Tuning indicators (“magic eye "valves) are also tested in sections, first normal

tests on the amplifier section, then atest on the shadow section. For the latter, moving the

Anode and Screen volts selector from the position given opposite “Shadow” mthe valve

chart, to that opposite “Test should cause adistinct change in shadow angle.

In the case of gas -filled valves, particularly mercury vapour types, it is important

to wait for one minute on the “Cathode Leakage 11 position before switching to “Rect "

or to !‘Mutual Conductance

.

1

1

This is to ensure that the cathode is at operating temperature

before anode voltage is applied.

Mercury vapour ana gas -filled triodes (thyratrons) are tested with the voltage settings

given but on Rectifier ”position. The grid volts should be reduced slowly from 15 and

at some lower '^alue the valve should start to conduct, as shown by movement of the meter

pointer to the “Good ”sector. The value obtained varies considerably with the type of

valve, and its rated “control ratio,” i.e., anode voltage /grid voltage at start of conduction.

NOTE :In the following six sections the setting of switches not mentioned is immaterial.

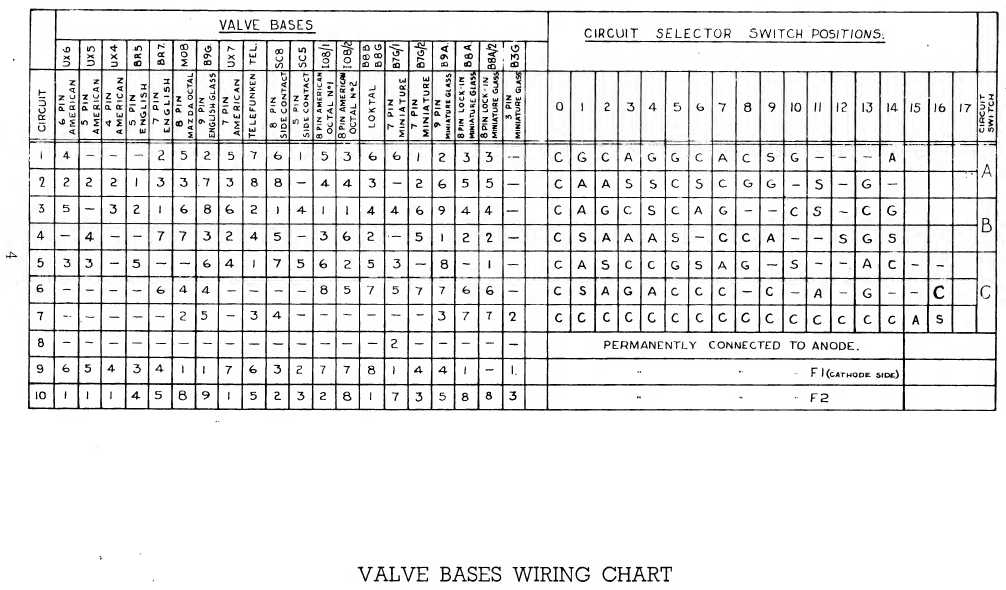

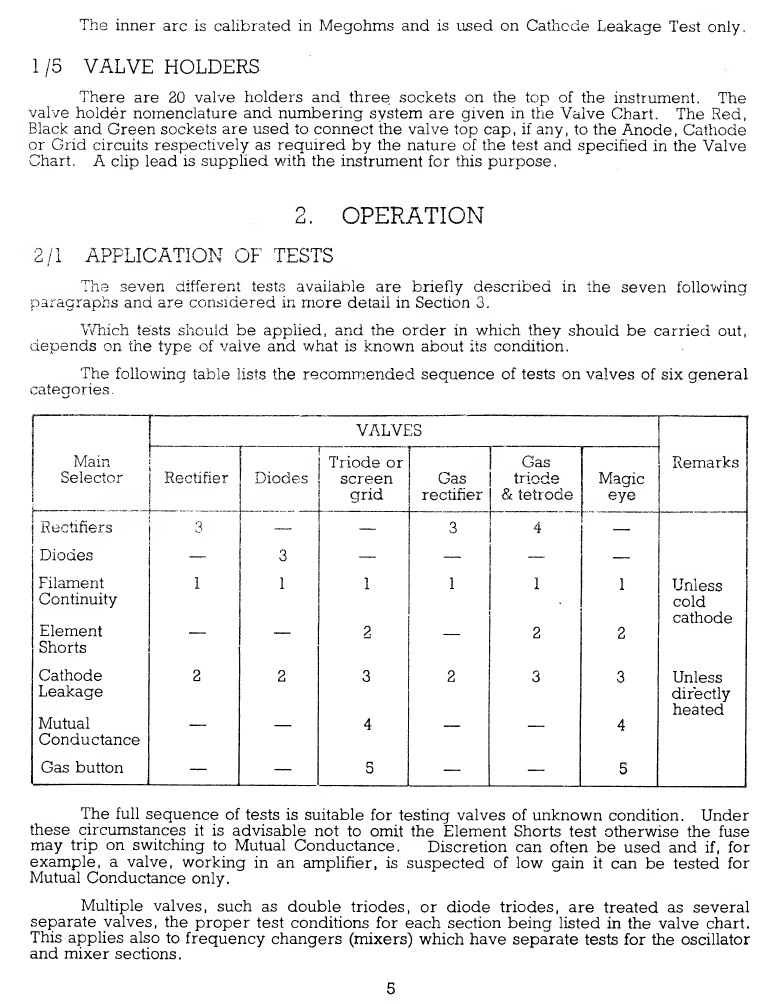

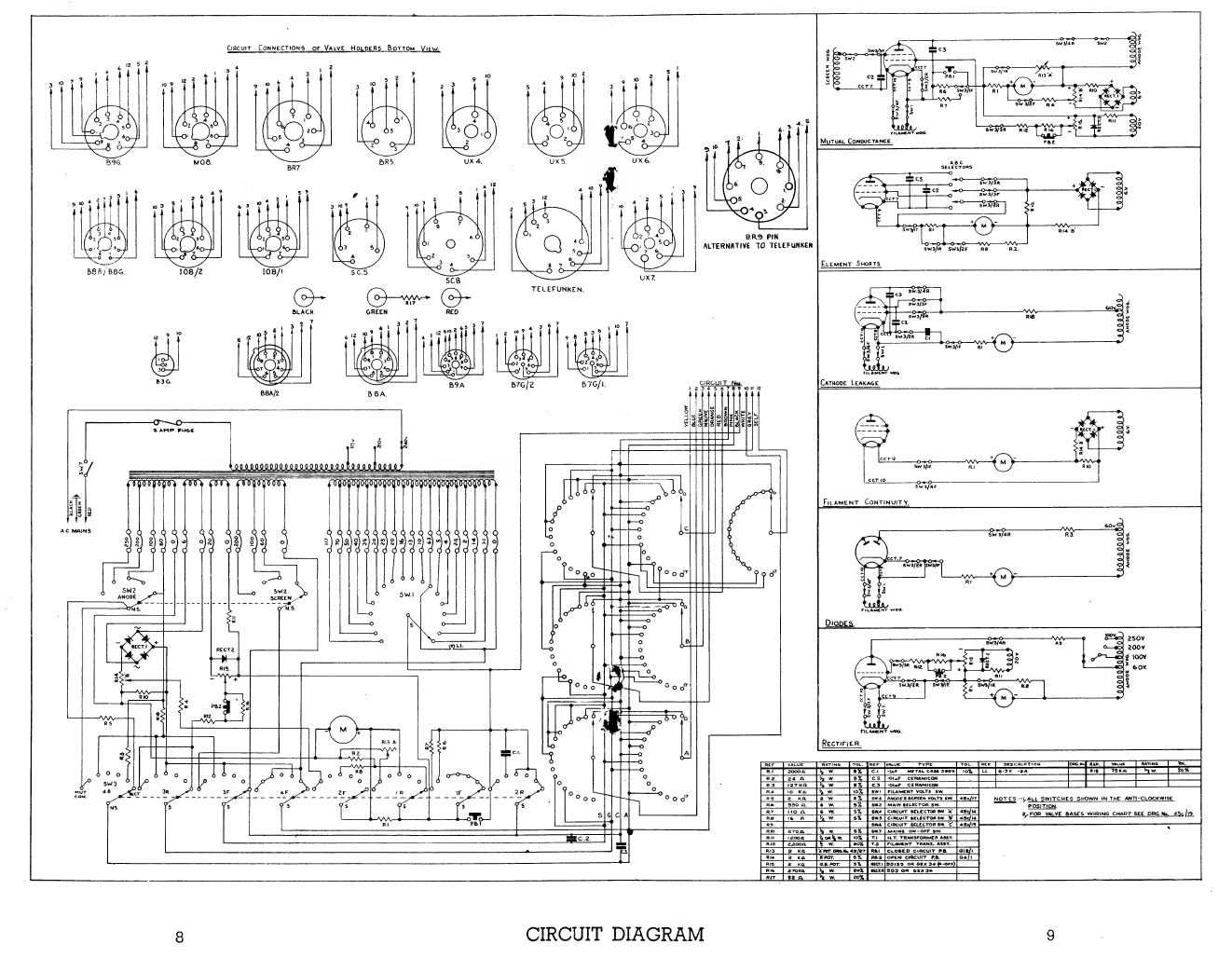

2/2 RECTIFIERS

•

Set ABC selectors to positions specified in Valve Chart, Anode/Screen switch to 100/100

then turn main selector to “Rect ”and read on coloured meter scale. Repeat for second anode

if any.

TESTING COLD CATHODE RECTIFIERS

When testing cold cathode rectifiers e.g. OZ-4 the anode screen volt switch should be

set to 250/200, which will cause the OZ-4 to strike. The anode screen volt switch should then

be returned to the 100/100 position when the correct emission will be indicated on the meter.

Failure of the OZ.4 to strike or the stopping of emission before the 100/100 switch position is

reached indicates afaulty valve.

Care should be taken when testing other rectifiers that the anode screen volt switch be

set to 100/100 as failure to do so will damage smaller types of rectifiers.

2/3 DIODES

Same as for rectifiers but main selector is at “Diodes.”

2/4 FILAMENT CONTINUITY

Set main selector on “Fil. Cont.” and if pointer moves to about half scale then the

filament is intact.

2/5 ELEMENT JjHORTS

Set main selector to “Element Shorts ”and the top cap, if any, io green socket. Set

ABC selectors initially to 000. Turn Aselector slowly from 0to 17 and back. If there is a

definite frieter reading on any switch position there is an internal short circuit in the valve.

Repeat with Band Cselectors. Also see Section 3/4.

2/6 CATHODE LEAKAGE

Set ABC selectors and filament volts as specified, then set main selector to “Cathode

Leakage.” The meter pointer will kick to the right, then fall back to some steady reading.

It is not possible to lay down ahard and fast rule as to the minimum acceptable

resistance as so much depends on the type of valve and the circuit in which it is used. As

ageneral guide, however, at least 2megohms should normally be obtained and areading

of 1megohm or less will usually indicate afaulty valve. Whether it need be rejected on

this account depends entirely on the circuit in which it is used.

2/7 MUTUAL CONDUCTANCE

Set filament volts, anode /screen volts, grid volts and ABC selectors as specified and

turn Aand Bknobs fully anti -clockwise then, and then only, set main selector to “Mutual

6