6

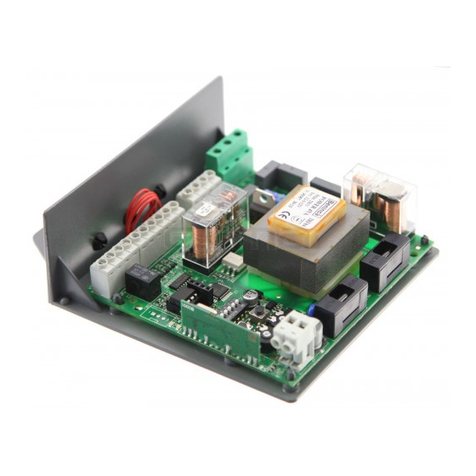

SA02M Control unit with microcontroller

The SA02M control unit with microcontroller can be used with motors having a power not exceeding 750W.

Attention: Whenever the power supply is restored and a Step-by-Step command is given to the control unit,

you must wait until the automation has completed the whole interval defined by the work time (wait until the

blinker switches off).

Installation instructions.

a) The electrical installation and functioning logic must comply with current standards.

b) Keep the power cables (for the motor and power supply) away from the control cables (buttons, photocells,

radio). To avoid interference use two separate sheaths (see EN 60204-1 15.1.3).

c) Check all the connections again before supplying voltage.

d) Check that the Dip-Switch settings are as required.

e) The Normally Closed contacts which are not in use should be short circuited.

f) If the direction of the motor rotation is not correct, invert the ”OPEN” - ”CLOSE” wires of the motor.

Input/Output functions

(1) Antenna Signal

(2) Antenna Shield

(3,8) SCA= Indicator lamp, Open gate

(4) P.P.= Input, Step-by-Step push-button (N.O. contact).

(5) Stop= Input, Stop push-button (N.C. contact).

(6) FTC= Input, photocell receiver (N.C. contact).

(7) +V= Common, all control inputs.

(8,9) OUT24VAC= Output, 24Vac auxiliary power supply (100mA max.).

(10,11) ELS.= Connection to 12V Electric lock

(12,13,14) To secondary of the Capacitor

(15,16,17) To primary of the Capacitor

(18,19) INPUT 230VAC= Control unit power supply, 230Vac, 50Hz (keep to phase/neutral).

(20,21) Lamp= Flashing light

(22,23,24) APRE/CHIUDE/COM= To relevant terminals of Motor 2, at 230Vac, 50Hz.

It is mandatory to connect the Ground wire (yellow/green) on the motor frame.

(24,25,26) COM/APRE/CHIUDE= To relevant terminals of Motor 1 at 230Vac, 50Hz.

It is mandatory to connect the Ground wire (yellow/green) on the motor frame.

If the control for the pedestrian entrance is to be used, connect the normally open (N.O.) button between the +V

input (common of controls) and the pin between P.P. and STOP.

The control unit is equipped with a built-in radio module for the reception of both fixed code and variable code

remote controls at a frequency of 433.92MHz.

To use a remote control its data should be stored in the unit memory. This procedure is shown hereunder. The

unit is able to memorize up to 14 different codes.

Dip-switch functions

DSW1 The operation of the “Step-by-Step button” and the remote control can be selected with this Dip-

Switch.

Off= ”OPEN” - ”STOP” - ”CLOSE” functioning

On= ”OPEN” - ”CLOSE” - ”OPEN” functioning.

DSW2 This enables or disables the automatic closure.

Off= Automatic closure disabled

On= Automatic closure enabled

DSW3 It enables or disables the multi-flat function.

Off= Multi-flat function disabled

On= Multi-flat function enabled

DSW4 It enables or disables the forewarning flashing light.

Off= Forewarning flashing disabled

On= Forewarning flashing enabled

Trimmer functions

TCA This allows the automatic closure time to be adjusted when this is enabled by positioning the DSW2

Dip-switch on ON.

Adjustment can be from a minimum of 1 to a maximum of 250 seconds.

The minimum time is obtained by rotating the trimmer completely anticlockwise.

TL This allows the working time of the automation to be adjusted. If the limit switches fail, the software