WWW.SYNERGYRCHELICOPTERS.COM 3

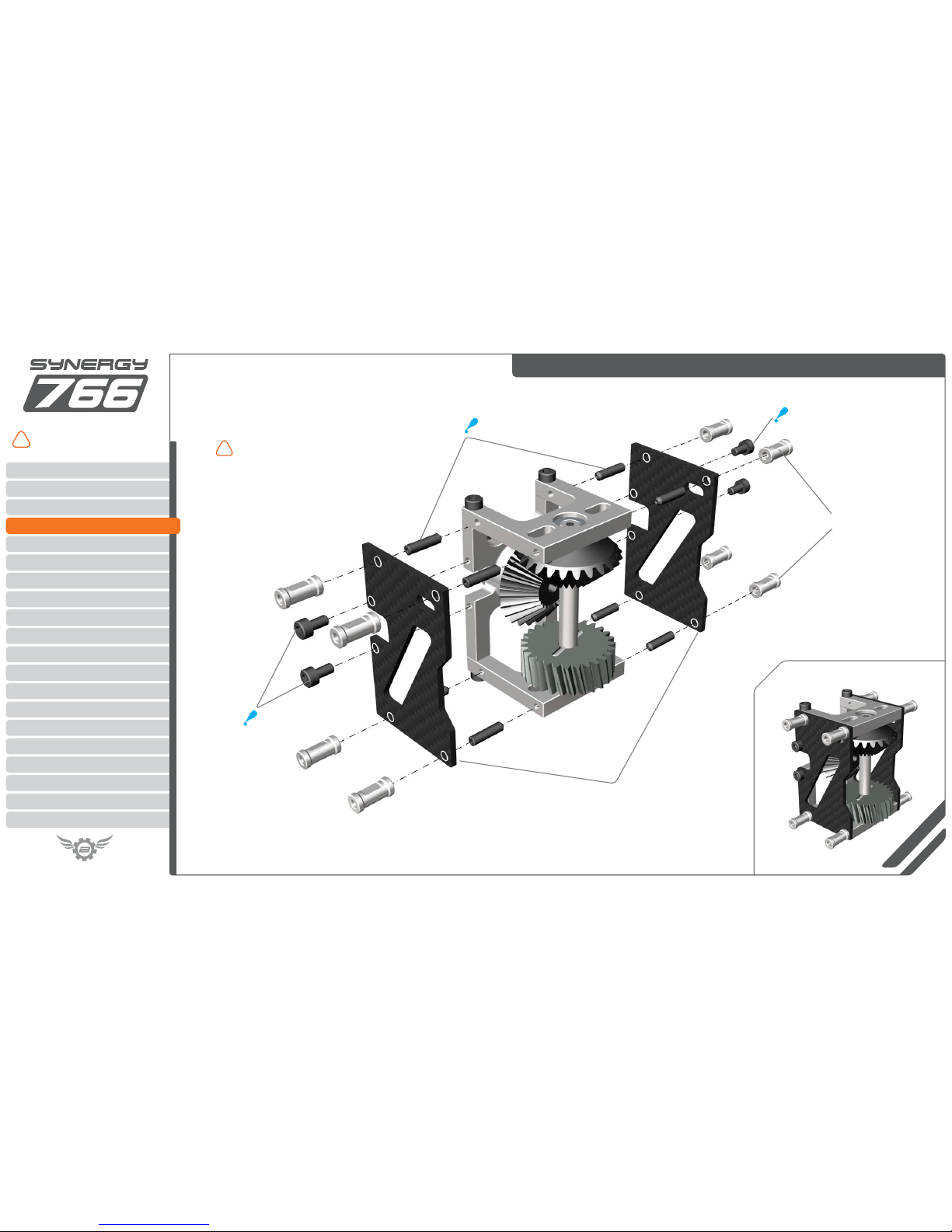

Components that are factory assembled

provide a reference for model assembly.

Disassembly and application of thread

lock is required where indicated.

!

FRAME SIDE 1

FRAME SIDE 2

LANDING GEAR

SPECIFICATIONS

TRANSMISSION

MAIN BEARING BLOCKS

BATTERY TRAY

TORQUE TUBE / BOOM / CONTROL ROD

MAIN AND TAIL BLADES

PANEL SYSTEM

OPTIONS AND CONFIGURATIONS

MAIN DRIVE

SWASH PLATE

SWASH PLATE LINKAGES

MOTOR

HEAD ASSEMBLY

PITCH LINKAGES

SERVO INSTALLATION

TAIL AND HUB

INTRODUCTION

SPECIFICATIONS

SPECIFICATIONS AND FEATURES

• Main Blades: 716-806mm

• Available Main Gear Ratio: 9.27-11.58*

• Available Tail Gear Ratios: 4.5 / 4.7 / 5.1*

• Available Boom Sizes: 716 / 766 / 806*

• Tail blades: 106-116mm

• Battery Conguration: 12s-14s

• 64mm frame width

*This kit includes the following:

• 13T main pinion

• 4.7 tail ratio (27T Pinion). See page 8.

• Boom, torque tube, and tail control rod lengths optimized for

766mm main blades. See pages 64-67 for specic sizes.

Optional parts are available from the Synergy RC Helicopters

website at http://www.mattbotos.com/store.

Main and tail blades are not included.

SPECIFICATIONS: MAIN FEATURES:

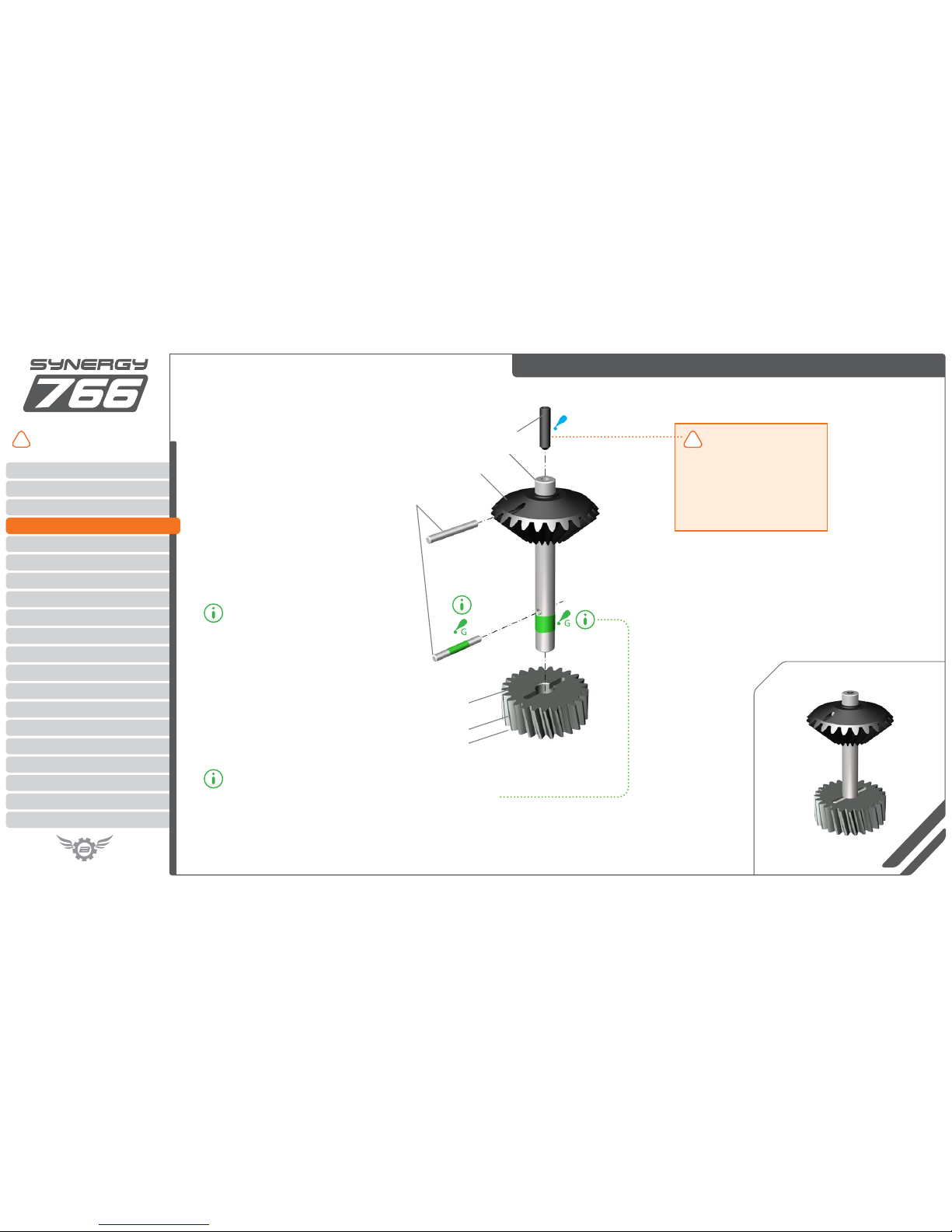

• CNC Machined Helical mod 1 main and auto gears

• Monster-mod 1.25 24T front and rear tail drive bevel gears

• Torque tube tail drive for high efciency

• Ultra-wide head for rigid, precise control

• Tunable blade grip pitch arm geometry

• 12mm Main Shaft / 10mm Spindle & rocker support

• Dual main shaft thrust bearings

• Serviceable dual-bearing swash plate system

• Quad progressive & adjustable head dampening

• Turnbuckle linkage adjustments

• Low disk loading

• Multiple tail drive ratios

• Locking battery tray with CG adjustment

• Optimized tail arm geometry

• Optimum boom options for each blade size

• 3 panel canopy system with high-visibility paint

• Grease ports for all 6 thrust bearings

• CNC Machined Delrin gears

• Designed and supported in the U.S.A