DIM121E 6 (10)

F-27507-1

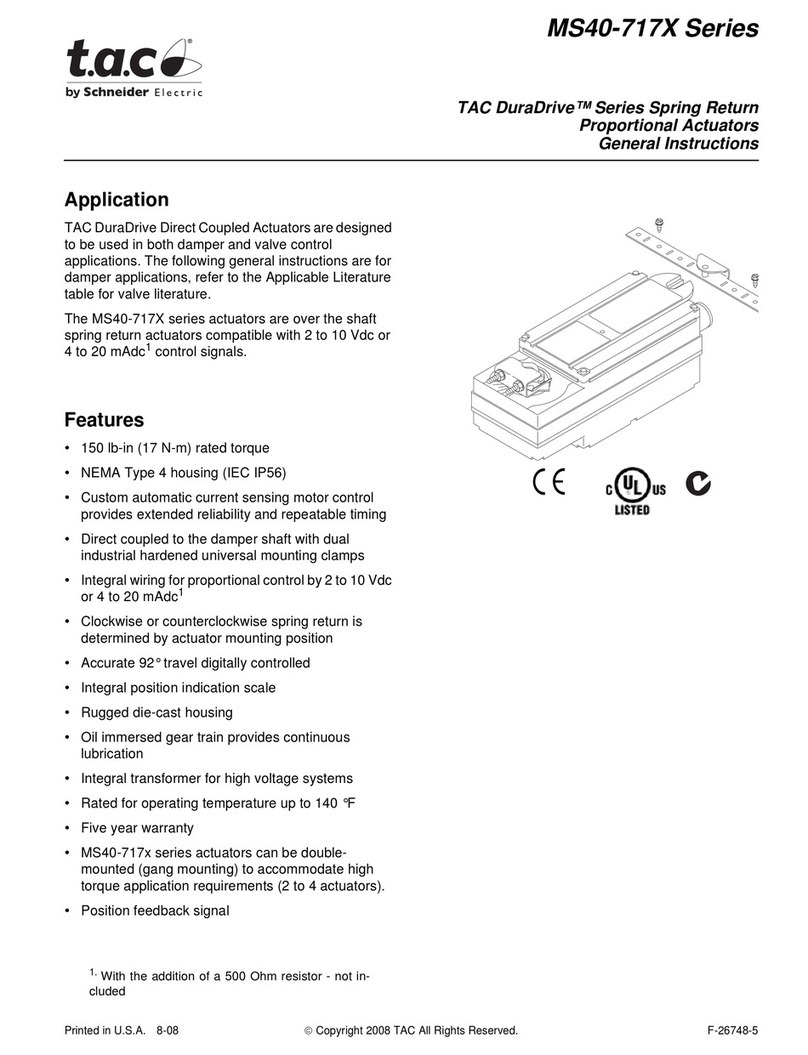

PROGRAM SWITCH SETTINGS

Figure 8

Function in the Description

“OFF” pos. “ON” position

1 Retract Extend (see sw7) Valve closing screw direction

2 Proportional Floating Control Mode

3 – Sequence Sequence control

4 0-10 V 2-10 V Input Voltage range

5 0-5 V, 2-6 V 5-10 V, 6-10 V Part of voltage range

6 60 s 300 s Running time (Floating control only)

7 Normal Inverted (see SW 1) Direction of movement

8 Normal Linear/Logarithmic Valve characteristic

9 Operation Stroke position Input signal/stroke calibration

adjust (mom.)

(*) There are nine switches in a row on the

circuit board. The factory shipped

default switch positions are all “OFF.”

1 Valve Closing Screw

Upon power up with switch 1 OFF the

actuator will fully retract before the input

control signal takes control. If switch 1 is

ON the actuator will fully extend before

the input control signal takes over. This

switch will change the proportional or

floating input signal to direct or reverse

action similar to switch 7

2 Control signal—Prop / Float

TAC Forta can either be controlled by a

Proportional signal (SW2 OFF), or a

floating signal (SW2 ON)

3 Sequence or parallel control—

– – – / SEQ

With sequence (or parallel) control (SEQ),

two actuators/valves can be controlled by

only one proportional control signal.

Switch 2 must be OFF, switch 3 must be

ON and switch 5 will configure the range.

Note if sequence or parallel control is not

used switch 3 must be in the off position

4 Voltage range

You can choose whether to use the control

signal voltage range 0-10Vdc (SW4 off)

or 2-10Vdc (SW4 on).

5 Part of voltage range—

0-5, 2-6 / 5-10, 6-10

Allows you to select 0-5/2-6v or 5-10/6-

10v working range.

If SW5 is OFF the 0-5/2-6v range is

selected, If SW5 is ON the 5-10/6-10v is

selected

Note switch 5 is only active if switch 2 is

OFF and switch 3 is ON.

6

If switch 2 is ON SW6 controls run time,

SW 6 OFF equals 60 sec, ON equals 300

sec run time.

7 Direction of movement—

NORM / INV

Changes the proportional or floating input

signal to direct or reverse action similar to

switch 1

8 Linearization

SW 8 OFF normal

SW8 ON Linear electronic control

The motorized valve characteristics can

be modified. If you wish for the

characteristics to be affected, the

setting LIN/LG will make the characteristics

of an equally modified percentage (EQM)

valve almost linear.

On the other hand, with LIN/LG setting a

motorized valve equipped with a linear

valve will operate with ”Quick open

characteristics.”

Note! For the actuator to register

new settings of the switches, the

supply voltage must be removed by

cutting power to the actuator or

lowering the manual override lever,

then change any of switches one

through 8 as required and then

restore power to the actuator or raise

the manual override level.

Please refer to illustration on page 2,

figure 2.

Note: After mounting the actuator on a

valve, dipswitch 9 must be momentarily

switched off to on to off with the actuator

powered for proper actuator valve

stroke calibration.

9 (OP/ADJ)

Input Signal/Stroke calibration SW9 OFF

normal operation

This switch is only used to calibrate the

input control signal and the valve stroke.

To calibrate, power to the actuator must

be on, momentarily turn switch 9 on and

then off. The actuator will automatically

match the control input signal to the valve

stroke (switch 9 must be left in the off

position for normal operation).

*See note below!

Refer to the following selection guides for selection of the available Actuator Valve combinations

VB-7xxx Selection Guide F-27490 or VB-8xxx/VB-9xxx Selection Guide F-27491 before using the

tables on pages 7, 8 and 9

ACTUATOR VALVE SELECTION