CONTENTS

3.

THEORY

OF

OPERATION

3-1

Outline

of

construction

and

functions

••.••.....•..••..••••••••

3-1-1

Overall

block

diagram

......•..•.••.•.•.•..••....••....•••

3-1-2

Outline

of

mechanical

section

.••.....•.•.•.••...•••...•.•

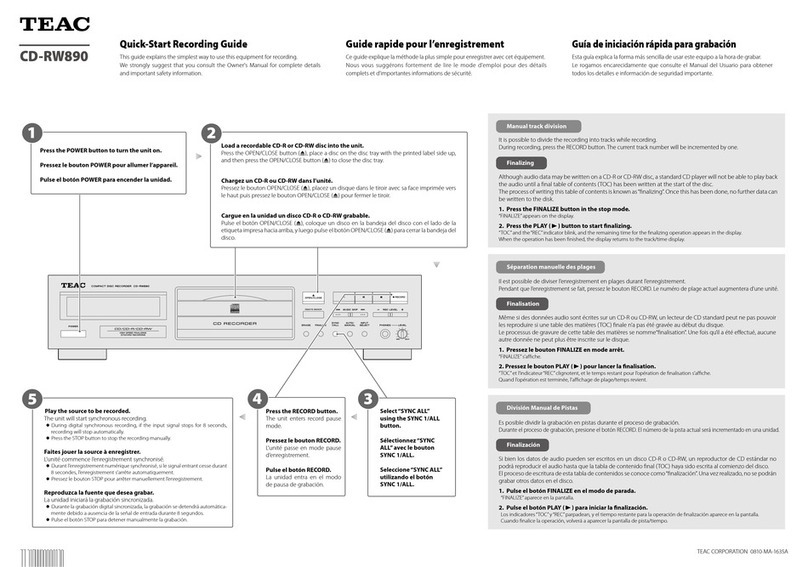

3-2

Operation

of

data

recording/reproducing

system

(PCBA

Drive

Control)

..•••••••••.••••.•.••••.••.•••.•••••••••••

3-2-1

Read

circuit

..........................................•..

3-2-2

Write

circuit

and

erase

circuit

••••••.•••.•••.•••••••••••

3-3

Operaiton

of

tape

drive

systm

(PCBA

Drive

Control)

....••••..•.

3-3-1

Servo

circuit

•...•.••....•..•.•••.•••.•.••..••...••.•...•

3-3-2

Other

control

circuits

••..........•.....•••..•..•..••...•

3-4

"D/CAS"

Interface

control

(PCBA

Interface

Control)

...........

.

3-4-1

CPU

.•.•.•..••••..........•..••••..................•.•.•..

3-4-2

3-4-3

3-4-4

3-4-5

3-4-6

3-4-7

3-4-8

ROM

RAM

Host

interface

control

........•••..•••......••••••.....••

DMAC

Counter/timer

...........................................

.

Write/read

control

..•.•.....••..•.•••....•......•.....••.

I/O

port

.....•••.•..•.••••..•....•••••..•••.••.•..•..••••

301

301

304

311

311

315

317

317

319

321

322

323

323

324

328

329

330

334

3-5

"SCSI"

Interface

control

(PCBA

Interface

Control).............

335

3-5-1

CPU.

. . . . . . . . . . . . . •• • • . . • . . . . . . • . . •• • • • . . . • . • • . . . . . • • . • • • . 336

3-5-2

3-5-3

3-5-4

3-5-5

3-5-6

3-5-7

3-5-8

ROM

RAM

Host

interface

control

......••.•...........•..............

DMA.C

•••••••••••••••••••••••••••••••••••••••••••••••••••••

Counter/timer

..........•............•....•.......•••.•••.

Write/read

control

..••......•...•.•.•..•••.•.••.....••.•.

I/O

port

................••.............••.........••.....

337

337

338

344

345

346

350

3-6

"BASIC"

Interface

control

(PCBA

Interface

Control)............

351

3-6-1

Configuration

.........••.................•.........•.....

351

3-6-2

Theory

of

operation

...•.....•..........................••

354

- i -