©Copyright Task Force Tips LLC 2019 LIE-100 December 30, 2019 Rev04

5

3.2 SPECIFICATIONS

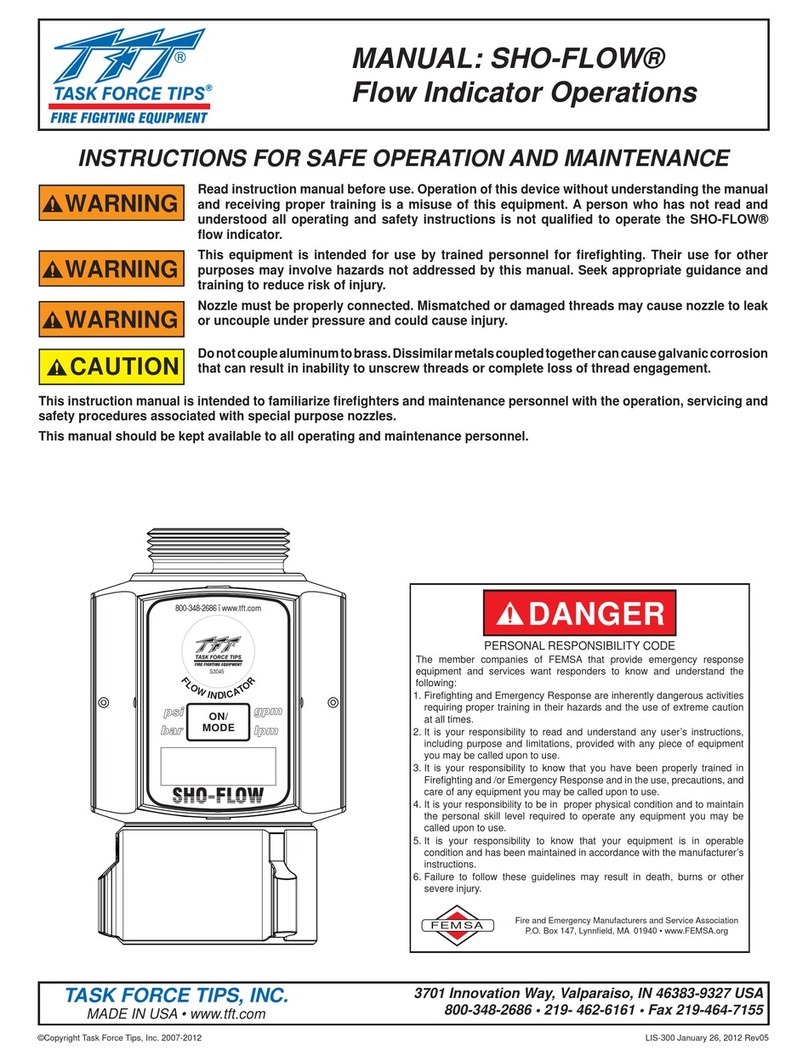

3.2.1 DEVICE SPECIFICATIONS

Model Name SHO-FLOW 1 SHO-FLOW 2 (Low Flow) SHO-FLOW 2 (High Flow)

Operating Flow Range 50-300 GPM

(200-1200 LPM)

100 - 500 GPM

(400 - 2000 LPM)

500 - 1250 GPM

(2000 - 5000 LPM)

Max Flow Range 350 GPM (1300 LPM) 600 GPM (2300 LPM) 1350 GPM (5200 LPM)

Min Flow Rate Required

to Connect

50 GPM

(200 LPM)

100 GPM

(400 LPM)

500 GPM

(2000 LPM)

Waterway Diameter 1.5” (38mm) 2.5" (65mm) 2.5” (65mm)

Flow Accuracy +/-2.5% Full Scale

Non-recoverable

Pressure Loss @ Max

Flow

15 PSI @ 300 GPM 10 PSI @ 500 GPM 10 PSI @ 1250 GPM

Max Operating Pressure 300 PSI (20 bar)

Hydrostatic Test Pressure 900 PSI (62 bar)

Operating Temperature -

Electronics -20-140°F (-30-60°C)

Length 6.3” (160mm) 7.4" (188 mm)

Width 3.9” (99mm) 4.9" (125 mm)

Weight 2.8 lbs (1.3 kg) 4.2 lbs (1.9 kg)

Materials Aluminum 6000 series hard anodized MIL8625 class 3 type 2, stainless steel 300 series,

POM, nitrile rubber, and CPVC

IP Rating IP65

Power Supply Self-powered, Water Flow Energy Harvesting

Backup Battery CR2032 enabled in app

3.2.2 APP SPECIFICATIONS

Wireless Communication Bluetooth® Version 4.1

Display SHO-FLOW Smart Phone App

Flow Units GPM, LPM GPS, LPS

Pressure Units (for calibration) PSI, BAR, KPA

3.3 COUPLINGS

The SHO-FLOW 1 is offered with standard hose threaded connections: 1.5” NH, 1.5” BSP, or 1.5” NPSH. The SHO-FLOW 2 is

offered with standard hose threaded connections: 2.5” NH, 2.5” BSP, or 2.5” NPSH. Inlets are rigid female threaded couplings. Fluid

is sealed using a hose gasket. Do not use thread sealant. Outlets are rigid male threads. Maximum torque 20 ft-lb (27 Nm).

CAUTION Mismatched or damaged threads may cause equipment to leak or uncouple under pressure.

Failure could result in injury. Equipment must be mated to matched threads.

CAUTION Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability to

unscrew the threads, or complete loss of thread engagement over time. Failure could cause injury.

Per NFPA 1962, if dissimilar metals are left coupled together, an anti-corrosive lubricant should be

applied to the threads and the coupling should be disconnected and inspected at least quarterly.

3.4 USE WITH SALT WATER

Use with salt water is permissible provided the equipment is thoroughly cleaned with fresh water after each use. The service life of

the equipment may be shortened due to the effects of corrosion, and is not covered under warranty.