tecan Columbus Washer User manual

Technical Manual for

Columbus Washer

Document Part No.: 30000294

2006-02

Document Revision No.: 1.7

Firmware Level: 4.xx

2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

TECAN Affiliates and Service Centers

Austria

Tecan Austria GmbH

Untersbergstrasse 1a

A-5082 Grödig/Salzburg

Austria

T +43 6246 8933 256

F +43 6246 72 770

Austria

Tecan Sales International GmbH

Untersbergstrasse 1a

A-5082 Grödig/Salzburg

Austria

Tel.: +43 6246 8933

Fax: +43 6246 72 770

Asia

Tecan Asia Pte Ltd.

80 Marine Parade

#10-09 Parkway Parade

Singapore 449269

Singapore

T +65 6444 1886

F +65 6444 1836

tecan@tecan.com.sg

Belgium

Tecan Benelux bvba

Vaartdijk 55

B-2800 Mechelen

Belgium

T +32 15 42 13 19

F +32 15 42 16 12

tecan-be@tecan.com

China

Tecan Group Ltd, Beijing

Representative Office

Room 2502, Building A

Jianwai SOHO

No. 39 Dongsanhuan Zhong Rd.

100022 Beijing

China

T +86 10 5869 5936

F +86 10 5869 5935

France

Tecan France SAS

26 avenue Tony Garnier

F-69007 Lyon

France

T +33 820 88 77 36

F +33 472 76 04 99

Germany

Tecan Deutschland GmbH

Theodor-Storm-Strasse 17

D-74564 Crailsheim

Germany

T +49 1805 8322 633 or

T +49 1805 TECANDE

F +49 7951 9417 92

Italy

Tecan Italia S.r.l.

Via F.lli Cervi

Palazzo Bernini

Centro Direzionale Milano 2

I-20090 Segrate (Mi)

Italy

T +39 02 215 21 28

F +39 02 215 97 441

Japan

Tecan Japan Co., Ltd.

Kawasaki Tech Center

580-16, Horikawa-cho,

Saiwai-ku

Kawasaki, Kanagawa 212-0013

Japan

T +81 44 556 7311 (Kawasaki)

F +81 44 556 7312 (Kawasaki)

T +81 66 305 8511 (Osaka)

Netherlands

Tecan Benelux bvba

Industrieweg 30

NL-4283 GZ Giessen

Netherlands

T +31 183 44 81 74

F +31 183 44 80 67

tecan-nl@tecan.com

Scandinavia

Tecan Nordic AB

Taljegårdsgatan 1

SE-431 53 Mölndal

Sweden

T +46 317 54 40 00

F +46 317 54 40 10

Spain (Barcelona)

Tecan Ibérica

Sabino de Arana 32

E-08028 Barcelona

Spain

T +34 93 490 0174

T +34 93 409 1237 (Helpdesk)

F +34 93 411 2407

helpdesk-sp@tecan.com

Spain (Madrid)

Tecan Ibérica

Gobelas 17 bjo. Izq. Urb. La Florida

E-28023 Madrid

Spain

T +34 91 151 7107

T +34 93 409 1237 (Helpdesk)

F +34 91 151 7120

helpdesk-sp@tecan.com

Portugal

Tecan Ibérica

Quinta da Fonte Edificio Pedro I

P-2780-730 Paço D'Arcos

Portugal

T +35 21 000 8216

Switzerland

Tecan Schweiz AG

Seestrasse 103

CH-8708 Männedorf

Switzerland

T +41 44 922 82 82

F +41 44 922 84 84

helpdesk-ch@tecan.com

United Kingdom

Tecan UK

Theale Court

11-13 High Street

Theale

UK-Reading RG7 5AH

United Kingdom

T +44 118 930 0300

F +44 118 930 5671

USA

Tecan US

4022 Stirrup Creek Road

Suite 310

Durham, NC 27703

USA

T +1 919 361 5200

F +1 919 361 5201

Toll Free US:

T +1 800 TECAN US or

T +1 800 832 2687

USA

Tecan Systems Inc.

2450 Zanker Road

San Jose, CA 95131

USA

T +1 408 953 3100

F +1 408 953 3101

Toll Free US/Canada:

T +1 866 798 3226

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS

PROVIDED IN THIS MANUAL BEFORE OPERATING THE

INSTRUMENT.

Notice

Every effort has been made to avoid errors in text and diagrams, however, Tecan

Austria GmbH assumes no responsibility for any errors which may appear in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefore reserves

the right to change specifications at any time.

We would appreciate any comments on this publication.

Tecan Austria GmbH

Untersbergstraße 1A

A-5082 Grödig/Salzburg

AUSTRIA / EUROPE

Telephone: 0043 (0)6246/8933

FAX: 0043 (0) 6246/72770

www.tecan.com

Copyright Information

The contents of this manual are the property of Tecan Austria GmbH and are not

to be copied, reproduced or transferred to another person or persons without our

prior written permission.

Copyright ©Tecan Austria GmbH

All rights reserved.

Printed in Austria.

Declaration for EU Certificate

See the back of this manual.

About this Manual

This technical manual describes the servicing of the Columbus Washer, designed

to wash microplates. It is intended only for service personnel.

This manual instructs how to:

•Install the instrument

•Operate the instrument

•Programming the wash procedure

•Definition on the wash parameters

•Cleaning and maintenance procedures

4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Warnings, Cautions and Notes

There are three types of informational notices used in this manual. These notices

highlight important information or warn the user of a potentially dangerous

situation. The following notices are:

Note

Gives helpful information.

Caution

Indicates a possibility of instrument damage or data loss if instructions are

not followed.

WARNING

INDICATES THE POSSIBILITY OF SEVERE PERSONAL INJURY, LOSS OF

LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS ARE NOT

FOLLOWED.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 5

Table of Contents

1. General

1.1 Overview......................................................................................... 1-1

1.2 Instrument Description ................................................................. 1-2

1.2.1 Rear Panel Connections.................................................................. 1-2

1.2.2 Connection Diagram for Columbus (1 Liquid Channel)*.................. 1-4

1.2.3 Connection Diagram for Columbus (4 Liquid Channels)*................ 1-5

1.2.4 Keyboard and Display Unit.............................................................. 1-6

1.3 Interconnection Diagram .............................................................. 1-7

2. Installation Procedure

2.1 Unpacking and Inspection............................................................ 2-1

2.2 Unpacking Procedure ................................................................... 2-2

2.3 Power Requirements..................................................................... 2-2

2.4 Installation Procedure................................................................... 2-3

2.4.1 Installing the Instrument ..................................................................2-3

2.4.2 Connecting the Waste Tubing......................................................... 2-3

2.4.3 Connecting the Solution Tubes ....................................................... 2-4

2.4.4 Fitting and Connecting the Liquid Sensors (Optional)..................... 2-5

2.4.5 Connecting the Barcode Reader (Optional)..................................... 2-6

2.4.6 Connecting the Printer (Optional).................................................... 2-6

2.4.7 Power Connections ......................................................................... 2-6

3. Firmware and Software Description

3.1 Instrument Software Features...................................................... 3-1

3.2 Onboard Software Menus............................................................. 3-2

3.2.1 Run.................................................................................................. 3-2

3.2.2 Prime ............................................................................................... 3-2

3.2.3 Rinse ............................................................................................... 3-3

3.2.4 Program........................................................................................... 3-6

3.2.5 Clear................................................................................................ 3-6

3.2.6 Show................................................................................................ 3-6

3.2.7 Adjust............................................................................................... 3-7

3.2.8 Service Menu................................................................................. 3-24

3.3 External Software ........................................................................ 3-61

3.3.1 Columbus Computer Software ...................................................... 3-61

3.3.2 Firmware Update........................................................................... 3-61

3.4 Serial Interface............................................................................. 3-62

3.4.1 Hardware Specifications................................................................ 3-62

3.4.2 Contents ........................................................................................ 3-65

3.4.3 A. Protocol..................................................................................... 3-67

3.4.4 Sequence Number......................................................................... 3-68

3.4.5 B. Commands - Overview.............................................................. 3-69

3.4.6 Commands - Description............................................................... 3-71

6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

3.4.7 D. Examples for Remote Control - Command Sequences.............3-88

3.5 Description of Error Messages...................................................3-95

4. Removing and Replacing the Instruments Cover

4.1 Removal of Instruments Top Cover..............................................4-1

4.2 Replacing the Instruments Top Cover .........................................4-3

5. Liquid System

5.1 Introduction ....................................................................................5-1

5.1.1 Liquid System Diagram....................................................................5-2

5.1.2 Dispensing System Description........................................................5-3

5.2 Replacement Procedure................................................................5-4

5.2.1 Replacing the Dispensing Pump......................................................5-4

5.2.2 Replacing the Solution Solenoid Valves (Instruments with Pinch

Valves) .............................................................................................5-6

5.2.3 Replacing the Solution Solenoid Valves...........................................5-7

5.2.4 Replacing the Dispense Solenoid Valve ..........................................5-8

5.2.5 Replacing the Aspirating Pump........................................................5-9

5.2.6 Replacing the Aerosol Pump..........................................................5-10

6. Mechanical System

6.1 Manifold Arm Movement System..................................................6-1

6.1.1 Description of Manifold Arm Movement Parts..................................6-2

6.1.2 Adjusting the Manifold......................................................................6-2

6.2 Plate Transport System.................................................................6-3

6.2.1 Plate Support ...................................................................................6-4

6.2.2 Leveling the Plate Support...............................................................6-5

6.2.3 Microplate Positioning System.........................................................6-7

6.3 Replacement Procedure................................................................6-8

6.3.1 Replacing the Manifold Arm Error Sensor........................................6-8

6.3.2 Replacing the Motor.........................................................................6-9

6.3.3 Replacing the Top Position Optical Switch.....................................6-10

6.3.4 Replacing the Plate Support Home Position Optical Switch ..........6-11

7. Electronic System

7.1 Introduction ....................................................................................7-1

7.2 Interconnection Diagram...............................................................7-2

7.3 Main Board......................................................................................7-3

7.3.1 Replacing the Main Board................................................................7-4

7.3.2 Replacing the Battery.......................................................................7-5

7.4 Power Supply Board ......................................................................7-6

7.4.1 Replacing the Power Supply Board..................................................7-7

7.5 Keyboard and Display Unit............................................................7-8

7.5.1 Replacing the Keyboard or Display Unit...........................................7-9

7.6 Manifold Detect Board.................................................................7-11

7.6.1 Replacing the Manifold Detect Board.............................................7-11

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 7

7.7 Fill Verification Board ................................................................. 7-13

7.7.1 Replacing the Fill Verification Board.............................................. 7-13

7.8 Optical Switches.......................................................................... 7-15

8. Serial Interface

8.1 Hardware Specifications............................................................... 8-1

8.1.1 Pin Designation ............................................................................... 8-1

8.1.2 RS-232-C Interface Lines................................................................ 8-2

8.1.3 Synchronization and Data Format................................................... 8-3

8.1.4 Daisy Chaining Instruments............................................................. 8-3

9. Description of Options

9.1 Instrument Options ....................................................................... 9-1

9.2 Liquid Detection Option................................................................ 9-3

9.3 Barcode Reader Option ................................................................ 9-4

9.4 Printer Option ................................................................................ 9-5

9.5 Manifold Detection Option............................................................ 9-6

9.6 Fill Verification Option .................................................................. 9-8

9.7 Aerosol Pump Option.................................................................... 9-8

9.8 Activating the Options .................................................................. 9-8

10. Maintenance

10.1 Cleaning Maintenance................................................................. 10-1

10.1.1 Cleaning the Manifold.................................................................... 10-1

10.1.2 Exchanging the Manifold ............................................................... 10-3

10.1.3 Exchanging the Plate Support....................................................... 10-5

10.1.4 Instrument Disinfection.................................................................. 10-6

10.2 Preventive Maintenance Plan..................................................... 10-8

10.2.1 Daily............................................................................................... 10-8

10.2.2 Weekly........................................................................................... 10-8

10.2.3 Every Six Months........................................................................... 10-8

10.2.4 Yearly (Service Technician Required)........................................... 10-8

10.3 Service Tools ............................................................................... 10-9

10.3.1 Adjustment Plate (Reference Plate).............................................. 10-9

10.4 Electrostatic Discharge Information........................................ 10-10

10.4.1 Generating Static......................................................................... 10-10

10.4.2 Preventing Electrostatic Damage to Equipment.......................... 10-11

10.4.3 Personal Grounding Methods...................................................... 10-11

11. Trouble Shooting

11.1 Introduction.................................................................................. 11-1

12. Instrument Specifications

12.1 Introduction.................................................................................. 12-1

Index

1. General

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-1

1. General

1.1 Overview

This is a technical manual for servicing the Columbus Washer.

The instrument is a microprocessor controlled washer, designed to wash

microplates.

The instrument can be fitted with either an 8, 12 or 16 way manifold or a 384 Well

Manifold.

The manifolds are fitted with one aspirating and one dispensing needle per well.

The instrument can store up to nine software user-defined plate types including

dispensing and aspirating positions as well as the shape of the plate.

The dispensing speed can be selected from five set speeds and dropwise.

These features allow the instrument to be used for all washing applications

including Cell Washing applications.

The instrument should only be opened by authorized personnel. Before the

instrument is opened the mains power cable must be disconnected from

the mains power socket.

Ensure that the instrument has been disinfected before it is serviced.

1. General

1-2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

1.2 Instrument Description

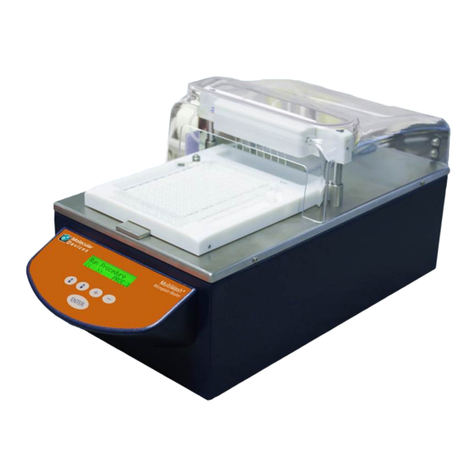

The diagram below shows the main components of the instrument:

Keyboard and

Display Unit

Manifold Arm

Manifold

Waste Sink

Plate Support

Guide Bar

POWER

Power ON LED

1.2.1 Rear Panel Connections

The instrument has the following connections on the back panel.

ON/OFF

Switch

Fuse

Compartment

Mains Power

Socket

Printer Connecto

r

or

Serial RS 232 fo

r

Remote Control

Hand held

Barcode

Reader

Bottle Holder with

Liquid Sensor for

each bottle

Waste

Tubing

(

red

)

A

erosol

Tubing

(

option

)

Inlets for channels 1 - 4

1. General

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-3

(Instrument with Pinch Valves)

ON/OFF

Switch

Fuse

C

ompartment

Mains Power

Socket

Printer Connector

or

Serial RS 232 for

Remote Control

Hand held

Barcode

Reader

Bottle Holder with

Liquid Sensor for

each bottle

Waste

Tubing

(red)

A

erosol

Tubing

(yellow)

Channel 1

Inlet Channel 2

Inlet Channel 3

Inlet Channel 4

Inlet

Prime

valve

All connected devices must be proved and listed with regulations

EN 60950, UL 1950 or CSA C22.2 No. 950 for Data Processing Devices

1. General

1-4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

1.2.2 Connection Diagram for Columbus (1 Liquid Channel)*

Printer

(

o

p

tion

)

Hand held

Barcode

Reader (option)

or

Com

p

uter for

Remote Control

Marked

red

Prime

valve

Bottle Holder with li

q

uid

sensor for each bottle

grey red

g

reen Waste

Bottle

Wash

Li

q

uid

Inlet

filter

Rinse

solution

Marked

g

reen

*Some of the instruments may include the prime valve.

1. General

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-5

1.2.3 Connection Diagram for Columbus (4 Liquid Channels)*

Printer (option)

Hand held Barcode

Reader (option)

or

Computer for

Remote Control

Wash

Liquid 2

Foam

Bottle

Marked

yellow

Marked

red

Water

Seperator

Aerosol

Filter

None Return

Valve

Marked

blue

Inlet

filter

Wash

Liquid 3

Rinse

solution

Waste

Bottle

Wash

Liquid 1

Inlet

filter

Bottle Holders with liquid

sensor for each bottle

grey red

green

purple

yellow

blue

Marked

purple

Marked

blue

Marked green

Marked grey

*Some of the instruments may include the prime valve.

1. General

1-6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

1.2.4 Keyboard and Display Unit

The Washer is operated via a keyboard and a control panel consisting of a two

row, sixteen digit Liquid Crystal Display (LCD) unit.

The top row of the display unit is used for messages and the bottom row for the

key functions or options.

A Light Emitting Diode (LED) in the center of the letter "O" of the word "POWER"

indicates when the Washer is switched ON.

Key 1 Key 2

Key 3

Key 4

Powe

r

ON LED

POWER

1. General

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-7

1.3 Interconnection Diagram

The diagram below shows how the various parts of the instrument are

interconnected.

Solenoid 4

Solenoid 3

Solenoid 2

Solenoid 1

Dispense

Solenoid

A

spirating Pump

Dispensing Pump

Plate Home Position

Optical Switch

Manifold Typeand

Plate MismatchBoard

Mains Input

ON/OFF Switch

Fuses

Printer / Serial

Connector

Power Supply Board

Manifold Arm

Motor

A

erosol Pump

Home Position

Optical Switch

Fill Verify and

Plate Mismatch

Board

CPU

EEPROM

Keyboard /

Display Unit

Orbital Shaking

Motor *

Plate Transport

Motor

Liquid

Detection

System

Barcode Reader

Prime Valve

*The Orbital Shaking option is not used.

2. Installation Procedure

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2-1

2. Installation Procedure

2.1 Unpacking and Inspection

The instrument is shipped in one carton, which contains:

•Instrument

•Accessory package which contains:

Spare manifold cover with two screws and Allen key

Operating manual

Mains power cable

Cleaning needles

2 spare fuses

Solution tube

3 spare 0 – ring seals for manifold

•Bottle set containing:

3 x 2.5 l bottles for the standard instrument

Li

q

uid Sensor S

y

stem

(

o

p

tional

)

Bottles

A

ccessor

y

p

acka

g

e

and o

p

eratin

g

manual

Instrument

2. Installation Procedure

2-2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

2.2 Unpacking Procedure

1. Visually inspect the container for damage before it is opened.

Report any damage immediately.

2. To place the instrument, select a location that is flat, level, vibration free,

away from direct sunlight, and free from dust, solvents and acid vapors.

Allow 10 cm distance between the back of the instrument and the wall or any

other equipment.

3. Place the carton in an upright position and open it.

4. Lift the instrument out of the carton and place it in the selected location.

5. Visually inspect the instrument for loose, bent or broken parts.

Report any damage immediately.

6. Compare the serial number on the rear panel of the instrument with the

serial number on the packing slip.

Report any discrepancy immediately.

7. Check the instrument accessories against the packing list.

8. Save packing materials for future use.

2.3 Power Requirements

The instrument is designed to operate at either 100 - 120 volt or 220 - 240 volt.

No voltage setting is required as the washer automatically senses the supplied

voltage.

The washer requires 2 x T 1.6 A / 250 V (slow blow) fuses.

WARNING

TO PREVENT THE RISK OF FIRE, THE MAINS FUSES SHOULD ONLY BE

REPLACED WITH THE SAME TYPE AND RATING OF FUSE.

2. Installation Procedure

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2-3

2.4 Installation Procedure

Before the instrument is installed and switched on, it should be left to stand

for at least three hours, so there is no possibility of condensation causing a

short circuit.

2.4.1 Installing the Instrument

•Unpack the instrument and check the contents.

See 2.2 Unpacking Procedure.

•Connect the solution tubes to the inlet connectors.

See 2.4.3 Connecting the Solution Tubes.

•Setup possible instrument options. See page 2 – 5 and 2 – 6.

•Connect instrument to the power supply. See 2.4.7 Power Connections.

•Define the plate parameters in the Adjust menu. See chapter 3.

•Program the wash procedure. See chapter 3.

2.4.2 Connecting the Waste Tubing

Turn the instrument onto the right hand side.

Slide the waste tube through the hole in the back panel.

Waste Tube Hole

A

erosol Tube Hole

(optional)

Connect the waste tube onto the top connector of the aspirating pump.

2. Installation Procedure

2-4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Standard Instrument

Solution Tubes to Manifold

A

spirating Tube to

WasteBottle

WasteTube Aspirating Pump

Dispensing

Pump

Turn the instrument back to the normal position.

Place the other end of the waste tubing into the waste bottle.

Connect the aerosol tube onto the aerosol pump if this option is fitted. This is not

necessary for the standard instrument.

Instrument with Aerosol Protection Option

A

erosol Bottle

A

erosol

Pump

Waste Bottle

Solution Tubes to Manifold

Aspirating Tube to Manifold

Waste Tube

A

spiratin

g

Pump

Aerosol Tube to Manifold

Dispensing Pump

Turn the instrument back to the normal position.

Place the other end of the aerosol tubing into the aerosol bottle.

2.4.3 Connecting the Solution Tubes

The solution tubes are connected onto the inlet connectors on the back panel of

the instrument. The instrument is supplied with four meters of tubing that can be

cut to the required length (maximum 1 meter).

Inlets for channels 1 - 4

Waste Tube

red

A

erosol Tube*

(optional)

Other manuals for Columbus Washer

1

Table of contents

Other tecan Laboratory Equipment manuals

tecan

tecan Columbus Washer User manual

tecan

tecan sunrise RC User manual

tecan

tecan MagicPrep NGS User manual

tecan

tecan sunrise User manual

tecan

tecan GENios User manual

tecan

tecan NanoQuant Plate User manual

tecan

tecan Infinite 200 PRO User manual

tecan

tecan HYDROFLEX PLUS User manual

tecan

tecan Te-Stack 10612253 User manual

tecan

tecan infinite 200 User manual