Listings/Approvals:

• UL GUIDE (MBPR) for Limit Controls per UL Standard

353 Limit Controls

• CUL per CSA Standard C22.2 No. 24-93 for tempera-

ture indicating and regulating equipment.

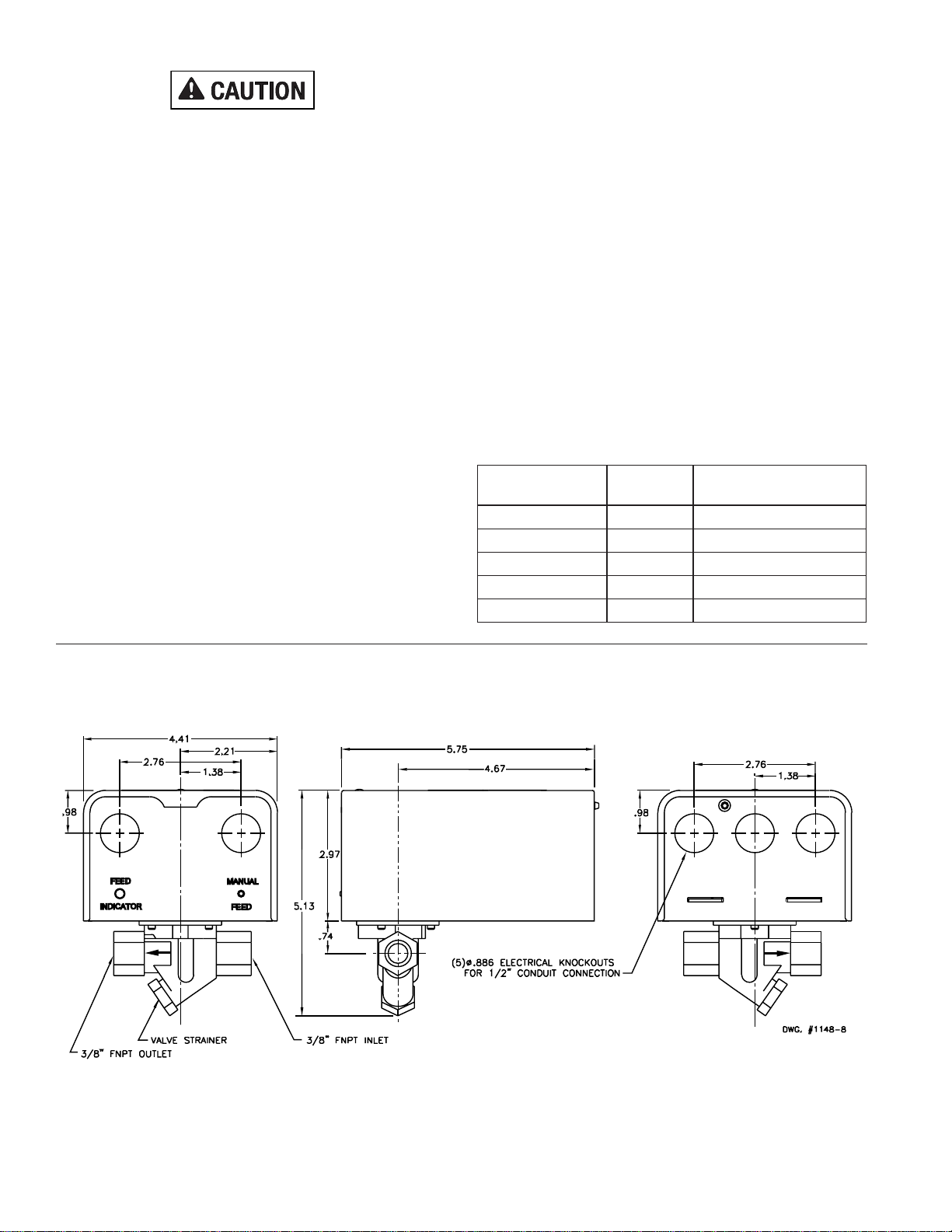

Process Connections: 3/8" FNPT or 3/8” NPT to 1/2" copper

fittings (included)

Enclosure:

NEMA Type 1 (For indoor use only.) Formed sheet metal

with powder coat/plated finish. Five openings for 1/2"

conduit fittings. (Not for use in hazardous locations.)

Maximum Inlet Pressure:

Maximum Outlet (Boiler) Pressure:

Maximum Media Temperature:

Maximum Ambient Temperature:

Feed Rate:

Feed Choices: LWCO Mode, Fixed Feed, or Manual Feed

Flood Protection Lockout

Excess Feed Indicator

GENERAL

The Electric Water Feeder (EWF), is an electronics based

water feeder for steam boilers. The EWF monitors the output

from a Low Water Cutoff (LWCO). When the LWCO detects a

low water condition, it signals the EWF, which initiates a

water-feed cycle. Since the EWF is fully programmable, it can

feed as long as the low water cutoff detects a low water

condition (LWCO mode) or fixed feed amounts. In addition,

the EWF allows the user to set Delays Before Feeding (DBF),

or hold delays after the low water cutoff signals water is

restored (HAW). The EWF also includes a programmable

excess feed indicator, (patent pending). The EWF blinks this

LED after it has fed more than a settable number of gallons

into the boiler over the past 30 days. This will help identify

systems that may need maintenance.

Instruction Sheet

Electric Water Feeder 102-170

SUPERCEDES:REVISIONDATEDAUGUST1,2004

#5401148-REVB EFFECTIVE:NOVEMBER10,2004

:rewoPtupnI

ledoMegatloV rewoP noitpmusnoC

1-021FWECAV021AV21

1-420FWE**CAV42AV01

Patent Pending

** 24 VAC to be supplied by an EXTERNAL Class 2 power source

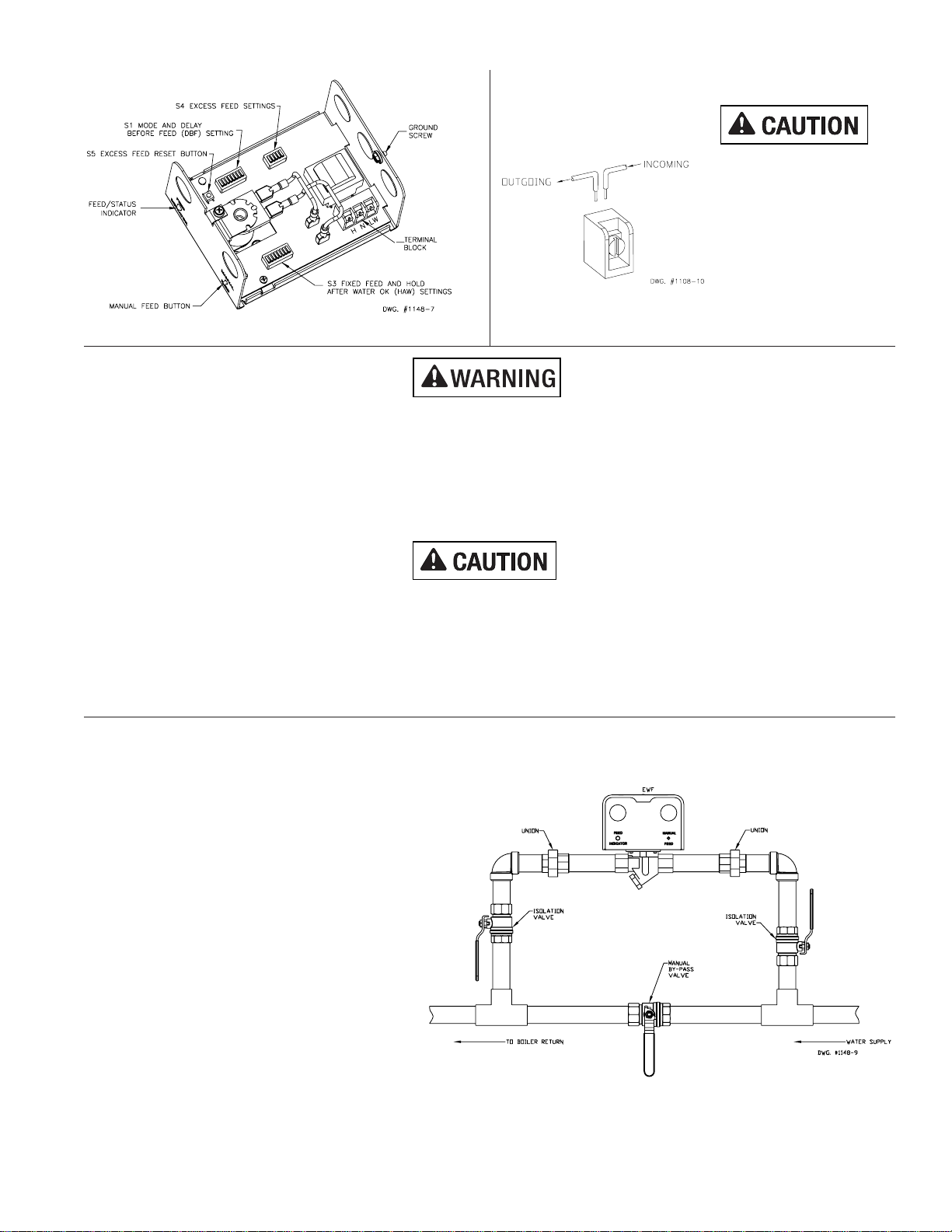

OPERATION

LWCOMode

When the mode switch of S1 (See fig. 9a) is set to the ON

position, the EWF will operate in LWCO mode. This causes

the EWF to feed water whenever the LWCO signals a low

water condition. Both the Delay Before Feeding (DBF), and

the Hold After Water OK (HAW), settings may be set in LWCO

mode. As soon as the EWF receives a low water signal from

the LWCO, the EWF starts feeding water to the boiler after

the DBF delay expires, if enabled. The EWF continues

feeding water to the boiler until the LWCO signals that the

water condition is normal and any HAW delay expires. If the

EWF feeds 10 gallons, Flood Protection Lockout occurs and

feeding stops immediately and a red LED is illuminated.

FixedFeed

When the mode switch of S1 is set to the OFF position, the

EWF will operate in Fixed Feed, (FF), mode. While in this

mode, the EWF will feed the number of gallons set by switch

S3 (See fig. 9a & c). While in Fixed Feed mode, only DBF

delays may be used. HAW settings only apply to LWCO

mode. After a feed cycle completes, if the LWCO still signals

a low water condition, the EWF will start another feed cycle. If

the EWF completes the second feed cycle and the LWCO still

signals a low water condition, the EWF will enter the Flood

Protection Lockout and a red LED is illuminated.

150 PSI (10.5kg/cm2)

15 PSI (1kg/cm2)

160°F (71°C)

100°F (38°C)

1 gpm (3.8 lpm)