©2001 PACE Inc., Laurel, Maryland Page 2 of 20

All Rights Reserved

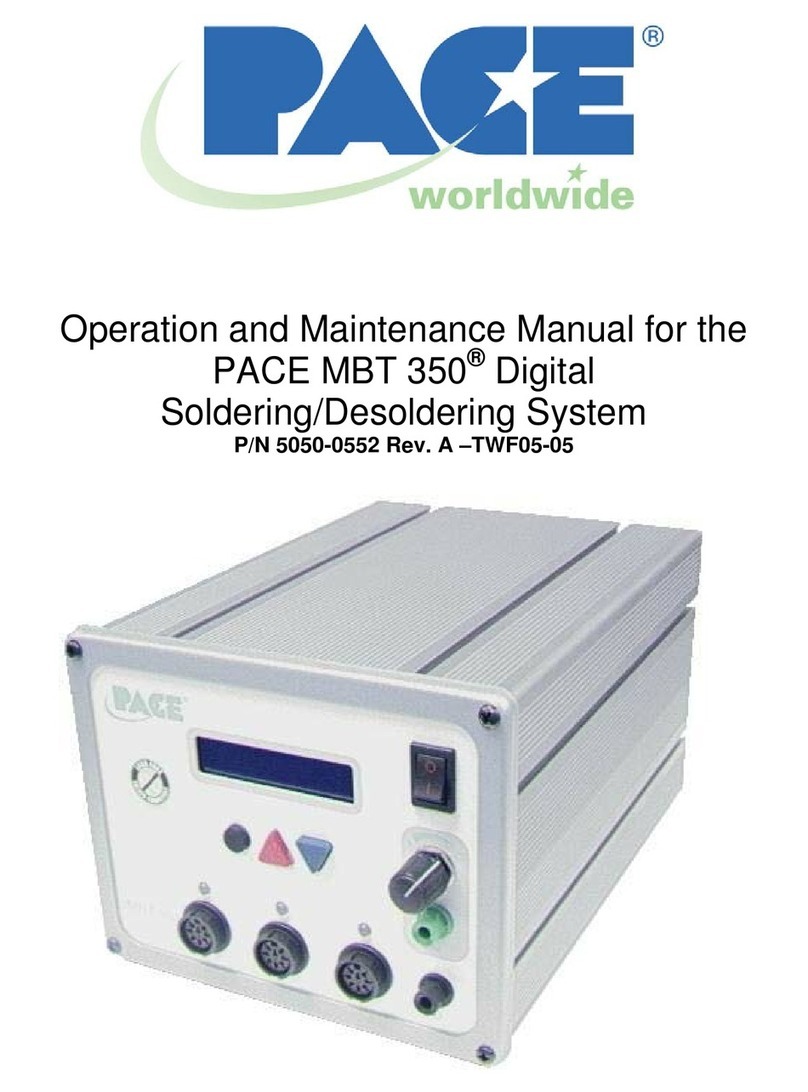

Title Page

General Information

Introduction ............................................................................................................. 3

Specifications..........................................................................................................3

Parts Identification .................................................................................................. 3

Safety..............................................................................................................................

Safety Guidelines, English Language.....................................................................4

Safety Guidelines, French Language .....................................................................4

Safety Guidelines, German Language.................................................................... 4

Safety Guidelines, Italian Language.......................................................................5

Safety Guidelines, Portuguese Language..............................................................6

Safety Guidelines, Spanish Language....................................................................6

Safety Guidelines, Swedish Language...................................................................7

System Set-Up

Mounting Options....................................................................................................8

Tip & Tool Stand ..................................................................................................... 8

Handpiece Connection............................................................................................ 8

System Power Up..........................................................................................................9

Heater Burn In...............................................................................................................9

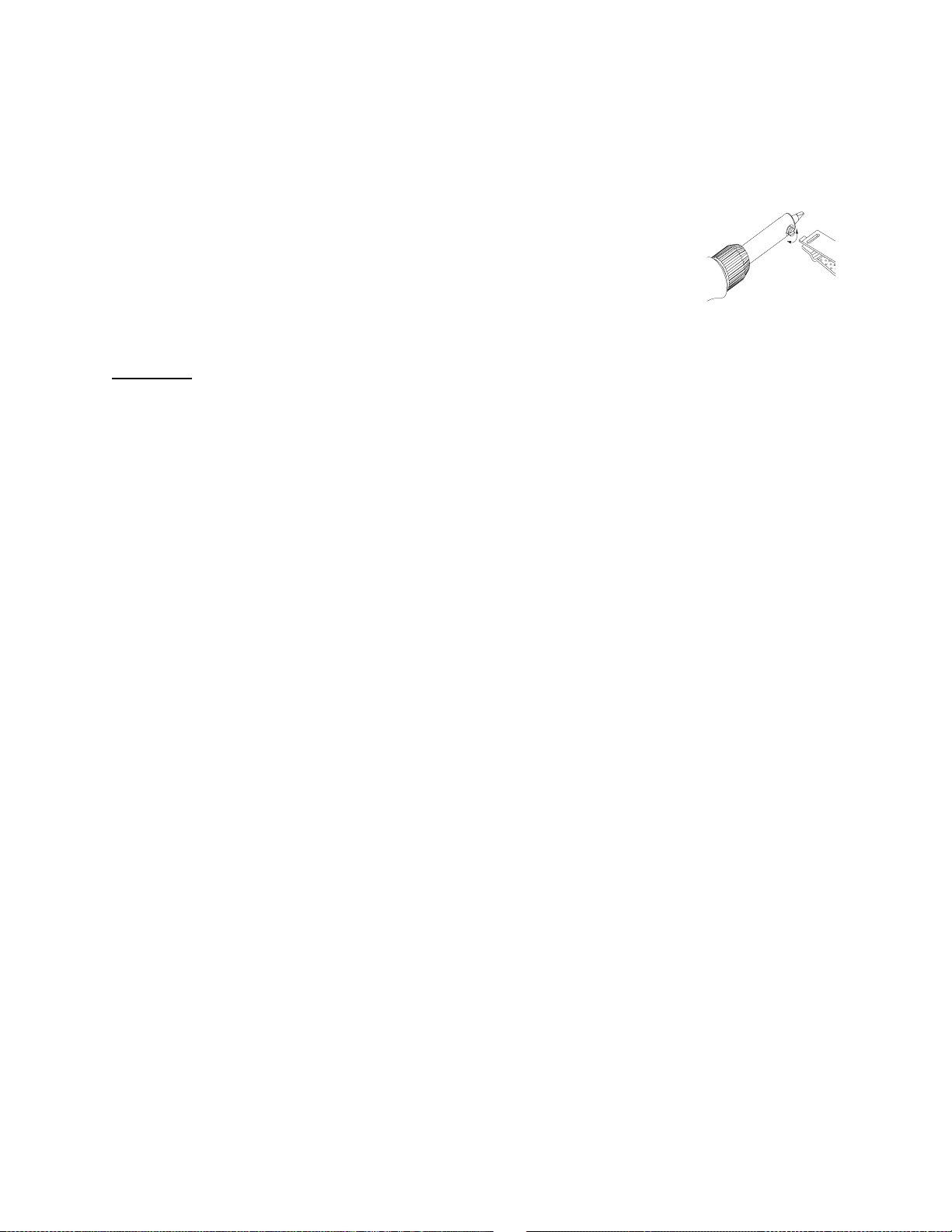

Tip Installation ..............................................................................................................10

Definitions.....................................................................................................................10

Quick Start Procedure.................................................................................................. 11

Operation......................................................................................................................11

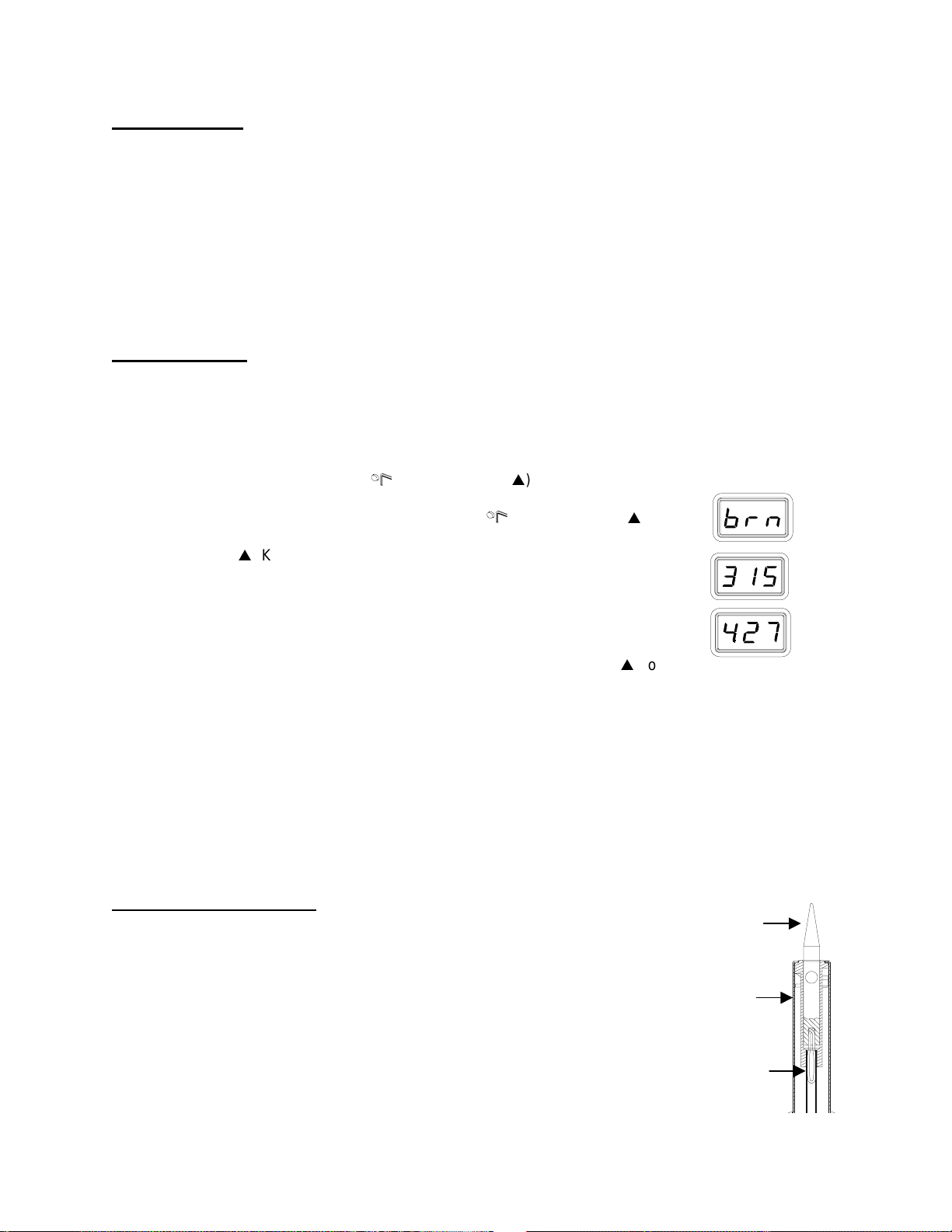

LED Display, Normal Operation...................................................................................12

LED Display - Temperature Adjust Mode..................................................................... 12

Temperature Setback...................................................................................................13

Auto Off Safety System................................................................................................13

Customizing Your System

Introduction ............................................................................................................ 14

Entering Set-Up Mode ...........................................................................................14

Password ...............................................................................................................14

Temperature Scale ................................................................................................14

Temperature Limits................................................................................................14

Offset Constant......................................................................................................15

Temperature Setback ............................................................................................15

Auto Off..................................................................................................................15

Temperature Display Impedance........................................................................... 16

Exiting Set-Up Mode..............................................................................................16

Factory Settings............................................................................................................16

Corrective Maintenance

System Accuracy and Calibration..........................................................................16

LED Display Message Codes................................................................................16

Power Source.........................................................................................................17

Handpieces............................................................................................................17

PS-90 Heater Replacement...................................................................................18

Packing List/Spare Parts..............................................................................................18

Service..........................................................................................................................19

Limited Warranty .......................................................................................................... 19

Contact Information......................................................................................................20