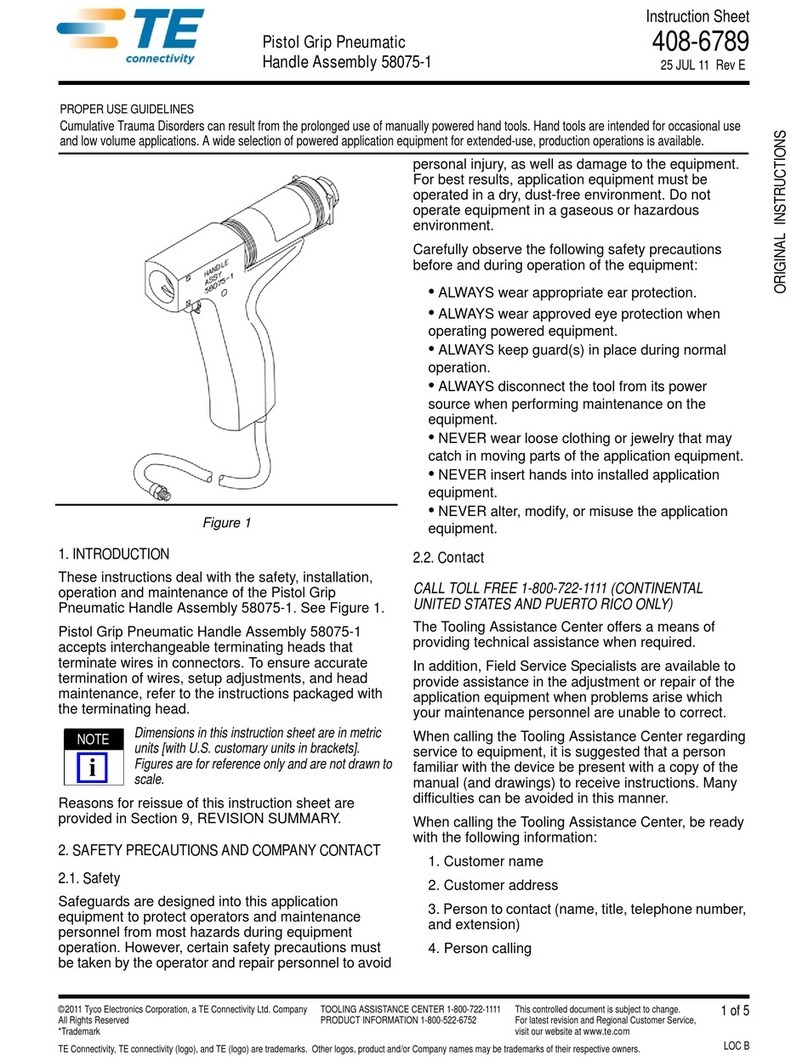

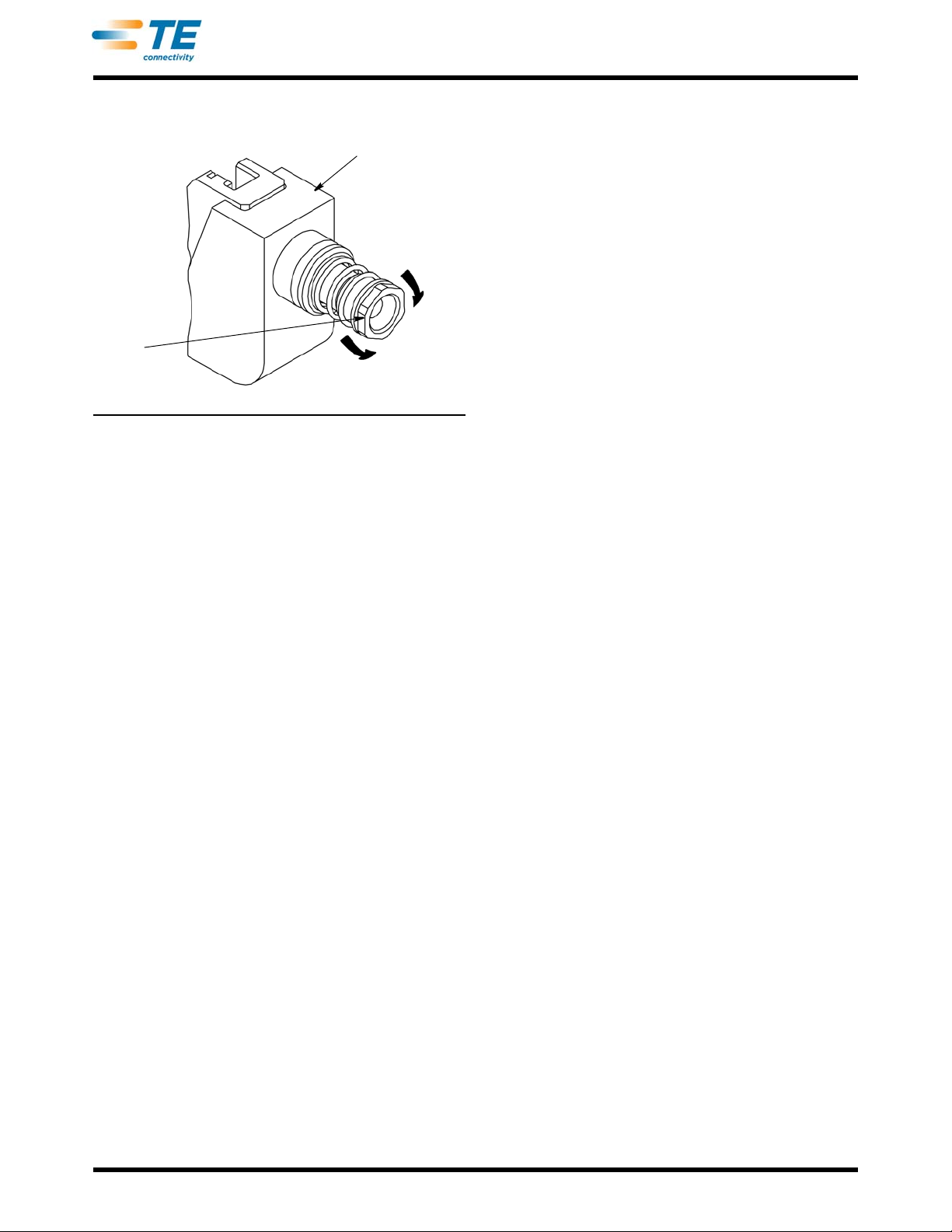

Head Removed from

Handle Assembly

Insertion

Rod

Adjuster

Clockwise to

Decrease

Wire Insertion Depth

Counterclockwise

to Increase

408-4406

4of 5

Rev C

Figure 6

2. If the wires are too deep in the contact slots, turn

the insertion rod adjuster clockwise. A 1/6-

revolution will decrease the wire insertion depth by

approximately 0.20 mm [.008 in.]. If the wires are

not deep enough in the contact slots, turn the

adjuster counterclockwise. A 1/6-revolution will

increase the wire insertion depth by approximately

0.20 mm [.008 in.]. See Figure 6.

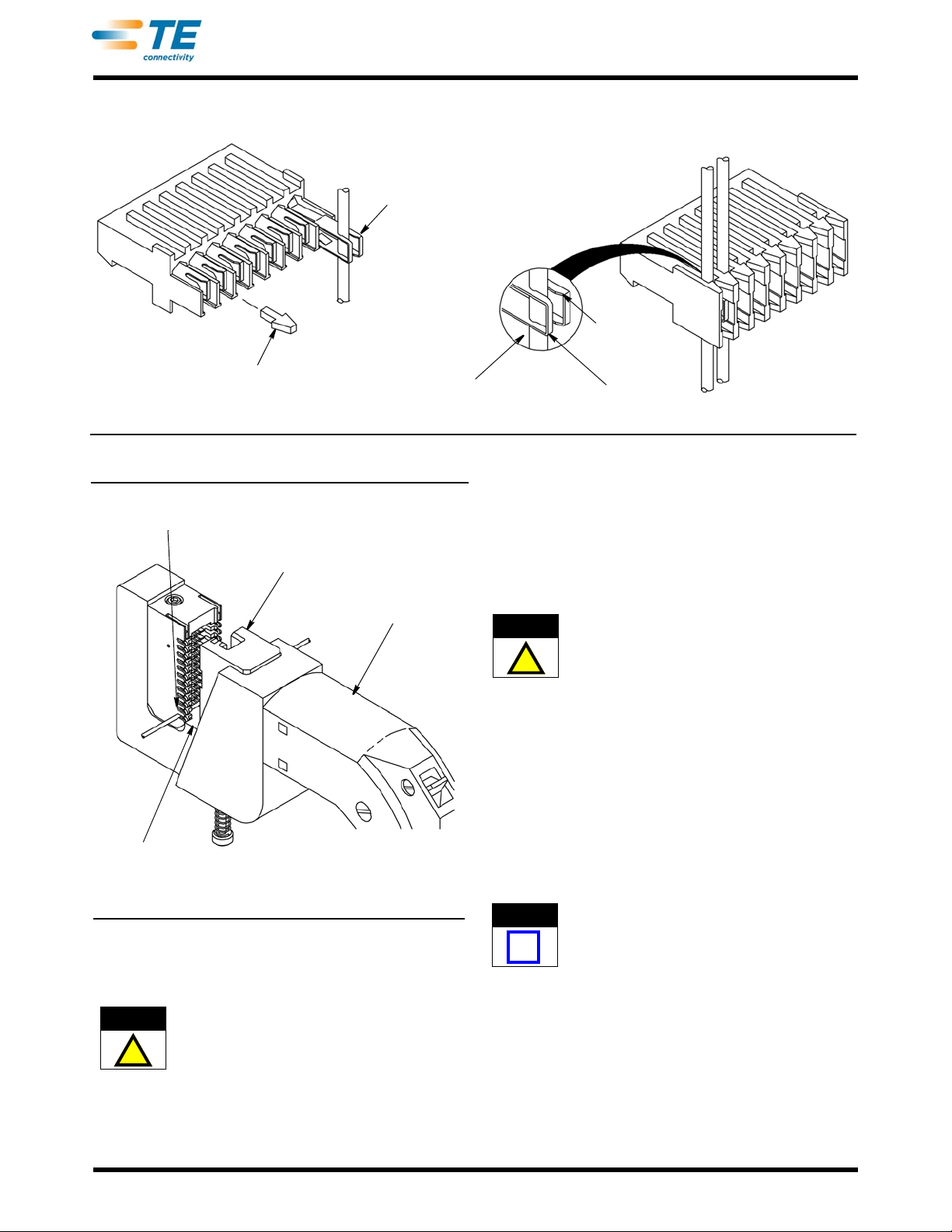

3. Install the head onto the handle assembly; then

terminate and inspect a test connector.

4. Repeat the adjustment as necessary until proper

wire insertion depth is obtained. DO NOT use a

tighter setting than required.

6. MAINTENANCE AND INSPECTION

TE recommends that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations.

6.1. Daily Maintenance

1. Remove dust, moisture, and other contaminants

with a clean, soft brush or a soft, lint-free cloth. Do

NOT use objects that could damage the head.

2. Make sure that all pins, rings, and other

components are in place and secure.

3. When head is not in use, store it in a clean, dry

area.

6.2. Periodic Inspection

Regular inspections should be performed by quality

control personnel. Though recommendations call for

at least one inspection a month, the frequency should

be based on amount of use, working conditions,

operator training and skill, and your established

company policies.

1. Remove all lubrication and accumulated film by

immersing the head in a suitable commercial

degreaser that will not affect paint or plastic.

2. Make certain all components are in place. If

replacements are necessary, refer to Section 7.

3. Check all bearing surfaces for wear. Replace

worn or damaged parts.

4. Inspect the head for flattened, chipped, or broken

surfaces. Replace worn or damaged parts.

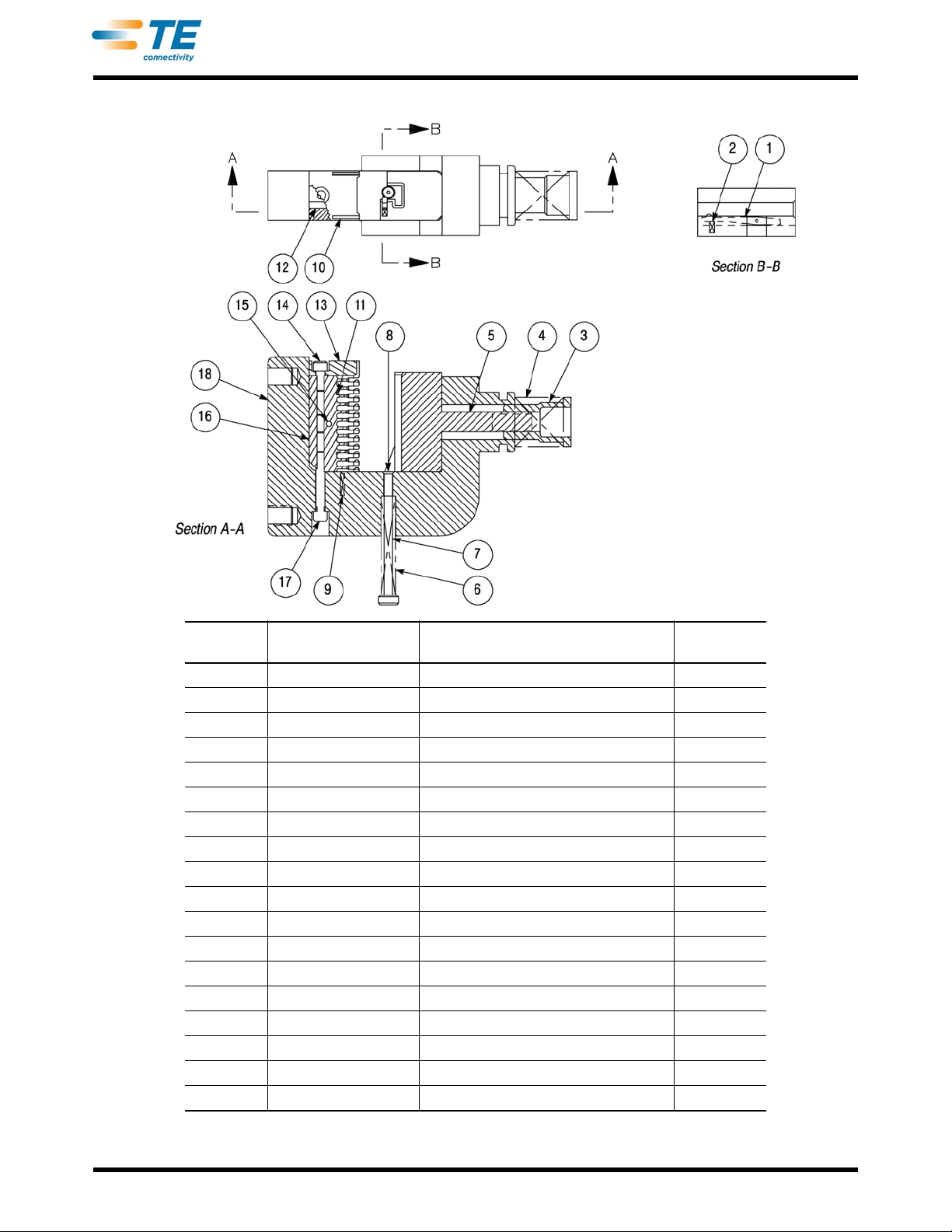

7. REPLACEMENT AND REPAIR

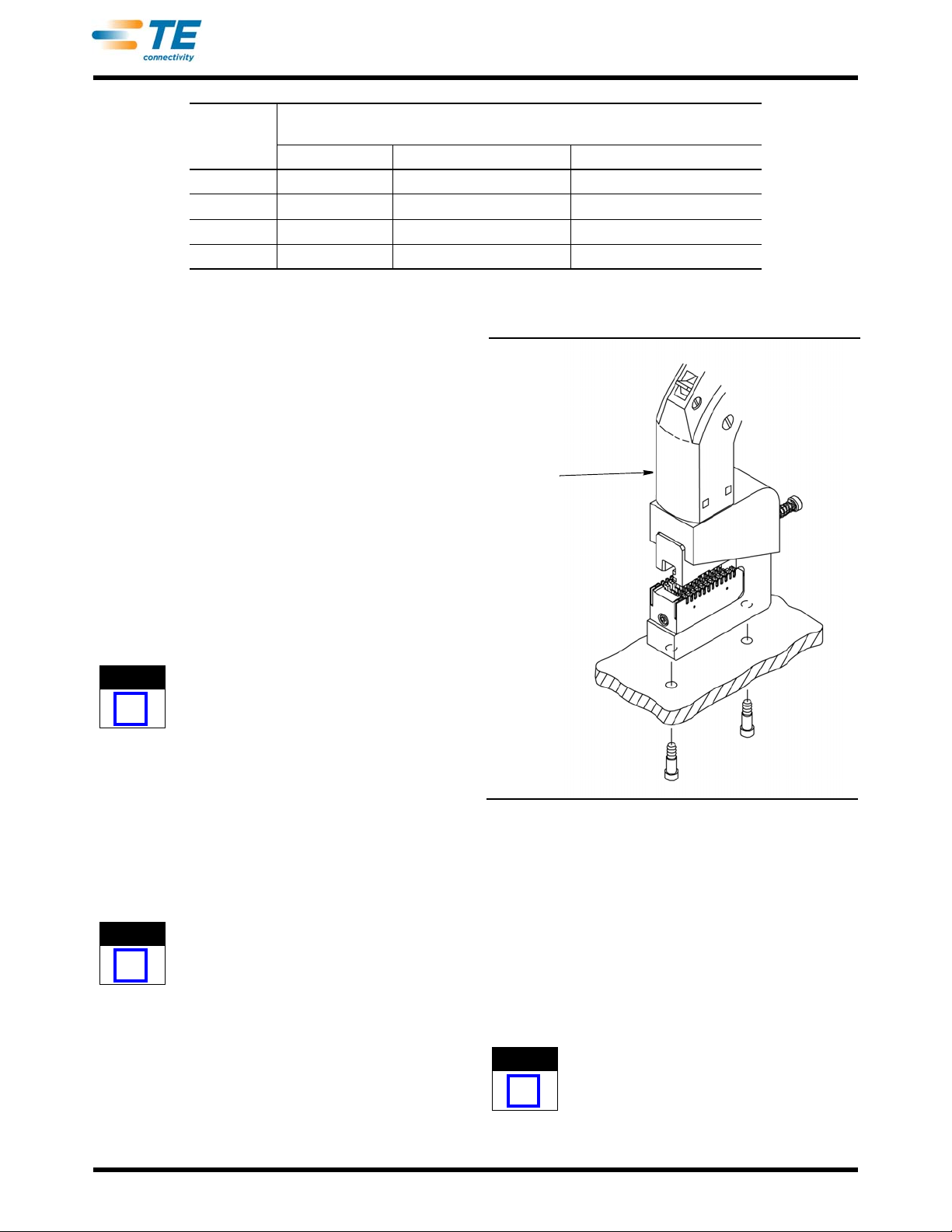

Replacement parts are listed in Figure 7. A complete

inventory can be stocked and controlled to prevent lost

time when replacement of parts is necessary. Order

replacement parts through your TE representative, or

call 1-800-526-5142, or send a facsimile of your

purchase order to 1-717-986-7605, or write to:

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

For customer repair service, call 1-800-526-5136.

8. REVISION SUMMARY

Revisions to this instruction sheet include:

•Changed company name and logo