Table of contents:

1 Introduction 3

2 Mechanical Integration 3

2.1 Mechanical Design 3

2.1 Compatibility with TeraRanger Evo sensors 4

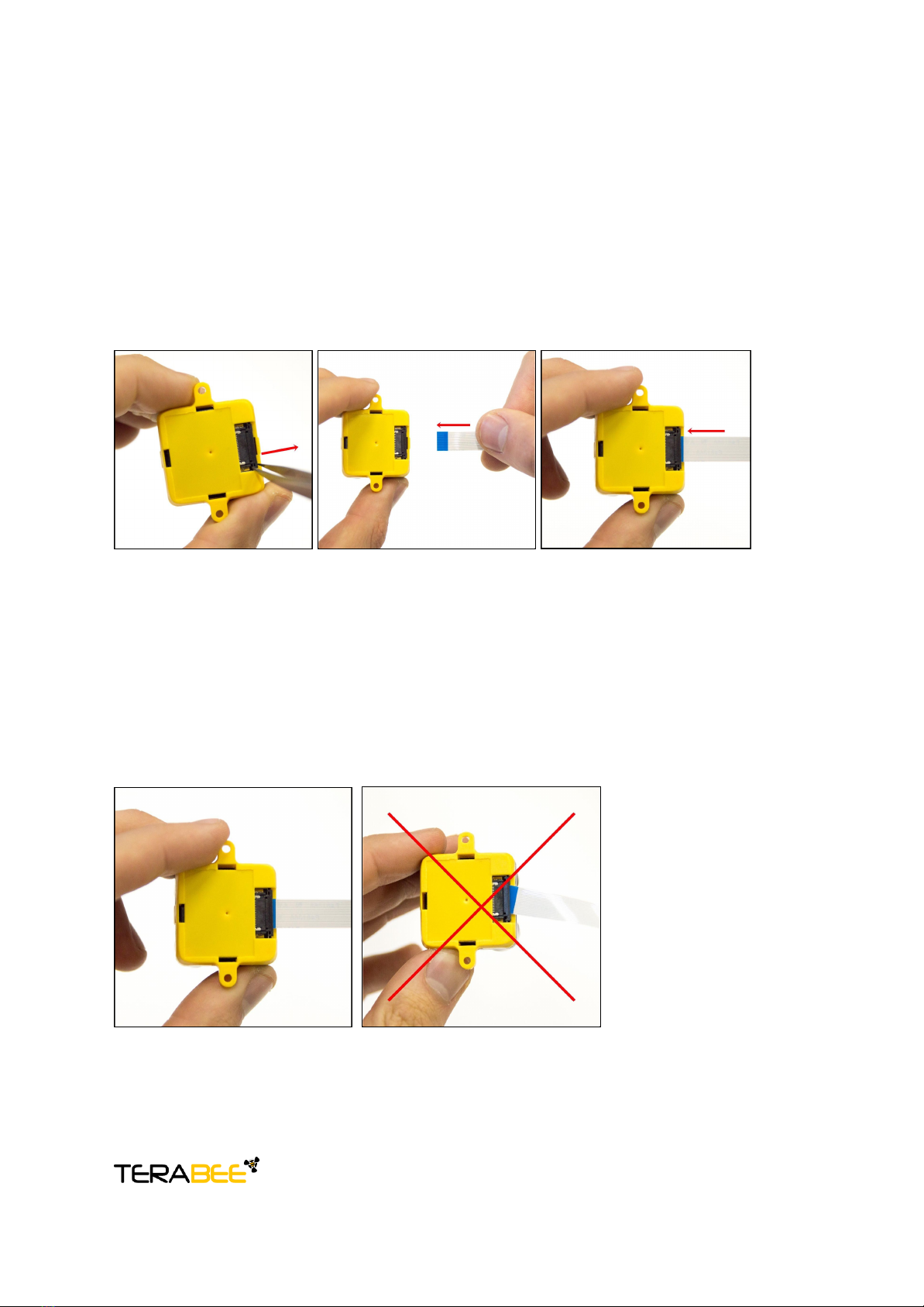

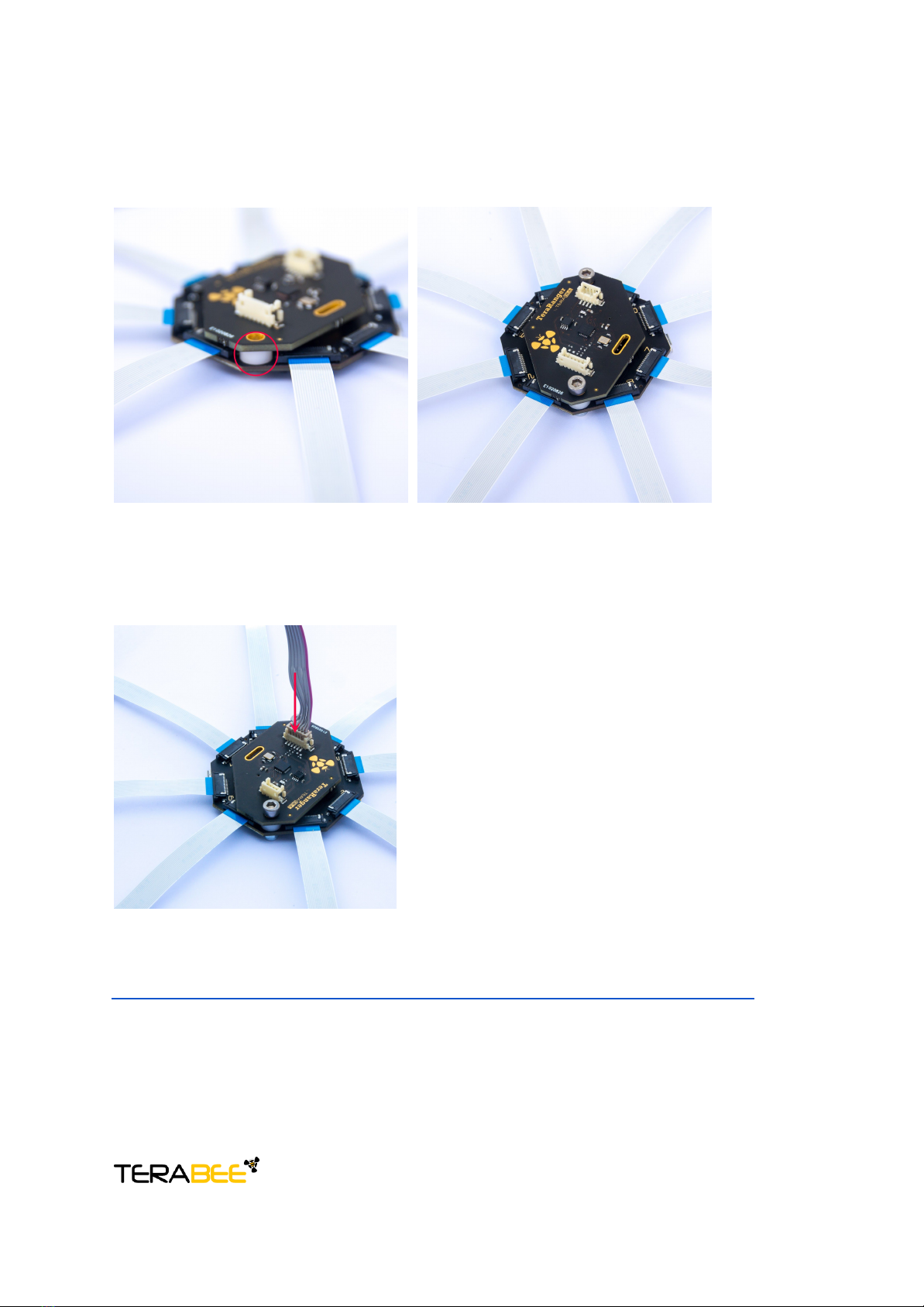

2.2 Handling during system assembly 6

2.3 Electrical characteristics 10

2.4 Additional interface for custom requirements 10

3 USB interface 11

3.1 Graphical User Interface 11

3.1.1 Basic Operation 11

3.1.1 Firmware Upgrade 12

3.2 Connecting the TeraRanger Hub Evo to a Host Computer 13

3.2.1 Prerequisites 13

3.2.2 Terminal Emulation Software 13

3.3 LEDs 15

4 UART interface 16

4.1 Pinout information 16

4.2 UART protocol information 17

4.3 Interface for visual signalization 18

5 Communication and Modes 20

5.1 Enable / Disable Hub Evo communication 21

5.2 Printout modes 21

5.2.1 Commands 21

5.2.2 Output format 22

5.3 Operating modes 23

5.3.1 Commands 23

5.4 Output-rate rate modes 23

5.4.1 Commands 24

5.5 Visual signalization 24

5.6 Internal Measurement Unit (IMU) options 25

5.6.1 Euler mode 25

5.6.2 Quaternion mode 26

5.6.3 Quaternions and linear acceleration 26

5.6.4 Commands 27

5.6.5 Output format 27

5.7 Command validation 30

.