Page 8 of 52

· Direct thermal printing

· Interfaces : Serial or parallel

· Auto Cutter : full cut/partial cut under software control is standard

· All metal construction

· Adjustable paper low sensor

· Paper auto load function

· ESC/POS Ò[1] The commands conform to ESC/POS

· Print speed of up to 80 mm/sec (3.1 in/sec); 640 dot lines/second)

· LEDs visible and DIP switches accessible without removing cover

· Paper capacity : 152 mm (6 in) diameter roll with 50 mm diameter core

· Overall size including 152 mm (6 inch) diameter roll of paper :

• MTP-2222: 163 mm x 115 mm x 231 mm(6.4"H X 4.5"W X 9.1"D)

• MTP-2232/2242: 163 mm x 170 mm x 231 mm(6.4"H X 6.7"W X 9.1"D)

· International character set : U.S.A., France, Germany, England, Denmark (2 choices), Sweden, Italy, Spain (2

choices), Japan, Norway, Latin America and Korea

· Barcode embedded symbologies: UPC-A, UPC-E, EAN 13, EAN 8, 3of 9. ITF, CODABAR, and Code 128

· Two resident font sizes

· Code pages 437, 850, 858, 860, 863, 865, and WPC 1252.

· Bit image mode

· Reverse video mode

· Black mark sensing (TOF mode)

1.3 Options for the MTP-2200 Series

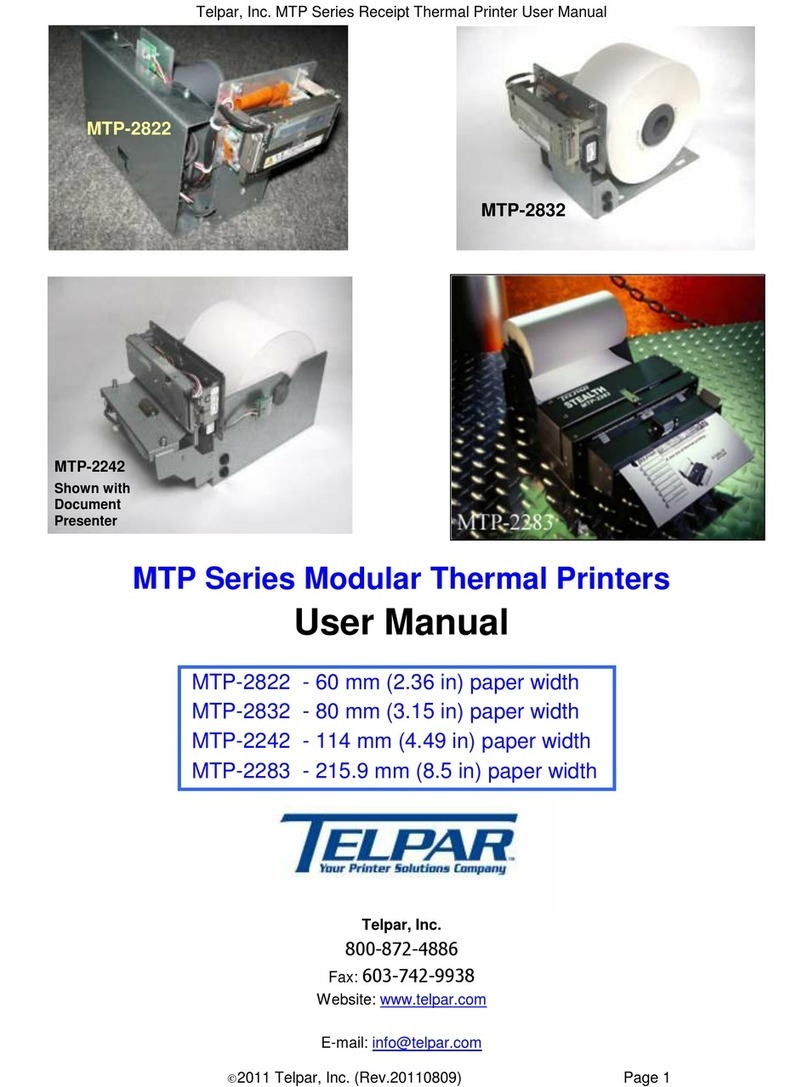

· Paper width :

• 60 mm (2.36 in) – MTP-2222

• 85 mm (3.35 inch) – MTP-2232

• 114 mm (4.49 in) – MTP-2242

· Microsoft®Windows®driver [2]

· Document Presenter (-P option)

· FLASH memory , 512Kbytes (F5 option)

· PAGE memory (RAM), 1Mbyte (P1 option)

1.4 General Specifications

· Resolution : 8 dots/mm (203 dots/in)

· Paper thickness : 0.06 mm to 0.10 mm maximum (.0024 in to .0039 in)

· Operating temperature : 5o C to 40o C (41o F to 104o F)

· Storage temperature : -20o C to 60o C (-4o F to 140o F)

· Operating humidity : 20-85% RH (non-condensing)

· Weight : Standard configuration without paper 2.0 kg (4.5 lbs.)

· Expected life of mechanism: 50 km minimum due to wear

· Expected life of cutter: 3 x 105cuts for the MTP-2242, 5 x 105cuts for the MTP-2222 and MTP-2232

1.5 Safety / Agency Information

Information Technology Equipment IEC 950

Product Safety: UL 1950 / EN60950

EMC: CFR47 / Part 15 / EN55022

File Number: 188263

Project: 00NK40431