18

To test if the heating element of the soldering iron is in working

condition:

Let whole assembly cool down to room temperature and unplug from

electricalsourcesbeforecontinuingthetestsbelow:

1. Followdisassemblingthehandpieceguide.

2. DothefollowingtestsonthehandpiecePCBboard:

Resistancevalueofheatingelement(RED)1923Ω

Resistancevalueofsensor(blue)1.2—3Ω

Note:resistancevalueofsensormayvaryaccordingtoambient

temperature

Aftertestingcheckresultswiththefollowing:

●If the resistance value is not as stated above replace the heating

element.

●Ifa0Ωorinfiniteresistancesaremeasuredcheckforshortsoropen

circuits.

●Itermittent readings can also be caused by cold solder double check

solderpointsiftheheatingelementhasrecentlybeenreplaced.

Theheatingelementcanbereplacedasfollows:

1. Followthestepsin“disassemblingthesolderingiron”.

2. Unsoldertheheatingelementwires(RED)andthesensorwires(blue).

3. The old heating element can now be detached from the hand piece

board.

4. Detachthemetal protectorlocatedat thebottom partof theheating

element.

5. Reattach the metal protector to the bottom part of the new heating

element.

6. PasstheNewheatingelementswires(RED)thrutheholeslocatedon

topoftheboard.

7. Soldertheheatingelement’swiresandthesensorwirestotheboard

8. SolderoneREDwireofheatingelementwithREDwireonPCB.

CAREandMAINTENANCE

7

CAUTION:Improperusagecancauseseriousinjurytopersonnel

and/orextensivedamagetoequipmentandworkingarea.Foryour

ownsafety,pleaseobservethefollowingprecautions.

●MicroprocessordrivenESDsafeequipment.

●3in1repairingsystemcombiningHotAirGun,SolderingIron,

andSmokeabsorberinonesophisticatedpackage.

●Digital control and display of hot air temperature, soldering

irontemperatureandairpressure,.

●Programmabletimer functionality from 6 to 9999 seconds for

automatingreworkingtasks.

●Userconfigurable 1 to 20minute idletoautostandby mode

(with5minutesasdefault)foradditionaldeviceprotectionand

powersaving.

●Builtin autocooling process that protects the systemand its

components from excessive heat, thereby, prolonging usage

life.

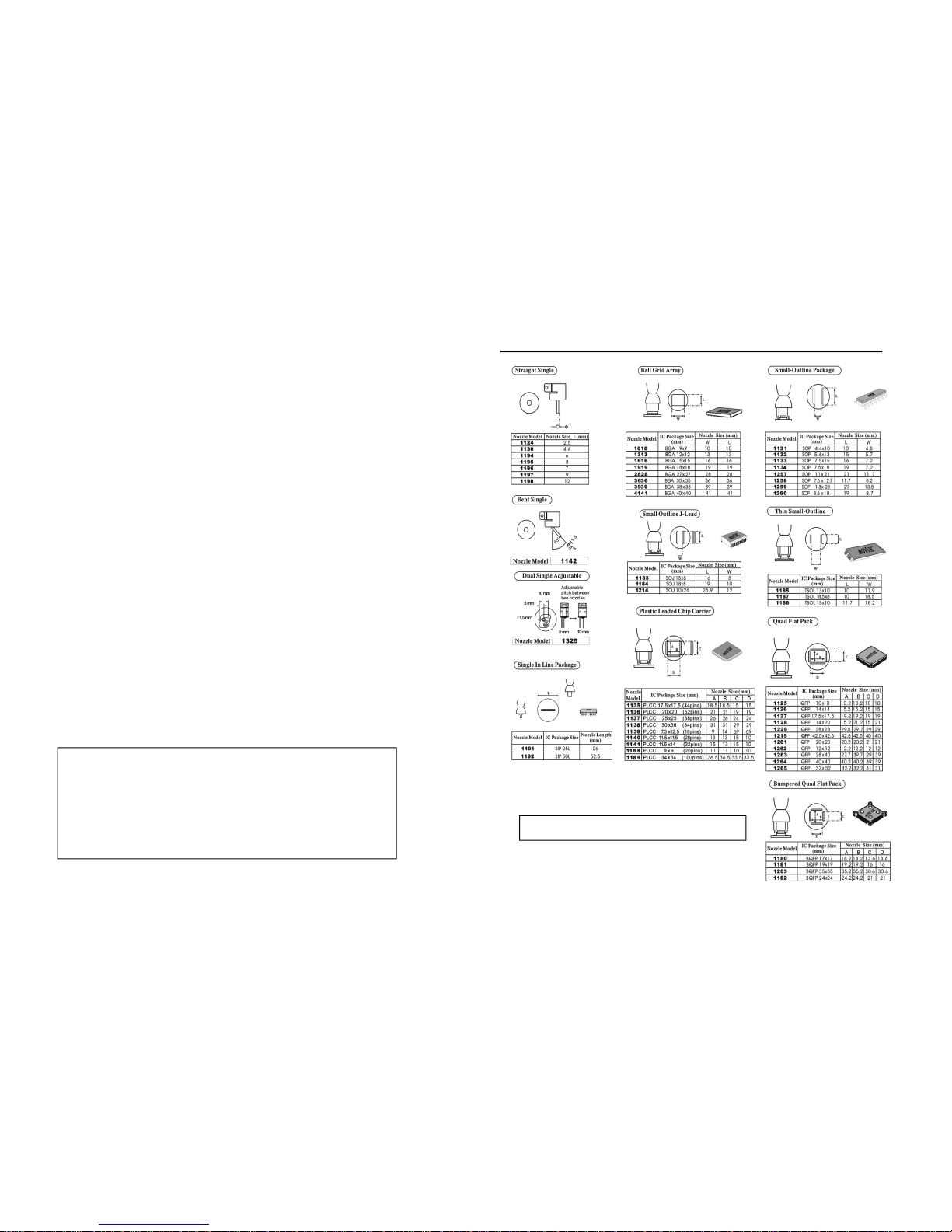

●Compatibilitywithvarioustypeofairnozzlesandsolderingiron

tips.(PleaserefertoMISCELLANEOUSsectionofthismanual.)

FUNCTIONSandFEATURES

●Check each component after opening the package to make

sureeverythingisingoodcondition.Ifthereareanysuspected

damage, don’t use the item and report the issue to your

dealer.

●Turn off power switch and unplug the unit from the mains

power source when moving the equipment fromone location

toanother.

●Donotstrikeorsubjecttheequipment(oritscomponents)to

physicalshock.Usecarefullytopreventdamageonanyparts.

●Makesuretheunitisalwaysgrounded.Alwaysconnectpower

toagroundedreceptacle.

SAFETYPRECAUTIONS