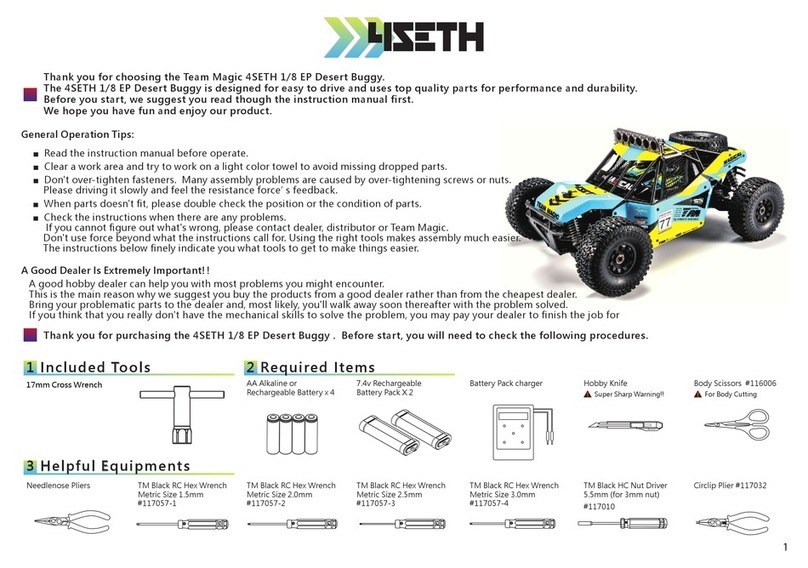

Thank you for choosing the Team Magic B8RS. Before you start building the B8RS, we suggest you read

though the instruction manual first. Be sure to check all assembly and performance tips before you

start. We hope you enjoy the fine building processes.

General Building Tips:

Read the instruction manual before building.

Clear a work area and try to work on a light color towel to avoid missing dropped parts.

Don't forge the thread lock. Be certain to use thread-lock on all the machine screws that thread into metal. Put it

on the screws that are secured with locknuts and the setscrews that secure the linkage stops, too. Don't skimp on

the thread-lock or you'll be searching in the dirt for screws that vibrated loose.

Don't over-tighten fasteners. Many assembly problems are caused by over-tightening screws or nuts. Don't use too

large a grip. Please go slowly and feel the resistance build. Just snug it up.

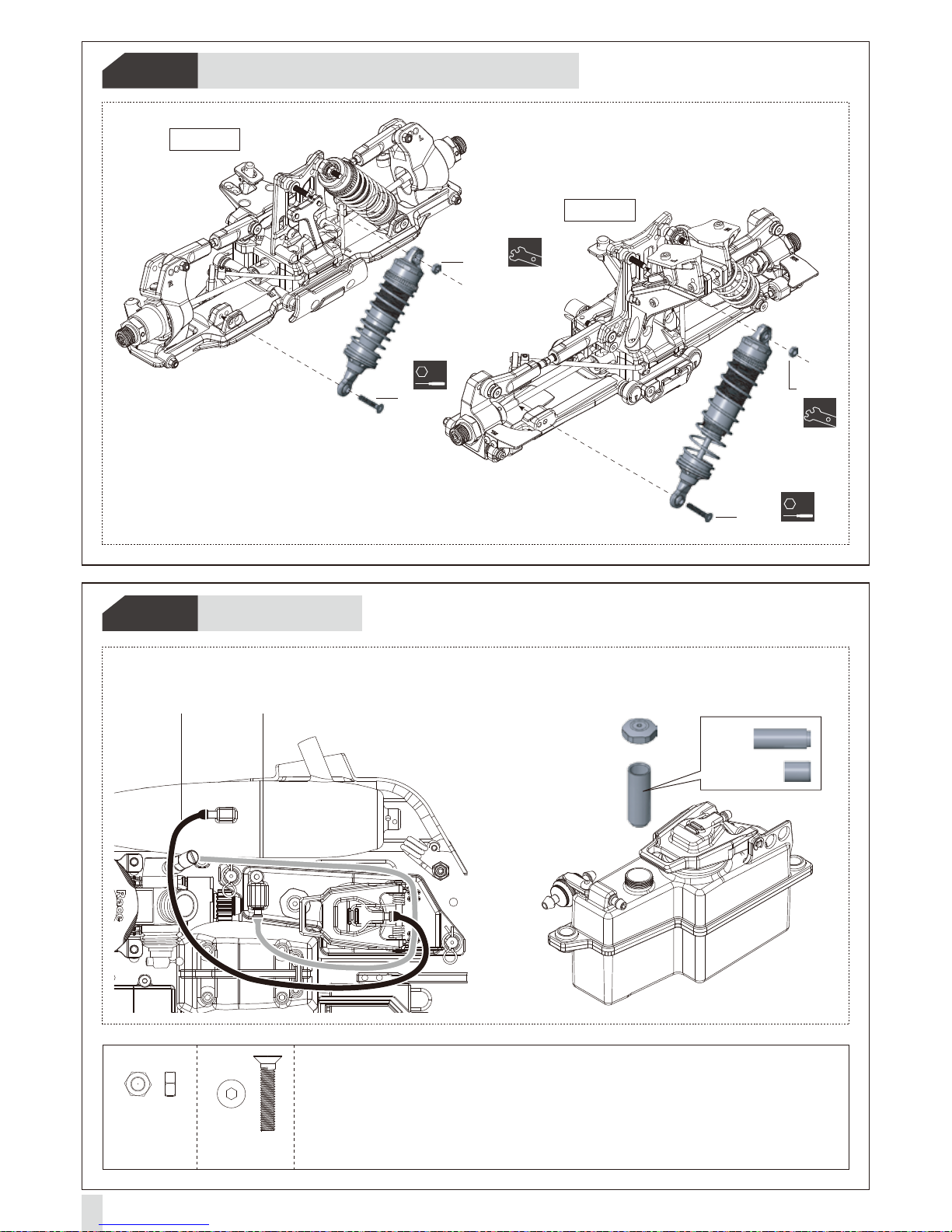

As you put more time and runs on the car, the suspension arms, and basically anything else that moves, can stretch

and wear. Though we have a very rigorous quality control program and make every effort to ensure that the parts

have the best possible fit when you get them. Unfortunately there is very little, or nothing we can do to prevent

these parts from wearing out. When the arms begin to wear you will notice that some slop develops between the

carrier or hub and the arms. This slop can be taken out by shimming the arm, hub or carrier. If you take a look at

any of the factory driver's cars you will definitely find that they use shims to take up some of the slop that occurs over

a period of time. The shims can also be used on the inside of the suspension arms in the same manner. When

shimming the parts, care must be taken not to add too many shims. The parts must still move freely without binding.

When it doesn't fit, please double check. If an assembly is not going together correctly, then either there really is a

bad fit (e.g. a part is damaged or defective) or a mistake in assembly. Always re-read the instructions when there

are any problems. If you cannot figure out what's wrong, always ask dealer, distributor or Team Magic. Don't use

force beyond what the instructions call for.

Using the right tools makes assembly much easier. The instructions below finely indicate you what tools to get to

make things easier. We don't want to scare you by saying that all these tools are required, but you will have an

easier time if you have them. Borrow them from a friend to check if necessary.

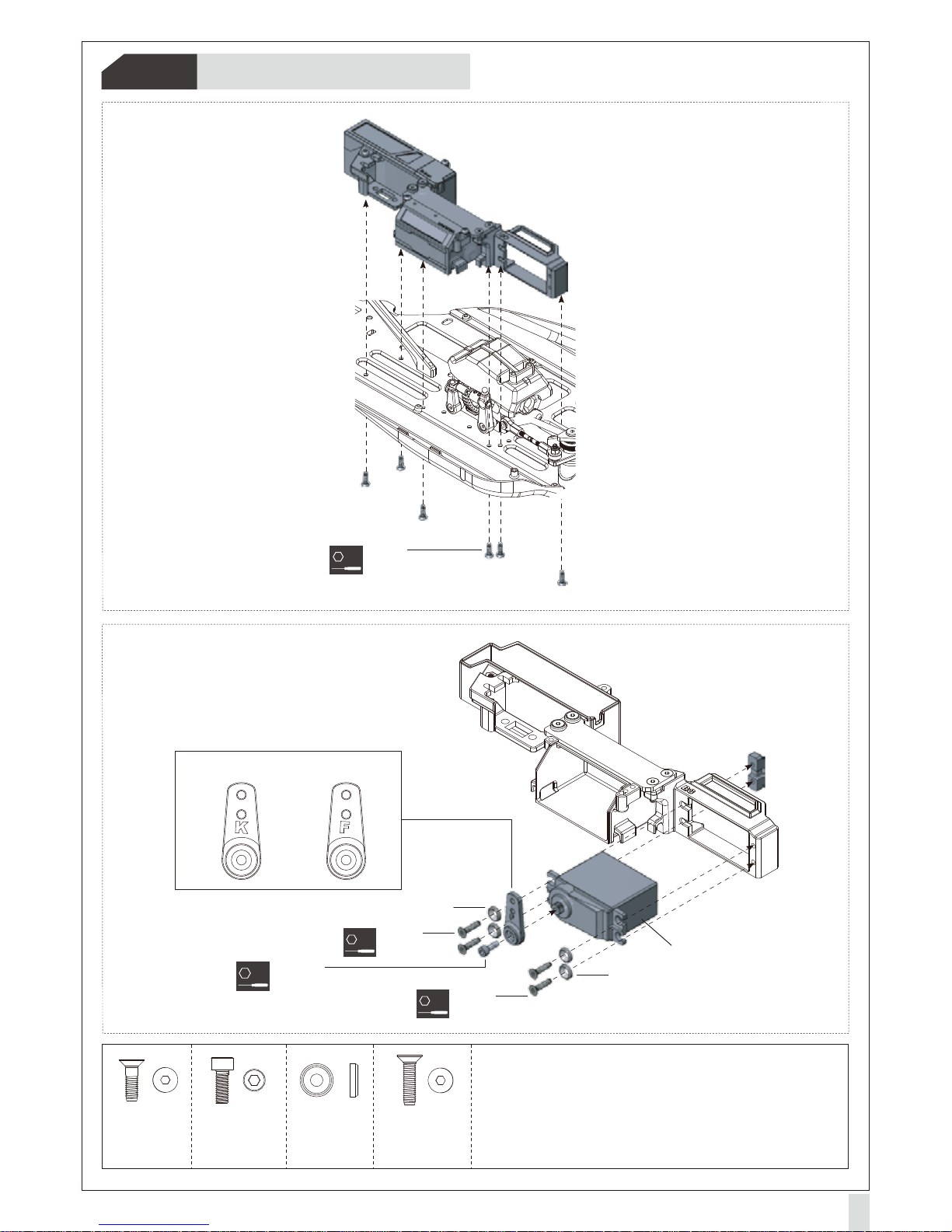

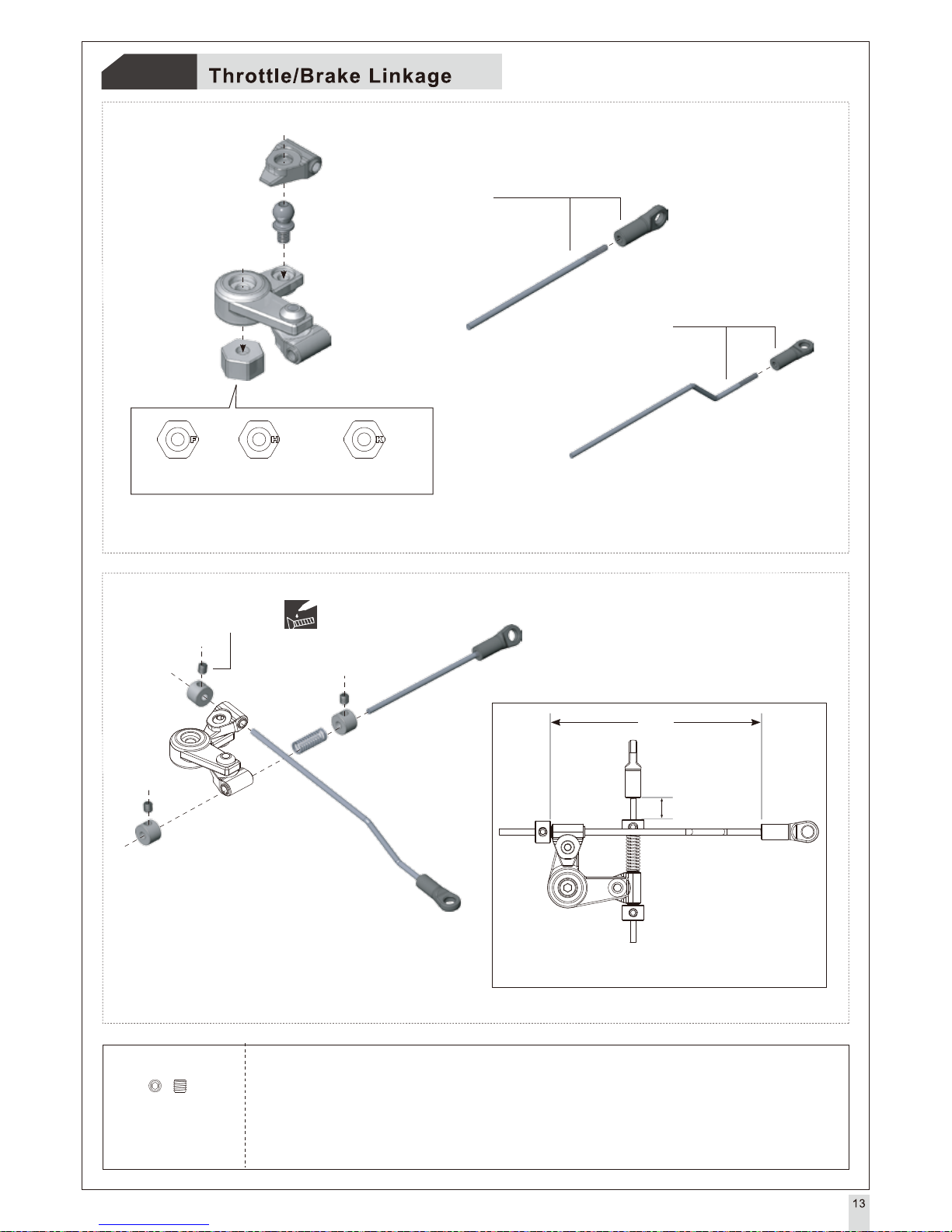

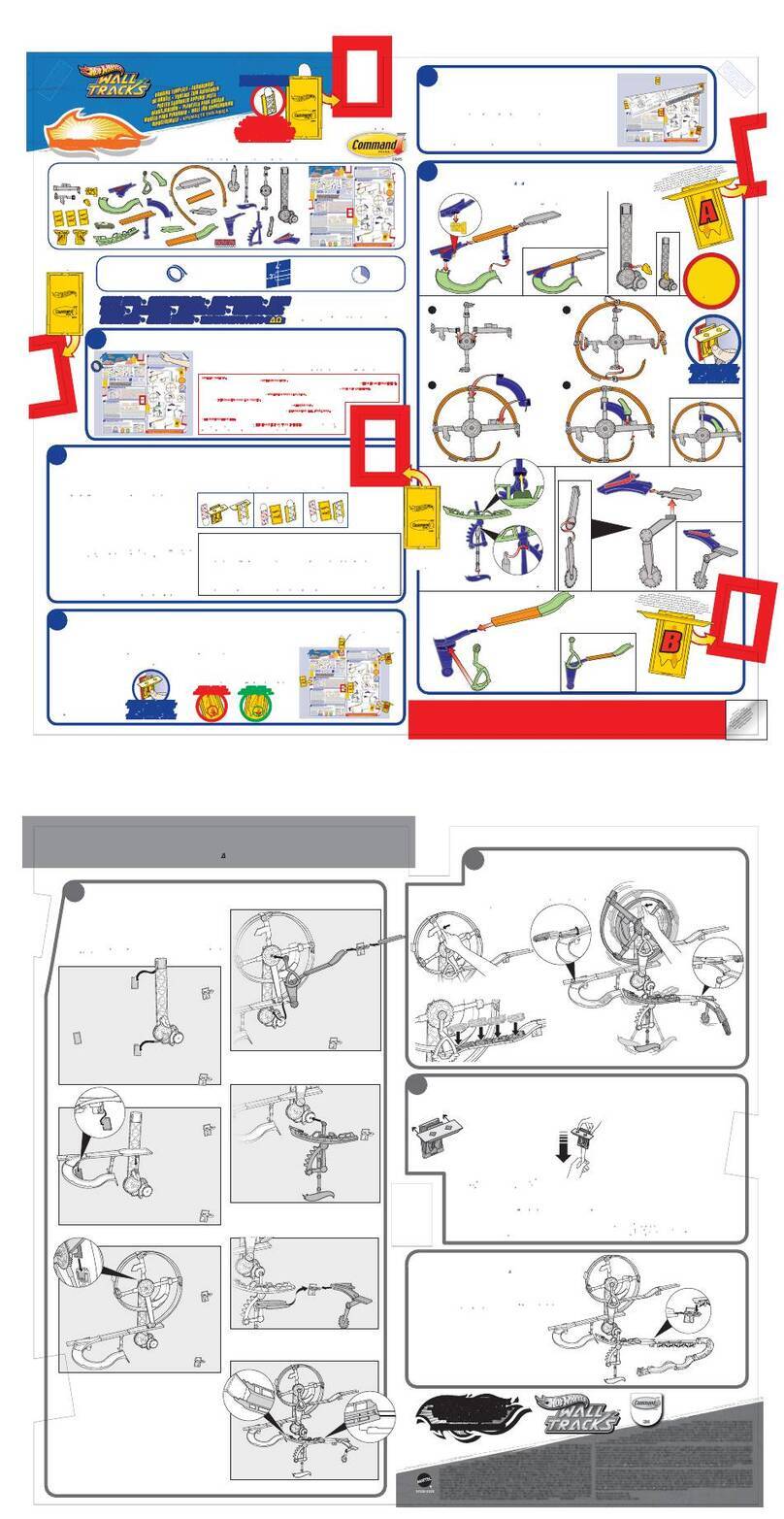

The assembly is arranged so that you will open the bag and finish that bag before you go on to the next bag.

Sometimes, you will have parts remaining at the end of a bag. These will become part of the following bags.

A Good Dealer Is Extremely Important!!

A good hobby dealer can help you with most assembly problems you might encounter. This is the main reason why

you should buy your kits from a good dealer rather than from the cheapest dealer. Bring your problematic parts to

the dealer and, most likely, you'll walk away soon thereafter with the problem solved. If you think that you really

don't have the mechanical skills to complete the assembly, you may pay your dealer to finish the job for you. We

can recommend good dealers to you if you need. Please send us mails for more information. Email:

DIGITALPROPORTIONAL

RADIO CONTROL SYSTEM

BATTERYLEVEL

STEERING D/R

ST.EPA-TH.EPA

SERVO REV.SW

LOW FULL

2 Channel Radio Set

(Read the instruction manual provided

with your radio system before using it)

Plug

THE POWER OF TEAM MAGICTHE POWER OF TEAM MAGIC

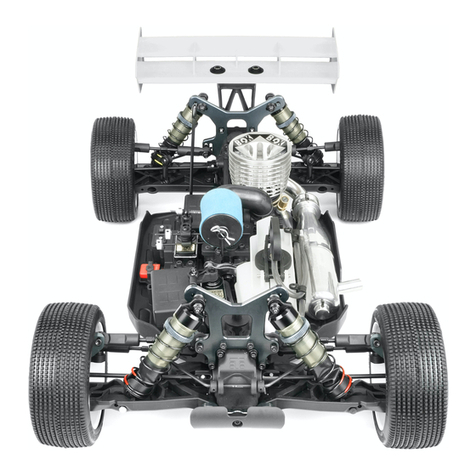

1Additional Items Needed For Operation

21 Class Off-road Engine Receiver Battery Pack

(Make sure the size is within

L86xW30xH23mm). We recommend

6v-800mah Ni-MH Lightweight

Rectangle Receiver Pack (AAA size)

#114045

IB 6v-1400mah Ni-MH Receiver

Pack (Turbo 35 approved)

#114052

Pipe Set

Tires

Body Paint

800

2