1Introduction

The purpose of this document is to give guidelines for use and integration of the TeraRanger

Evo Thermal sensors with (a) UART backboard, and/or (b) USB backboard using these

standard communication interfaces.

1.1 About TeraRanger Evo Thermal

TeraRanger Evo Thermal is the thermographic addition to the TeraRanger Evo sensor

family. It provides a 32x32 pixel resolution in a compact and affordable design, available in 2

versions.

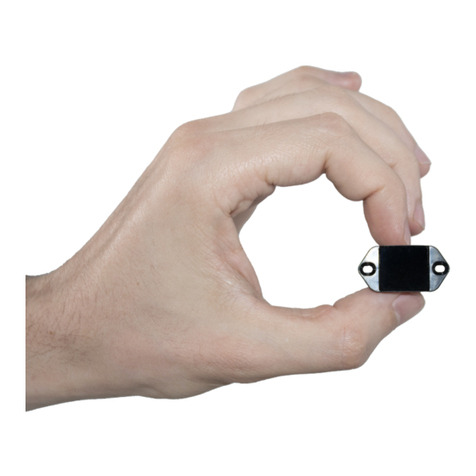

Figure 1. TeraRanger Evo Thermal two versions

Evo Thermal 90 benefits from a wide 90 degree Field-of-View for monitoring larger areas.

The sensor also has a smaller and lighter design (10 grams).

Evo Thermal 33 offers longer range, higher sampling rate (14Hz) and a more detailed

thermal image because of the narrower Field-of-View.

By using passive infrared thermal technology, Evo Thermal sensors operate in a broad

range of conditions including indoors, outdoors, sunlight, complete darkness and poor

visibility. Because thermal data does not reveal identity, personal privacy is at all times

protected.

To learn more about sensor technical specifications, please see TeraRanger Evo Thermal

Specification sheet.

2Mechanical integration

The mechanical design of the main sensor module (black) allows easy assembly to its

backboard (yellow) using a simple ‘clip-in’ technique. When you clip the two together, ensure

there is no visible gap between the black and yellow parts. The yellow backboard has two

mounting holes for final installation. Please reference Figure 2 for visual instructions.

Copyright © Terabee 2018

Terabee, 90 Rue Henri Fabre

01630, St Genis-Pouilly, France (next to CERN)

3/20