©2012 Tyco Electronics Corporation, a TE Connectivity Ltd. company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or company names may be trademarks of their respective owners.

1of 3

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com

408-8340

180° Cable Clamp

Assembly 1424035-1 24 MAY 12 Rev B

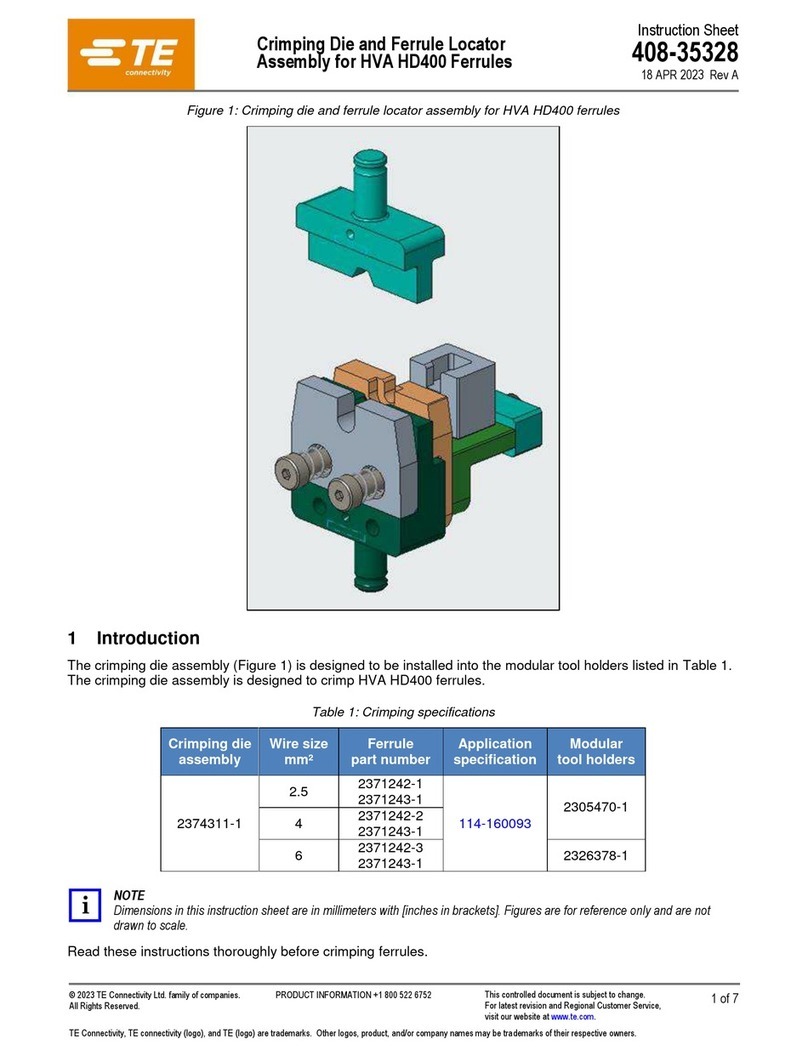

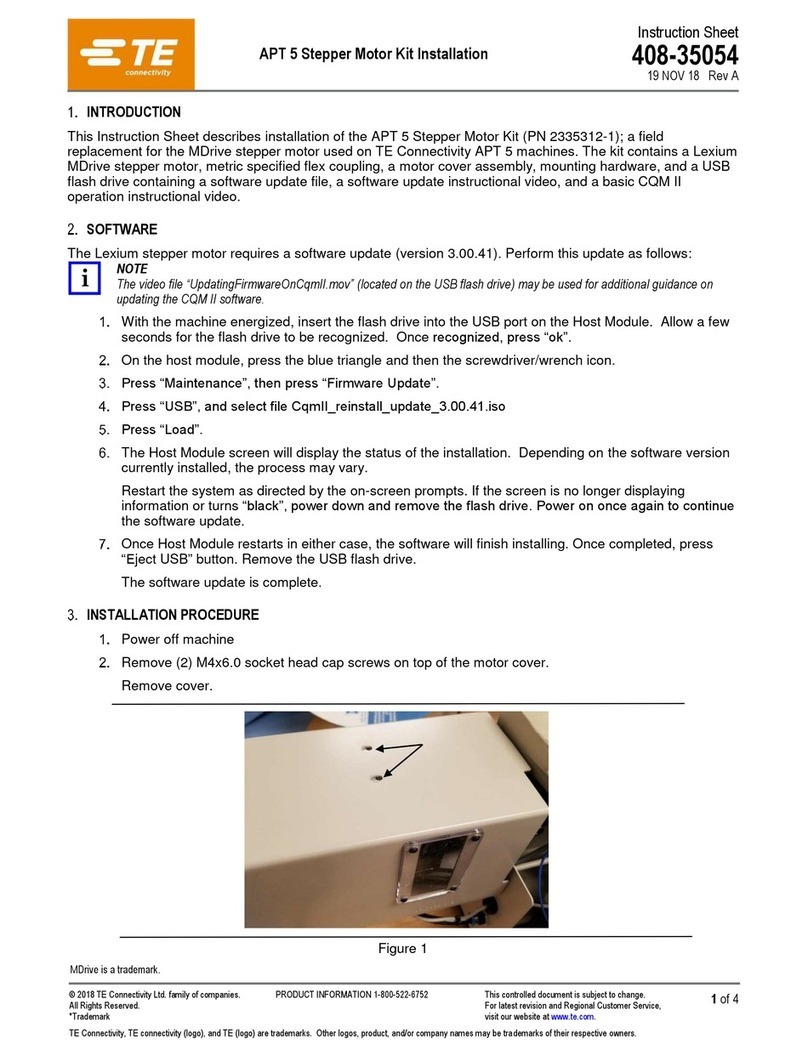

Figure 1

1. INTRODUCTION

The 180° Cable Clamp Assembly 1424035-1 is

designed to be used in CHAMPOMATOR* 2.5 Bench

Terminating Machine762734-[ ]. The machine must be

equipped with a clamp solenoid valve (shown in

Figure 4) and a controller having software at

Rev. 3.03.05 or later. To use the machine without

these requirements, use 180° Cable Clamp Assembly

768830-1 and follow the instructions packaged with

that cable clamp.

The cable clamp permits the machine to apply

discrete-wire jacketed cable to AMPLIMITE* .050

Series connectors, AMPLIMITE HDE connectors,

CHAMP* connectors, and AMPMODU* MT

connectors.

All dimensions on this sheet arein millimeters [with

inch equivalents in brackets]. Figures and

illustrations are for identification only and are not

drawn to scale.

Make sure to retain all material in the bench

terminating machine documentation package for

reference.Fordetailedinformationontheoperation

of the machine, refer to Customer Manual

409-5839 which is supplied with the machine.

Reasons for reissue of this instruction sheet are

provided in Section 8, REVISION SUMMARY.

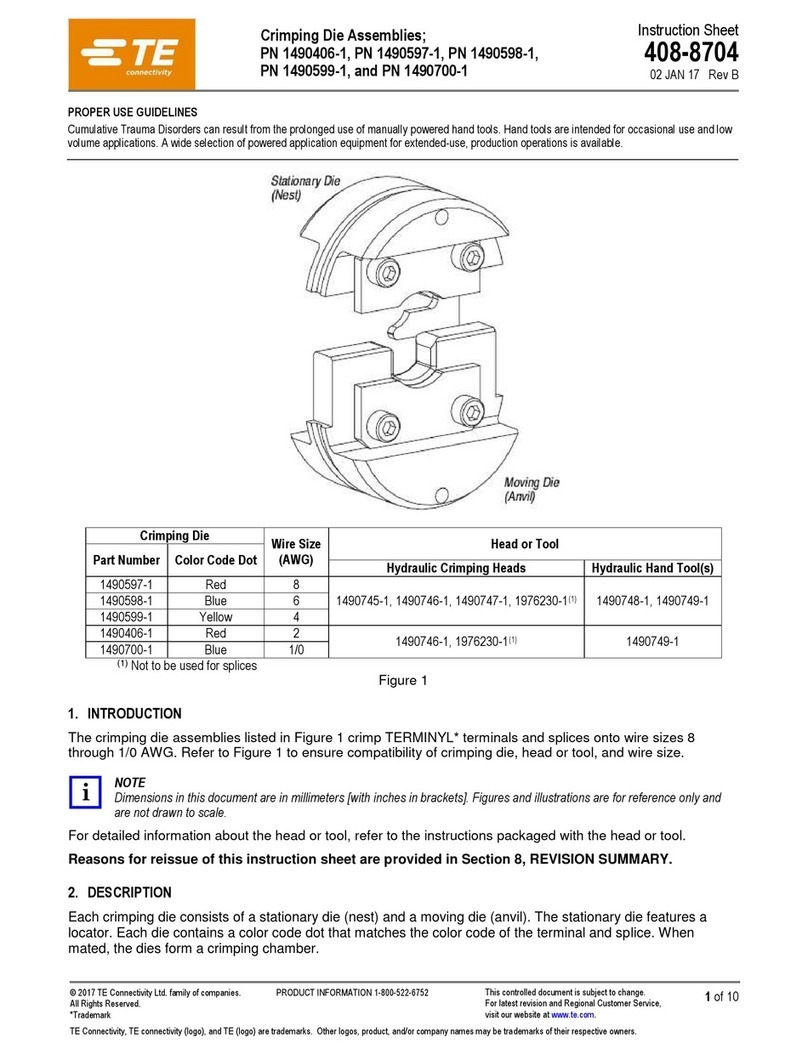

2. DESCRIPTION (Figure 1)

The cable clamp is capable of being adjusted to give a

1805 cable breakout, and it can also be offset for the

angle-exit option when applying AMPLIMITE .050

Series connectors with the machine.

During operation, the operator places the cable into

the cable clamp, and places the wires in the wire

holder, which holds the cable wires in place during the

termination process, helping to keep the loose wires

out of the operator's way.

As the wires are terminated, the clamp follows the cam

track and moves to provide the desired breakout

length. The clamp eventually bottoms in the cam track,

determining the position of the cable with respect to

the connector.

After all terminations have been completed, the

machine moves to the forward home position. At this

time, the operator unclamps the cable, then presses

the machine's “INDEX” and “LOAD” buttons. The

machine carriage and cable clamp then move to their

respective home positions, permitting the operator to

remove the completed cable assembly from the

machine.

Make sure that the cable assembly does not get

caught on the cable clamp, or damage to the cable

assemblycould result.This isparticularly important

when processing the second-end connector on a

short cable assembly.

Cam Track

Cam

Air-Activated

Cylinder

Fitting

Jaw

Cable Clamp

Bracket

Indicator

Wire Holder

Clamp

Bracket

ORIGINAL INSTRUCTIONS