Teracom TSM400-4-CP User manual

TSM400-4-CP_R1.7 –November 2023 Page 2

1. Short description

TSM400-4-CP is a multi-parameter sensor that supports MODBUS RTU protocol over the RS-485

interface. The sensor measures barometric pressure and CO2concentration. The MODBUS device

integrates an advanced non-dispersive infrared sensing element (NDIR) for CO2measurements. The

measurement principle is based on the absorption of infra-red (IR) light with specific wavelengths by

CO2molecules. The CO2sensing element is temperature compensated for better accuracy. Self-

calibration is available for carbon dioxide measurements. It is done if the sensor is left in fresh (around

400 ppm CO2concentration) air.

The basic sensing element for barometric pressure is factory calibrated and it does not require any

lifetime recalibration.

The MODBUS CO2and pressure sensor TSM400-4-CP is housed in a slim plastic enclosure. The bottom

part of the enclosure is suitable for installation on standard flush-mounted/cavity wall boxes ø68mm,

with installation openings on 61 mm.

2. Features

•LED indicator for status of communication;

•Long-term stability based on digital signal processing;

•Self-calibration on fresh air for CO2measurements;

•RS-485 interface carrying up to 32 nodes;

•Changeable bitrate and other communication parameters;

•Firmware update via the interface.

3. Applications

•Indoor air quality (IAQ);

•CO2storage facilities leakage control;

•Smart ventilation systems;

•Restaurants and breweries CO2level monitoring.

4. Specifications

•Physical characteristics

Dimensions: 81 x 81 x 30mm

Weight: 66g

•Environmental limits

Operating temperature range: -20 to 60°C

Operating relative humidity range: 5 to 95% (non-condensing)

Storage temperature range: -20 to 60°C

Storage relative humidity range: 5 to 95% (non-condensing)

Ingress protection: IP20

•Power requirements

Operating voltage range (including -15/+20% according to IEC 62368-1): 4.5 to 26VDC

Current consumption: 25mA@5VDC (Peak: 150mA@5VDC)

•CO2measurements

Range: 400 to 5000ppm

Accuracy: ± (40ppm + 5%)

Resolution: 1ppm

Calibration: Manual/Automatic

TSM400-4-CP_R1.7 –November 2023 Page 3

•Pressure measurements

Range: 10 to 1200hPa

Accuracy (min): ±1.5% (25°C, 750hPa)

Accuracy (max): ±2.5% (-20°C to + 85°C, 300 to 1100hPa)

Resolution: 1hPa

•Interface

Response time ≤ 50ms

Master response time-out ≥ Response time + Answer time

The answer time depends on the number of bits and the baud rate

•Warranty

Warranty period: 3 years

5. Pinout

Pin

Description

UTP wires color

1-W

Not used

+5÷30V

Positive power supply

Brown/White Tracer

GND

Ground (negative) supply

Brown

A+

Line A+ (RS485+)

Blue/White Tracer

B-

Line B- (RS485-)

Blue

TERM

For termination, connect to B-

6. Installation

Two-Wire MODBUS definition according to modbus.org:

“A MODBUS solution over a serial line should implement a “Two-Wire” electrical interface in

accordance with EIA/TIA-485 standard. On such a “Two-Wire” topology, at any time one driver only

has the right to transmit. In fact, a third conductor must also interconnect all the devices of the bus -

the common.”

Attention:

For proper operation of the interface, terminators (120 ohms resistors) must be installed at both

ends of the bus. The device has a built-in 120 ohm resistor and to terminate the line, “B-“and

“TERM” must be shortened.

A daisy-chained (linear) topology for multiple sensors should be used. UTP/FTP cables are

mandatory for interconnection.

TSM400-4-CP_R1.7 –November 2023 Page 4

7. Installation tips

The location and the mounting position of the sensor have a direct effect on the accuracy of the

measurement. The tips below will ensure good measuring results:

•Sensor shall be installed about 1.2-1.4 m above the floor;

•To avoid solar radiation, the sensor should not be installed next to windows or directly in the

sunlight;

•Sensors shall be installed in a place with sufficient air circulation.

TSM400-4-CP sensor is intended for installation on a cavity wall box with 68mm diameter and 61

mm screw spacing.

8. Status indicator

The status of the device is shown by a single LED, located inside the box:

•If the LED blinks for a period of 1 second, the sensor works properly;

•If the LED blinks for a period of 3 seconds, there isn‘t communication with the controller;

•If the LED doesn‘t blink, there isn‘t a power supply.

9. CO2 Calibration

The device has the capability to automatically and manually calibrate carbon dioxide

measurements. It is advised by the sensor element's manufacturer to perform calibration on a

weekly basis.

The determination of whether the calibration is done manually or automatically depends on the

information stored in MB register with PDU address 2002.

The automatic self-calibration (ASC) feature ensures the device maintains the highest long-term

stability without requiring any manual actions from the user.

The algorithm for automatic self-calibration assumes that the sensor is exposed to an atmospheric

CO2 concentration of 400 ppm at least once per week.

TSM400-4-CP_R1.7 –November 2023 Page 5

Manual Calibration Procedure:

To manually calibrate the device, follow these steps:

•Place the device in a fresh air environment with a CO2 concentration of 400 ppm.

•While the sensor is in operation, press and hold the button.

•The “status” LED will start flashing once every second.

•After the 5th flash, the “status” LED will turn off and wait for the button to be released to

initiate calibration.

•Release the button.

•The calibration procedure will begin, indicated by the “status” LED staying continuously lit

for approximately 5 seconds.

•After a successful calibration, the “status” LED will flash 3 times in 1 second. In the case of a

failure, it will flash rapidly (15 times within a 3-second period).

•Following the calibration, the device will enter its standard operation mode.

10. Factory default settings

Disconnect the sensor from the bus (switch off the power supply).

Press and hold the “config” button. Don’t release the button, connecting the sensor to the bus

(switch on the power supply).

The “status” LED will be ON for 3 seconds and after this will flash for 7 seconds. After the 10-th

second the LED will be ON.

Release the button. The sensor will restart with factory default settings.

11. Firmware update

The firmware of the sensor can be updated with a Teracom controller which supports

MODBUS RTU or MBRTU-Update software. For more details, ask your dealer.

TSM400-4-CP_R1.7 –November 2023 Page 6

12. Modbus address table

Register name

R/W

FC

PDU

Address

(Decimal)

Logical

Address

(Decimal)

Offset

(Decimal)

Data size

Default

Valid values

RS-485 address

R/W

03/06

10

40011

40001

16-bit uns. integer

1

1-247

Baud rate*

R/W

03/06

11

40012

40001

16-bit uns. integer

19200

2400, 4800, 9600,

19200, 38400, 57600

Parity, data, stop bits *

R/W

03/06

12

40013

40001

16-bit uns. integer

1

1=E81, 2=O81, 3=N81

Data order

R/W

03/06

13

40014

40001

16-bit uns. integer

1

1=MSWF (MSW, LSW)

2=LSWF (LSW, MSW)

Device code

R

03

14

40015

40001

16-bit uns. integer

0x00C8

FW version

R

03

15

40016

40001

16-bit uns. integer

Vendor URL

R

03

18

40019

40001

64 bytes UTF-8

teracomsystems.com

Float test value (MSWF)

R

03

82

40083

40001

32-bit float

-9.9(0xC11E6666)

Float test value (LSWF)

R

03

84

40085

40001

32-bit float

-9.9(0xC11E6666)

Signed integer test value

R

03

86

40087

40001

16-bit sig. integer

-999(0xFC19)

Signed integer test value (MSWF)

R

03

87

40088

40001

32-bit sig. integer

-99999(0xFFFE7961)

Signed integer test value (LSWF)

R

03

89

40090

40001

32-bit sig. integer

-99999(0xFFFE7961)

Unsigned integer test value

R

03

91

40092

40001

16-bit uns. integer

999(0x03E7)

Unsigned integer test value (MSWF)

R

03

92

40093

40001

32-bit uns. integer

99999(0x0001869F)

Unsigned integer test value (LSWF)

R

03

94

40095

40001

32-bit uns. integer

99999(0x0001869F)

CO

2

, ppm

R

03

106

40107

40001

32-bit float

Pressure, hPa

R

03

108

40109

40001

32-bit float

CO

2

, ppm

R

03

206

40207

40001

32-bit float

Pressure, mmHg

R

03

208

40209

40001

32-bit float

CO

2

, ppm

R

03

603

40604

40001

16-bit uns. integer

Pressure, hPa

R

03

604

40605

40001

16-bit uns. integer

CO

2

, ppm

R

03

703

40704

40001

16-bit uns. integer

Pressure High-Word, mmHg x 100

R

03

704

40705

40001

16-bit uns. integer

Pressure Low-Word, mmHg x 100

R

03

705

40706

40001

16-bit uns. integer

Automatic self-calibration (ASC)

R/W

03/06

2002

42003

40001

16-bit uns. integer

0

0-disable, 1-enable

CO

2

multiplier **

R/W

03/16

2115

42116

40001

32-bit float

1.000

CO

2

offset **

R/W

03/16

2117

42118

40001

32-bit float

0.000

Pressure multiplier **

R/W

03/16

2119

42120

40001

32-bit float

1.000

Pressure hPa offset **

R/W

03/16

2121

42122

40001

32-bit float

0.000

Pressure mmHg offset **

R

03

2123

42124

40001

32-bit float

0.000

The shown logic decimal addresses are calculated with offsets 40001 (holding registers).

MSWF - Most significant word first - (bits 31 … 16), (bits 15 … 0); LSWF - Least significant word first - (bits 15 … 0), (bits 31 … 16);

PDU address - Actual address bytes used in a Modbus Protocol Data unit

When a floating-point value is not available, the returned value is “NaN” (e.g. in case of measurement error).

When a 16-bit signed integer value is not available, the returned value is “-32768” (e.g. in case of measurement error).

* The settings will take effect after restarting the device by power-off, power-on.

** Measured sensor values can be corrected by employing a multiplier and an offset.

The corrections are the results of the following calculations:

Corrected CO2= Measured CO2× CO2Multiplier + CO2Offset

Corrected Pressure (hPa) = Measured Pressure (hPa) × Pressure Multiplier + Pressure Offset (hPa)

Using a multiplier and an offset allows precise adjustments to the sensor readings, ensuring accurate CO2and pressure values.

After obtaining the corrected pressure in hPa, it can then be converted to mmHg.

13. Recycling

Recycle all applicable material.

Do not dispose of with regular household refuse.

Table of contents

Other Teracom Security Sensor manuals

Popular Security Sensor manuals by other brands

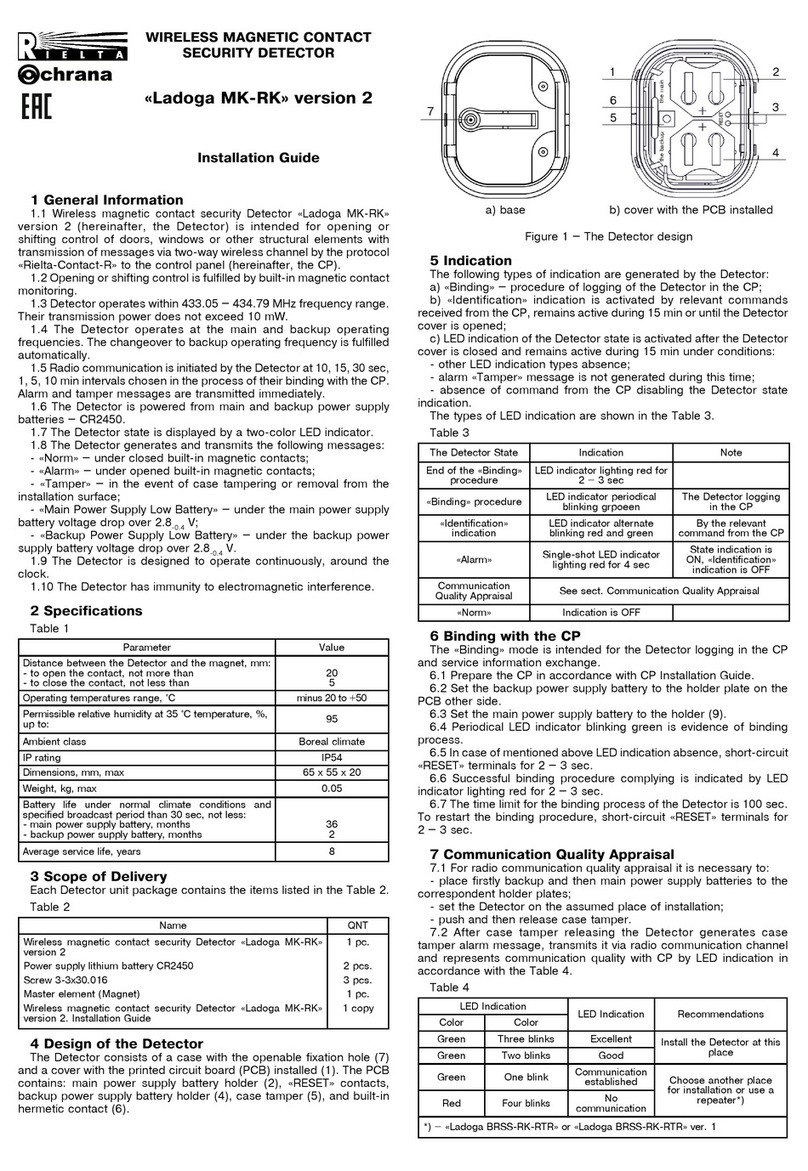

Rielta

Rielta Ladoga MK-RK version 2 installation guide

PCB Piezotronics

PCB Piezotronics ICP 113A22 Installation and operating manual

Wenglor

Wenglor P1KK008 operating instructions

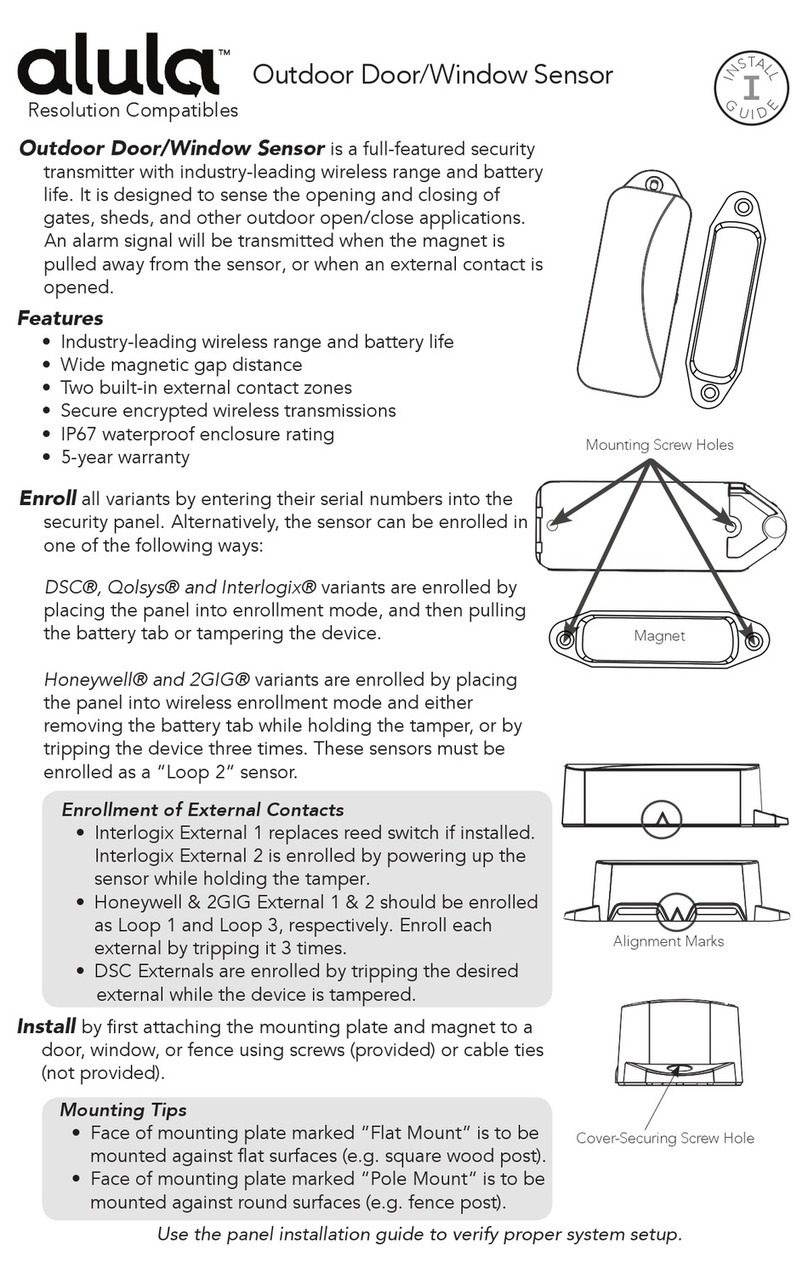

Alula

Alula RE307 manual

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL IR 180 Information

Sun Microsystems

Sun Microsystems FI316 user manual