

Swashplate & Washout Assembly

A46

Flybar Blade Grip & Rotor Head Assembly

A47

Rotor Head to Swashplate Assembly

A48

Rotor Head Installation

A49

Flybarless Head & Inner Swash Driver Assembly

A50

Flybarless Head Installation

A51

Elevator Servo Linkage

A52

Aileron Servo Linkage

A53

Pitch Servo Linkage

A54

Throttle Servo Linkage

A55

Radio Plate

A56

Canopy and Rotor Blades