Page <1> V1.028/03/16

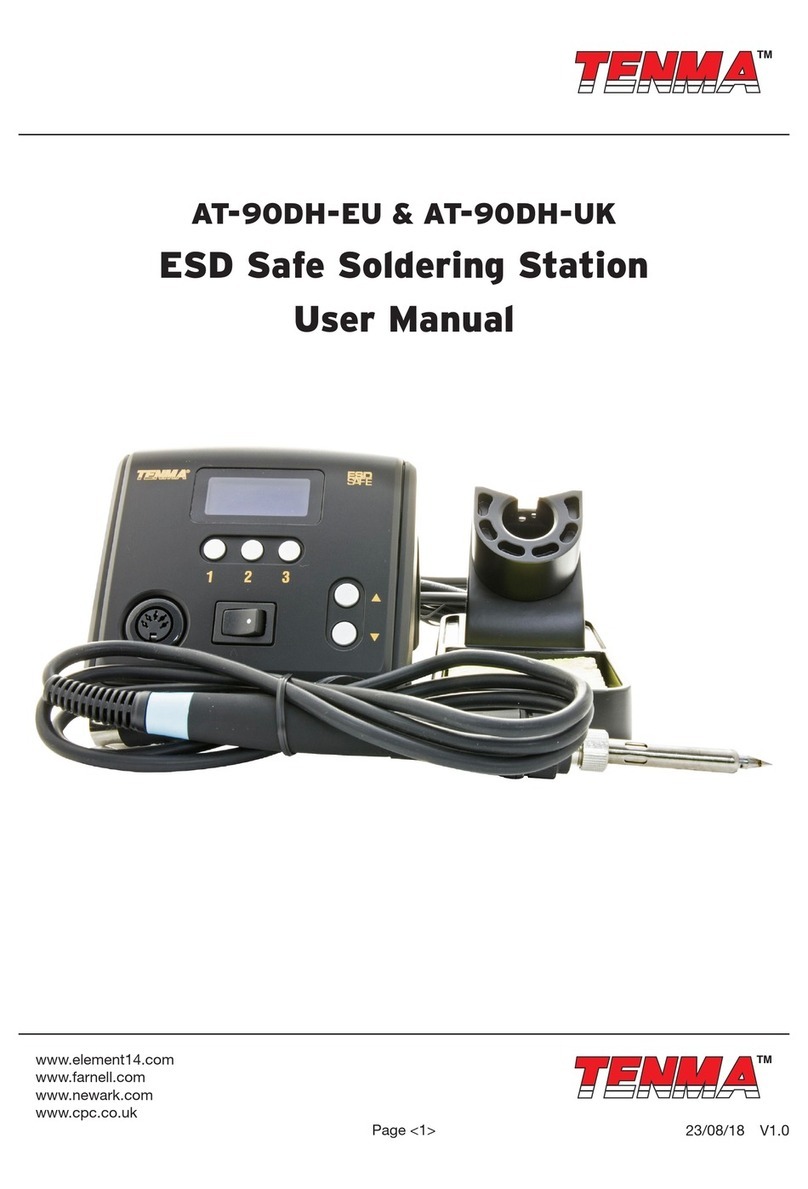

AT90DH Soldering Station

User’s Manual

AT-90DH is a soldering station which has big power consumption and is particularly designed for lead-free soldering. It is

used for SMD electronic components’ soldering and de-soldering in factory or workbench.

In this instruction manual, “Warning” and “Caution” are dened as follows.

!WARNINGS:

Warning : Use only original manufacture’s specied heating element for the included iron.

Misuse may potentially cause injury to user or physical damage to the objects involved. For your own safety, be sure to

comply with these precautions.

Caution:

• Before using this unit, make sure to comply with the cautioned measurements to protect the user against the risks of elec-

tric shock, injury, re or other damage.

• To ensure use safety, use only the original parts manufactured specially for this unit.

Non-authorized replacement parts may cause damage and void all product warranties and liabilities.

• Maintenance should only performed by a qualied technician appointed by the manufacturer. Contact your distributor for

details.

• When power is on, the tip temperature is between; 100°C (°F) and 500°C (°F)

• Since mishandling may lead to burns or re, be sure to comply with the following precautions.

• Do not touch the metallic parts near the tip.

• Do not use the product near ammable items.

• Advise other people in the work area: the unit can reach a very high temperature and should be considered potentially

dangerous.

• Turn the power off when the unit is not being used or supervised.

• Before replacing parts or storing the unit, turn the power off and allow the unit to cool down to room temperature.

• To prevent damage to the unit and ensure a safe working environment, be sure to comply with the following precautions.

• Do not use the unit for application other than soldering and de-soldering.

• Do not rap the soldering iron against the workbench to shake off residual solder, or otherwise subject the iron to

severe shocks.

• Do not modify the unit.

• Use only genuine factory replacement parts.

• Do not allow the unit to get set or otherwise subject it to liquids. Do not use with wet hands or wet surface.

• The soldering process will produce smoke, so make sure the area is well ventilated.

• When using the unit, do not do anything that may cause bodily harm or physical damage.

Packing List:

ATTEN90DH main Unit 1 unit

Iron stand (with sponge) 1 set

Soldering iron 1 pc

Power plug 1 pc

Manual 1 copy