INSTALLATION

NOTE: If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Items Required

Norbar torque transducer to suit capacity of test with suitable torque display instrument.

Location

Ensure location can cope with weight of loader.

Locate ISO 1500 on a level surface at a comfortable working height.

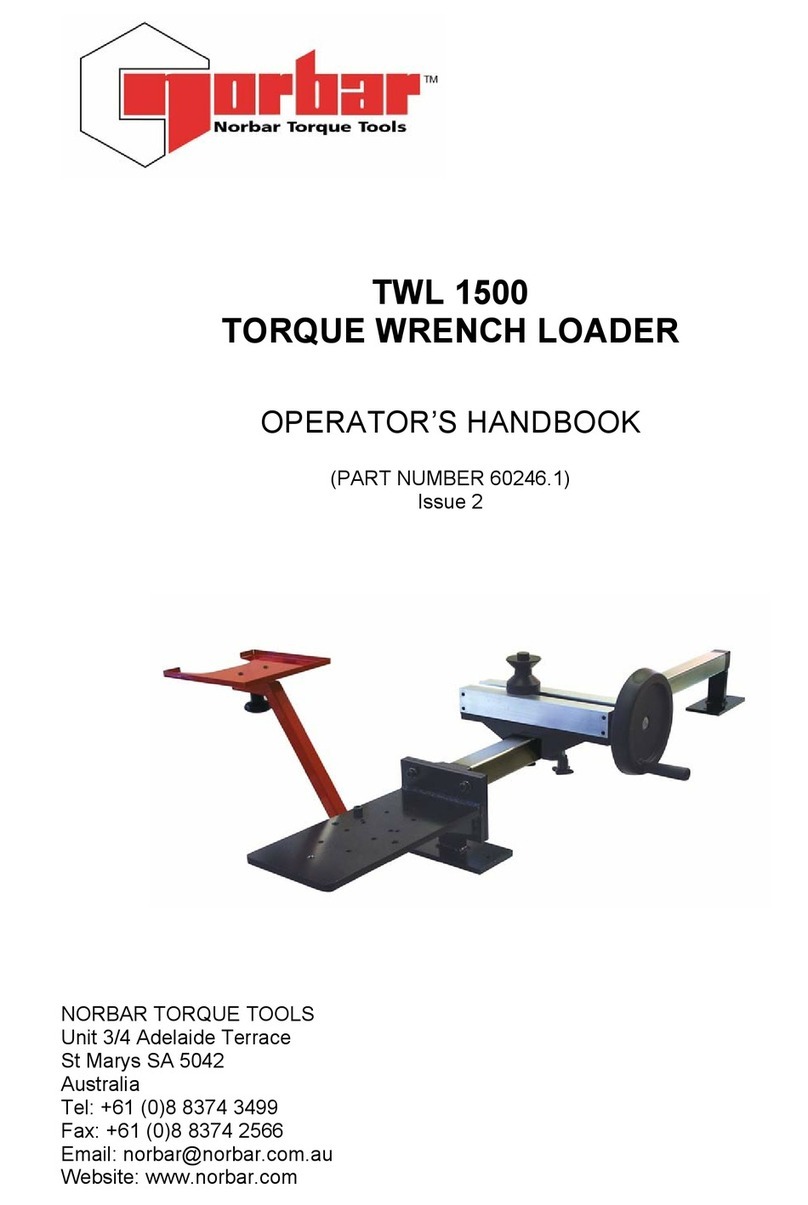

Rotating Lever

Slide “Rotating lever” from the back and secure with the 2 circlips provided (see drawing on page 3).

Tool Reaction Post

Slide “Tool reaction post” on to the reaction bar.

Horizontal and Vertical Operation

The loader is shipped in the horizontal mounting position.

To change to the vertical position push the “ORIENTATION RELEASE

HANDLE” (see drawing on page 3) to “RELEASE” position.

Pull the “ROTATING LEVER” to rotate the ISO 1500 90 degrees.

Pull the “ORIENTATION RELEASE HANDLE” to “CLAMP” position.

Check the ISO 1500 is clamped in position.

The loader is ready for vertical use.

IMPORTANT: ALWAYS ENSURE THE “ORIENTATION RELEASE

HANDLE” IS LOCKED BEFORE LOADING.

NOTE: When rotating the ISO 1500 ensure the transducer lead is not

caught up in the mechanism.

Reaction Plate for Small Torque Wrenches (Optional)

To use small torque wrenches a smaller reaction plate may be required.

Fix using M8 socket cap screws provided with reaction plate.

Tighten to 20 N∙m.

Torque Measurement

Select the lowest capacity torque transducer to cover the wrench to be

tested.

Mount the male square of the transducer into the female square of the gearbox, use adaptors to suit.

Place collar over the transducer and lock by rotating through 90 degrees.

Connect a transducer lead from the transducer to the instrument.

Ensure the instrument functions correctly. (If in doubt see operators manual).