INSTALLATION MANUAL

1) GENERAL INFORMATION

TheDEIMOSAC A600actuatorishighlyversatileintermsofinstallation

options due to the extremely low position of the pinion, the actuator’s

compact nature and the height and depth adjustment features it oers.

Manual emergency operation is extremely easy to perform using just

a release lever.

Stopping at end of travel is controlled by electromechanical micros-

witches.

2) TECHNICAL SPECIFICATIONS

Power supply 110 - 120V 60Hz

220-230V 50/60 Hz(*)

Motor revolutions 1400 min-1

Power input 400 W

Capacitor 14 µF (220-230V)

50 µF (120V)

Thermal protection 150° C

Insulation class F

Pinion module (stan-

dard) 4mm (14 teeth)

Leaf speed (standard) 9 m/min

Max. leaf weight - stan-

dard**

600kg (≈6000N)

Pinion module (fast) 4mm (18 teeth)

Leaf speed (fast) 11m/min

Max. leaf weight - fast** 370kg (≈3700N)

Max. torque 18Nm

Reduction ratio 1/30

Impact reaction See paragraph “APPLICATION OF ACTIVE

PROTECTION DEVICES”

Lubrication Lifetime greased

Manual operation Lever-operated mechanical release

Type of use Residential

Control unit SHYRA AC SL

Environmentalconditions

from -20°C to + 55°C

Protection rating IP24

Noise level <70dBA

Operator weight 8,1 kg (≈81N)

Dimensions See Fig. G

Maximum cycle

5 cycls/h with 50s operation

(*) Special supply voltages to order.

** There are no minimum or maximum dimension restrictions for the

guided part that can be used.

3) TUBE ARRANGEMENT Fig.A

Installtheelectricalsystemreferringtothestandardsinforceforelectrical

systems CEI 64-8, IEC 364, harmonization document HD 384 and other

national standards.

4) PREPARATION FOR MOTOR MOUNTING FIG.B

Make a hole in the ground to accommodate the concrete pad, with an-

chors embedded in the base plate for fastening the gearbox assembly,

keeping to the distances featured in FIG.B.

5) REMOVING THE COVER Fig.C

• Unscrewtherelevanttwofrontscrews(FIG.C-rif.1).

• Pushasillustrated(FIG.C-rif.2-rif.3)toreleasethecoverfromthetwo

rear blocks (FIG.C - rif.3A e FIG.C - rif.3B).

• Liftthecover(FIG.C-rif.4).

6) MOUNTING THE MOTOR FIG.D

7) MOUNTING DRIVE ACCESSORIES FIG.E-E1

Recommended rack types (FIG.H)

8) RACK CENTRING WITH RESPECT TO PINION FIG.I-J1-K

DANGER -Welding must be performed by a competent person

issued with the necessary personal protective equipment as

prescribed by the safety rules in force FIG.L.

9) FASTENING LIMIT SWITCH BRACKETS FIG.F

10) STOPS FIG.L

DANGER -The gate must be tted with mechanical stops to halt

its travel both when opening and closing, thus preventing the

gate from coming o the top guide. Said stops must be fastened

rmlytotheground,afewcentimetresbeyondtheelectricstoppoint.

Note: the safety edge (Fig. L ref.1) must be installed so that it is not

triggered by the mechanical stops.

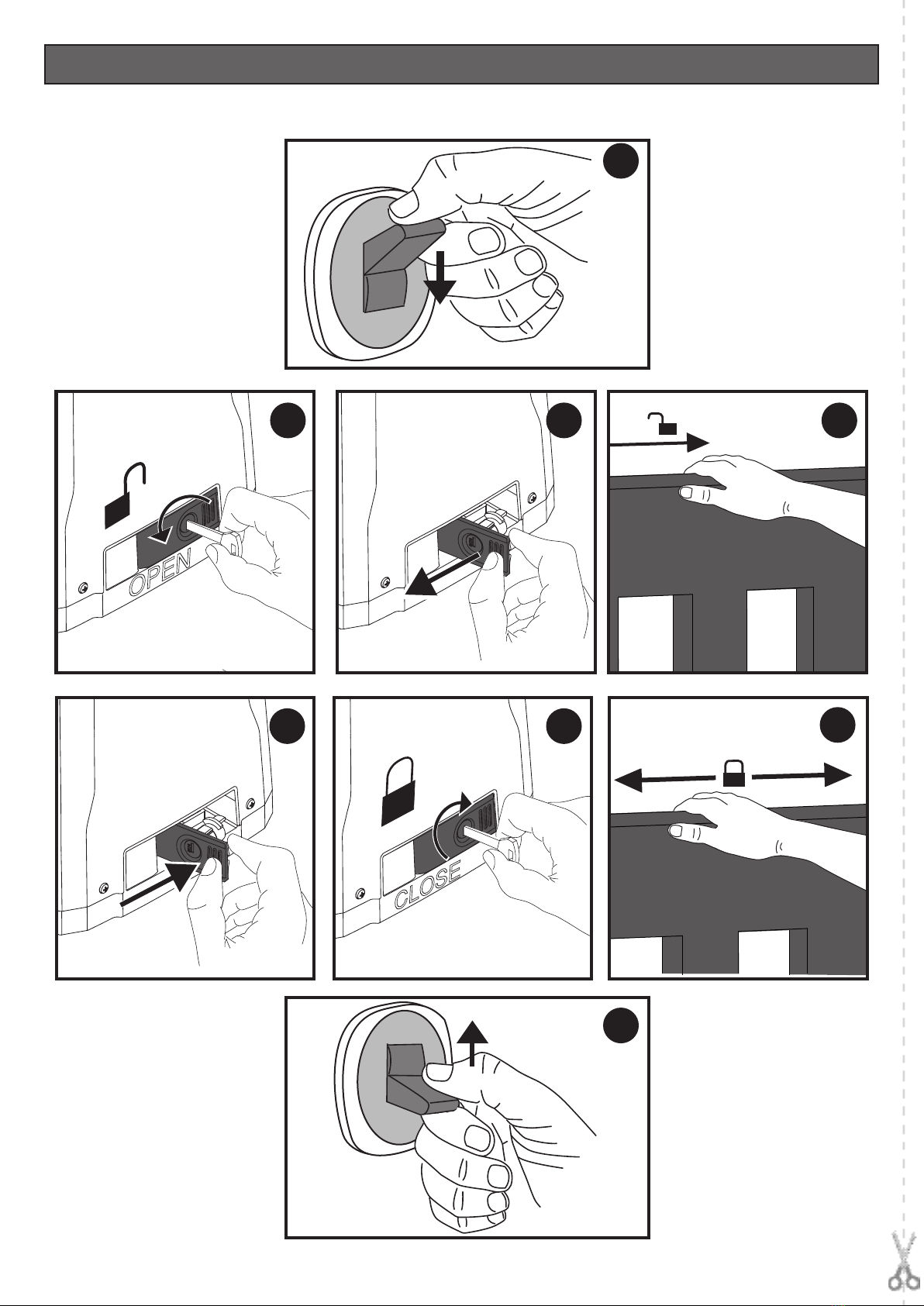

11) MANUAL RELEASE (See USER GUIDE -FIG.3-).

Warning Do not JERK the gate open and closed, instead push it

GENTLY to the end of its travel.

12) TERMINAL BOARD WIRING Fig. M

Remove the board cover releasing it as per the instructions (Fig. M1-M2-

M3).

Once suitable electric cables have been run through the raceways and

the automated device’s various components have been fastened at the

predetermined points, the next step is to connect them as directed and

illustratedinthediagramscontainedintherelevantinstructionmanuals.

Connect the live, neutral and earth wire (compulsory).The mains cable

mustbeclampedinthe relevantcablegland(FIG.M-ref.X)and while the

earth wire with the yellow/green-coloured sheath must be connected

in the relevant terminal (FIG.M-ref.Y).

WARNINGS - When performing wiring and installation, refer to the

standards in force and, whatever the case, apply good practice princi-

ples. Wires carrying dierent voltages must be kept physically separate

from each other, or they must be suitably insulated with at least 1mm

of additional insulation.

Wires must be secured with additional fastening near the terminals,

using devices such as cable clamps. All connecting cables must be kept

far enough away from dissipaters.

13 SEETHECONTROLUNIT’SUSERGUIDEFORINFOR

MATION ON SETTING THE MOTOR’S PARAMETERS

DANGER – The torque adjuster must be calibrated before the

automation becomes operational.

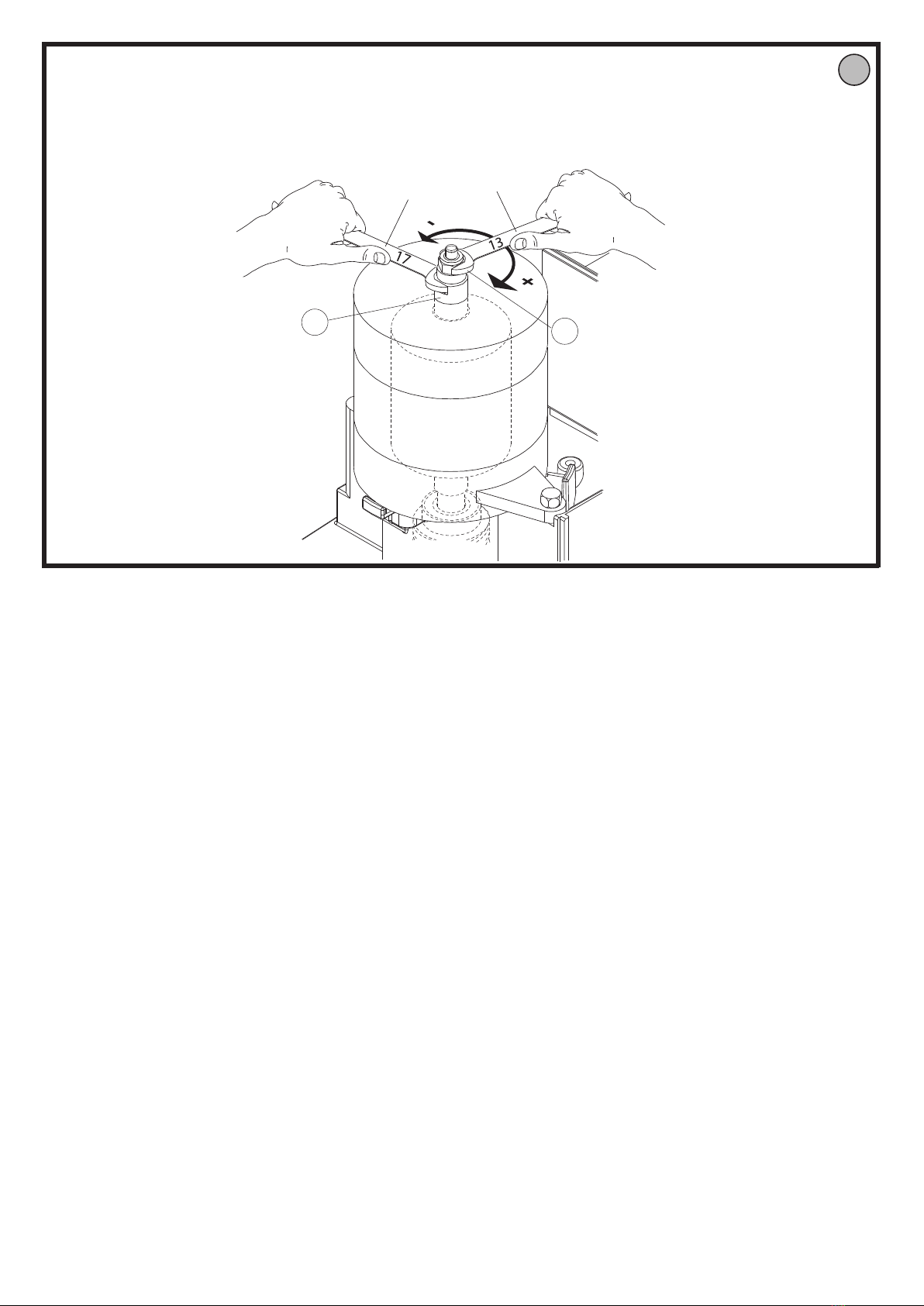

14) TORQUE ADJUSTMENT

The adjustment must be carried out in compliance with the safety re-

gulations in force. To this end, proceed as follows:

• Disconnectthepowersupply.

• Removethexingscrewsofthegearmotorcasing.

•

With the seventeen spanner NOT supplied, block the drive shaft (Fig.

N. – ref.“A”).

WithanotherthirteenspannerNOTsupplied,screwintheself-locking

nut (Fig. N – ref. “B”) to increase the torque, or loosen it to decrease

the torque.

• Replacethegearmotorcasingandxitwiththescrews.

15) APPLICATION OF ACTIVE PROTECTION DEVICES

If the motor is not manned, install type“C”or“E”safety devices according

to EN12453 and in compliance with EN12978. If the dangerous edges

of the door are protected with active strips, check the declared data are

compatible with the driving unit. In particular check that:

a. the extra travel exceeds 30 mm;

b. the maximum speed exceeds 9m/min (11m/min for the fast version);

c. the temperature range is at least -20°C +55°C;

d. the response time is compatible with the motor;

e. the strip is suitable to the type of edge to be protected;”

ATTENTION: Vérier que la valeur de la force d’impact mesurée

aux endroits prévus par la normeEN 12445, est inférieure aux

indications de la norme EN 12453.

WARNING! Incorrect settings can result in damage to property and

injury to people and animals.

20 - DEIMOS AC A 600

D812460 00100_02