LIMITED WARRA TY STATEME T

Taco, Inc. will repair or replace without charge (at

the company’s option) any Taco igh Efficiency

circulator or circulator part which is proven defec-

tive under normal use within three (3) years from

the date of manufacture.

In order to obtain service under this warranty, it

is the responsibility of the purchaser to promptly

notify the local Taco stocking distributor or Taco

in writing and promptly deliver the subject product

or part, delivery prepaid, to the stocking distribu-

tor. For assistance on warranty returns, the pur-

chaser may either contact the local Taco stock-

ing distributor or Taco. If the subject product or

part contains no defect as covered in this war-

ranty, the purchaser will be billed for parts and

labor charges in effect at time of factory exami-

nation and repair.

Any Taco product or part not installed or operated

in conformity with Taco instructions or which has

been subject to misuse, misapplication, the addi-

tion of petroleum-based fluids or certain chemi-

cal additives to the systems, or other abuse, will

not be covered by this warranty.

If in doubt as to whether a particular substance

is suitable for use with a Taco product or part, or

for any application restrictions, consult the

applicable Taco instruction sheets or contact

Taco at (401-942-8000).

Taco reserves the right to provide replacement

products and parts which are substantially similar

in design and functionally equivalent to the

defective product or part. Taco reserves the right

to make changes in details of design, construc-

tion, or arrangement of materials of its products

without notification.

TACO OFFERS THIS WARRA TY I LIEU OF

ALL OTHER EXPRESS WARRA TIES. A Y

WARRA TY IMPLIED BY LAW I CLUDI G

WARRA TIES OF MERCHA TABILITY OR

FIT ESS IS I EFFECT O LY FOR THE DURA-

TIO OF THE EXPRESS WARRA TY SET

FORTH I THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRA TIES ARE I LIEU OF

ALL OTHER WARRA TIES, EXPRESS OR

STATUTORY, OR A Y OTHER WARRA TY

OBLIGATIO O THE PART OF TACO.

TACO WILL OT BE LIABLE FOR A Y SPE-

CIAL, I CIDE TAL, I DIRECT OR CO SE-

QUE TIAL DAMAGES RESULTI G FROM THE

USE OF ITS PRODUCTS OR A Y I CIDE TAL

COSTS OF REMOVI G OR REPLACI G

DEFECTIVE PRODUCTS.

This warranty gives the purchaser specific rights,

and the purchaser may have other rights which

vary from state to state. Some states do not

allow limitations on how long an implied warranty

lasts or on the exclusion of incidental or conse-

quential damages, so these limitations or exclu-

sions may not apply to you.

A Taco Family Company

2017

8

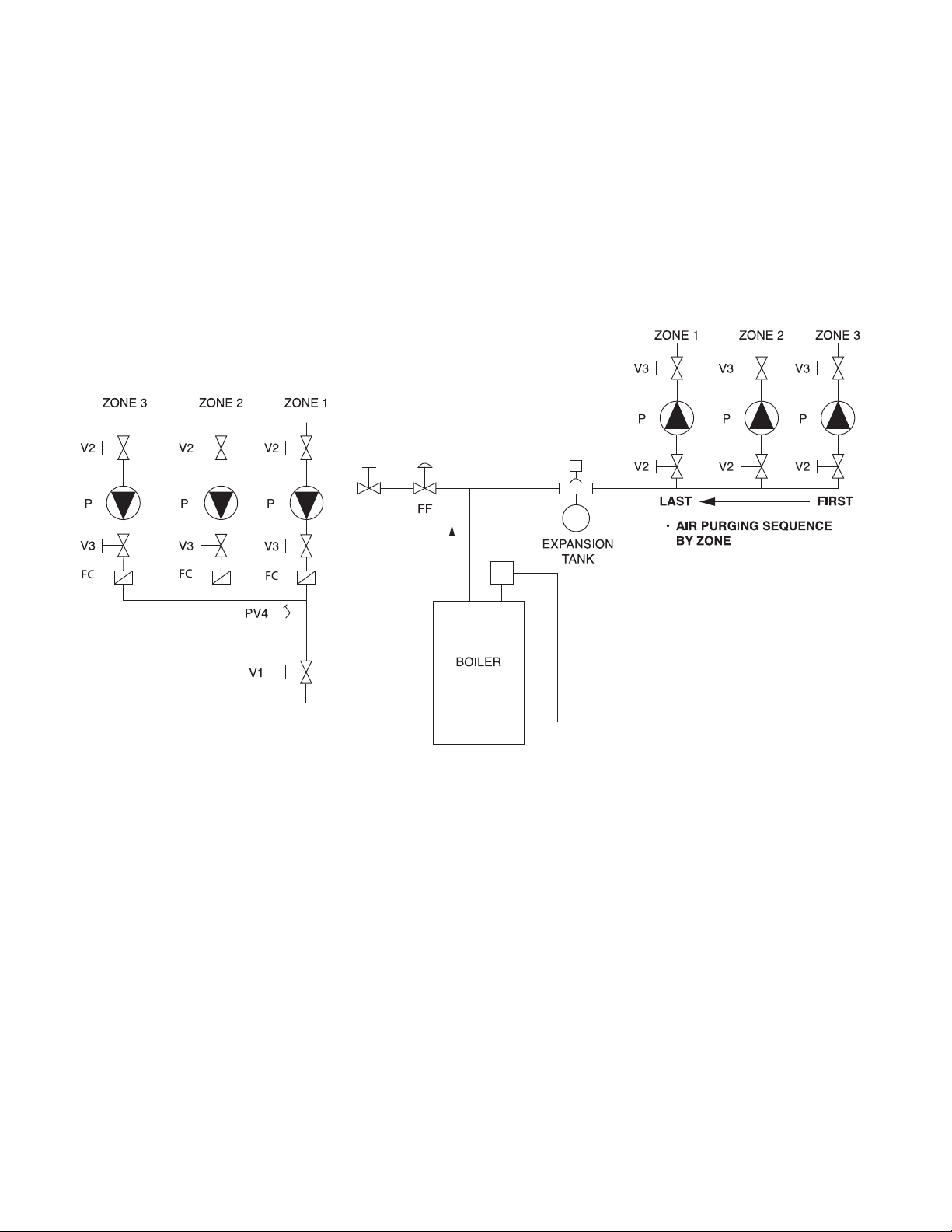

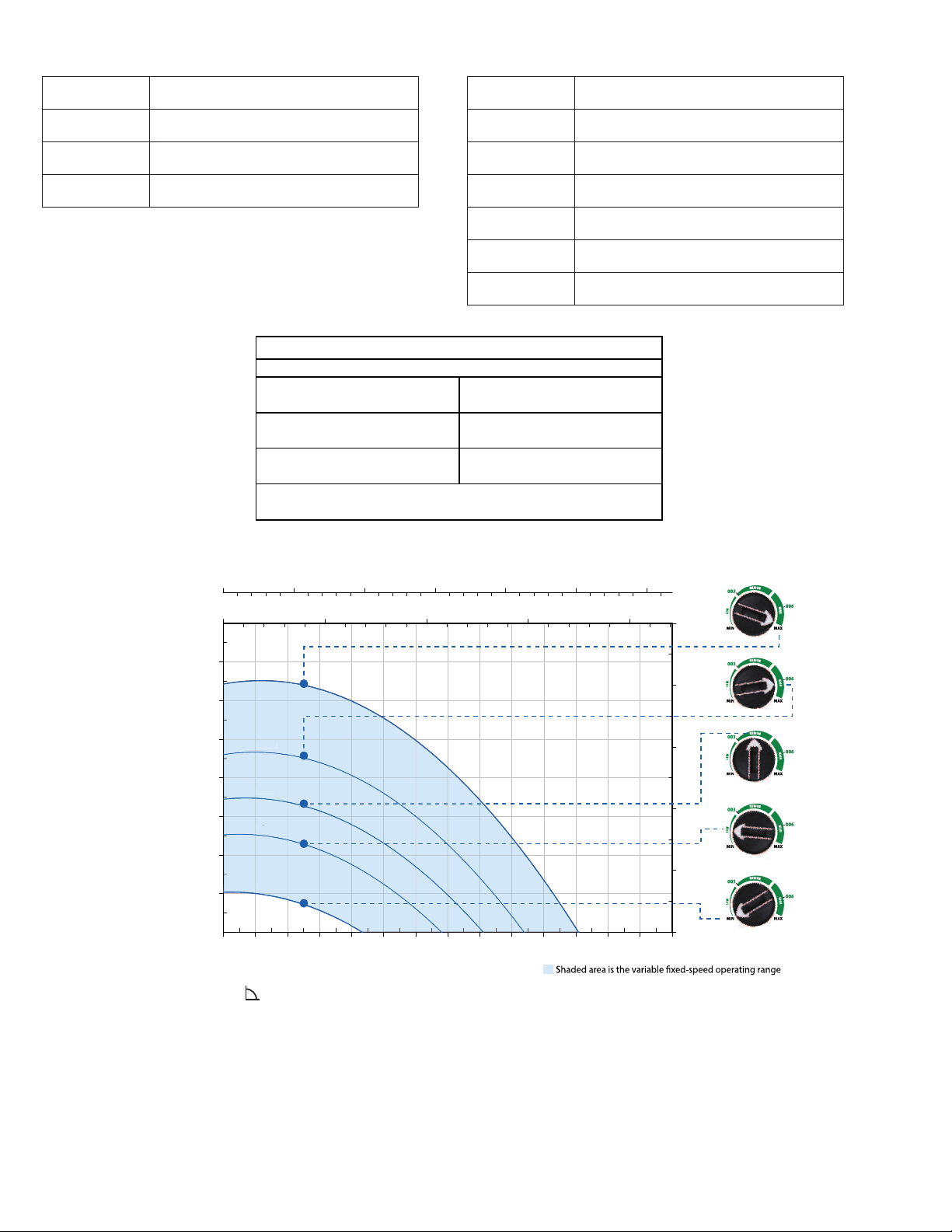

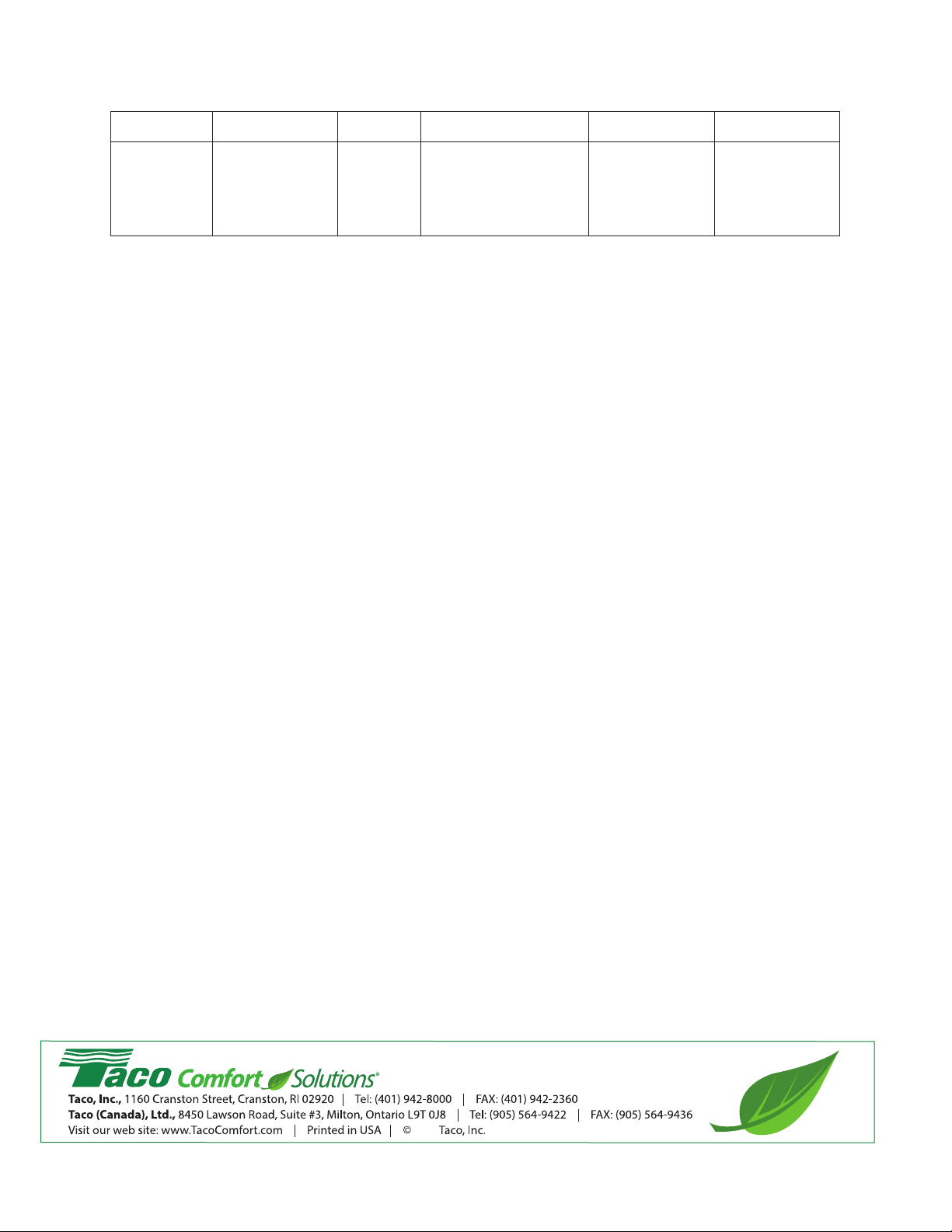

TACO GRU DFOS WILO B&G / XYLEM ARMSTRO G LAI G

003

006

UP 15-18

UP 15-10

UP 10-16

Z-15

ecocirc e3-4

ecocirc e3-6

NBF-8, 9, 10, 12

SSF- 9, 12

Astro 225 BS

Astro 225 SSU

Astro 220 SSU

E1 Series

E3 Series

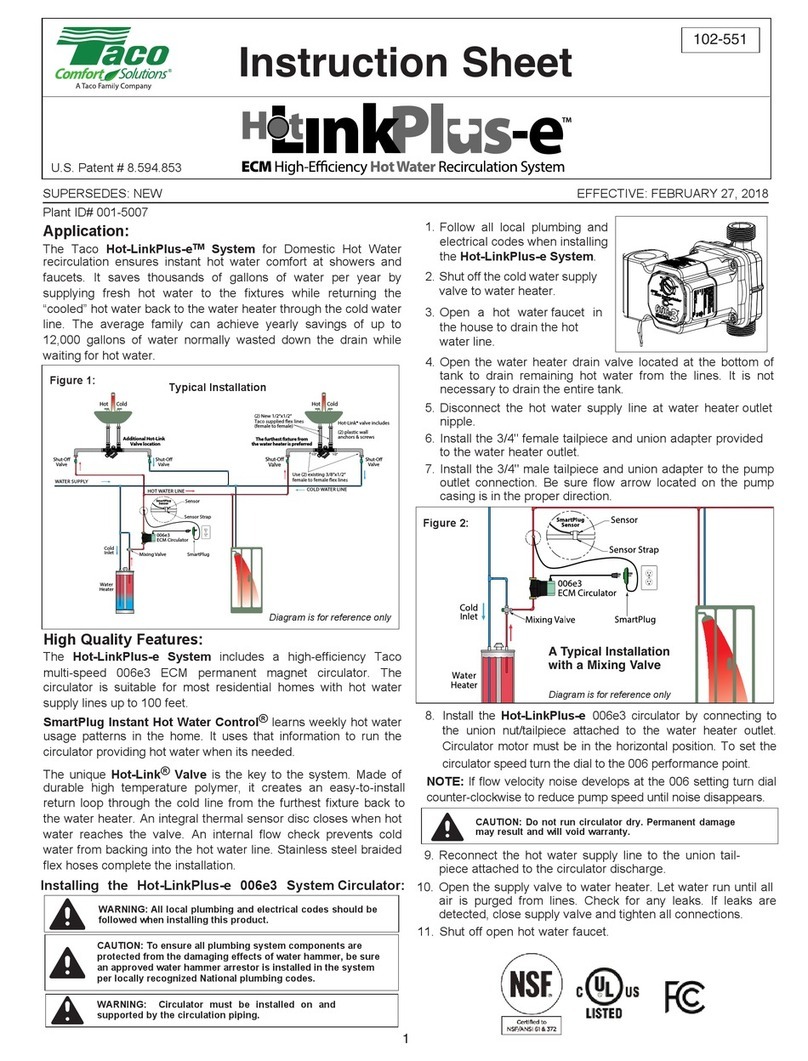

006e3 Replacement Chart