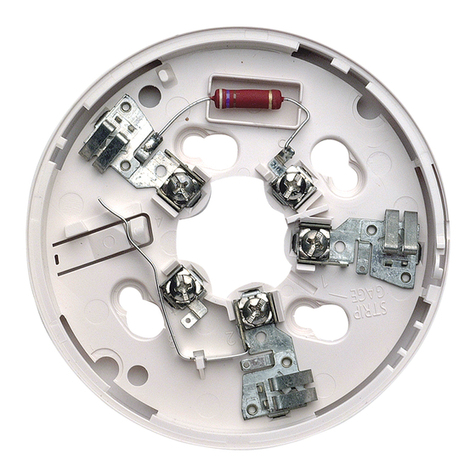

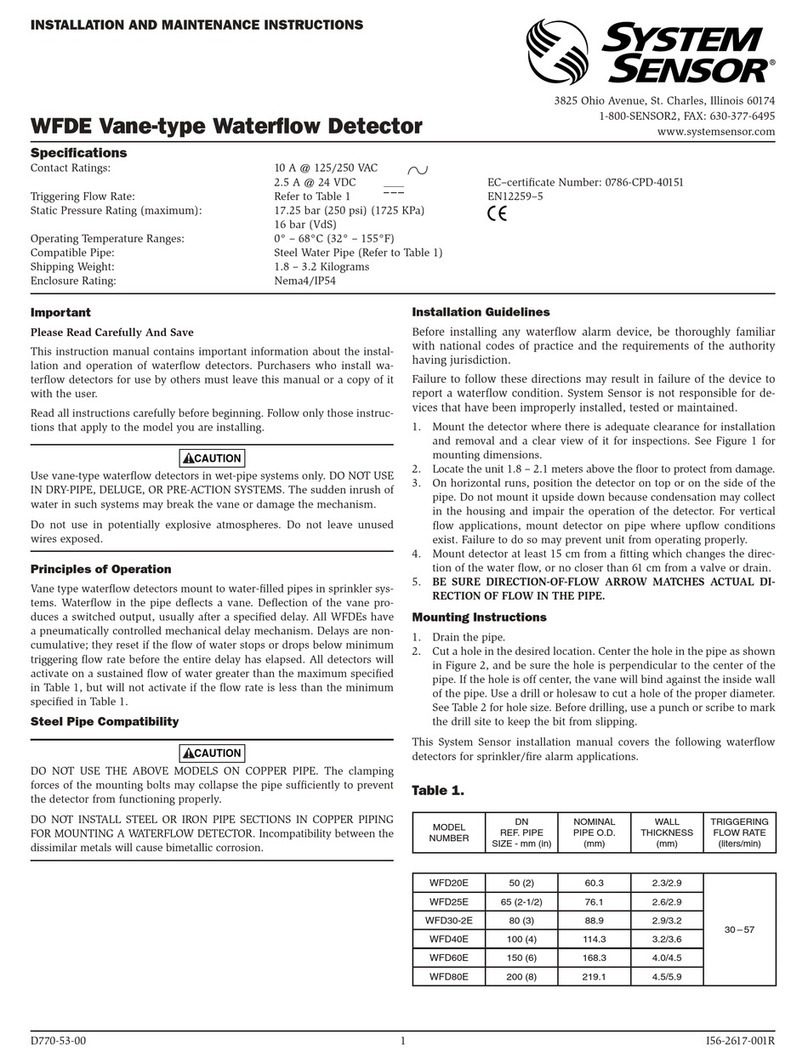

MOUNTING

Mount the mounting plate directly to an electrical box. The plate will mount

directly to 4-inch square, 4-inch octagon, 3 ½-inch octagon, single gang and

double gang junction boxes.

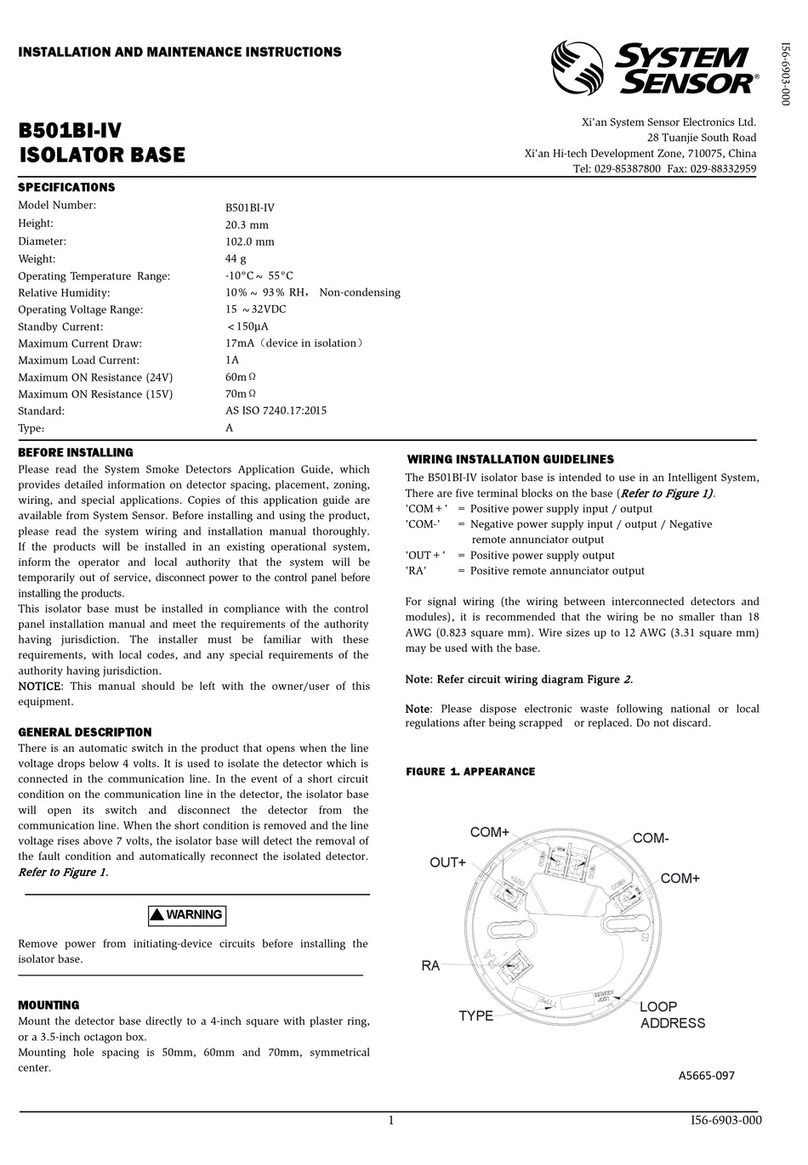

1. Connect field wiring to terminals, as shown in Figure 3.

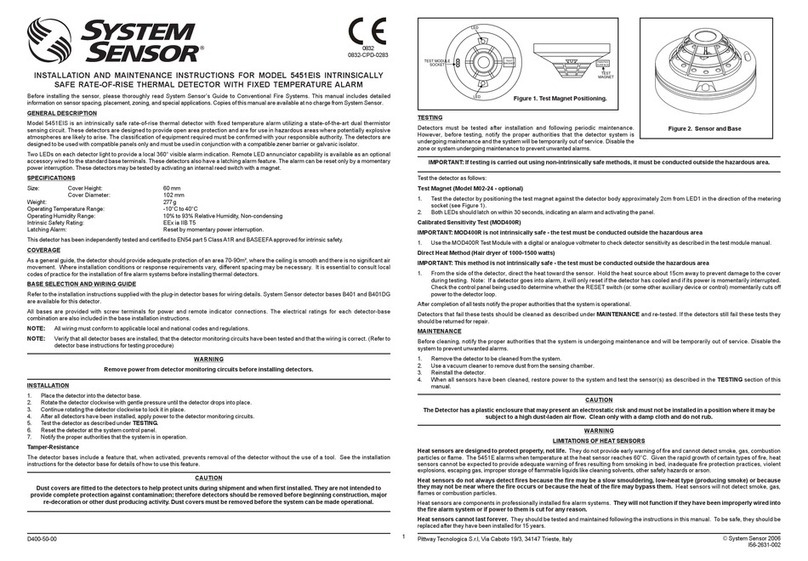

2. Attach the mounting plate to the junction box as shown in Figure 2.

3. To mount the base, hook the tab on the base to the groove on the

mounting plate.

4. Then, swing the base into position to engage the pins on the product

with the terminals on the mounting plate.

5. Secure the base by tightening the mounting screws.

6. Install a compatible smoke detector as described in the installation

manual for the detector.

INSTALLATION AND WIRING GUIDELINES

All wiring must be installed in compliance with all applicable local codes

and any special requirements of the local authority having jurisdiction. Proper

wire gauges should be used. The conductors used to connect smoke detectors

to control panels and accessory devices should be color-coded to reduce the

likelihood of wiring errors. Improper connections can prevent a system from

responding properly in the event of a fire.

For signal wiring (the wiring between interconnected detectors), it is recom-

mended that the wire be no smaller than 18 AWG (0.823 square mm). Wire

sizes up to 12 AWG (3.31 square mm) may be used with the base. The base

will be shipped with the screw terminals set for 14 AWG wiring. If 12 AWG

wire is used, back out the screws to allow the wire to fit beneath the clamp-

ing plates.

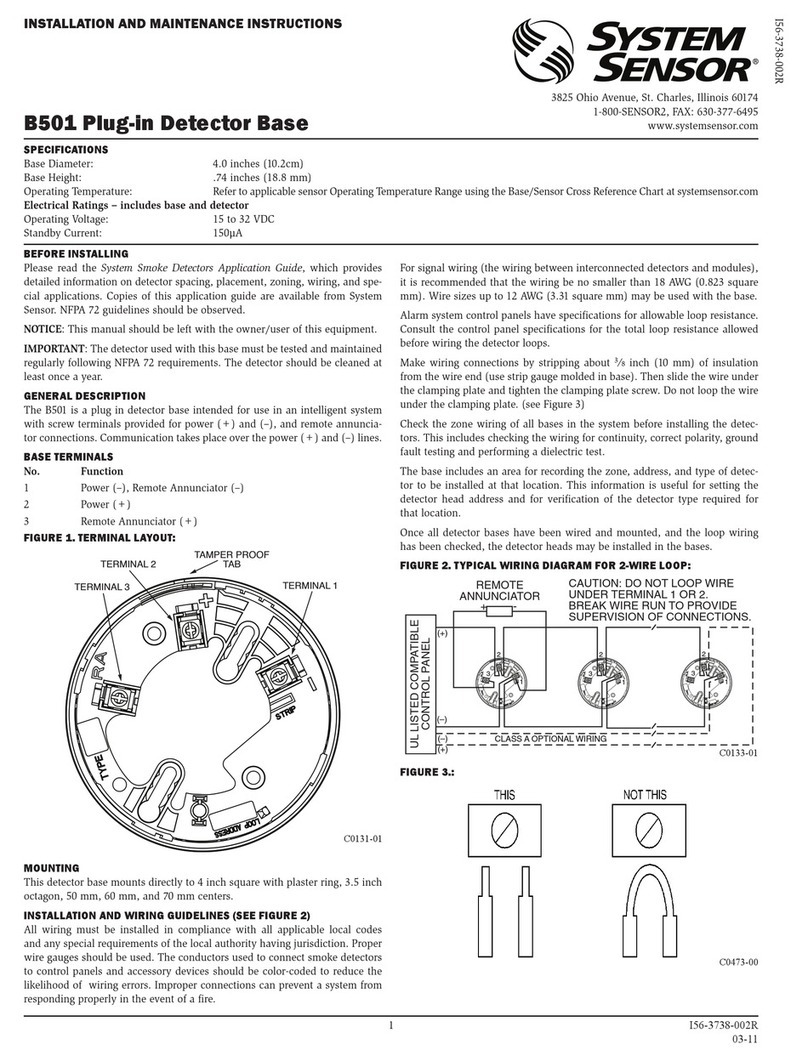

Make electrical connections by stripping about 3/8 inch (10 mm) of insulation

from the end of the wire (use strip gauge molded in base). Then slide the wire

under the clamping plate and tighten the clamping plate screw. Do not loop

the wire under the clamping plate. (See Figure 4)

Wire the normally open (NO) line to terminal 3 (see Figure 3). Insert the nor-

mally closed (NC) line of the relay to terminal 1 and the relay common line

to terminal 2. Wire the communication lines in (–) and out (–)to terminal 4.

Insert the communication line in (+) and out (+) to terminal 5.

Check the zone wiring of all bases in the system before installing the detec-

tors. This includes checking the wiring for continuity, correct polarity, ground

fault testing and performing a dielectric test.

The base includes an area for recording the zone, address, and type of detec-

tor being installed. This information is useful for setting the detector head

address and for verification of the detector type required for that location.

Once all detector bases have been wired and mounted, and the loop wiring

has been checked, the detector heads may be installed in the bases.

Alarm system control panels have specifications for allowable loop resistance.

Consult the control panel specifications for the total loop resistance allowed

before wiring the detector loops.

The base uses a latching relay that can change states if it is subjected to me-

chanical shocks or jarring. As a result, even though relay contacts are in the

open state when the base is shipped from the factory, the contacts may have

closed during shipment.

Connecting an auxiliary control circuit to closed relay contacts can cause an

unexpected, and possibly dangerous, activation of that circuit. Therefore, do

NOT connect an auxiliary control circuit to the relay contacts (terminals 1, 2,

and 3) before ensuring that the relay contacts are in their open state. Ensure

that the contacts are open by applying power to the bases WITHOUT the de-

tector heads installed.

SCREWS

(NOT SUPPLIED)

BOX

(NOT SUPPLIED)

PLATE

FIGURE 2. MOUNTING THE BASE TO AN ELECTRICAL BOX:

C0148-03

2 I56-3741-002R

06-10