_......

Welcome

Double-XT

·cR·

Graphite

Plus

Owner

~

Thank

y

ou

for

choo

sing T

ea

m

Lo

si

an

d

the

value-packed

Do

ubl

e-X

T '

CR

'

Graph

ite

Plu

s

ki

t. As

you

probabl

y

kn

ow,

'Jearn

Los

i

has

be

en

the

pion

ee

r in

offering

feature

-

pa

ck

ed,

ra

ce-re

ad

y,

rac

e-w

inn

i

ng

RIC

car

and

t

ru

ck

kits.

Th

e

D

ouble

-XT 'CR'

Graphit

e

Plus

is

pe

rh

aps

the

bes

t

examp

le

of

this.

Titan

ium

;

carbon

fiber

/g

ra

phi

te;

precision

-

ma

c

hin

ed,

li

ghtwe

ight al

uminum;

and

space-age

coated

part

s cr

eate

a

Lru

ly

sta

te-

of

-

the

-

art

ra

ce

t

ru

ck.

Now

yo

u

can

build

a truck

like

the

ones

used

by T

ea

m L

os

i drivers

to

dominat

e

ra

cing

thr

ougho

ut

the

coun

tr

y-

winn

ing e

very

Modifi

ed Nati

ona

l

Championship

for

the

p

ast

two

years!

As always,

please

ta

ke a

mom

e

nt

to r

ead

through

the

instructions

befo

re

star

ting

the

act

ual asse

mbl

y.

Also

ch

ec

k out

•

the

tech ti

ps

for

tuning

idea

s.

Good

luck,

and

thank

you

for ch

oosi

ng

Team

Losi.

1.

INTRODUCTION

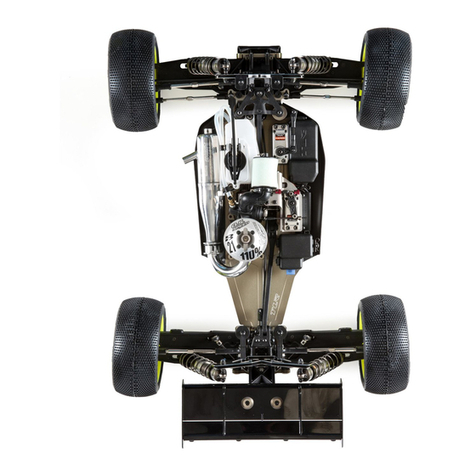

DOUBLE-XT 'CR' GRAPHITEPLUS COMPLETED KIT DIMENSIONS

Lengt

h:

15.5"

Wheelbase:

11

.4

" Front Width: 12.5" Rear Widt

h:

12.6" Heigh

t:

5.5"

All dimensions at ride height. Weight will vary depending

on

accessories.

NOTES & SYMBOLS USED

ljt.

!i!ijl

This

is

a common figure number found at the beg

in

ning

of

eac.:

h new

illu

stration throughout the manual.

0 Step I. - Each Slep throughout the entire manu

al

has a

check

box

to the le

ft

of i

i.

As

yn

u

wm

plete each step, mark the

box with a check. Ifyou need to take a break and return to build-

ing at a later time you will be

ab

le to locate the exacr step where

yo

u

left

off.

"N

OTE:Trusisa common n

ote.lt

is

used to call attention to

spec

ifi

c deta

il

s ofa certain step

in

the assemb

ly

.

&

IM

PORTANT NOTE: Even if you are familiar

wi

lh

T

ea

m Losi kits, be sure and

pa

y attention to these notes.

They

point

out

very importantdetails during the assembly process. Do

not ignore these not

es!

,......, This wrench

de

signatesa p

erf

onnance

tip. These tips

are not necess

ar

y,

but

can improve the

pe

rformance

of

your

Graphite

Plus

'CR' truck.

In

illustrations where it is important to note which

direc

ti

on parts

ar

c pointing,a helmet

li

ke this one will be incl

ud

ed

in the

illu

st

ration.

Th

e helmetw

ill

alwa

ys

face the front

of

the car.

Any reference to the right

or

left s

id

e w

ill

relate to the direc

ti

on of

the helme

L.

KIT/MANUAL ORGANIZATION

The kit is composed

of

different bags marked A through G. Each

ba

g conrains

all

of the parts necessary to complete a particular

sec

ti

on of the

Graphite

Plu

s'CR'. Some

of

these bags have s

ub

as-

sembly bags within them.

It

is

essential that you open only one

bag at a

tim

e and

follo

w the corre

ct

assembly sequence, other i

wise you may face

diffi

cu

lti

es in finding the correctpart. It is helpf

ul

to read through the instructions for an entire bag prior to b

f.'!-'111

ningasse

mb

ly.

Ke

y nu

mb

ers (

in

parenthesis) have been

a

ss

i

~

p

wd

to each partand remain the same throughout themanual. In soml

illustra

ti

on

s,

parts which havealready been installed

ar

e not

sho''

n

so that the current steps can

be

illustrated more

cl

ea

rl

y.

For your conven

ie

nce, an actual

-s

iz

e hardware

id

entifica

tion guide

is

included with each ste

p.

To check a part, hold it

against the silhouette until the correct

p:m

is identified. In som

t'

cases extra hardware has been s

up

p

li

ed

for parts that may b

l'

easy to lose.

Th

e molded parts in the

Grapltit

e

Plus

'CR' arc manufac·

lured to demanding tolerance

s.

When screws are tightened to lhe

point of being snug,

thP

p

art...,

art>

held firmly in plac

e.

For th

is

reason it

is

very

im

portant that

sc

rews not be overtightened

in

any ofthe plastic parts.

To insure that parts are not lost

dur

ing construction,

it

is

recommended that you work overa towel or marto

pr

event

pan

s

from rolling away.

IMPORTANT SAFETY NOTES

l.

Select an area for assembly thatis

awa

y from the reach

of

small children.

Th

e

pa

r

is

in

th

ekit

are

small

and

can

be

swallowed

by

clzildretz,

c

ausing

choking

and

po

ss

ib

le

inl

ema

l

injury

.

2.

The

shock fluid a

nd

greases supplied should

be

kept out

of

c

hi

ldren's reach.

Th

ey

are

not

intended

for

human

consumption.'

3.

&ercirecarewhen using

any

hand tools, sharp instrument

s,

or power tools during construction.

4.

Ca

refull

y

read

all

manufacturer's

w

arnin

gs

and

c

autions

for

any glues, chemicals, or paints that may be used for assembly and

operating purposes.