2800 LAURA LANE lMIDDLETON, WI 53562 l(800) 288-9383 lFAX (608) 836-9044 lwww.tcs-basys.com

8

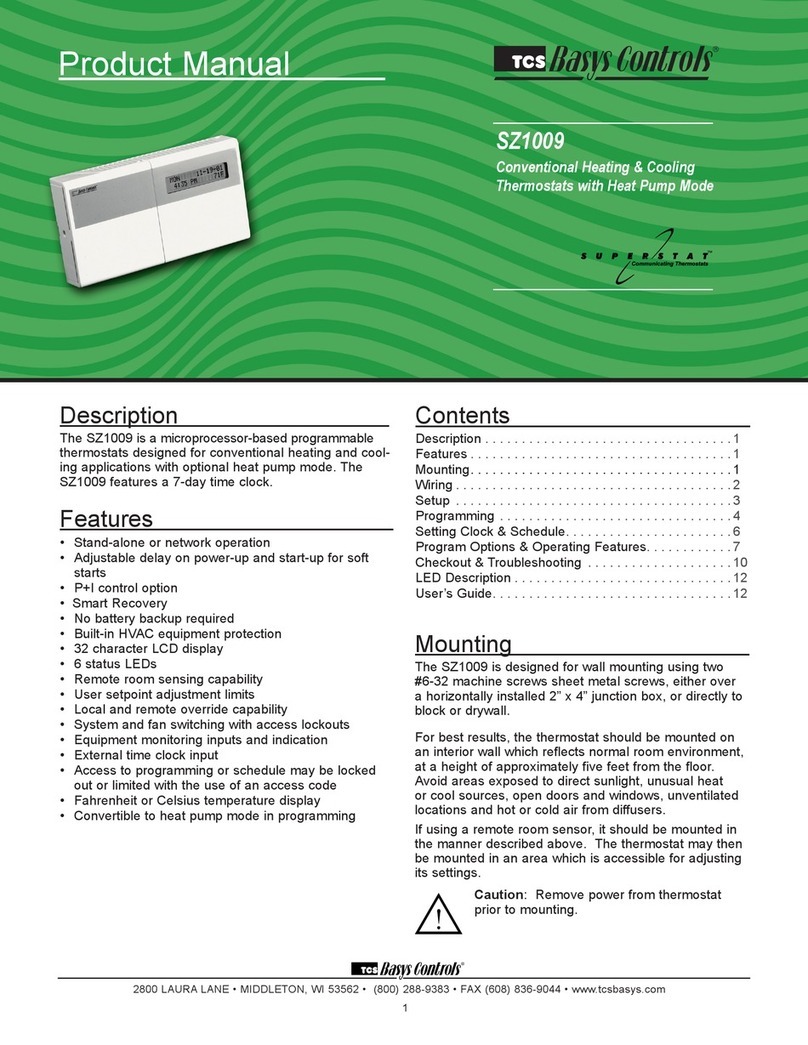

Operation

UNOCCUPIED SETBACK

The SZ1009, SZ1022, SZ1031 and SZ1035 operate in either

an occupied or unoccupied mode. During the occupied mode,

the occupied heating and cooling setpoints will be maintained,

and the fan will operate according to its occupied setting.

During the unoccupied mode, the unoccupied heating and

cooling setpoints will be maintained, and the fan will operate

according to its unoccupied setting. The occupied LED will

be lit when the unit is operating in the occupied mode.

The occupied schedule may be set utilizing the internal time

clock or DI3 may be used with an external time clock, where-

as when DI3 is closed, the unit is in the occupied mode. The

Smart Recovery function is disabled when DI3 is used for

external time clock.

OVERRIDE

A timed override is available on the face or through momen-

tary contacts. The amount of time the unit will be overridden

is set from 0 to 255 minutes in the programming. This over-

ride only activates when the thermostat is operating in the

unoccupied mode. Both the software and the service button

allows you to view the time remaining in the override mode.

If the occupant desires to return the thermostat to unoccupied

operation before that time interval is up, they may press the

button on the face or the momentary contact again.

Continuous override is available through the DI3 contact or

the software. If DI3 is set to external override, the unit will be

in the occupied mode whenever the DI3 contact is closed.

When using this option, the timed override may still be acti-

vated.

The software allows you to override the thermostat by putting

the override parameter into the remote mode, and thus dis-

abling the timed override.

SETBACK AND OVERRIDE APPLICATIONS

In most applications, it is desired to maintain a regular sched-

ule, and allow timed override with the button on the face or

with a remote momentary contact.

To allow a regular schedule, and also automatically override

with the use of an occupancy or light sensor, set DI3 to exter-

nal override and set it up so that the contact is closed when

you want the override.

For applications where a room might not be used on a regular

schedule, such as conference rooms, set DI3 to external time

clock and close the contact when you want the room occu-

pied, such as with a switch or wind-up timer. If each occupan-

cy period is about the same, (theaters, meetings) another

option is to set the DI3 to external override, and use the timed

override button to put the unit in occupied mode.

To make the unit always occupied, set DI3 to external time

clock and short the DI3 terminal to ground.

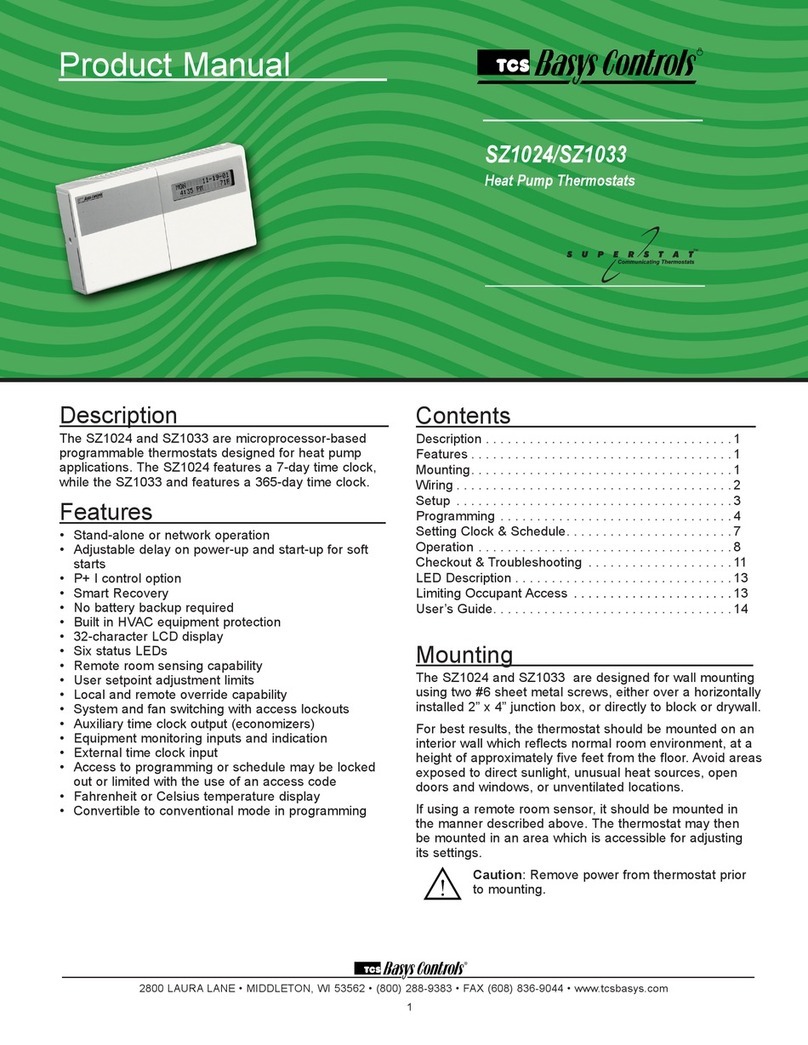

DISCHARGE AIR TEMPERATURE SENSING

The SZ1024 and SZ1033 accept a remote discharge air sensor

for monitoring purposes. (See setup instructions for dipswitch

placement for this option.)

Choose YES in programming screen #30 only if you are using

a discharge air sensor and you want to enable the discharge air

temperature high and low limit functions. If NO is chosen, the

discharge air will still be monitored.

When the function is enabled, a HIGH LIMIT and LOW

LIMIT are entered in steps #31 and #32. If the HIGH LIMIT

is reached, the fan and heating stages will be turned off and

will remain off until the discharge air temperature falls 3°

below that limit. If the LOW LIMIT is reached, the fan and

cooling stages will be turned off and will remain off until the

discharge air rises 3°above that limit. When either limit is

reached, the service LED will be on until normal operation

resumes.

The discharge air span is 0°F to 150°F (-17.8°C to 65.6°C).

OUTDOOR AIR TEMPERATURE SENSING

The SZ1009, SZ1031 and SZ1035 accepts a remote 1000 Ω

outdoor temperature sensor for monitoring purposes. (See

setup instructions for dipswitch placement for this option.)

Choose YES in programming screen #33 only if you are using

an outdoor air sensor and you want to enable the outdoor air

heating and cooling lockout functions. If NO is chosen, the

outdoor air will still be monitored.

When the function is enabled, a COOLING LOCKOUT

TEMP and HEATING LOCKOUT TEMP are entered in steps

#34 and #35. If the outdoor temperature falls below the

COOLING LOCKOUT TEMP, all cooling stages will be

locked out and will remain locked out until the outdoor air

temperature rises 2°above the lockout temperature. If the out-

door temperature rises above the HEATING LOCKOUT

TEMP, all heating stages will be locked out and will remain

locked out until the outdoor air temperature falls 2°below the

lockout temperature.

The outdoor air span is -40°F to 160°F (-40.0°C to 71.1°C).

FAN PROVING

The SZ1009, SZ1022, SZ1031 and SZ1035 allow DI1 to be

set for fan proving to protect equipment on fan failure. To uti-

lize this function, input a pressure or current switch which

tells when the fan is running. If the thermostat closes its fan

contact, and the DI1 is not closed after thirty seconds, the sys-

tem will go to OFF, disabling all outputs, the fan LED will

turn off, and the service LED will be lit until the system is

manually reset by switching the system to a mode other

than OFF.