TECH ST-480 User manual

ST – 480

Declaration of Conformity No. 60/2010

Hereby, we declare under sole responsibility that the ST-480

230V 50Hz thermoregulator manufactured by TE H,

headquartered in Wieprz 1047A, 34-122 Wieprz, is compliant

with the Regulation by the Ministry of Economy. (Journal of Laws

Dz.U. 155 Item 1089) of July 21, 2007 implementing provisions

of the Low Voltage Directive (LVD) 2006/ 5/EC of January 16,

2007.

The ST-480 controller has been tested for electromagnetic

compatibility (EM ) with optimal loads applied.

For compliance assessment, harmonized standards were

used:

PN-EN 60730-2- :2006.

- 2 -

ST – 480

ATTENTION!

High voltage!

Make sure the regulator is disconnected from

the mains before working on the power

supply (cable connections, device installation,

etc.)!

All connection works must only be carried out

by qualified electricians.

Before activating the controller, measure the

motor resetting efficiency and inspect wire

insulation.

- 3 -

ST – 480

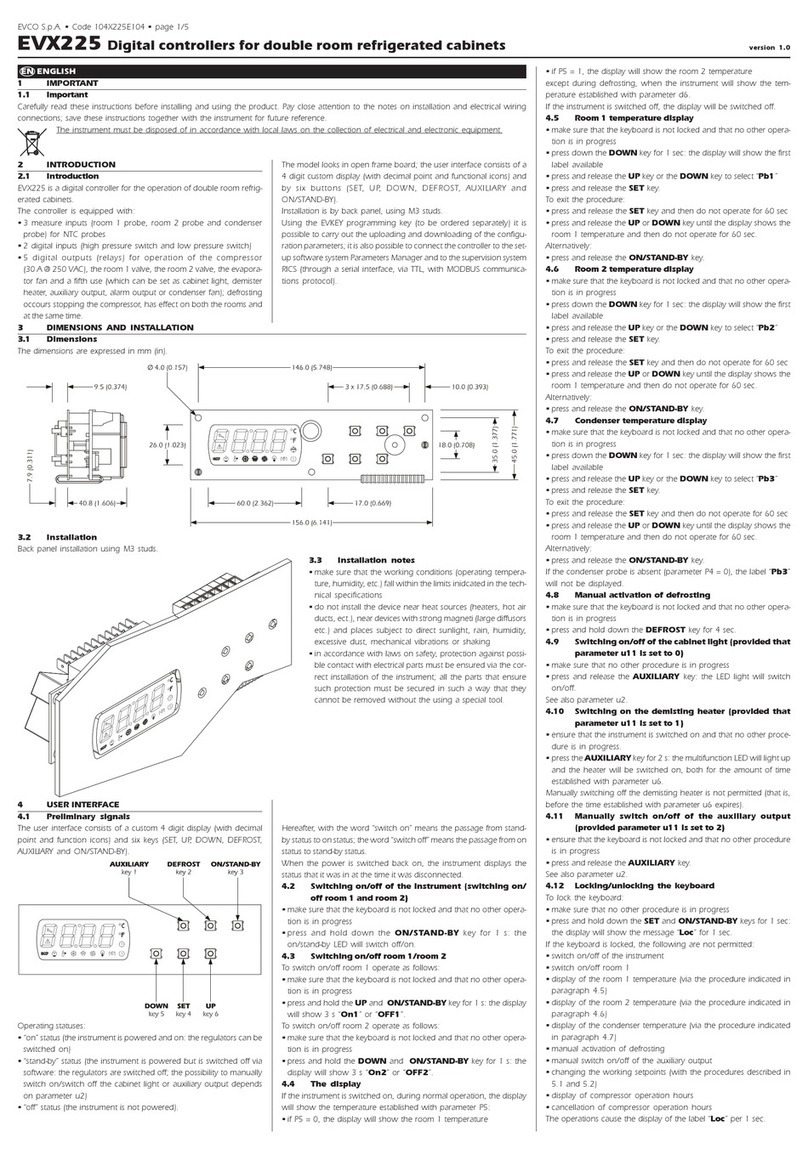

I. Description

ST–480 temperature controller is intended for use with central

heating boilers equipped with feeding screw. It controls water circulation

pump, domestic hot water pump, floor heating pump, circulation pump,

blower (fan) and fuel feeder. It incorporates a valve control module and

can operate with two mixing valves (via additional ST-61 modules),

conventional (two-state) room controller or RS-port communication, GSM

module or Ethernet module.

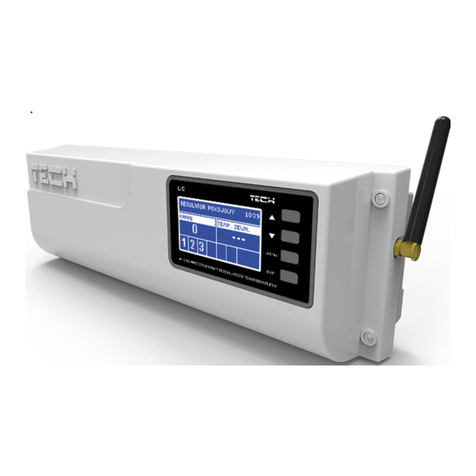

The advantage of the controller is the ease of use. The user can

change all parameters using the pulser knob. Another advantage is the

large and easy-to-read display where the current boiler operation

parameters are shown.

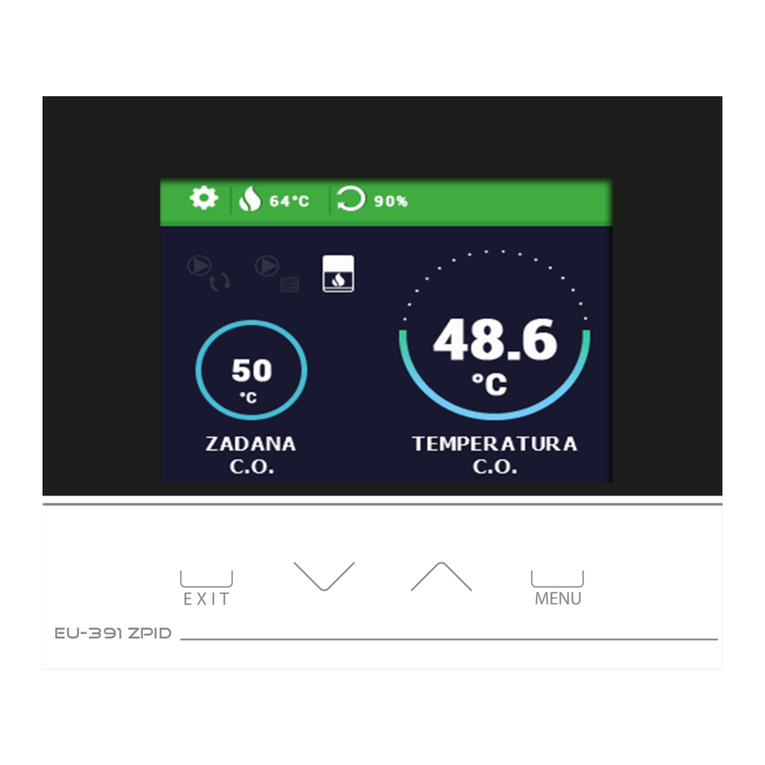

Exemplary view of the main screen:

Any remarks regarding the programme should be reported to the

boiler manufacturer. Each driver should be adjusted according to

individual needs depending on the fuel type used and the boiler type.

TE H shall not be held liable for wrong adjustment of the controller.

I.1. Basic terms

Operation– once activated the controllers enters the operation mode

and a "WORKING" message appears on the display. It is the basic state

of the controller where the blower is operating continuously and the

feeder operation time is set by the user (both operation time and pause

time can be set).

Sustain mode– the mode is entered automatically if the temperature is

higher than or equal to the preset temperature. In such a case the

controller feeds the fuel slowly to reduce the temperature smoothly and a

- 5 -

ST – 480

"SUSTAIN" message appears on the display. Both pause time and

operation time in sustain mode have to be configured for the temperature

to be reduced properly.

II. Functions of the controller

This chapter describes the controller functions, methods of changing

the settings and use of the menu with the pulser (knob). The main

controller screen displays boiler operating parameters. Operation mode

and a number of other settings can be selected by the user according to

the individual needs.

I.2. Main page

Main page is displayed on the graphic display during normal

operation of the controller. Other main screens are displayed according

the operation mode.

Once the pulser knob is pressed the first level menu appears. The

display shows three initial menu options. Further options are available

after turning the knob. An option can be selected by pressing the knob.

Similar procedure is followed when changing the parameters. In order for

the changes to be input they need to be confirmed by pressing the pulser

after the "CONFIRM" message appears. If the user does not intend to

make any changes in a function the pulser should be pressed after the

"CANCEL" message is displayed. Select "EXIT" in the menu or use EXIT

button to exit the menu.

Stand-by mode button located on the controller housing allows

disabling all operating units quickly, if necessary. It serves as an

additional emergency protection to cut-off power supply to all operating

units of the controller (feeder, fan, pumps).

ATTENTION: Power supply to the controller is not cut-off in the stand-by

mode.

I.3. Screen view

The user can select one of three main screens of the temperature

controller operation using that function. They include:

➔central heating screen (displays current boiler operation mode)

valve (displays working parameters of the valve)

➔valve 1 (displays working parameters of the first valve).

- 6 -

ST – 480

➔valve 2 (displays working parameters of the second valve).

NOTE The valve parameter views are available only if the valves have

been properly preinstalled and configured by a technician.

II.1.Preset temperature of the central heating system

The option is used to set the boiler temperature. The user can

change the boiler temperature within the range of 45O to 80O. The

preset central heating system temperature can also be changed directly

in the main screen of the controller by turning the pulser knob.

Additionally, the preset central heating system temperature can be

adjusted using the room temperature reduction function (see Item II.15)

and the weekly control function (see Item II.6). The preset temperature

is a sum of all those values but it may not exceed the range of 45O to

80O.

II.2. Preset temperature of hot domestic water

The option is used to set the temperature of hot domestic water.

The temperature is adjustable within the range between 40° and 75° .

II.3. Manual operation

For your convenience the controller is equipped with a Manual operation

module. When this function is active each actuator (blowing, central heating

pump, hot water pump, additional circulating or valve pump) can be switched

on or off independently and each active mixing valve can be closed, opened or

stopped.

- 7 -

ST – 480

You can start the motor of your selected device by pressing the pulser.

The device will remain activated until the pulser is pressed again.

Additionally, an option to control the blowing power is available where you

can set any fan speed in manual mode.

II.4. Weekly control

The function is used to programme daily changes in the boiler

temperature. The preset temperature deviations are within the range of

+/-100 .

Step #1:

The user needs to set current time and date first (Installer menu >

lock).

Step #2:

The user sets temperature values for individual days of the week (Set

mode 1):

Monday– Sunday

Select specific hours and required deviations from the preset temperature

(how many degrees the temperature should rise or drop) for each day of

the week. Additionally, the preset values can be copied to facilitate the

operation.

Example

Monday

preset: 3 00 , temp. -10° (temperature change– 10° )

preset: 4 00 , temp. -10° (temperature change – 10° )

preset: 5 00 , temp. -10° (temperature change – 10° )

In such a case, if the temperature preset on the boiler is 60º , it will

drop 10º to 50º between 3 a.m. and 6 a.m. on Monday.

- 8 -

ST – 480

As an alternative to the temperatures being preset separately for

individual days, the temperatures can also be set collectively, in the

second mode, for the working days (from Monday to Friday) and the

weekend (Saturday and Sunday) separately - Set mode 2.

Monday - Friday; Saturday - Sunday

Similarly to the previous mode it is necessary to select specific times and

required deviations from the temperature preset for the working days

(Monday - Friday) and the weekend (Saturday, Sunday).

Example

Monday - Friday

preset: 3 00 , temp. -10° (temperature change – 10° )

preset: 4 00 , temp. -10° (temperature change – 10° )

preset: 5 00 , temp. -10° (temperature change – 10° )

Saturday - Sunday

preset: 16 00 , temp. 5° (temperature change +5° )

preset: 17 00 , temp. 5° (temperature change +5° )

preset: 18 00 , temp. 5° (temperature change +5° )

In this case, if the preset boiler temperature is 60º , the temperature

will drop 10º to 50º between 3 a.m. and 6 a.m. on each day from

Monday to Friday. However, the temperature will rise 5º to 65º during

weekend (Saturday, Sunday) between 4 p.m. and 7 p.m.

Step #3:

The user enables one of two preset modes (Mode1, Mode2) or

disables the weekly control option.

Once the mode is enabled the value of the deviation currently set is

displayed on the main page of the controller next to the preset central

heating system temperature. This, additionally, indicates that the weekly

control is active.

Data deletion function is a simple method to remove all previously saved

weekly programme settings to enter new settings.

II.5.Feeding time

This option is used to set the fuel feeder operation time. The time should

be set according to the fuel being used and the boiler type.

II.6. Feeding pause

Feeding pause time is used to set the pause time in feeder operation. The

- 9 -

ST – 480

pause length should be adapted to the fuel type combusted in the boiler. Wrong

selection of operation and/or pause times may result in boiler malfunctioning

i.e. the fuel may be not fully combusted or the boiler may not reach the preset

temperature. Selection of appropriate times will ensure proper operation of the

boiler

II.7. Temperature alarm

The function is activated in the operation mode only (i.e. when the boiler

temperature is lower than the preset temperature). If the temperature is not

rising for a period defined by the user in that function an alarm is activated: the

feeder and the blower are turned off (the pump is turned on and off

independently) and sound is produced. A message reading “Central heating

system temperature is not rising” appears on the display. The alarm is cancelled

by pressing the pulser knob.

II.8. Blowing rate

The function controls the fan operating speed. The adjustment range is

between 1 and 100% (equivalent to fan speeds). The higher the speed is, the

faster the fan operates where 1% stands for the minimum fan speed and 100%

is the maximum speed.

II. . Pump operation modes

This function allows you to select one of the following four boiler operation

modes:

II. .a) House heating

When you select this option the controller switches over to a mode where

heating is provided only to heat the central heating circuit. The central heating

pump begins to run above the pump activation temperature (factory set at 38O

- 10 -

ST – 480

- see Section III.g). The pump will turn off below this temperature (minus a

hysteresis of 2° ).

II.9.b) Boiler tank priority

In this mode, the boiler tank (hot water) pump will be switched on first to run

until the set-point temperature is reached (see Section II.e), after which the

pump will be turned off and the H circulating pump will be enabled.

The central heating pump will run all the time until the boiler tank temperature

drops below its set-point by the hot water hysteresis value. At that moment the

H pump will turn off and the HW pump will turn on (both pumps operating

alternately).

In this mode the fan and the feeder are run only up to 62O as measured at the

boiler (instantaneous set-point) so as to prevent overheating of the boiler.

NOTE: The boiler must be fitted with check valves on the central heating and

hot water pump circuits. The valve mounted on the hot water pump is to

prevent drawing hot water from the boiler tank.

II. .c) Pumps in parallel

In this mode both pumps begin to run together (in parallel) above the pump

activation temperature. However, these temperatures may vary for each pump,

depending on your settings (see Sections III.g-h). When this is so one of the

pumps will switch on earlier than the other one, but after both thresholds are

crossed both pumps will run together. The central heating pump will run all the

time while the hot water pump will turn off when the boiler tank set-point

temperature is reached. It will turn on again when the temperature drops by

the preset HW hysteresis value below its set-point.

- 11 -

ST – 480

II. .d) Summer mode

Once this function is activated the central heating pump will be off and the

DHW pump will turn on above the preset activation temperature (see Section

III.h) and will work continuously until the temperature drops below the

activation temperature by the hot water hysteresis value or until the following

conditions are met:

(boiler temperature) + 2° ≤ (boiler tank temperature)

In summer mode you only enter the set-point temperature of the boiler,

which is also understood to mean the set-point temperature of the boiler

tank.

II.10. Sustained operation

This option is used to set simultaneously the feeder and blower

operating time while the boiler is in the sustain mode.

II.11. Sustain pause

The sustain pause function is used to set the break time in fuel

feeding in the sustain mode. Inappropriate selection of working and

pause times may result in further temperature rise or unintended boiler

shutdown or even lead to conditions where the fuel in the fuel tank gets

fired.

II.12. Fan in sustain mode

The option allows selection of appropriate working and pause times

during the fan operation in sustain mode.

II.15. Room temperature reduction

After the room controller reaches the preset temperature, the preset

boiler temperature (set in the installer menu - see Item III.16) will drop

by the value set there. The reduced temperature will not be lower

however than the minimum preset central heating temperature.

Example: Temperature preset on the boiler: 55º

Room temperature reduction: 15º

Minimum temperature set on the boiler: 45º (factory setting)

Once the preset room temperature is reached (signalled by the room

controller) the temperature preset on the boiler will drop to 45º i.e. only

by 10º although the room temperature reduction is 15º . At the same

- 12 -

ST – 480

time a message reading "!-10º" will be shown in the main display next to

the preset boiler temperature.

II.16 Factory settings

The controller is pre-configured for operation. However, it should be

adapted to individual needs. Factory settings can be restored at any

time. Selection of “factory settings” option will result in all boiler settings

(saved in user’s menu) being lost and reset to boiler manufacturer’s

settings. Individual boiler parameters can be set at that point again.

ATTENTION: Restoration of factory settings will not cause the changes

in service settings to be deleted.

II.17 Information about the programme

This function allows the user to check the controller programme

version.

III. Installation menu

The functions of the installation menu should be set by the person

installing the boiler or service personnel of the manufacturer.+

III.a Main valve

- 13 -

ST – 480

III.a.1 Switch on

This feature allows you to temporarily make the valve inactive.

III.a.2) Set-point valve temperature

This setting is used to set the circuit temperature to be maintained by the

mixing valve. This is the main temperature based on which the room

thermostat reduction function is to be run (see Section III.a.10). The room

thermostat reduction function is set separately for the H system (setting in the

user menu) and separately for each of the valves.

III.a.3) Temperature control

This parameter determines the sampling (control) frequency of the water

temperature downstream of the valve for the central heating or hot water

system. If the sensor indicates a change in temperature (deviation from set-

point), then the solenoid will open or close partially by a preset step to restore

the set-point temperature.

III.a.4) Opening time

You can use this function to set the time for the full opening of the valve,

that is to say, how long it takes to open the valve to 100%. This time should be

selected according to your valve actuator (shown on the nameplate).

- 14 -

ST – 480

III.a.5) Single step

You can use this function to set a percentage value for a single step in the

operation of valve opening, that is to say the maximum percentage value of

opening or closing that the valve can move in a single step (maximum

movement of the valve in one measurement cycle).

III.a.6) Minimum opening

Use this function to set the minimum value for valve opening. Below this

value, the valve will not close shut.

III.a.7) Type of valve

You can use this option to select the type of valve: central heating

or floor type.

III.a.8) Weather program (weekly valve program)

In order to enable the weather function an outdoor sensor should be

installed in a place not exposed directly to sunlight or weather conditions.

After installing and connecting the sensor the Weather program function must

be enabled in the controller menu.

For the valve to work properly enter set-point temperatures (downstream

of the valve) for the following four intermediate outside temperatures:

TEMP. FO -20

TEMP. FO -10

TEMP. FO 0

TEMP. FO 10

Heating curve - curve which is used to determine the set-point temperature of

- 15 -

ST – 480

the controller based on the outside temperature. In our controller this curve is

established based on four temperature set-points selected for their respective

outside temperatures. Set-point temperatures must be provided for the

following outside temperatures: -20º , -10º , 0º and 10º .

The more points there are available for constructing the curve, the greater

is its accuracy, which allows you to determine its shape in a flexible way. In our

case, four points seem to be a very good compromise between accuracy and

ease of setting its shape.

Where in our controller:

XA = -20º , X = 0º ,

XB = -10º , XD = 10º ,

YA, YB, Y , YD – set-point valve temperatures for their corresponding outside

temperatures: XA, XB, X , XD

After weather control is enabled the valve set-point parameter is

calculated based on the heating curve. By changing this parameter you can

decrease or increase all the weather control settings.

III.a. ) Return protection

This feature allows you to enable protection for the boiler from excessively cold

water returning from the main circuit, which could cause the boiler to suffer

from low-temperature corrosion. The return protection function works to ensure

that when the temperature is too low the valve will close partially until the short

circuit of the boiler reaches the desired temperature. This feature also protects

the boiler from a dangerously high return temperature to prevent water from

boiling.

When this function is enabled you need to set the minimum and maximum

return temperatures.

III.a.10) Room thermostat reduction

This function is active only when the unit is operated with a (standard or

- 16 -

ST – 480

TE H) room thermostat. When the room thermostat reaches the desired

temperature in the house/flat (reports heated up condition), the valve will close

to such an extent so that the temperature downstream of the valve drops by

the <room thermostat reduction> temperature.

NOTE: If the installation includes a TECH room thermostat with S

communication (four-wire cable), you may choose an option providing dynamic

control for the mixing valve (see Section III.a.11)

III.a.11) Operation of TECH thermostat

This setting is active only if the controller is connected with a TE H room

thermostat (with RS communication) and allows a choice in how the thermostat

is to work together with the mixing valve:

temperature reduction – when you select this mode after heating up

the house/flat to your required temperature set-point temperature the TE H

room thermostat will lower the set-point temperature of the valve by the pre-

set room thermostat reduction value (see Section II.a.10);

dynamic changes - when you select this mode after heating up the

house/flat to the set-point temperature the TE H room thermostat will work as

per the following settings:

Change in valve set-point. This setting determines by how many

degrees the valve temperature is to increase or decrease with a single unit

change in room temperature. This function is closely related to the oom

temperature difference parameter.

oom temperature difference. This setting is used to define the single

unit change in the current room temperature (accurate to 0.1° ) at which there

is to occur a specific change in the set-point temperature of the valve.

Example:

setting: oom temperature difference 0.5ºC

setting: Change in set-point valve temperature 1ºC

setting: Set-point valve temperature 40ºC

setting: Set-point room thermostat temperature 23ºC

Case 1. If the room temperature rises to 23.5º (by 0.5º ) the valve will close

to such an extent as to have 39º as a set-point (by 1º ).

Case 2. If the room temperature drops to 22º (by 1º ) the valve will open to

such an extent as to have 42º as a set-point (by 2º ).

- 17 -

ST – 480

III.a.12) Factory settings

This parameter allows you to restore the mixing valve settings saved by

the manufacturer. By restoring the factory settings you will not change the

valve type setting (central heating or floor type).

III.b) Valve 1

NOTE: ontrol with an additional valve (1 or 2) is only possible after you

purchase and connect the controller to an additional control module (ST-61),

which is not provided as standard equipment with the controller. In order to

control two valves you need to connect two ST-61 modules.

The options presented in this chapter are used to adjust the operating

settings of an additional mixing valve. In order for the valve to work properly

and meet your expectations it should be configured with its parameters set like

in the case of the main valve.

- 18 -

ST – 480

III.b.1)Registration.

To register an additional valve enter the serial number of the control module of

the ST-61 mixing valve servo (look for the five-digit number on the cover of

this module). Without this number the valve cannot be activated.

III.b.2) Switch on (setting as for the main valve - see Section

III.a.1).

III.b.3) Set-point valve temperature (setting as for the main valve

– see Section III.a.2)

III.b.4)Room thermostat

If the valve is to be operated with a room thermostat, you should

select its type:

module controller (traditional two-state type – “from the module”),

standard or TE H controller (traditional two-state type – “from the

controller”),

TE H algorithm controller (RS communication),

room temperature difference (setting as for the main valve – see

Section III.a.11),

set-point change (setting as for the main valve – see Section III.a.11).

III.b.5) Temperature control (Setting as for the main valve – see

Section III.a.3).

III.b.6) Opening time (Setting as for the main valve – see Section

III.a.4)

III.b.7) Single step (Setting as for the main valve – see Section III.a.5).

III.b.8) Minimum opening (Setting as for the main valve – see Section

III.a.6).

III.b. ) Type of valve (Setting as for the main valve – see Section

- 19 -

ST – 480

III.a.7).

III.b.10) Weather program (weather control) (Setting as for the

main valve – see Section III.a.8).

III.b.11) Return protection - (Setting as for the main valve – see

Section III.a.9).

III.b.12) Additional sensors

When two mixing valves are used and you select this function you will be

able to select the sensors from which temperature data are to be retrieved for a

valve (for return and outside temperature sensors). Temperatures can be

retrieved from the sensors of the valve being set (Own) or as per the controller

sensors (Main controller).

III.b.13) Room thermostat reduction (Setting as for the main

valve – see Section III.a.10).

III.b.14) External sensor adjustment

The external sensor is to be adjusted during installation or after prolonged

use of the thermostat if the outside temperature displayed deviates from the

actual one. Adjustment range: -10 to +10 O with an accuracy of 1O

III.b.15) Factory settings (Settings as for the main valve – see Section

III.a.12)

III.b.16) Valve removal

This function is used to completely remove a valve from the controller

memory. Valve removal is used for example when removing or replacing a

module (the new module requires to be registered again).

- 20 -

Table of contents

Other TECH Controllers manuals