© 2005 D420 - 06/05 2 of 24

Table of Contents

Table of Contents ...........................................................2

Display and DIP Switches ..............................................2

Dip Switch Settings ................................................2

Access Level...........................................................3

Display and Symbols Description ...........................4

User Interface ........................................................5

Display Menus................................................................6

View Menu ..............................................................6

Adjust Menu............................................................7

Miscellaneous Menu .............................................10

Testing the Control ....................................................... 11

Sequence of Operation................................................. 12

tekmarNet®4 Communication ............................... 12

Outdoor Reset ...................................................... 12

Boiler Temperature Control .................................. 14

tekmar Stager Operation ...................................... 17

Zone Load Shedding ............................................ 17

Domestic Hot Water Temperature Operation ....... 17

DHW with Low Temperature Boilers ..................... 19

Setpoint Temperature Operation...........................19

Pump Operation....................................................20

Error Messages ............................................................21

Troubleshooting ............................................................23

Warranty .......................................................................24

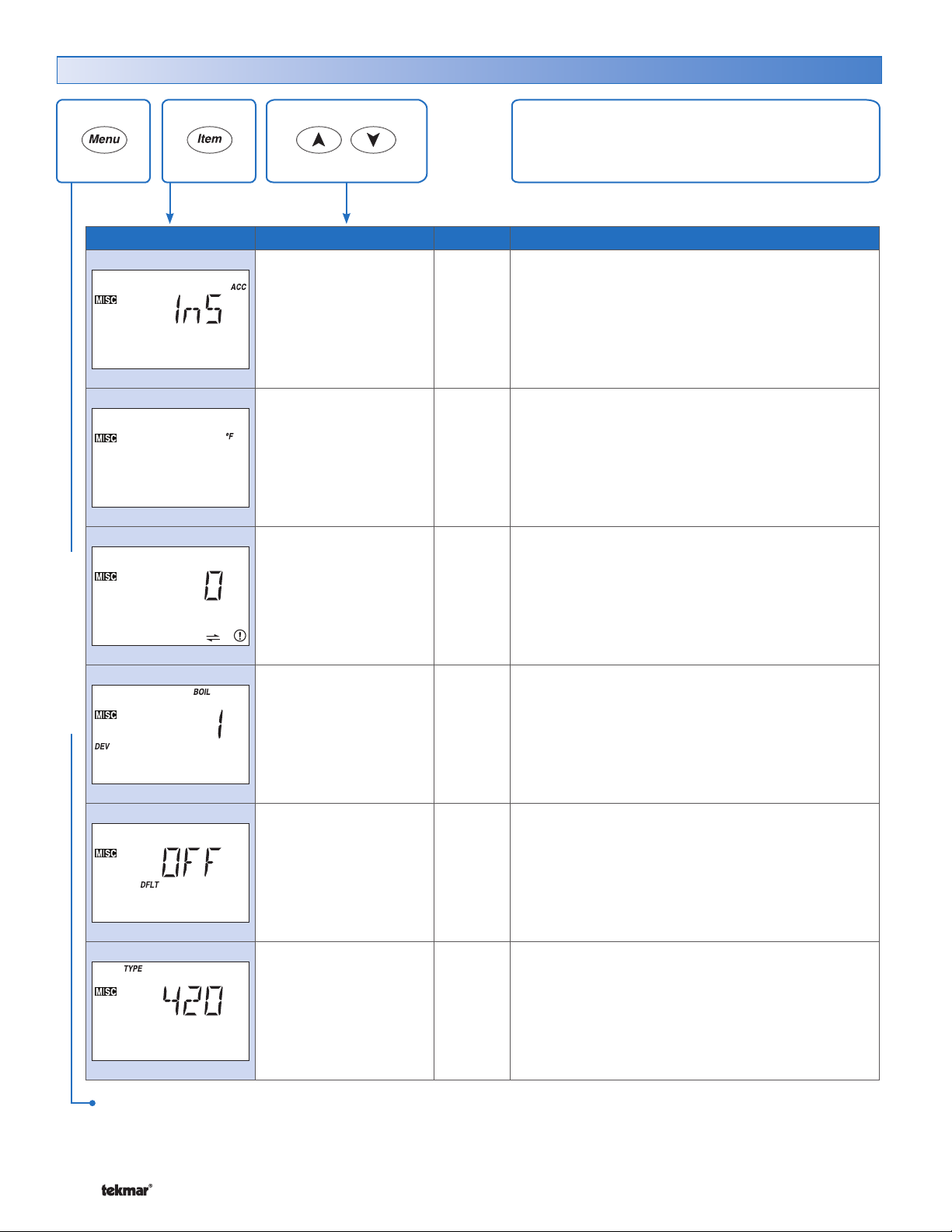

Set the DIP switch settings prior to making adjustments

to the control through the user interface. Setting the DIP

switches determines which menu items are displayed in

the user interface.

If you change a DIP switch setting while the control is

powered up, the LCD display returns to the View menu.

Lock/Unlock

Use the Lock/Unlock DIP switch to lock and unlock the Access

Level of the 420 and all connected tN4 devices, including

tN4 thermostats. For details, see “Access Levels”

• Once locked, the access level in all devices cannot be

viewed or changed.

• To determine if the control is currently locked a small

segment representing a padlock is viewed in the bottom

right hand corner of the display.

• To unlock the Access Level, set the DIP switch to

Unlock.

• To lock the Access Level, set the DIP switch to Lock.

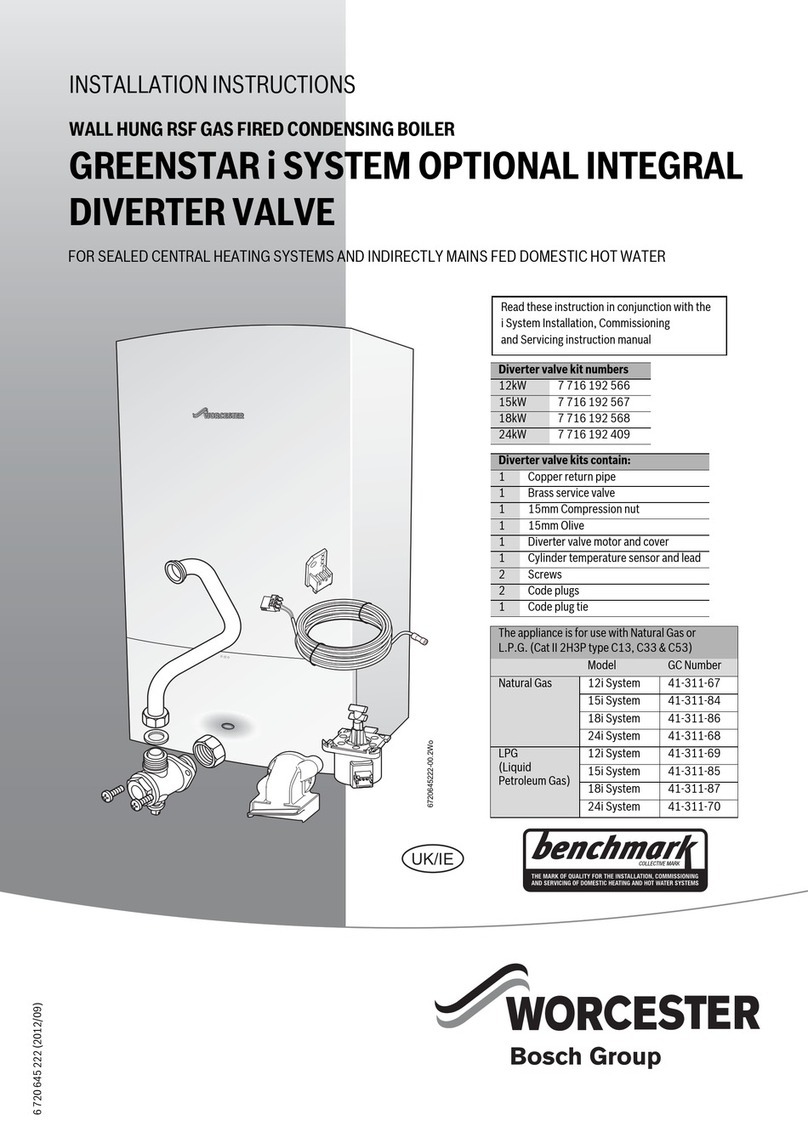

Dip Switch Settings

Display and DIP Switches

51

52 53 54 55 56 57 58 60 61 62 63 64

Boiler DHW Setpoint C

59

C Com Boil OutVlv

Demand Demand 24 V (ac) DHW

R

65

+

Mod (dc)

–

DHW Primary

10 A

max.

66 67 68 69

N

Pump NPump

tN4

H7006B

Boil On-Off / Mod

Off / tekmar Stager

PoweredOutput 1 VA

DHW Valve:

24 V (ac) 8 VA

Made in Canada

Meets Class B: Canadian

ICES & FCC Part 15

Test

Boiler Reset Module 420

Item

Menu

tektra 991-01

Demands: 20 - 260 V (ac)

Relay Rating: 115 V (ac) 5 A

/

Do not apply power

6B

Boil On-Off / Mod

Off / tekmar Stager

/