TECNA T Series User manual

OPERATING MANUAL

Hydraulic breakers T series

ENGLISH

REV 9.0.0 - 2021

The data specified here only serves as a product description.

A conclusion about a certain condition or suitability for a particular application

cannot be derived from the information given here. The information does not absolve the user from

making his/her own assessments and conducting tests. Keep in mind that our products are subject

to a natural wear and ageing process.

© All rights reserved by TECNA Group Srl, including the industrial property rights.

Every power of disposal such as the right to copy and transfer is reserved.

A sample configuration is shown on the front page.

The product delivered can thus deviate from the figure.

OPERATING MANUAL - Hydraulic breakers T series

TECNA Group Srl

Zona Industriale, Via Abruzzo 86

70021 Acquaviva delle Fonti (BA) ITALY

Headquarters: Via Principe Amedeo 146

74121 Taranto (TA) ITALY

phone +39 (0)80 7810000 / +39 (0)80 3050136

fax +39 (0)80 3051812

www.tecnaonline.com

0CONTENTS

PAR DESCRIPTION

0CONTENTS

0 CONTENTS 2

1 GENERAL INFORMATION 3

1.1 FOR THE OPERATING PERSONNEL 3

1.2 LIABILITY 4

1.3 FOR BETTER UNDERSTANDING OF THIS MANUAL 4

2 SAFETY 5

2.1 INTENDED USE 5

2.2 QUALIFICATION OF THE PERSONNEL 5

2.3 PROHIBITION, WARNING, MANDATORY AND INSTRUCTION SIGNS ON THE DEVICE 6

2.4 BASIC SAFETY INSTRUCTIONS 7

2.4.1 General instructions 7

2.5 DUTIES OF THE OPERATOR 10

2.6 PERSONAL PROTECTIVE EQUIPMENT 10

3 SCOPE OF DELIVERY 11

3.1 SCOPE OF DELIVERY 11

4 PRODUCT DESCRIPTION 12

4.1 TECHNICAL SPECIFICATIONS 12

4.2 DEVICE DESCRIPTION 12

4.3 PRODUCT IDENTIFICATION 13

5 TRANSPORT AND STORAGE 14

5.1 TRANSPORT AND STORAGE / MANUAL TRANSPORTATION 14

5.2 TRANSPORTATION USING A LIFTING TOOL 15

5.3 MOVING THE SUPPORT FRAME USING THE MOUNTED HYDRAULIC BREAKER 16

5.4 STORAGE 16

6 MOUNTING THE HYDRAULIC BREAKER 17

6.1 UNPACKING 17

6.2 MOUNTING CONDITIONS 17

6.3 REQUIRED TOOL 17

6.4 NECESSARY ACCESSORIES 17

6.5 MOUNTING 18

6.6 FITTING AND REMOVING THE PLUG TOOL 20

6.7 CONNECTING THE HYDRAULIC BREAKER HYDRAULICALLY 22

7 COMMISSIONING 25

7.1 FIRSTCOMMISSIONING;RE-COMMISSIONINGAFTERASTANDSTILL 25

8 OPERATION 26

8.1 OPERATING RANGE 26

8.2 SITE SELECTION 26

8.3 INFORMATION REGARDING THE MODE OF OPERATION 27

8.4 PROCESS FLOW 31

8.5 UNDERWATER OPERATION 31

9 TOOL 32

9.1 TOOL 32

10 MAINTENANCE (DIN EN 31051) 33

10.1 CLEANING AND SERVICING 33

10.2 INSPECTION AND MAINTENANCE 34

10.2.1 Establishing pressure relief on the hydraulic system 34

10.2.2 Log 34

10.2.3 Information regarding the maintenance and inspection body 34

10.2.4 Maintenance and inspection plan 35

10.3 REPAIRS 37

10.3.5 Nitrogen charging of the oil nitrogen accumulator 37

10.3.6 Replacing hydraulic lines and hoses 38

10.4 SPARE AND WEAR PARTS 38

11 REMOVING THE HYDRAULIC BREAKER FROM THE SUPPORT FRAME 39

11.1 REMOVING THE HYDRAULIC BREAKER FROM THE SUPPORT FRAME 39

12 DISPOSAL 41

12.1 DISPOSAL 41

13 CAUSE OF MALFUNCTION AND TROUBLESHOOTING 42

13.1 CAUSE OF MALFUNCTION AND TROUBLESHOOTING 42

14 ANNEX 43

14.1 TOOL PASTE 43

14.2 PROOF OF MAINTENANCE 44

OPERATING MANUAL - Hydraulic breakers T series

2/44

REV

0.0

CONTENTS

0

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

1GENERAL INFORMATION

PAR DESCRIPTION

1.1 FOR THE OPERATING PERSONNEL

LX 18 HF40 HF56 HF280 HP 60

HF15 HF45 CLA400 HF350 ALG 80

HF16 HF48 HF120 HF400 ALG 120

HF21 HF50 aD168 MpA480 ALG 160

HF24 HF51 HF206 HF640 GOA 2** SERIES

HF32 HF55 HF250 GOA 3** SERIES

This operating manual gives you information regarding the safety, structure, functioning, operation

and maintenance of the hydraulic breakers listed below:

This operating manual ensures smooth and safe operation for a long time if the instructions are

observed carefully.

Applicable documents

• Spare parts catalogue including the parts list and drawings

• Technical details regarding the hydraulic breakers

Applicable documents regarding supplied components (see section "14. ANNEX" on page 43)

• See the parts list for the operating manual and data sheets of the individual components

Detailed information regarding the scope of the provided documents can be found in the

“delivery order”.

Safekeeping this operating manual

The operating manual (including the applicable documents) must be stored near the hydraulic

breaker such that it is always accessible.

OPERATING MANUAL - Hydraulic breakers T series

3/44

REV

0.0

GENERAL INFORMATION

1

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

1GENERAL INFORMATION

PAR DESCRIPTION

1.2 LIABILITY

TECNA is not liable for any material defect and guarantee claim in case of damage caused due

to improper use and unauthorised interferences not provided for in this mounting instruction.

Details regarding material defect claims can be found in the General Terms and Conditions provided

by TECNA.

Unauthorised structural modications to the hydraulic breaker are not permitted for safety reasons.

In addition, you cannot make any changes in the installation (connections among other things).

Parts and components have been specially designed for the hydraulic breaker. We would also like

to specifically draw your attention to the fact that parts and special equipment that has not been

delivered by us, has also not been approved by us. Installing and/or using such products can affect

the safety.

4/44

REV

0.0

GENERAL INFORMATION

1

1GENERAL INFORMATION

PAR DESCRIPTION

1.3 FOR BETTER UNDERSTANDING OF THIS MANUAL

CONVENTIONS

DANGER!

This danger sign indicates an imminent, great danger that, in all probability, causes severe injuries

or even death in some cases if the dangerous situation is not dealt with properly.

WARNING!

This danger sign indicates a possible danger that can cause severe injuries or even death in some

cases if the danger situation is not dealt with properly.

CAUTION!

This danger sign indicates a potentially dangerous situation that can cause minor or moderate

physical injuries or material damage if such a situation is not dealt with properly.

NOTE

This sign indicates additional information.

DANGER

WARNING

CAUTION

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

The hydraulic breaker has been manufactured in accordance with the generally accepted norms of

technology. Nevertheless, there is danger to persons or property if you do not observe the following

basic safety instructions and warnings about instructions in this operating manual.

• Read this operating manual thoroughly and in its entirety before you mount the hydraulic

breaker and work with it.

• Keep the operating manual such that it is always easily accessible to all users.

• Always pass on the hydraulic breaker to a third party together with the operating manual.

INTENDED USE

Adhere to the operating conditions and capacities mentioned in the Technical Details.

The hydraulic breaker is a technical equipment and not meant for private use.

The intended use also assumes that you have thoroughly read and understood this operating manual

and particularly chapter "2 SAFETY".Any other use or any use in excess thereof is considered as

improper and thus strictly prohibited.

The operator and/or the user of the hydraulic breaker are responsible for all the damage caused

due to improper use.

The hydraulic breaker is not suitable for operation in an explosive environment and the parameters

and information in the mounting instruction are applicable at sea level.

The following is included under intended use:

• Following all the notes from the mounting instruction,

• Following the requirements, prohibitions and warnings and

• Adhering to the inspection and maintenance intervals.

2SAFETY

PAR DESCRIPTION

2.1 INTENDED USE

2SAFETY

PAR DESCRIPTION

2.2 QUALIFICATION OF THE PERSONNEL

The mounting, commissioning and operation, removal and maintenance (including maintenance

and servicing) require basic mechanical and hydraulic knowledge and knowledge of the relevant

technical terms.

Hence, these jobs may only be carried out by one relevant qualified person or an trained person

under the supervision of a qualified person in order to ensure operational safety.

A qualified person is someone who can assess the work assigned to him/her, detect possible

dangers and take suitable safety measures based on his/her professional training, knowledge and

experiences and his/her knowledge about the relevant regulations.

A qualified person must adhere to the relevant technical rules.

OPERATING MANUAL - Hydraulic breakers T series

5/44

REV

0.0

SAFETY

2

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

2SAFETY

PAR DESCRIPTION

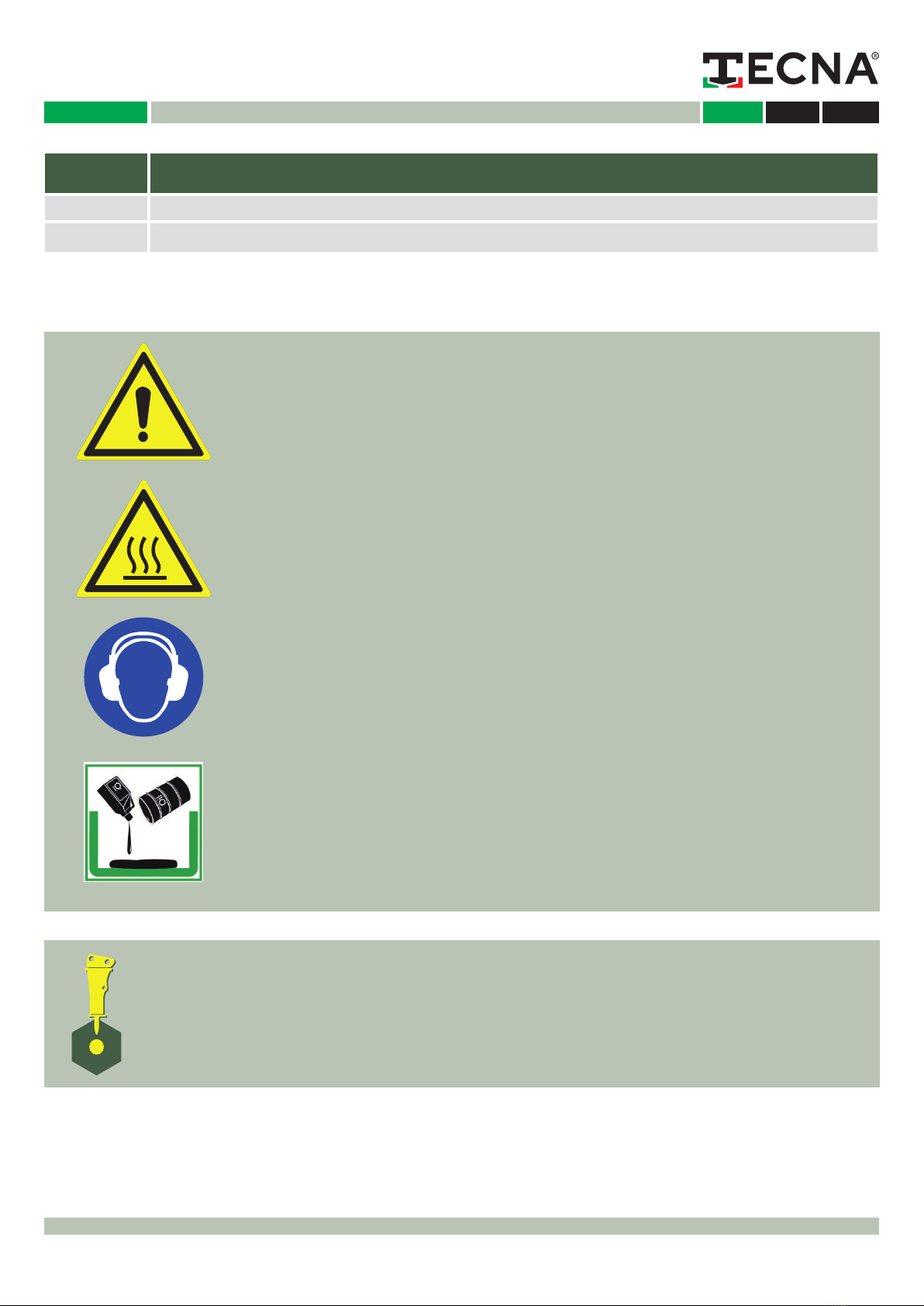

2.3 PROHIBITION, WARNING, MANDATORY AND INSTRUCTION SIGNS ON THE DEVICE

6/44

REV

0.0

SAFETY

2

The following signs are affixed on the hydraulic breaker (DIN 4844):

WARNING ABOUT A DANGER AREA!

WARNING ABOUT A HOT SURFACE!

USE EAR MUFFS

DISPOSE OF THE WASTE OIL IN ACCORDANCE WITH THE STATUTORY

REQUIREMENTS.

More prohibition, warning, mandatory and instruction signs of components may be affixed

on the support frame and on attachments of the support frame. Information regarding

the individual prohibition, warning, mandatory and instruction signs can be found in the

relevant operating manual.

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

2SAFETY

PAR DESCRIPTION

2.4 BASIC SAFETY INSTRUCTIONS

7/44

REV

0.0

SAFETY

2

The potential of danger changes due to the interplay of the hydraulic breaker and the support frame

because the hydraulic breaker is mounted on the support frame. This operating manual does not

replace the operating manual of the support frame on which the hydraulic breaker is mounted.

This operating manual must be read and followed.

The safety instructions help to prevent personal injury or damage to property when dealing with

the hydraulic breaker and the environment. All users must read these safety instructions and follow

them at all times.

In addition to the operating manual, the universally valid as well as local regulations regarding accident

control, safety at work and rules for environment protection must be provided and observed.

Follow the instructions about using the hydraulic breaker in the support frame operating manual.

• Use the hydraulic breaker only if it is in a technically sound condition.

• Repair the defects in the hydraulic breaker immediately. Inform TECNA immediately in case of

malfunctions. Do not make any modifications or re-constructions in the hydraulic breaker,

otherwise the declaration of conformity becomes invalid and the operating permit is terminated.

• Check the hydraulic breaker for visible defects such as cracks in the casing, screws, covering

caps or seals.

• You may not fundamentally modify or re-construct the hydraulic breaker.

• Use the hydraulic breaker within the range of capacity only, which is specied in the Technical Details.

• Do not use the hydraulic breaker in explosive environments if there is no explicit permission for it.

• Close the front panel of the support frame before you start working with the hydraulic breaker.

• Wear the necessary protective equipment, e.g. protective helmet, ear muffs, protective clothing

among other things as per the requirements.

• Do not wear loose clothing or jewellery that could get caught in the operating elements or other

parts of the support frame.

• Persons who are under the influence of alcohol, drugs or medicines may not transport, mount,

commission, operate or repair the hydraulic breaker.

• Only ask for standard signs and that too from one person only when working on the site.

• The minimum age limit for the operating personnel is 18 years.

• Fasten all the loose objects such as tools and remove these objects from catwalks, levels, etc.

• Ensure that all the safety equipment belonging to the hydraulic breaker is available, installed

properly and is fully functional. You may not change the position of the safety equipment,

handle it or make it ineffective.

• Ensure that the activated user can be brought into a safe position (e.g. immediate stop) by using

a proper EMERGENCY STOP function.

• Follow the warning and instruction signs attached to the hydraulic breaker. In addition, ensure

that these signs are not removed and that they are always legible.

2.4.1 GENERAL INSTRUCTIONS

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

PAR DESCRIPTION

2.4 BASIC SAFETY INSTRUCTIONS

8/44

REV

0.0

SAFETY

2

2.4.1 GENERAL INSTRUCTIONS

• Comply with the prescribed purity level as per ISO 4406 (c) of the hydraulic pressure medium

• You can find information regarding the purity level in the support frame operating manual.

• Take measures to ensure that there are no dangerous situations for persons and property

parameters if the need arises to stop the safety equipment for commissioning or maintenance

work for instance. Follow the above-mentioned support frame operating manual for this.

RISK OF BURNS!

The hydraulic breaker heats up intensely during operation and can get very hot when in operation

and may cause burns.

»Allow the hydraulic breaker to cool down before you touch it.

»Protect yourself with heat-resistant protective clothing e.g. gloves.

»Follow the ISO 13732-1 and EN 982 standards as well.

• The guarantee is applicable solely for the delivered design.

• The guarantee expires in case of incorrect mounting.

• Pay attention to high-voltage lines, underground cables and feed lines so that they are not

damaged during operation. If they are damaged, measures must be taken immediately such that

there is no danger due to it.

• Do not work with the hydraulic breaker if any persons are present on the hydraulic breaker.

• Depending on the type of connection, keep in mind the pressure condition when connecting to

the hydraulic system and when separating from the hydraulic system. The hydraulic system must

be operated at zero pressure in case of an emergency.

• Keep persons and animals away from the sphere of activity of the hydraulic breaker during all the

mounting and maintenance work.

• Never leave the hydraulic breaker unsupervised during the mounting and maintenance work.

• The hydraulic breaker may not be operated without the safety equipment and protective caps

attached by TECNA or those installed by customers.

• The defective components must only be replaced with the original parts having the same

hydraulic and mechanical data, otherwise the safety and functioning cannot be maintained.

• All the safety equipment, fastenings as well as hydraulic connections and lines must be regularly

checked for flawless condition.

• In case of injuries, visit a doctor who is knowledgeable about these injuries.

• Use sufficient respiratory protection in case of lot of dust formation or dust containing asbestos.

DANGER

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

PAR DESCRIPTION

2.4 BASIC SAFETY INSTRUCTIONS

9/44

REV

0.0

SAFETY

2

2.4.1 GENERAL INSTRUCTIONS

FOR TRANSPORTATION

• Follow the transportation instructions on the packaging.

FOR MOUNTING AND REMOVING

• Follow the instructions of the manufacturer when using mechanical and hydraulic changing

equipment.

• Follow the support frame-specific instructions and the safety instructions of the support frame

manufacturer when mounting without changing equipment.

• Connect the connections to the support frame at zero pressure before you mount the hydraulic

breaker.

• Only use a proper tool for that.

• Lay the lines such that they are not damaged.

• Ensure before commissioning that all the seals and fasteners at the ends are fit correctly and are

undamaged such that liquids and foreign bodies cannot enter into the hydraulic breaker.

• Pay attention to utmost cleanliness when mounting so as to avoid impurities from entering the

hydraulic lines, which could lead to wear and malfunctions in the hydraulic breaker and support frame.

FOR COMMISSIONING

• Ensure that all the hydraulic connections are covered or closed. Operate a fully installed hydraulic

breaker only.

FOR CLEANING

• Close all the openings using suitable protective equipment such that the cleaning agents do not

enter the system.

• Use a suitable cleaning device for cleaning and follow the instructions regarding the cleaning device.

• Wear protective clothing (e.g. protecting goggles, face mask among other things) when dealing

with compressed air or pressurised water.

FOR MAINTENANCE

• Carry out the prescribed maintenance work at intervals specified in the operating manual.

• Ensure that no line links, connections and components come off till the system is under pressure.

• Do not search for leakages with bare hands; the pressure medium can come out with high pressure

which can cause injuries.

FOR DISPOSAL

• Dispose of the hydraulic breaker as per the country-specific regulations.

• Dispose of the pressure medium or grease as per the country-specific regulations.

• Dispose of the pressure medium residues or grease in accordance with the valid safety data

sheets for pressure mediums and grease.

• Consult TECNA or your dealer when using biodegradable mediums.

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

2SAFETY

PAR DESCRIPTION

2.5 DUTIES OF THE OPERATOR

10 /44

REV

0.0

SAFETY

2

The operator of the hydraulic breaker must train personnel regularly on the following topics:

• Following and using the operating manual as well as the legal regulations

• Intended operation of the hydraulic breaker

• Following the instructions of the site management and the operating instructions of the site

operator

• Behaviour in case of an emergency

2SAFETY

PAR DESCRIPTION

2.6 PERSONAL PROTECTIVE EQUIPMENT

The instructions from the regulations, rules, national laws and ordinances must be adhered to.

Follow the country-specific rules and regulations as well.

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

3SCOPE OF DELIVERY

PAR DESCRIPTION

3.1 SCOPE OF DELIVERY

11 /44

REV

0.0

SCOPE OF DELIVERY

3

The following is included in the scope of delivery:

• Hydraulic hammer according to technical specification and "order specification".

• Check the scope of delivery for completeness.

• Check the scope of delivery for possible transportation damage, also see section

“5. TRANSPORT AND STORAGE” on page 14.

• Check whether the operating manual is suitable for the hydraulic breaker.

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

4PRODUCT DESCRIPTION

PAR DESCRIPTION

4.1 TECHNICAL SPECIFICATIONS

See “Technical Details”.

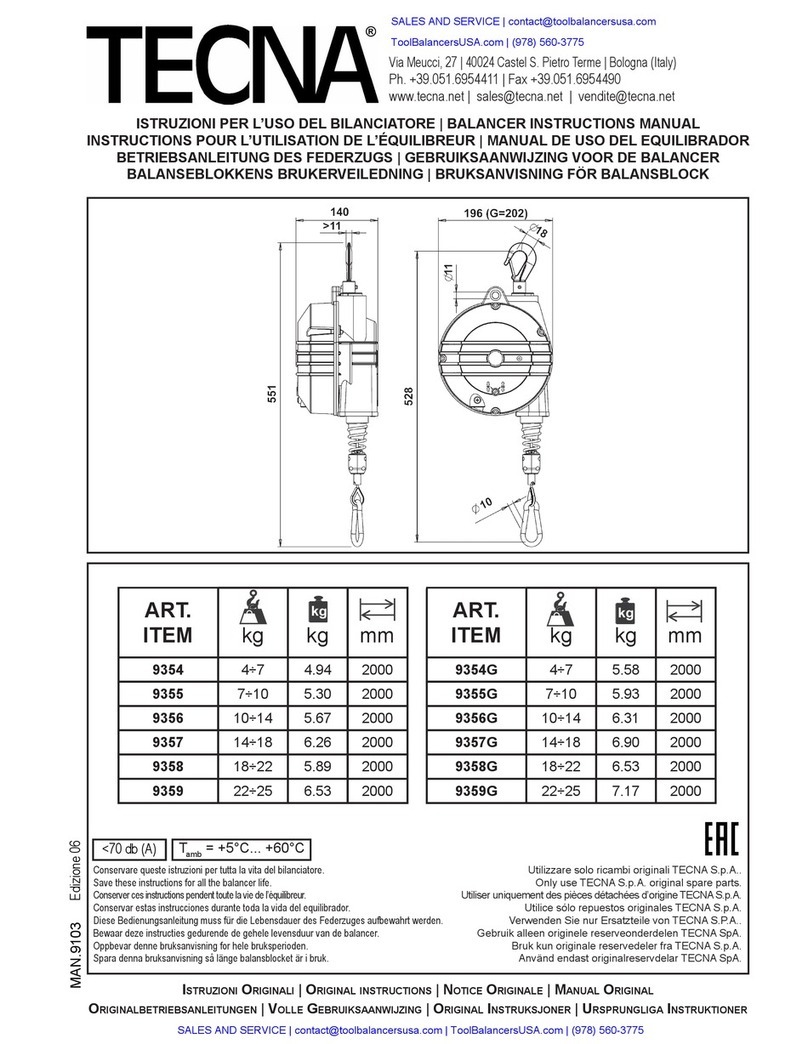

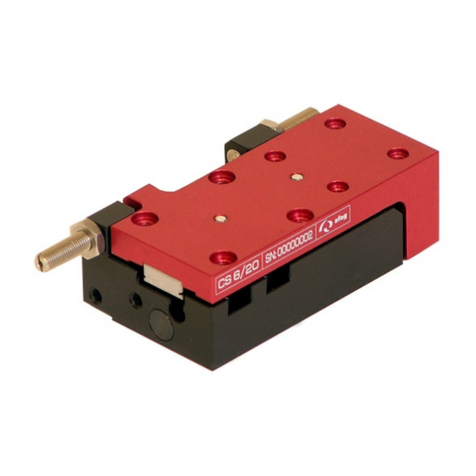

FIGURE 1 – Breaker

4PRODUCT DESCRIPTION

PAR DESCRIPTION

4.2 DEVICE DESCRIPTION

A sample design has

been shown in the

following figure.

The delivered

hydraulic breaker can

thus deviate from

the figure

Inform your dealer or TECNA, if the Technical Details are not provided during the delivery.

1. Support for the quick-change

device

2. Locking pins

3. Tool

4. Retaining wedges

5. Hydraulic connection - OUT

6. Hydraulic connection - IN

OPERATING MANUAL - Hydraulic breakers T series

12 /44

REV

0.0

PRODUCT DESCRIPTION

4

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

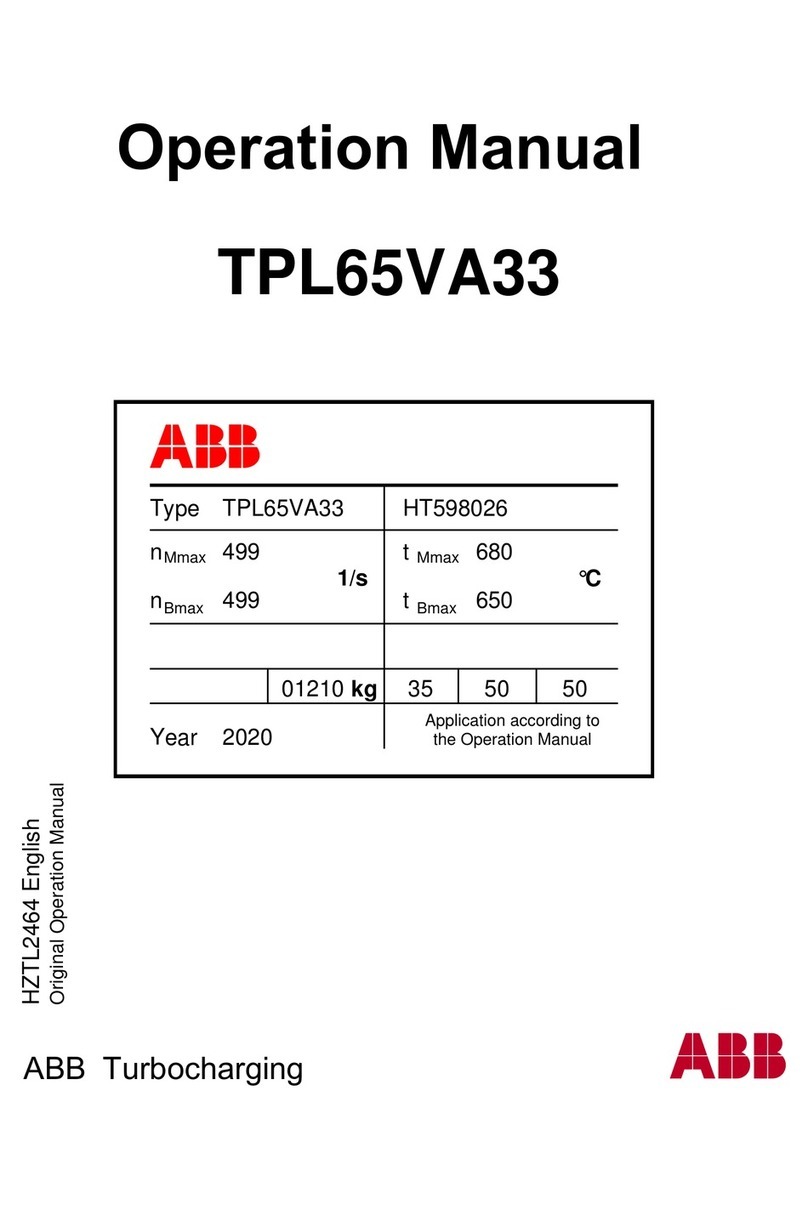

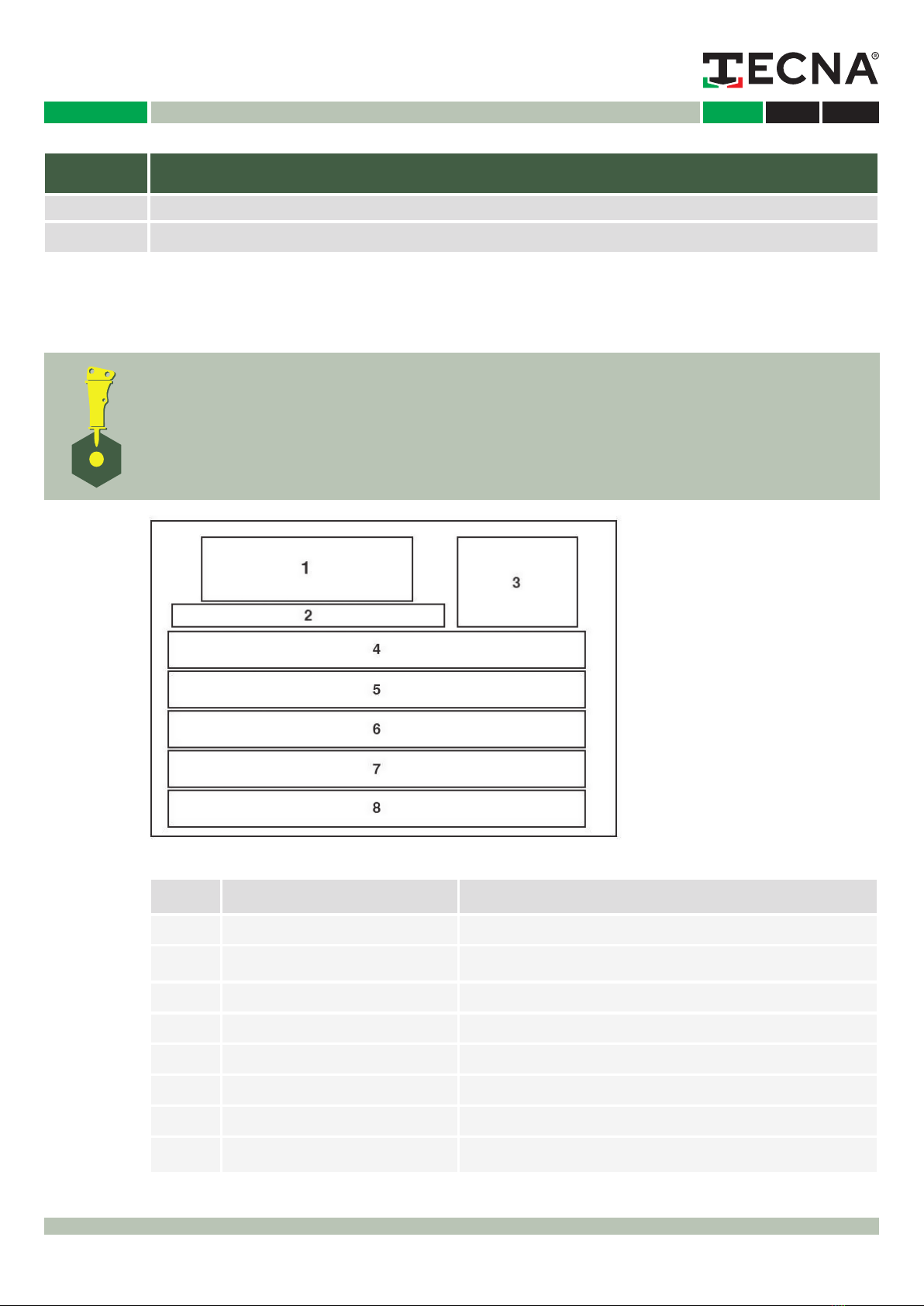

INFORMATION ON THE IDENTIFICATION PLATE

The meaning of the information on the identification plate is clarified with the help of the

numbered fields from the following figures and the table.

4PRODUCT DESCRIPTION

PAR DESCRIPTION

4.3 PRODUCT IDENTIFICATION

NTYPE OF INFORMATION INFORMATION OR EXAMPLE

1Manufacturer logo TECNA, Italian Excellence

2Name and address of the

manufacturer TECNA Group Srl, Via Principe Amedeo 146, 74121 Taranto, TA (I)

3CE mark CE

4Model name z. B.: HF40

5Serial number z. B.: 1234

6Input power (max) z. B.: KW 22

7Breaker working pressure z. B.: bar 120

8Date of manufacture

(year and week) z. B.: 2009

FIGURE 2 – Identification plate

TABLE 1 – Information regarding the identification plate

The identification plate is attached on the left side on the hydraulic breaker.

OPERATING MANUAL - Hydraulic breakers T series

13 /44

REV

0.0

PRODUCT DESCRIPTION

4

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

5TRANSPORT AND STORAGE

PAR DESCRIPTION

5.1 TRANSPORT AND STORAGE / MANUAL TRANSPORTATION

DANGER OF MATERIAL DAMAGE AND PERSONAL INJURIES!

The hydraulic breaker or tool can fall down if not transported properly and cause damage to

the hydraulic breaker or the tool and/or personal injuries since the parts could be sharp-edged,

heavy, oily, unstable, loose and bulky.

»Ensure a stable position when transporting to the mounting location and secure the cargo from

shifting.

»Use personal protective equipment (e.g. gloves, work shoes, protective goggles, work clothing, etc.).

»Follow the national laws and regulations for safety at work, health protection and transportation.

»Do not transport the hydraulic breakers on parts which have low stability, e.g. connecting hoses.

PAY ATTENTION TO THE FOLLOWING POINTS WHEN TRANSPORTING MANUALLY:

• Use a suitable technique for lifting, putting down and moving.

• Use personal protective equipment (e.g. gloves, work shoes, protective goggles, work clothing, etc.).

• Do not transport the hydraulic breakers on parts which have low stability, e.g. connecting hoses.

DANGER OF DAMAGE TO HEALTH!

There is a danger of damage to health when lifting the hydraulic breaker or tool.

»Use a suitable technique for lifting, putting down and moving or use suitable lifting tools

during manual transportation.

Transportation damage must be notified to TECNA or your dealer within a week of delivery to the

following address:

TECNA Group S.r.l

Zona Industriale, Via Abruzzo 86

70021 Acquaviva delle Fonti (BA) ITALY

Tel. +39 (0) 80 7810000 / +39 (0) 80 3050136

Fax +39 (0) 80 3051812

info@tecnaonline.com / www.tecnaonline.com

You must comply with the environmental conditions specified in the Technical Details for the

transportation and storage.

DANGER

CAUTION

Information regarding the weight of your hydraulic breaker can be found in the Technical

Details.

OPERATING MANUAL - Hydraulic breakers T series

14 /44

REV

0.0

TRANSPORT AND STORAGE

5

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

5TRANSPORT AND STORAGE

PAR DESCRIPTION

5.2 TRANSPORTATION USING A LIFTING TOOL

BRUISES AND FRACTURES!

If the hydraulic breakers fall down, they could cause severe injuries, e.g. bruises, fractures.

»Use suitable lifting tools for transportation.

»Pay attention to the prescribed position of the lifting straps.

DANGER OF MATERIAL DAMAGE AND PERSONAL INJURIES!

The hydraulic breaker can fall down if not transported properly and cause damage to the hydraulic

breaker and/or personal injuries. Parts of the hydraulic breaker can become disjointed or twisted.

»For transporting, do not fasten the hydraulic breakers on parts which have low stability,

e.g. connecting hoses.

»Ensure that the sling gear does not rest on parts which have low stability.

Take into consideration the following points during transportation:

• Properties of the load (e.g. weight, centre of gravity, fastening and suspension points).

• Manner of suspending or lifting the load.

Ensure that the load bearing capacity of the lifting tool is sufficient for transporting the hydraulic

breaker safely. Use textile sling gears – in accordance with DIN EN 1492-2.

• Tighten the lifting strap on the hydraulic breaker as shown in FIGURE 3 and ensure that the

lifting strap does not go over the attachments (e.g. connecting hoses).

FIGURE 3 – Position of the lifting strap

Please contact TECNA

for more information

regarding the

transportation.

DANGER

WARNING

OPERATING MANUAL - Hydraulic breakers T series

15 /44

REV

0.0

TRANSPORT AND STORAGE

5

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

5TRANSPORT AND STORAGE

PAR DESCRIPTION

5.3 MOVING THE SUPPORT FRAME USING THE MOUNTED HYDRAULIC BREAKER

TRANSPORTATION ON THE LOADING PLATFORM

The hydraulic breaker must be positioned flat on the loading platform if the support frame is being

transported by a different vehicle.

The hoses must not get damaged during the transport, e.g. due to crushing because they are bent

to a great extent.

Follow the instructions in the support frame operating manual when moving the support

frame using the mounted hydraulic breaker.

16 /44

REV

0.0

TRANSPORT AND STORAGE

5

5TRANSPORT AND STORAGE

PAR DESCRIPTION

5.4 STORAGE

The hydraulic breaker can be stored for up to six months in the company as long as the following

criteria are met:

• The hydraulic breaker should be stored in the downward direction perpendicular to the tool so

that the existing seals are not damaged due to the dead weight of the hydraulic breaker.

DANGER OF MATERIAL DAMAGE AND PERSONAL INJURIES!

The hydraulic breaker must be secured as per the regulations for perpendicular storage to

prevent it from falling down so that there is no damage to the hydraulic breaker and/or personal

injuries. Parts of the hydraulic breaker can become disjointed or twisted.

»Secure the hydraulic breaker properly from tipping over.

• Store in dry and well ventilated rooms only and protect it from soil humidity.

• Cover with a sheet for protecting from dust and dirt.

• Close all connections using closing plugs.

• After opening the transport package, close it again properly for storage purposes.

Consult TECNA for storage exceeding six months.

DANGER

OPERATING MANUAL - Hydraulic breakers T series

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

6MOUNTING THE HYDRAULIC BREAKER

PAR DESCRIPTION

6.1 UNPACKING

6MOUNTING THE HYDRAULIC BREAKER

PAR DESCRIPTION

6.2 MOUNTING CONDITIONS

Dispose of the packaging as per the country-specific regulations.

Contact your dealer for more information regarding the accessories.

You must comply with the environmental conditions specified in the Technical Details for mounting.

The quick-changer must be attached properly to the support frame and must be functional.

6MOUNTING THE HYDRAULIC BREAKER

PAR DESCRIPTION

6.3 REQUIRED TOOL

You can mount and remove the hydraulic breaker using commercial tools.

6MOUNTING THE HYDRAULIC BREAKER

PAR DESCRIPTION

6.4 NECESSARY ACCESSORIES

You need the following accessories for mounting the hydraulic breaker on the support frame:

• Hydraulic hoses (for connections, see Technical Details of the hydraulic breaker and the support

frame operating manual).

OPERATING MANUAL - Hydraulic breakers T series

17 /44

REV

0.0

MOUNTING THE HYDRAULIC BREAKER

6

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

6MOUNTING THE HYDRAULIC BREAKER

PAR DESCRIPTION

6.5 MOUNTING

DANGER OF MATERIAL DAMAGE AND PERSONAL INJURIES!

Fan incorrectly mounted hydraulic breaker can cause considerable damage to property and

persons. An incorrectly fastened hydraulic breaker can move in an uncontrolled manner and

damage other equipment.

»Basic mechanical and hydraulic knowledge is necessary for mounting the hydraulic breaker.

The hydraulic breaker may be mounted only by qualied personnel (see section "2.2 QUALIFICATION

OF THE PERSONNEL” on page 5).

»Ensure that the hydraulic hammer is fastened securely.

DANGER DUE TO USAGE OF AN INCORRECT HYDRAULIC BREAKER RANGE!

Mounting an incorrect hydraulic breaker range can lead to uncontrolled actions and injure persons

or damage the hydraulic breaker and / or the support frame.

»Check whether you are using the correct hydraulic breaker on the basis of the model name on

the identification plate.

»Check the scope of delivery for completeness.

»Check the scope of delivery for possible damage due to transportation.

»Check whether the operating manual is suitable for the hydraulic breaker.

1. You must ensure that the surroundings are clean before mounting and removing so that dirt

does not enter the oil circuit. Only use nonlinting fabric or speciality paper for cleaning purposes.

2. Bring the jib of the support frame in an optimal position so as to hold the hydraulic breaker with

the quick-changer.

3. Hold the hydraulic breaker with the quick-changer.

Have a sufficiently big collection container, enough cloth and mediumbinding materials

ready to collect or absorb the hydraulic oil coming out.

Follow the instructions of the quick-changer manufacturer.

DANGER

DANGER

OPERATING MANUAL - Hydraulic breakers T series

18 /44

REV

0.0

MOUNTING THE HYDRAULIC BREAKER

6

www.tecnaonline.com - info@tecnaonline.com

ENGLISH

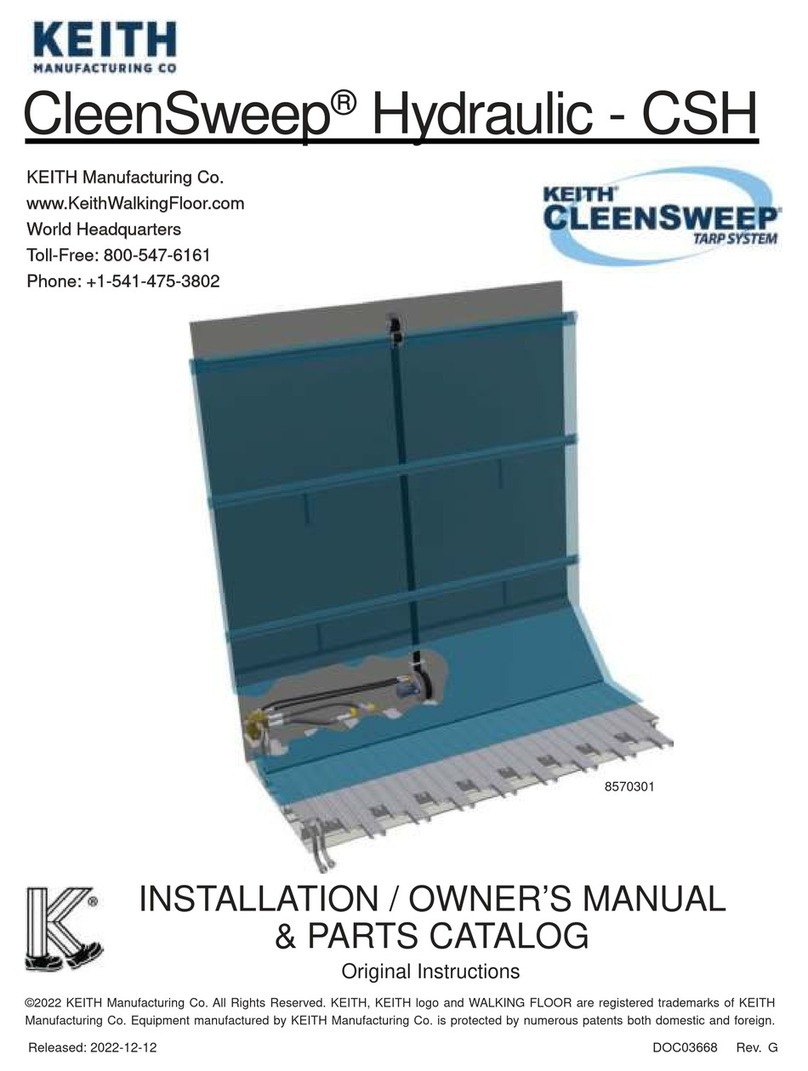

4. Secure the hydraulic breaker on the quick-changer.

PAR DESCRIPTION

6.5 MOUNTING

FIGURE 4: Holding the hydraulic breaker

FIGURE 5: Securing the hydraulic breaker

OPERATING MANUAL - Hydraulic breakers T series

19 /44

REV

0.0

MOUNTING THE HYDRAULIC BREAKER

6

This manual suits for next models

29

Table of contents

Other TECNA Industrial Equipment manuals