CONTENTS

1

T12 9009918 (1−2016)

CONTENTS

Page

IMPORTANT SAFETY INSTRUCTIONS −

SAVE THESE INSTRUCTIONS 4.........

OPERATION 7.

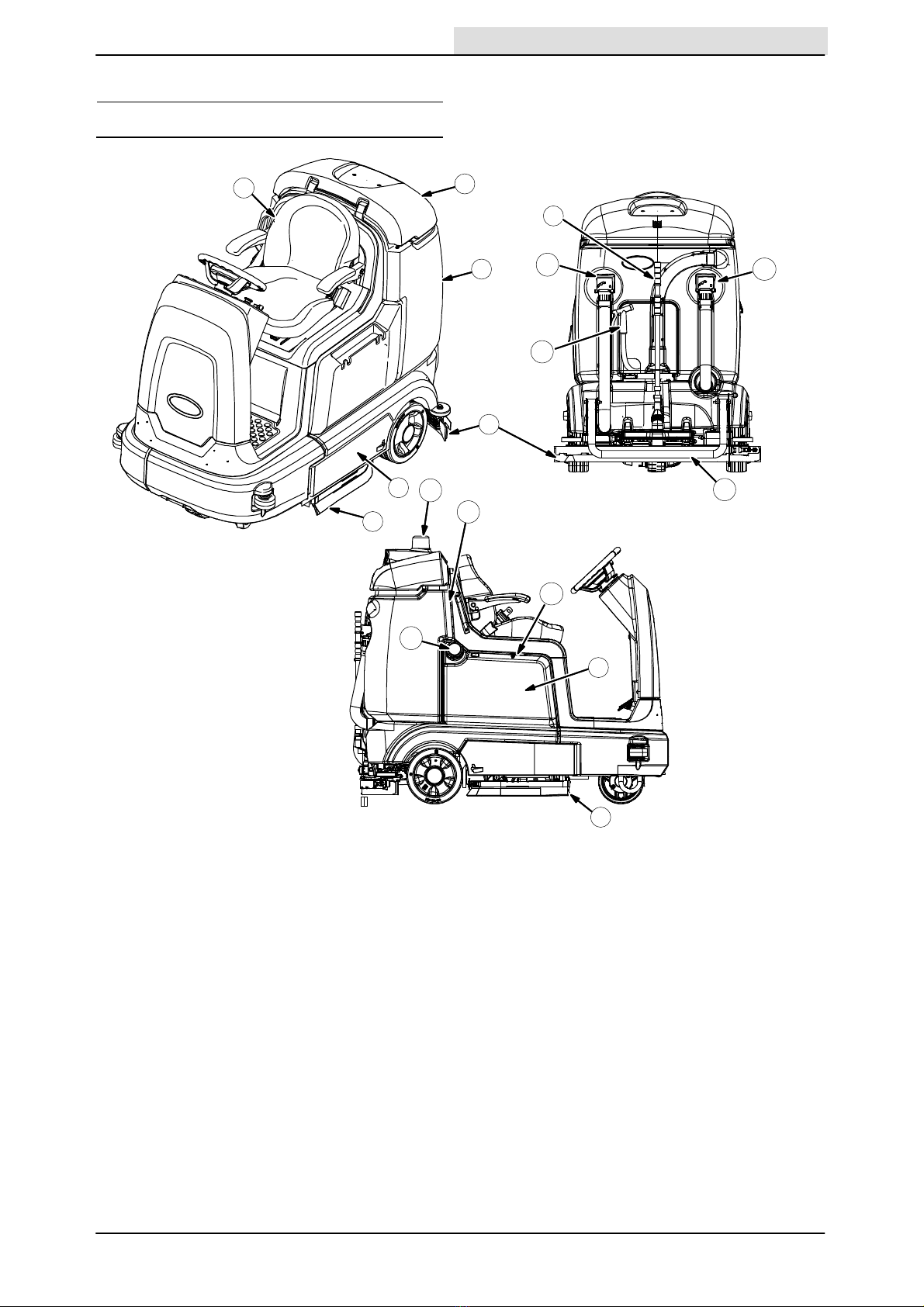

MACHINE COMPONENTS 7.............

CONTROLS AND INSTRUMENTS (T12) 8.

TOUCH PANEL (T12) 9..................

CONTROLS AND INSTRUMENTS

(T12XP) 10

TOUCH PANEL (T12XP) 11...............

SYMBOL DEFINITIONS 12................

INSTALLING BATTERIES 13..............

OPERATION OF CONTROLS 14..........

BATTERY DISCHARGE INDICATOR 14.

HOUR METER 14.....................

RECOVERY TANK FULL INDICATOR 14.

EMERGENCY SHUT−OFF BUTTON 15.

OPERATING / HAZARD LIGHT SWITCH

(OPTION) 15......................

OPERATOR SEAT 16..................

SEAT BELTS (Deluxe Seat Option Only) 16

SEAT SUPPORT 16...................

CONTRAST CONTROL BUTTON 17....

CONFIGURATION MODE BUTTON 17..

PROPEL PEDAL 17...................

DIRECTIONAL SWITCH 17............

BRAKE PEDAL 17....................

VACUUM FAN / SQUEEGEE BUTTON 18

SOLUTION ON / OFF BUTTON 18......

HOW THE MACHINE WORKS 18..........

BRUSH AND PAD INFORMATION 19......

WHILE OPERATING THE MACHINE 20....

PRE−OPERATION CHECKLIST 20.........

STARTING THE MACHINE 21.............

FILLING THE SOLUTION TANK 21........

ec−H2O SCRUBBING (ec−H2O MODE) 21

CONVENTIONAL SCRUBBING MODE 22

ec−H2O BUTTON (OPTION) 22...........

SETTING BRUSH PRESSURE 23.........

SETTING SOLUTION FLOW 23...........

SCRUBBING 24.........................

DOUBLE SCRUBBING 25.................

WATER PICKUP MODE

(NO SCRUBBING) 26..................

STOP SCRUBBING 26...................

DRAINING AND CLEANING THE

RECOVERY TANK 27.................

DRAINING AND CLEANING THE

SOLUTION TANK 29..................

TURN OFF THE MACHINE 30.............

FAULT INDICATOR(S) 31.................

WARNING CODES 32....................

OPTIONS 33.

SPRAY NOZZLE (OPTION) 33..........

VACUUM WAND (OPTION) 34..........

REAR SQUEEGEE GUARD (OPTION) 35

SIDE BRUSH (OPTION) 36............

ADJUSTING BACKUP ALARM VOLUME

(OPTION) 36.........................

MACHINE TROUBLESHOOTING 37.......

Page

MAINTENANCE 40.........................

MAINTENANCE CHART 40...............

YELLOW TOUCH POINTS 42.............

LUBRICATION 42........................

STEERING CHAIN (T12XP ONLY) 42...

STEERING GEAR CHAIN 42...........

REAR SQUEEGEE CASTERS 42.......

BATTERIES 43

CHECKING THE ELECTROLYTE LEVEL

(WET / LEAD ACID

BATTERIES ONLY) 43...........

CHECKING CONNECTIONS /

CLEANING 43.....................

GEL BATTERIES 43...................

CHARGING THE BATTERIES

(OFF−BOARD CHARGER) 44.......

BATTERY WATERING SYSTEM

(OPTION) 45......................

CIRCUIT BREAKERS 46..................

ELECTRIC MOTORS 47.................

SCRUB BRUSHES 48....................

DISK BRUSHES AND PADS 48.........

REPLACING DISK BRUSHES OR

PAD DRIVERS 48..................

REPLACING DISK SCRUB PADS 49....

CYLINDRICAL BRUSHES 50...........

REPLACING CYLINDRICAL SCRUB

BRUSHES 50......................

SIDE BRUSH (OPTION) 51...............

REPLACING THE SIDE BRUSH 51.....

SQUEEGEE BLADES 52.................

REPLACING (OR ROTATING) THE

REAR SQUEEGEE BLADES 52......

LEVELING THE REAR SQUEEGEE 55..

ADJUSTING THE REAR SQUEEGEE

BLADE DEFLECTION 56............

REPLACING OR ROTATING THE SIDE

SQUEEGEE BLADES 57............

REPLACING OR ROTATING THE

SIDE BRUSH SQUEEGEE BLADES

(OPTION) 58....................

SKIRTS AND SEALS 60..................

RECOVERY TANK SEAL 60............

SCRUB HEAD SKIRTS (DISK SCRUB

HEADS ONLY) 60..................

BELTS 60.

CYLINDRICAL BRUSH DRIVE BELTS 60

TIRES 60.

PUSHING, TOWING, AND TRANSPORTING

THE MACHINE 61.....................

PUSHING OR TOWING THE MACHINE 61.

TRANSPORTING THE MACHINE 61.......

MACHINE JACKING 63...................

ec−H2O MODULE FLUSH PROCEDURE 64

STORAGE INFORMATION 66.............

FREEZE PROTECTION 66.............

PREPARING THE MACHINE FOR

OPERATION AFTER STORAGE 68..

PRIMING THE ec−H2O SYSTEM 70.......