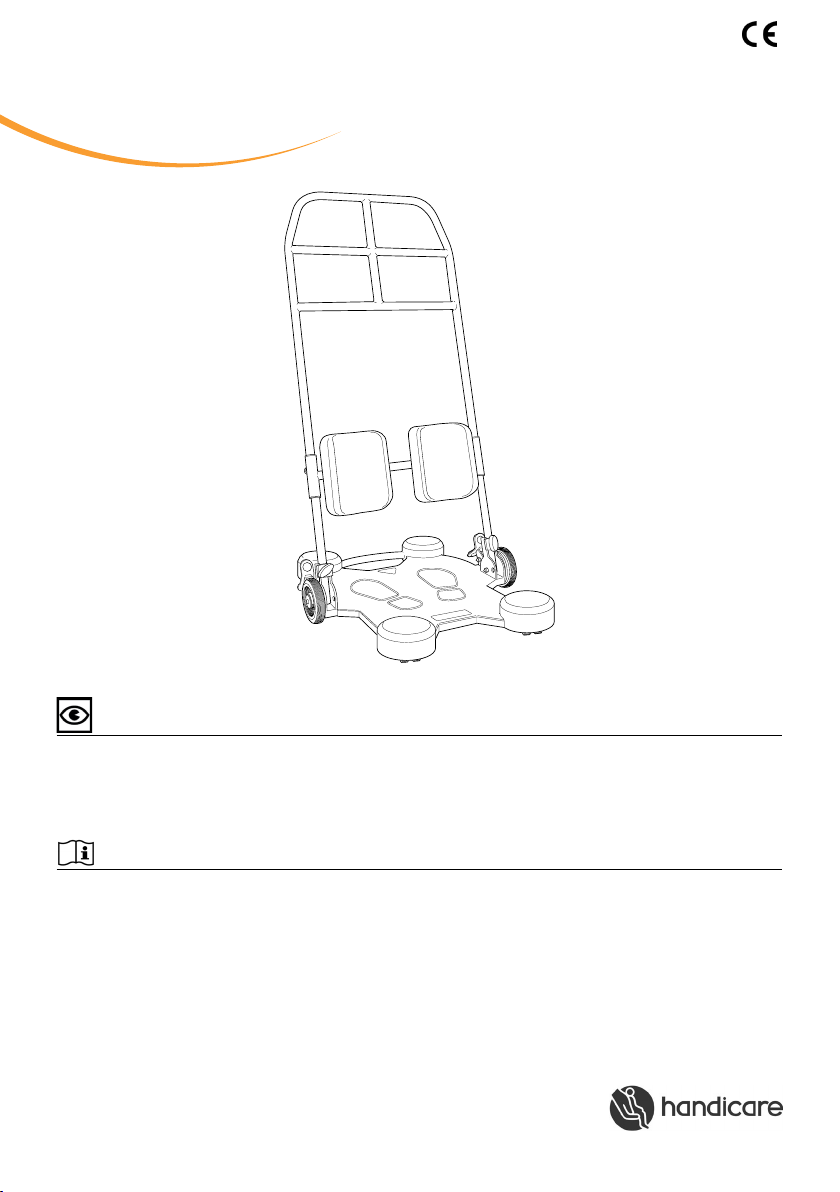

Spare parts - Spare part list

Article no. Product Unit Components Images

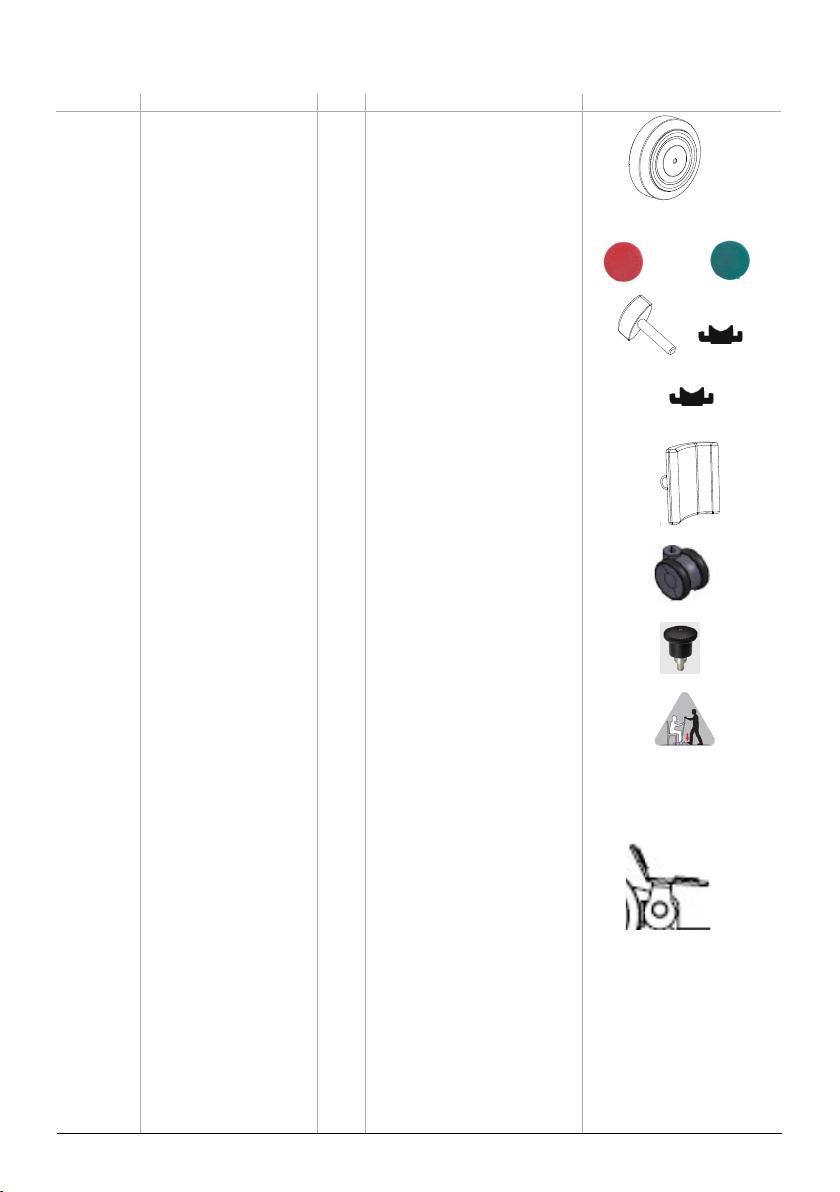

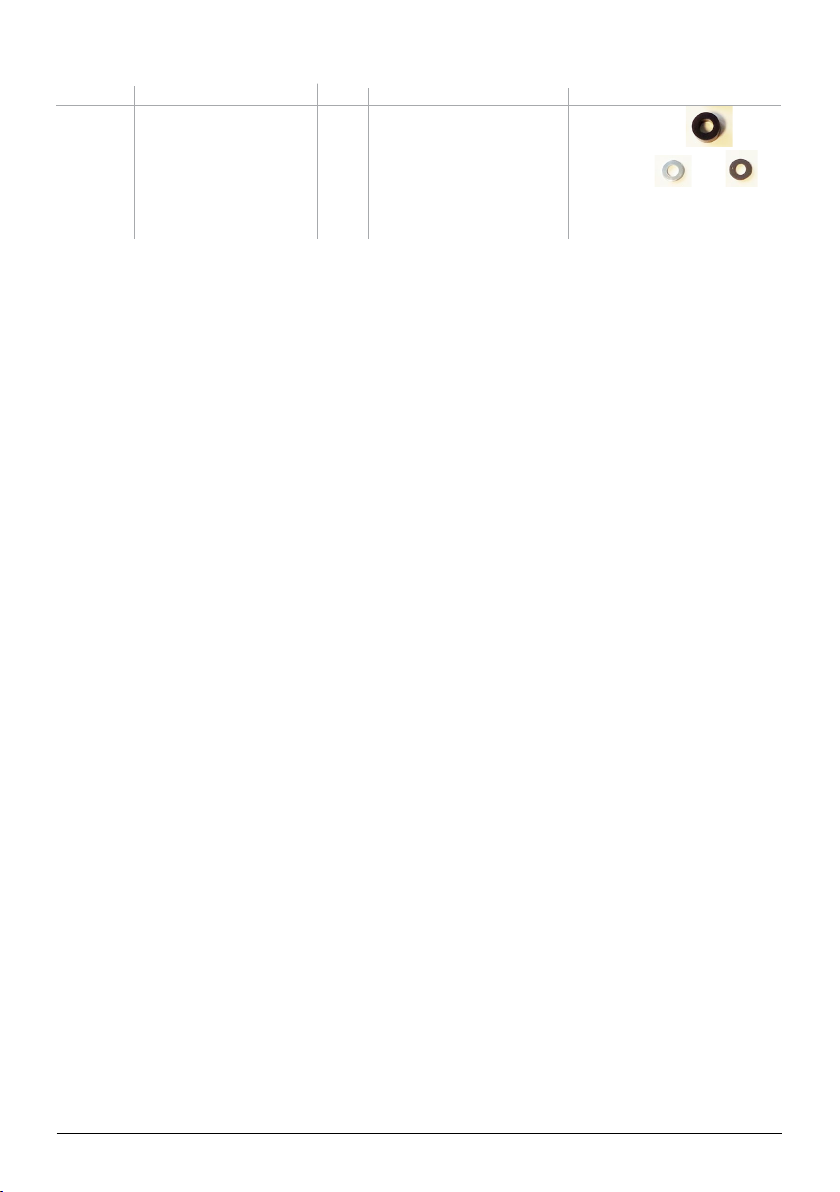

7332 Castors 125mm 1 set 2 x Castor 125mm

2 x Washer

2 x Screw

2 x Nut

7318-10 Brake pads red 1 set 10 x Brake pads red

7319-10 Brake pads green 1 set 10 x Brake pads green

7322 Wing handles 1 set 10 x Wing handle M8x40

10 x Catch for Wing handle

7320 Stop for Wing handle 1 pce 1 x Catch for Wing handle

7321 Wing handle (old version) 1 pce 1 x Wing handle

S/N before xxxxxxxxxx500001

7333 Leg support kit 1 set 1 x Leg support

2 x Mounting fixture for leg support

8 x Screw for bracket M6x16

7331 Castor swirvel 75mm 1 set 4 x Castor swirvel 75mm

4 x Screw

4 x Locking nut

4 x Washer

7326 Locking pins 1 set 10 x Locking pin for leg support

7327 Instruction label 1 set 10 x Instruction label

7328 Brake shoe antislip 0,9 mm 1 set 10 x Brake shoe antislip 0,9

7329 Brake shoe antislip 1,5 mm 1 set 10 x Brake shoe antislip 1,5

7330 Brake kit L and R 1 set 1 x Brake pedal left

1 x Brake pedal right

1 x Brake shoe left

1 x Brake shoe right

2 x Nut MHM Din 1587 M8fzb

2 x Spring washer

2 x Carrier bult

2 x Washer black

2 x Washer white M8

2 x Screw M6x20

2 x Washer white M6

´ 2 x Nut Din 985 M6fzb

2 x Green plastic button

2 x Red plastic button

2 x Friction 3M tape

6SystemRoMedicTM

7318 7319

7322

7333

7331

x 10 x 10

7332

x 10

x 10

7326

x 10

7327

x 10

7320

7330

x 2