WELCOME DOUBLE-XT

•cR•

OWNER!

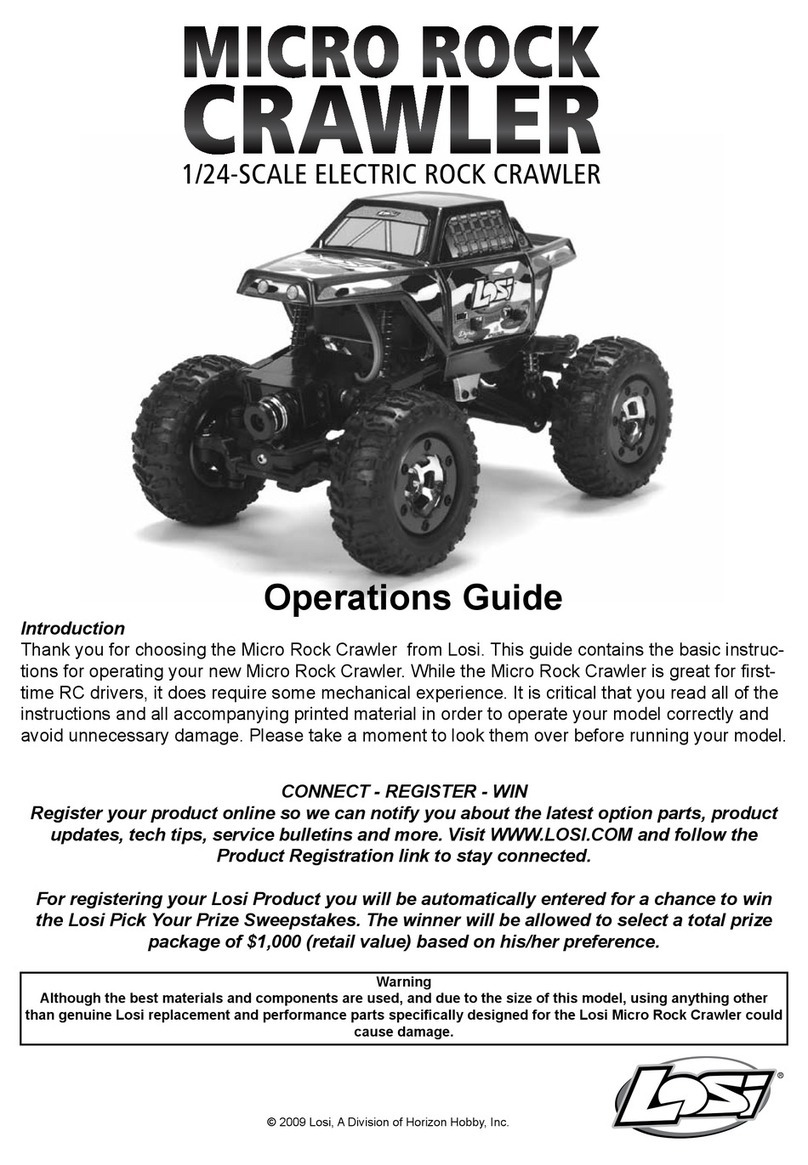

Thank

you

for

purchasing the new

Team

Losi Double-XT '

CR

'. This kit has been developed using the latest

technology and design techniques available. Oouble-X technology debuted

of

at the '93

IFMAR

World Championships,

and proceeded to dominate qualifying. Since then,

the

Oouble-X line of cars and trucks have been in a class

by

themselves.

The

'CR

' takes advantage of countless race winning laps, incomparable design and exclusive composite

materials that

have

all

combined to make

Team

Losi famous worldwide. Our goal is not only to make the chassis pe

rf

orm

better, but also easier to tune for your particular track.

Before beginning assembly

of

this kit, please take a moment to read through the entire instruction manual. This will

help minimize building time and get you on the track sooner.

You

should find our sequential assembly process to

be

quick

and

easy

to follow.

We

have included assembly tips throughout

the

manual as well as a separate tuning section to

help you

set-up

your 'CR' for optimum performance.

Good luck, and thank you

for

choosing

Team

Losi.

1. INTRODUCTION

•

DOUBLE-XT'CR' COMPLETED

KI

T DIMENSIONS

Front Width: 12.5"

Length:

15.5"

Wheel

base

:

11

.4

•

All

dimensions at ride height.

NOTES

&SYMBOLS

USED

•

Note:

this

is

a common note. It

is

used to call atten-

tion to

specific

details

of

a certain step in the assembly.

@ IMPORT

ANT

NOTE: Even

if

you are familiar with

Team

Losi

k~s.

be

sureand payattention to these notes. They

pointout

very

important details abouta certain step

in

the as-

sembly.

Do

notignore these notes!

RJ

This

flag

designates a performance tip. These tips

are not

necessary,

but can improve the performance

of

your

Double-XT '

CR'

truck.

KIT/MANUAL ORGANIZATION

The

Team

Losi

Oouble·XT

'CR'

is composed of different

bags

marked A through H. Each bag contains all

of

the

parts

necessary to complete a part

icular

section

of

the

Double·XT

'C

R' truck. Some

of

these bags have subassem-

bly

bags within

them.

It is essential that you open only one

bag

at a time and follow the correct sequence, otherwise

you

may

face

difficulties

in

finding the right part. It is helpful

to read through the instructions for an entire bag prior to

starting assembly.

Key

numbers (in parenthesis) have been

assigned to

each

part and remain the same throughout the

manual.

For

yourconvenience,

an

actual size hardware iden·

tification guide

Is

included with each step.

To

check a part,

hold it against

the

silhouette until the correct part is identi·

lied.

In

some cases extra hardware has been supplied to .

I

Rear Width: 12.6' Height: 5.5'

Weight will vary depending on accessories.

replaceeasilylostparts. Differentfits have

been

designed

into plastic parts (i.e. press, net, loose).

To

insure that parts

are not lost during construction, it

is

recommended that

you work over a towel or mat to prevent parts from rolling

away.

IMPORTANT SAFETY NOTES

1.

Select an area for assembly that is away from the

reach

of

small children.

The

parts in the kit are small and

can

be

swallo

wed

by

children, causing choking

and

possible

internal injury.

2. The shock fluid and greases supplied should be

kept out

of

children's reach. They were

not

intended for

human consumption!

3.

Exercise care when using any hand tools, sharp

instruments, and power tools

dur

ing construction.

4.

Carefully read

all

manufacturer's warnings andcau·

tions tor any glues

or

paints that may

be

used for assembly

purposes.

TOOLS REQUIRED

Team

Losi has supplied all allen wrenches and a spe-

cial wrench that is needed for assembly and adjustments.

The follow

in

g common tools will also be required: Small

flatblade screwdriver, needle nose pliers, regular pliers, scis·

sors

or

other body cutting/trimming tool. 3/16', 1/4', and 3/

8"

nut drivers are optional.