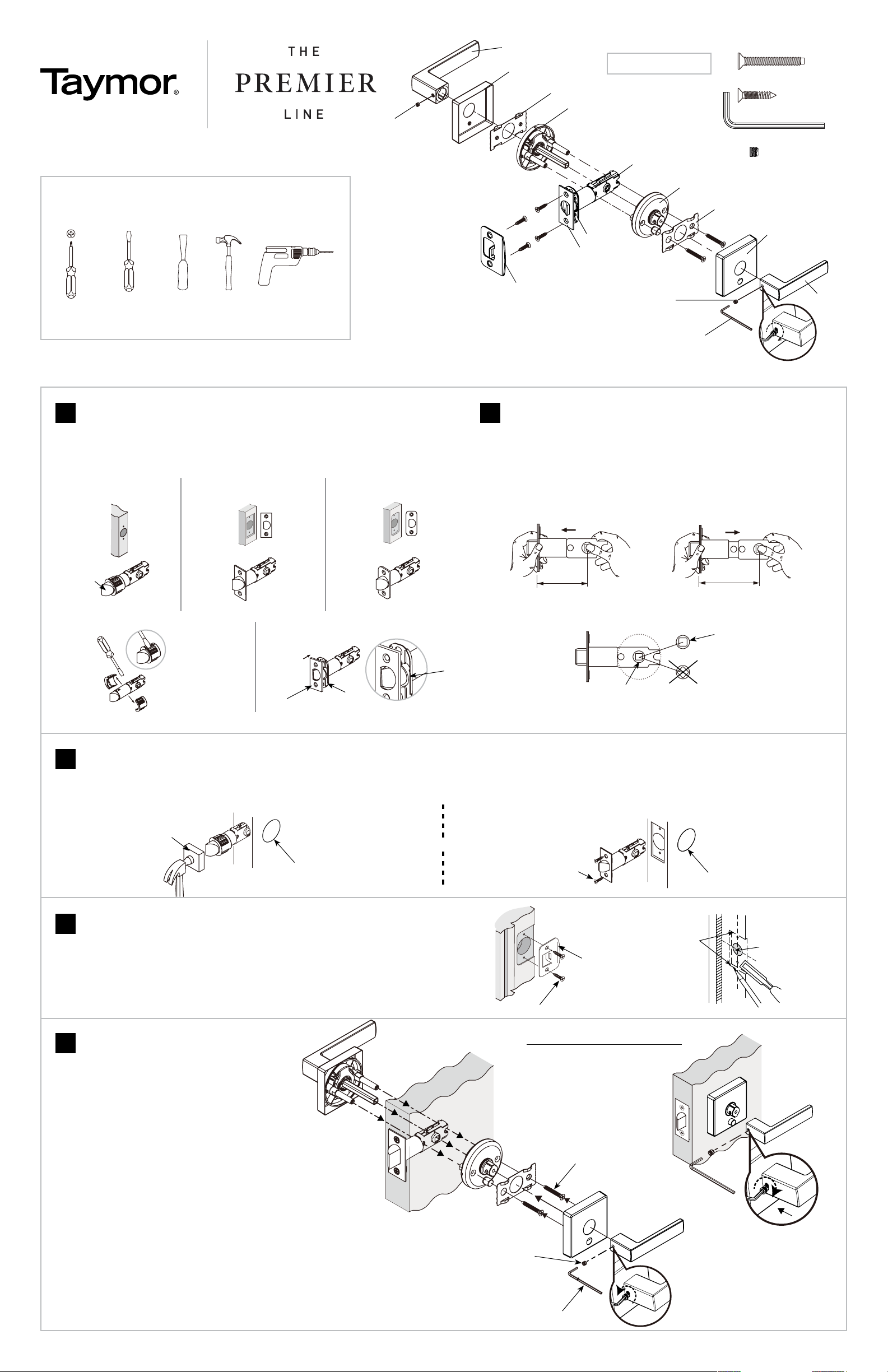

INSTALL LATCH

A. Drive-in Latch: Insert latch into the door edge and tap it into place using a wood

block (not included) until it is flush with the door edge.

3

B. Faceplate Latch: Secure to the door edge using latch screws (BB). If it does not sit

flush with the door edge, mark an outline using the faceplate and chisel 1/8”

(3 mm) deep or until the faceplate is flush.

OR

(BB)

WOOD BLOCK

BORE HOLE

BORE HOLE

TOOLS NEEDED

CAUTION: Use of manual tools recommended. When using power tools,

adjust to lowest torque setting.

PHILLIPS

SCREWDRIVER

FLAT HEAD

SCREWDRIVER

(OPTIONAL)

CHISEL

(OPTIONAL)

HAMMER

(OPTIONAL)

HAND DRILL

(OPTIONAL)

12

CHOOSE YOUR LATCH TYPE

To change the latch from a drive-in latch to a faceplate latch, remove the sleeve using

a screwdriver (A1), attach selected faceplate to backplate (A2) and fasten to latch.

DRIVE-IN

LATCH SQUARE FACEPLATE

MORTISE LATCH RADIUS FACEPLATE

MORTISE LATCH

REMOVE

SLEEVE

ADJUST THE BACKSET

The backset is the distance from the door edge to the center of the spindle cam.

The spindle cam must sit straight (B3) and at the center of the bore hole to install

the lever. The two most common backset measurements are 2-3/8” (60 mm) or

2-3/4” (70 mm). To change the backset from 2-3/8” (60 mm) (B1) to 2-3/4” (70 mm)

(B2) pull the spindle cam away from the faceplate.

A1 A2

BACKPLATE

NOTE: The bevel of

latch bolt should

face the door jamb

B3 SPINDLE CAM

RIGHT

WRONG

MUST SIT IN

CENTRE OF DRILLED

DOOR HOLE

B1 B2

2-3/8 (60 mm) 2-3/4 (70 mm)

ENSURE LIP OF

BACKPLATE IS

FACING TOWARDS

FACEPLATE

INSTALL STRIKE PLATE

A. Secure the strike plate to the door jamb using wood strike screws (BB).

B. If there is no hole for the latch bolt, mark a centerline on the door jamb that aligns with

the centerline of the door latch. Drill one 1” (25 mm) hole 5/8” (16 mm) deep.

C. Use the strike plate to make an outline on the door jamb and chisel 1/8” (3 mm) deep

until it sits flush.

D. Drill two 1/8” (3 mm) drill holes and secure the strike plate to the door jamb.

4

(BB)

STRIKE PLATE

1/8” (3 mm) ONE (1) 1” (25 mm)

HOLE

5/8” (16 mm)

DEEP

FACEPLATE

INSTALL LOCKSET

A. Remove the interior lever from the lock

mechanism by loosening the set screw

with the Allen Key (CC). Remove the

interior rose by twisting and pulling it off

the interior lock mechanism.

B. Install exterior lock assembly inserting

square spindle and posts through latch.

Note: For privacy functions, the emer-

gency release hole can be positioned

either above or below the lever.

Note: For entry function, spindle must be

positioned vertically.

C. Attach the interior lock assembly to the

exterior assembly using the mounting

screws (AA). Note: For privacy functions,

ensure the lock button aligns with the

emergency release hole on the exterior

side.

D. Re-attach interior rose to lock mecha-

nism.

E. Re-attach interior lever with the set

screw (DD) using the Allen Key (CC).

5

CONTINUED ON BACK PAGE

EXTERIOR INTERIOR

EXTERIOR SIDE

INTERIOR SIDE

Note: To ensure correct alignment of the lever, tighten the mounting screws

on the interior lock mechanism while holding the exterior lever upwards.

REPLACING AN EXISTING LOCK (NO DOOR PREPARATION NECESSARY)

INSTALLATION INSTRUCTIONS FOR 1948 STYLE

COMPONENTS AA Mounting Screws (2)

BB Latch & Strike Plate Screws (4)

CC Allen Key (1)

DD Set Screws (2)

Exterior Rose Bracket

Latch

Exterior Lever

Rose Cover

Exterior Rose &

Lock Assembly

Set Screw

Interior Rose Bracket

Allen

Key

Interior Lever

Interior

Rose

Lock Assembly

Face Plate

Set Screw

Back Plate

Strike Plate

.

D.

B.

C.

AA

DD

CC

A.

E.