Teral LHW-e User manual

Model : LHW-e/LPW-e/LPW-7W/ LKW-e

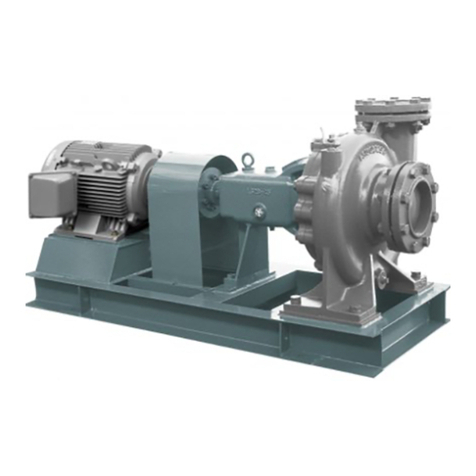

LFE/LFE-e

Coolant Pump

Coolant Pump

Instruction Manual

I

Limited warranties

1. In the event of a failure or breakage under proper use of the product during the warranty period,

equipment supplied by Teral Inc. shall be repaired or replaced free of charge within the scope of the

relevant part, provided that such failure or breakage is attributable to inadequacy of the design or

workmanship of the equipment.

The warranty period of this product shall be one year after the date of delivery.

2. The warranty mentioned in the above clause shall be only the mechanical warranty of the defective part,

and shall not cover any expenses or other damage arising from the failure or breakage.

3. In the event of the following failures and breakage, the costs of the repairs shall be borne by the user.

(1) Failures and breakage attributable to equipment that was not delivered by Teral Inc.

(2) Failures and breakage after the expiration of the warranty period

(3) Failures and breakage caused by disasters or force majeure, such as fire, acts of God, or

earthquakes

(4) Failures and breakage resulting from repairs or modifications made without the consent of Teral

Inc.

(5) Failures and breakage when parts other than those designated by Teral Inc. are used

(6) Failures and breakage caused by use or storage outside the specification range

4. Teral Inc. shall not be liable for the damage caused by incorrect or reckless use of the pump. Cost and

expenses incurred for sending engineer(s) in such a case shall be borne by the user.

5. If the cause of the failure is unclear, necessary actions shall be determined through mutual

consultation.

<Chargeable repair>

Investigation and repair work after the warranty period shall become chargeable. For any failures that have

occurred within the warranty period but that fall outside the above-mentioned warranty coverage, Teral Inc.

shall carry out repairs and investigation for a fee.

II

Purpose of this manual

The purpose of this manual is to provide the user with detailed information necessary to properly operate,

maintain and inspect the pump. Incorrect operation of this product may lead to an unexpected accident.

Please use the product correctly according to this instruction manual.

This manual contains the following information and is intended for persons experienced in the operation of

pumps, or for those who have been trained by such experienced operators. Only qualified personnel such

as licensed electrical engineers are allowed to carry out the electrical wiring work.

Contents (Page)

Limited warranties .................................................................................................................................... I

Purpose of this manual........................................................................................................................... II

Contents.................................................................................................................................................... II

1. Safety precautions...............................................................................................................................1-1

1.1 Types and meanings of safety signs and graphic symbols.........................................................1-1

1.2 Safety precautions.......................................................................................................................1-1

1.3 Location of warning labels and caution labels.............................................................................1-4

2. Configuration and overview of the pump.............................................................................................2-1

2.1 Part names and functions............................................................................................................2-1

2.2 Standard specifications ...............................................................................................................2-2

3. Installation ...........................................................................................................................................3-1

3.1 Before using the pump ................................................................................................................3-1

3.2 Precautions for installation..........................................................................................................3-1

3.3 Precautions for piping work.........................................................................................................3-4

3.4 Precautions for wiring work.........................................................................................................3-5

4. Operation.............................................................................................................................................4-1

4.1 Check items before test operation...............................................................................................4-1

4.1.1 Check items related to the electrical system.......................................................................4-1

4.1.2 Check items related to the pump.........................................................................................4-1

4.2 Running the pump (test operation)..............................................................................................4-2

5. Maintenance and inspection................................................................................................................5-1

5.1 Precautions for maintenance and inspection..............................................................................5-1

5.2 Replacement of the V-ring (for LPW65-e)...................................................................................5-2

5.3 Maintenance checklist.................................................................................................................5-4

6. Troubleshooting...................................................................................................................................6-1

1-1

1. Safety precautions

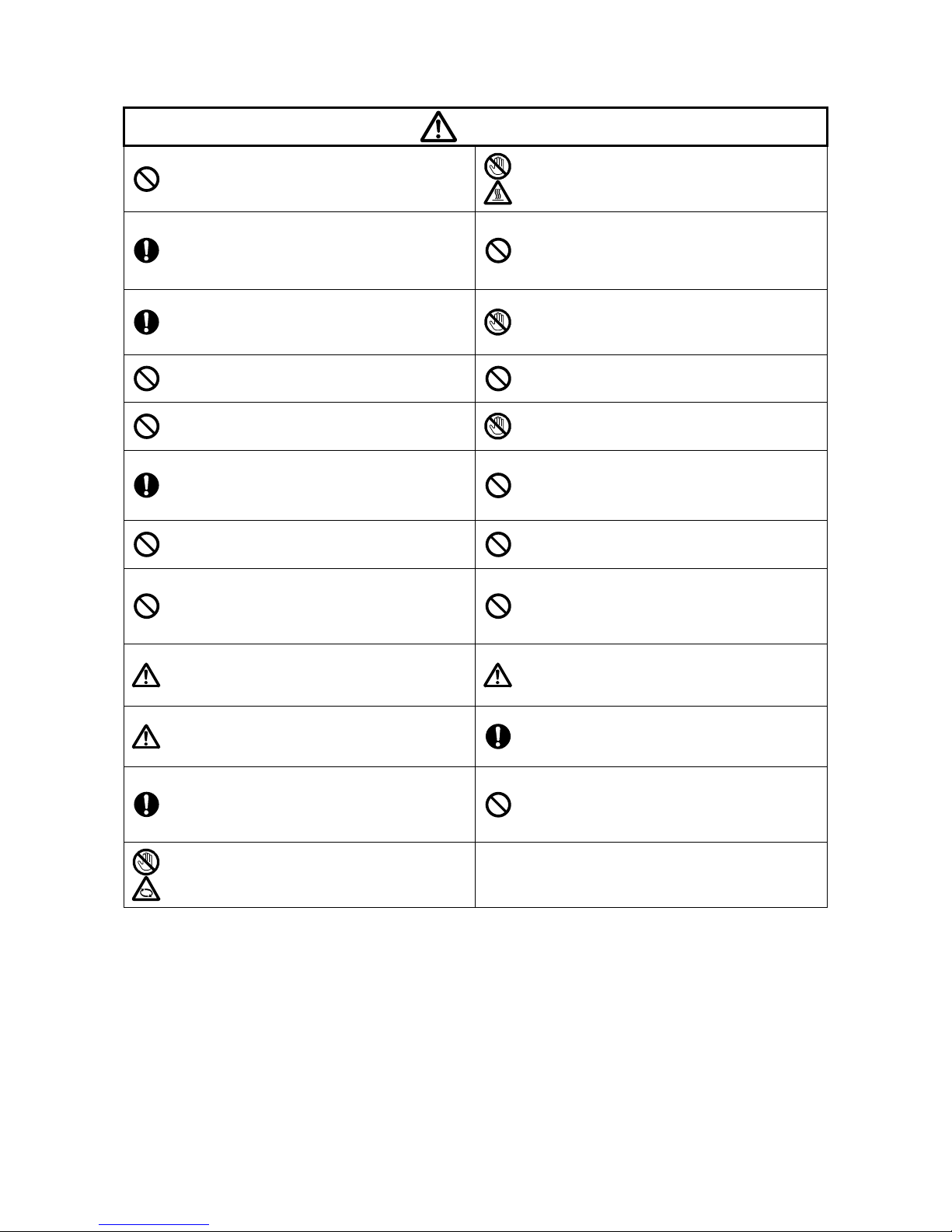

1.1 Types and meanings of safety signs and graphic symbols

This instruction manual divides precautions into the following four categories according to the level

of hazards (or the severity of the accident). In addition, prohibited or mandatory actions as well as

cautions are indicated with a graphic symbol.

Be sure to understand the meanings of the following terms and comply with the content

(instructions) of the instruction manual.

Explanation of warnings Explanation of the graphic symbols

Safety sign Meaning

Don’ts Do not touch Do not

disassemble Do not touch

with wet

hand

Do not

expose to

water

Danger

Indicates an imminently hazardous

situation. Failure to observe this will

result in death or serious injury. These graphic symbols indicate prohibited actions (that

must NOT be done).

Warning

Indicates a potentially hazardous

situation. Failure to observe this will

result in death or serious injury.

Do’s

This graphic symbol indicates mandatory

actions (that must be done).

Caution

Indicates a potentially hazardous

situation. Failure to observe this will

result in minor or moderate injury or

property damage. Caution Electric

shock hazard Rotation

hazard Hot surface

Note

Indicates information that is in

particular to be noted or emphasized. These graphic symbols indicate existing hazards to

beware of.

1.2 Safety precautions

Danger

Once the main power is turned on, do not touch any live parts.

A high voltage applied to live parts may cause a serious electric shock, thus leading to death.

Do not use the product in any explosive atmosphere.

Otherwise, it may lead to an injury or fire.

Warning

Properly move the unit according to lifting

instructions.

Otherwise, the unit may fall, thus leading to an injury or

damage.

Do not carry out any work with/on the pump that is

being lifted.

Otherwise, the unit may fall, thus leading to an injury or

damage.

Only those who are authorized by the site manager

are allowed to operate the pump.

Operation by unskilled personnel may lead to an unforeseen

accident.

Installation, maintenance, and inspection must

only be carried out by personnel who have been

trained to handle the pump.

Operation by unskilled personnel may lead to an unforeseen

accident.

Only qualified personnel, such as licensed electrical

engineers, are allowed to carry out electric work.

Otherwise, it may lead to an electric shock, fire, failure, or

other problems.

Use high-quality wiring equipment and devices,

and carry out wiring work safely and securely

according to the technical standards for electrical

facilities, as well as the indoor wiring regulations.

Otherwise, it may lead to an electric shock, fire, or other

problems.

Do not connect the ground wire to a gas pipe or

water pipe.

Such a connection is illegal and leads to an electric shock,

explosion, or fire.

Securely install the ground wire and ensure to

carry out grounding work.

Otherwise, it may lead to an electric leak or electric shock.

Do not run the unit if abnormal condition is observed

in any operation, movement, parts, etc.

Otherwise, it may lead to an injury, failure, or various

accidents.

Correctly and securely connect the wires

according to the wiring diagram within the terminal

box and the instruction manual.

Incorrect wiring may cause a fire, electric shock, failure, or

other problems.

1-2

Warning

Be sure to keep the terminal box cover attached

during the operation of the pump.

Otherwise, it may lead to an electric shock.

Be sure to install the coupling cover during the

operation of the pump.

Otherwise, it may lead to an injury or damage.

After detaching the companion flange from the

pump, screw a pipe into it.

Otherwise, it may lead to damage or leakage.

Do not forcibly bend, pull, or pinch the power cable

or any lead wires of the product.

Otherwise, it may lead to an electric shock or fire.

Check the wiring sections and wires for any

looseness.

A loose connection may cause a fire or electric shock.

Before starting the maintenance or inspection

work, be sure to stop the pump and turn off the

main power of the panel board.

Otherwise, it may lead to an electric shock, injury, damage,

or leakage.

Before starting the unit or carrying out

maintenance/inspection work, ensure that all the

relevant workers are informed of the operation and

that there are no workers in the dangerous zone.

Otherwise, it may lead to an unforeseen accident.

Before rotating the main shaft by hand to check its

smooth rotation, be sure to turn off the main power.

Otherwise, it may lead to an injury or damage.

After turning on the power, do not touch any parts of

the pump other than those required for operation.

Otherwise, it may lead to an electric shock or injury.

Do not perform long hours of zero-discharge

operation continuously.

Otherwise, the temperature and pressure may increase

inside the pump, thus damaging the pump or causing steam

to blow off.

Do not put your fingers or foreign objects into any

openings or rotating part of the motor during

operation.

Otherwise, it may lead to an injury or damage.

For overhaul, replacement of parts, or repairs, ask

the vendor or the service center specified by Teral.

If unskilled personnel carry out work that requires special

knowledge, it may lead to an accident or failure.

In the event of a power failure, be sure to turn off the

power switch.

Otherwise, the pump may suddenly start up on restoration of

the power, thus leading to an injury.

Caution

Do not use the unit outside the range of the product

specifications.

Otherwise, it may lead to an electric shock, fire, leakage,

failure, or other problems.

Do not use the unit at an incorrect power voltage.

An incorrect voltage may damage the motor.

Do not use a single pump unit as the only means of

directly operating key facilities or sustaining life.

In the event of a failure, the water supply may stop. Ensure to

make a backup unit available for operation.

Before unpacking the delivered container, check

that the container is placed in the correct

orientation (not upside down). Carefully unpack the

container, while paying special attention to nails.

Otherwise, it may lead to an injury or damage.

Ensure that the floor at the unit’s installation place is

waterproofed and fitted with drainage.

Otherwise, it may lead to serious damage in the event of

leakage.

Do not install two or more different cables or

control wires in one pipe or duct.

Otherwise, it may lead to malfunction of the product or other

equipment.

Do not step on the pump or motor.

Otherwise, it may lead to an injury, damage, or other problems. Do not expose the motor to water.

Otherwise, it may lead to an electric shock, electric leak,

failure, or other problems.

Operate the controls carefully.

Otherwise, it may lead to an injury or damage. Never run the pump dry.

Otherwise, it may lead to damage or a fire.

Before operation, thoroughly clean (flush) the inside

of the piping to remove foreign matter.

Otherwise, the piping system may be contaminated with

foreign matter, thus leading to an accident or a pump failure.

1-3

Caution

Do not put a cloth or other covering on the motor.

Otherwise, it may lead to overheating or ignition. Do not touch the motor body while the pump is

running or immediately after the pump has stopped.

Otherwise, you may get burns from the hot surface.

In the event of an alarm or abnormal condition that

cannot be resolved, immediately stop the

operation, turn off the power, and then contact Teral

or its service provider.

Otherwise, it may lead to an accident.

Do not run the pump with tools or other objects

placed on the unit.

Otherwise, it may lead to an injury or damage.

Check that the delivered items are exactly what you

ordered.

The use of a wrong product may cause an injury or failure.

Do not hold the strainer located on the tip of the

pump.

Otherwise, the strainer may come off, thus leading to an injury

or damage.

Do not place any obstacles around the product that

may hinder ventilation.

Otherwise, it may lead to a fire.

Do not place any combustibles around the product.

Otherwise, it may lead to a fire.

Do not run the pump at a frequency exceeding 60

Hz (50 Hz for models dedicated to 50Hz).

Otherwise, it may lead to motor burnout or a fire.

Do not touch the impeller, tie bolt, strainer, or other

parts of the pump with bare hands.

Otherwise, it may lead to an injury or damage.

Ensure to install an overcurrent protective device.

The user is required by the technical standards for electrical

facilities to install one. Otherwise, it may damage the product,

thus leading to a fire or failure. It is also recommended to

install protective devices such as a ground fault interrupter.

Do not use the unit for pumping any fluids beyond

the specified viscosity limit.

Otherwise, it may lead to motor burnout or a fire.

Do not run the pump with its strainer removed.

Otherwise, it may lead to an injury or damage.

Do not touch any terminals or wires when

measuring the insulation resistance.

Otherwise, it may lead to an electric shock.

Do not touch the Impeller after removing the

strainer.

Otherwise, it may lead to an injury.

Once you turn off the power, wait until the pump

stops completely. Do not restart the pump until it

does.

Otherwise, the main shaft may be subjected to an excessive

load, which makes the service life of the pump shorter.

Do not use thinner or benzine for cleaning the

product.

Otherwise, the product may be discolored or its coating may

be peeled off.

If you use a solvent for cleaning the product, pay

attention to handling of the solvent as well as the

environment of use.

Otherwise, it may lead to poisoning.

When you lift the product, pay attention to its center

of gravity.

Otherwise, the product may topple over or fall, thus leading to

an injury.

Dispose of the product as industrial waste.

Be sure to conduct inspection according to the

Maintenance checklist.

Otherwise, you cannot prevent potential failures, thus leading

to a higher risk of accidents.

When you lift the product by hand, pay attention to

its weight. Do not allow a single person to lift a

product heavier than 15 kg.

Otherwise, it may put strain on the body, thus leading to an

injury.

Do not put your fingers or foreign objects into the

immersion detecting hole.

Failure to observe this may lead to an injury or

damage.

1-4

Motor name plate

1.3 Location of warning labels and caution labels

The figure shows the locations of warning labels and caution labels. If these labels become dirty and

illegible or if they are peeled off, replace them with a new one.

Warning

Caution

Observe all the warnings and cautions affixed to

the machine as well as those described in this

instruction manual.

2-1

2. Configuration and overview of the pump

This chapter describes the standard specifications of the pump. If you have purchased a customized

product, some information in this chapter may not be applicable to your unit. Refer to the delivery

specifications for the details separately.

Caution

Do not use this product under any conditions other than those

provided in the specifications. Otherwise, it may lead to an electric

shock, fire, leakage, or failure.

2.1 Part names and functions

Motor

Discharge port

Suction port (with strainer)

Air vent valve

If air cannot be released from the pump to the

atmosphere on the discharge piping, you can

discharge air using this valve to prevent dry

running.

Immersion detecting hole (LHW-e, LKW-e,

LPW40/50-e,LPW40/50-7W)

If liquid leakage occurred from the immersion

detecting hole, check the shaft sealing part.

Coupling (LPW65-e)

Coupling cover (LPW65-e)

Warning

Caution

Be sure to keep the coupling cover and the strainer attached during

the operation of the pump. Failure to observe this may lead to an

injury.

Caution

Do not put your fingers or foreign objects into the immersion

detecting hole. Failure to observe this may lead to an injury or

damage.

※

The appearance is different according to the model.

Representing model

(The drawing shows LPW40-e) LPW65-e

2-2

2.2 Standard specifications

If you have purchased our standard product, refer to the “Standard specifications” table. If you have also

purchased a customized product with special specifications, refer to the delivery specifications.

・Standard specifications

Model※1LHW-e LKW-e LFE/LFE-e LPW-e LPW-7W

Nominal diameter(mm) 20 20 32/50/65 40/50/65 40/50

LPW40:Water-soluble coolant, liquids

of similar viscosity to water containing

additives (anti-rust agents) and the

like (up to 32 mm2/s for LPW40C, up

to 150 mm2/s for LPW40D※2)

Quality Water-soluble coolant

(dynamic viscosity 1mm2/s)

LPW50/65:Water-soluble coolant

Applicable

liquid

Temperature 0 to 60 °C (No frozen liquid is allowed.)

Installation location

Indoors; height above sea level: 1,000 m or less; ambient temperature: 0 to

40°C; humidity: less than RH85% (no condensing); place not exposed to direct

sunlight; place without any corrosive gas, explosive gas, or vapor in the

atmosphere

Suction casing

(Suction cover)

Discharge casing FC200 FC200 FC200 FC200

Intermediate

casing ARLS ARLS

+(SUS304) - FC200

Impeller ARLS ARLS FCD450 FCD450

Motor Equivalent

to

SUS420J2 S35C S35C LPW40/50:S45C

Material

Main

shaft Pump - LPW65:S45C

Shaft sealing structure Sealless structure(without mechanical seal)

Type Totally-enclosed fan-cooled indoor type

IP protection IP44 LPW40/50:IP44

LPW65:IP55 IP54

Power※33-phase

50/60Hz

200/200-220V

3-phase

60Hz

200-220V

3-phase

50/60Hz

200/200-220V

3-phase

60Hz

208-230/460V

Insulation

class Class F

Motor

Number of poles

2P

Coating color Munsell N1.5

* 1 All the models that the suffix “-e” is appended to the model name are the products with a built-in

premium efficiency (IE3-equivalent) motor.All the models that the suffix “-7W” is appended to the

model name are the products with a built-in UL standard motor.

* 2 Note that the product can be used for the water containing additives (anti-rust agents) such as

water-soluble or non water-soluble coolant, but cannot be used for water.

* 3 Limit the fluctuations of the power voltage within ±10% of the rated voltage, and also limit the

fluctuations of the frequency between –5% and +3% of the rated value. Avoid continuous

operation if the voltage is not within ±5% of the rated value or if the frequency is not within ±2% of

the rated value.

*

3-1

3. Installation

3.1 Before using the pump

Upon receiving the pump, check the following points first.

The container may greatly incline depending on its center of gravity.

Caution

Before unpacking the delivered container, ensure that the container is

placed in the correct orientation (not upside down). Pay special attention to

nails especially when opening a wooden crate. Otherwise, you may get

injured.

(1) Check the nameplate to verify that the delivered product is exactly what you ordered.

(2) No part of the product is damaged during transportation.

(3) All fastening parts including bolts and nuts are securely tightened.

(4) All the accessories that you ordered have been delivered. (Note that the direct operation type

contains the pump and the accessories such as bed in separate packages.)

Warning

Do not hold the strainer on tip of the pump during handling. Failure to

observe this may cause the strainer to come off, resulting in an injury or

damage.

Caution

When lifting the product by hand, pay attention to its center of gravity and

weight. Do not allow a single person to lift a product heavier than 15 kg.

Failure to observe this may cause the burden on the body, resulting in an

injury.

Caution

Do not run the pump at a frequency exceeding 60 Hz (50 Hz for models

dedicated to 50Hz). Failure to observe this may cause an overload and

burnout of the motor.

3.2 Precautions for installation

(1) Install the product in a well-ventilated place with minimum exposure to dust and moisture. In

particular, avoid installing the product in a place where the pumping liquid may be splashed on the

motor section.

Warning

Do not install the product in a place exposed to high temperature and

moisture.

Failure to observe this may cause heating, ignition or electric leakage.

(2) Install the product so that the motor can take air in.

(3) Securely install the product on a flat place without any wobbles.

3-2

(4) Select a convenient place to conduct maintenance and inspection. Secure space for

maintenance.

(5) It is necessary to make a mounting hole larger than the outside diameter of the pump section so

that the pump section can fit into the tank (oil tank). See the dimensional outline drawing.

(6) Install the pump so that the main shaft becomes vertical.

(7) Use the product with the pump section immersed under the oil level. The suction port should be at

least t mm away from the bottom surface of the tank (oil tank) to prevent the strainer from getting

clogged with cutting powder, dirt, or other materials. If cutting powder, dirt, or other materials are

predicted to accumulate on the bottom of the tank, ensure as large a distance as possible from the

bottom at the design stage. Model h t

LHW-e 45 5

LPW40-e(-7W) 65 25

LPW50Z-e 51 25

LPW50ZL-e(-7W) 36 20

LPW65-e 100 50

LKW-e 45 5

LFE32/LFE32-e 60 20

LFE50/LFE50-e 75 20

LFE65-e 100 20

(8) For model LKW-D-e, refer to the drawing below

and assemble the pump main body and

accessories such as bed.

Note

Always keep the liquid level in the tank (oil

tank) above the Minimum liquid level.

Keep the suction port of the pump at least t

mm away from the bottom of the tank (oil

tank), and at least 5 mm away for LKW-D-e

(series operation).

All

models In case that pipes and a strainer

are installed (except for LHW-e)

LKW-D-e

Discharge

Bed

Bush 11/4x3/4B

Street elbow 3/4B

Flexible hose 20Ax500L

Tank

bottom

Min. liquid

level

Suction

No.1

pump

No.2

pump

At least

5mm

3-3

(9) Install the product at a place where a secondary hazard does not occur in the event of any liquid

leak.

(10) If the system could be exposed to the freezing temperature in winter, be sure to apply antifreeze

measures such as heat insulation and heater installation to the pump, valves, piping, etc.

(11) Securely install the pump.

Note

Securely fix the pump in place with the bolts. Otherwise, it may lead to

abnormal vibration or other problems.

(12) To lift the pump, pass a rope or the like through the hanging hole of a casing for the model LHW-e,

LPW40/50-e, LPW40/50-7W and pass a rope or the like through the eyebolt of motor for LPW65-e,

LKW-e, LFE/LFE-e. Do not lift he equipment with the pump attached. Failure to observe this may

cause the equipment to break and fall down.

(13) Use extreme care so as not to give an impact or offset load to the pump section during pump

lifting or conveyance. The pump may greatly tilt depending on its center of gravity.

Warning

Before lifting the pump, refer to the catalog, dimensional outline drawing,

and other documents to check the weight of the units. Do not lift any units if

its weight exceeds the rated load of the hoisting equipment/devices.

Caution

When lifting the pump by hand, pay attention to its center of gravity and

weight. Do not allow a single person to lift a product heavier than 15kg.

Otherwise, the pump may topple over or fall, thus leading to an injury.

(14) If the pumping liquid is cold, condensation may occur inside the motor while the pump is stopped.

Take measures to prevent condensation, for example, by installing the pump in a sufficiently dry

room or by heating and insulating the motor even when the pump is stopped.

(15) Carry out touchup painting at a time interval suitable for the environment of use. Depending on the

humidity, condensation, and other conditions, rust may form on areas such as threaded parts,

worked areas, anticorrosive-coated sections.

(16) Do not put a cover or filter over the motor. Otherwise, the temperature may increase inside the

motor, thus leading to product damage, fire, or other problems.

3-4

3.3 Precautions for piping work

(1) The pipes must be as short and straight as possible with minimal joints and valves. Use pipes

whose bore size is equal to or larger than the discharge port of the pump. If the piping size is small

or there are many bends, the discharge rate may become low.

(2) Ensure to provide adequate pipe supports so that the weight of the piping system will not be

applied directly to the pump body.

Caution

Do not allow the weight of the pipes to rest on the pump.

Failure to observe this may cause the main shaft from coming off center,

resulting in equipment damage, vibration, and noise.

(3) Do not forcibly screw a pipe into the pump. Otherwise, it may break the joint.

(4) Securely connect the pipes so that the connections are kept completely airtight without leakage.

Prevent leaks of liquid and air with seal tape, liquid packing, or other means. Firmly wind the seal

tape while paying attention not to block the piping.

(5) Use a tank (oil tank) with as large a capacity as possible.

* It is recommended to use a capacity of at least three times the discharge volume per minute.

Too small a capacity may cause problems such as the rise of liquid temperature, premature

strainer clogging with cutting powder, and lower discharge rate caused by bubbles.

When pouring a pumping liquid into a tank (oil tank), gently pour it so as not to trap air in.

(6) Do not allow a large amount of cutting powder, dirt, or other contaminants from entering the pump

section. Failure to observe this may clog the pump strainer, damage the pump, or significantly

deteriorate the performance. Before using the coolant pumps, implement the treatment of liquid

through a net cage, a chip conveyor, a magnetic separator, etc as per the table below.

Pumps that can be used after primary treatment LPW-e,LPW-7W

Pumps that can be used after secondary treatment All models

(7) If water hammer may occur, attach a pressure damper (e.g. accumulator).

(8) The pump is packaged with a companion flange for the discharge port. Use it as needed. When

using the flange, be sure to install the supplied O-ring.

(9) If there is an upward curve on the discharge pipe, ensure that air can be vented from the section.

(10) If you provide a relief pipe on the discharge side of the pump, also provide a sluice valve in the

middle of the relief pipe to adjust the relief volume.

Note

If the amount of liquid released from the relief pipe is too much, the liquid

temperature easily rises in the tank (oil tank).

(11) On completion of the piping work, be sure to clean the tank (oil tank) to prevent the suction of

foreign matter.

3-5

3.4 Precautions for wiring work

Danger

Use high-quality wiring equipment and devices, and carry out wiring work

safely and securely according to the technical standards for electrical

facilities, as well as the indoor wiring regulations.

Only qualified personnel such as licensed electrical engineers are allowed

to carry out electrical wiring work. Unqualified persons are prohibited by

law to carry out wiring work, and it is very dangerous.

Danger

Securely connect the terminals of the power cable. Loose terminals may

cause the motor to run in open-phase condition, thus leading to motor

burnout.

(1) Be sure to install a ground fault interrupter and an overload protection device on the primary

power side of the pump.

* The starting current of Top Runner efficiency (equivalent to IE3) motor and UL standard

motor-equipped products tends to become higher than that of standard efficiency (IE1)

motor-equipped products. Therefore, when switching from an IE1 motor-equipped product, it is

necessary to verify the applicability of its ground fault interrupter and overload protection device. If

you have any questions, contact your nearest office of Teral.

Note

When switching from an IE1 motor-equipped product, it is necessary to

verify the applicability of its protection device on the primary side of the

pump.

Failure to observe this may cause the protective device to trip on startup.

(2) When connecting to terminals, securely connect to the power according to the below figure.

3-6

(3) Be sure to attach a ground wire to prevent an electric shock.

Connect the ground wire to the ground terminal inside the terminal box of the motor.

Warning

Connecting a ground wire to gas or water pipes is illegal and extremely

dangerous.

(4) To prevent the terminal block and power cable of the motor from being pulled, fasten the power

cable to the terminal box with the cable lock.

Warning

Do not change the orientation of the terminal box.

Failure to observe this may cause the liquid to entering the terminal box,

thus leading to an electric shock.

(5) To prevent overload and burnout of the motor, it is recommended to use a thermal relay for motor

protection.

(6) Carry out adequate dust-proofing and drip-proofing using a connector or gland so that cutting

powder and liquid coolant do not enter the terminal box through the external wiring hole.

(7) Pass the power cable through a metal tube or a metal conduit for shielding, and connect a ground

wire to the outer surface of the tube.

(8) Limit the fluctuations of the supply voltage within ±10% of the rated voltage, and also limit the

fluctuations of the frequency between –5% and +3% of the rated value. Although you can run the

pump in these ranges, avoid continuous operation if the voltage is not within ±5% of the rated

value or if the frequency is not within ±2% of the rated value. Otherwise, it may overload the pump,

thus leading to motor damage or a fire.

Even if the power fluctuations fall within the allowable ranges, the pump characteristics, motor

characteristics, and the temperature rise of the motor may differ from those at the rated voltage

and frequency.

(9) For direct operation type, set the circuit so that the pumps starts from No.1 then No.2 (or together)

and stops from No.2 then No.1 (or together).

3-7

Warning

Never start the operation with No. 2 pump nor operate No.2 pump only; it

will cause idle operation, leading to the product damage.

(10) Precautions for using the inverter drive

• Ensure that the electric current during operation does not exceed 90% of the rated value.

• Ensure that the minimum frequency is set to 20Hz.

(Contact us if you need to run the drive at 20Hz or lower.)

• When driving a 400V-class motor, contact Teral. In some cases it might be necessary to take

measures for inverter surge.

• An inverter-driven motor generates a magnetic sound which may be annoying compared with

the drives using commercial power supply. Although this magnetic sound does not cause an

adverse effect on the quality of the motor, some inverters allow the user to adjust the tone by

changing the carrier frequency. However, changing the frequency may reduce the allowable

output of the inverter. Pay particular attention when selecting the inverter.

• If the pump and motor produce resonance during normal operation, do not run them in the

range of the rotation speed.

Caution

Do not run the pump at a frequency exceeding 60 Hz (50 Hz for models

dedicated to 50Hz). Failure to observe this may overload the motor,

causing it to burnout. If the models dedicated to 60Hz are run at 50Hz, the

performance will deteriorate.

(11) For LPW65-e, be sure to connect the terminals of power cables in a reversed-phase (by

exchanging R with T of the power cables). If the terminals are connected in a positive phase, the

pump rotates in the reverse direction, which may cause damage. For the other models, connect

the terminals of power cables in a positive phase.

Caution

For LPW65-e, be sure to connect the terminals of power cables in a

reversed-phase (by exchanging R with T of the power cables). If the

terminals are connected in a positive phase, the pump rotates in the

reverse direction, which may cause damage.

4-1

4. Operation

4.1 Check items before test operation

4.1.1 Check items related to the electrical system

(1) Check that the equipment is correctly wired.

(2) Check that the terminals are securely connected.

(3) Check that the equipment is securely grounded.

(4) Check that the setup value of the overload protection device is consistent with the rated current

value of the motor.

(The rated current of pump should be included in the setting range of the device around the

middle.)

Warning

Do not use the product at any voltage other than the rated value.

Excessive voltage may cause a fire or electric shock.

4.1.2 Check items related to the pump

Caution

Do not allow a large amount of foreign matter from entering the pump.

Failure to observe this may cause damage to the sliding parts (e.g.

bearings) inside the pump, leakage or unusual noise.

(1) Ensure that the liquid level in the tank (oil tank) is above the “Minimum liquid level.”

Caution

Never run the pump dry (running the pump when the liquid level

is below the Minimum liquid level). Failure to observe this cause

the sliding parts inside the pump to seize up.

(2) Check the rotation direction. Normal rotation is clockwise when viewed from the

motor side. (See the right figure.)

(3) To rotate the shaft by hand, insert a flat-blade screwdriver through the fan cover of

the motor and turn its shaft (Remove the end cap from the motor shaft). If the

rotation is stiff or not uniform, there may be some rust or foreign matter inside the

pump. Inspect the pump in such a case.

(4) After rotating the shaft by hand, install the end cap again.

Warning

Before rotating the main shaft by hand to check it, be sure to turn off the

main power.An unexpected start of the pump may cause an accident.

(5) Open the air vent valve to release air. After the air release, close the air vent valve. If no air vent

valve is provided, open the valve on the discharge piping to release air.

Rotation direction

4-2

(6) If you run the motor at variable speed with the inverter, be sure to check the following points

through test operations.

· The pump may produce resonance depending on installation conditions. If the pump

produces resonance, avoid that frequency.

· If the operation frequency is low or the dynamic viscosity of the pumping liquid is high, the

pump may not discharge any liquid.

· Do not run the pump at a frequency exceeding 60 Hz (50 Hz for models dedicated to 50Hz).

Failure to observe this may cause burnout of the motor.

Caution

Do not run the pump at a frequency exceeding 60 Hz (50 Hz for models

dedicated to 50Hz). Failure to observe this may cause an overload and

burnout of the motor. If the models dedicated to 60Hz are run at 50Hz, the

performance will deteriorate.

4.2 Running the pump (test operation)

Warning

Be sure to attach the cover of the terminal box of the motor.

Failure to observe this may cause an electric shock.

Warning

Be sure to keep the coupling cover and the strainer attached during the

operation of the pump. Failure to observe this may cause an injury.

Warning

Do not operate the pump if any abnormal condition is observed or if there

is anything wrong with the parts, components, etc. during the check before

test operation. Failure to observe this may cause an injury, failure,

accident, or other problems.

Warning

If the liquid used exceeds 40°C, do not touch the pump.

Failure to observe this may cause burn on the skin due to high temperature

of the pump.

Warning

Do not touch the motor during operation or immediately after the stop of

operation.

Failure to observe this may cause burn on the skin due to high temperature

of the pump.

4-3

(1) Check the rotation direction of the pump by turning ON and OFF the power switch once or twice.

For LKW-D-e (series operation), turn ON in the order of No.1 pump and No.2 pump or both pumps

simultaneously, and turn OFF in the order of No.2 and No.1 or both simultaneously. Normal

rotation is clockwise when viewed from the motor side. (For LPW65-e, be sure to connect the

terminals of power cables in a reversed-phase (by exchanging R with T of the power cables). If

the terminals are connected in a positive phase, the pump rotates in the reverse direction, which

may cause damage.)

If the pump rotates in reverse, swap two of the three wires of the power cables.

Caution

Do not check the rotation direction by running the pump dry. Running the

pump dry even for a short time may cause damage to the sliding parts (e.g.

bearings) in the pump, leakage or unusual noise.

Caution

Avoid reverse rotation because it may cause a failure.

For the model LPW65-e, be sure to connect the terminals of power cables

in a reversed-phase to prevent the reverse rotation.

Caution

Do not run the pump dry, and do not allow a large amount of air or foreign

matter from entering the pump. Failure to observe this may cause damage

to the sliding parts (e.g. bearings) in the pump, disability of pumping,

leakage or unusual noise. It may also heat the pump, thus leading to burns.

(2) If an air vent valve is installed on the pump, slightly open the valve upon startup, and confirm that

liquid is discharged.After confirming the discharge, ensure to close the air vent valve.

(3) Turn on the power to start the pump. For LKW-D-e (series operation), run the pump in the order of

No.1 pump and No.2 pump or both pumps simultaneously

Warning

Never start the operation with No. 2 pump nor operate with No.2 pump

only; it may cause the pump dry running, leading to the product damage.

(4) During the initial period of pump operation and circulation, gradually open the sluice valve on the

discharge side to circulate liquid at a flow rate (flow velocity) higher than the normal operation.

(5) Adjust the sluice valve on the discharge side so that the specified pressure is achieved. Do not

continue no-discharge operation for a long time. Long hours of continuous no-discharge operation

will increase the liquid temperature in the pump. Therefore, allow a small amount of liquid to flow

as per table below, or if you no longer use the liquid, stop the pump. Too hot liquid may reduce the

service life of the motor or damage the shaft seal.

Model Minimum flow of liquid (L/min)

LHW-e, LFE/LFE-e 2

LKW-e, LPW-e,LPW-7W 6

4-4

Warning

Do not perform long hours of no-discharge operation continuously.

Failure to observe this may increase the temperature in the pump, resulting

in an unexpected failure.

(6) When the liquid level is too low, the pump may take air in and decrease the discharge rate, thus

making it impossible to pump the liquid. Keep the liquid level above the “Minimum liquid level”

indicated in the Dimensional outline drawing. Note that, however, this liquid level changes

depending on the viscosity and liquid surface condition. For safety, set the liquid level high

enough, but at a level below the “Maximum liquid level” indicated in the outline drawing.

(7) For the frequency of the startups and shutdowns, refer to the table below.

Model Allowable frequency of the startups

and shutdowns (times / hour)

LHW-e, LPW40/50-e, LPW40/50-7W,

LKW-e, LFE/LFE-e 60

LPW65-e 20

Caution

Minimize the frequency of startups and shutdowns of the pump because

their high frequency may quickly damage the pump.

(8) In the event of a power failure during operation, be sure to turn off the power.

(9) Before restarting the pump, confirm that the pump has completely stopped.

Caution

Before restarting the pump, be sure to check that the pump has completely

stopped. Turning on the power while the pump is still rotating causes an

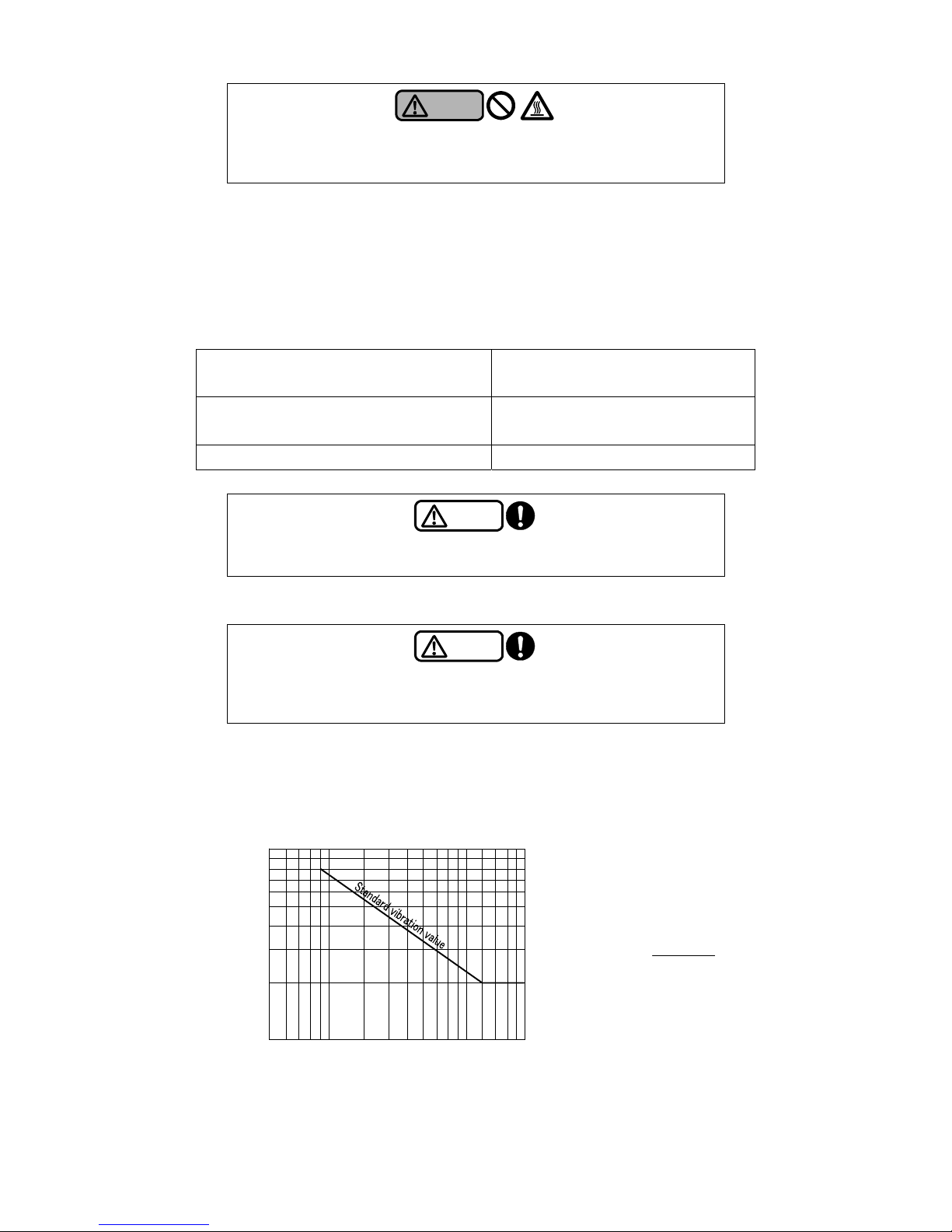

excessive torque on the pump and may cause a failure.

(10) Avoid sudden pressure fluctuations during the operation of the pump.

(11) Check for any abnormal pressure, electric current, vibration, noise, and other conditions. If you

find any abnormal conditions, take appropriate actions after consulting the Section “6.

Troubleshooting (page 5-4).”

Refer to the following chart for vibration vs. rotation speed.

Rotation speed (min-1)

Standard vibration value at the bearing section

[For reference only]

Relation between the total amplitude (a)

and the vibration velocity (V)

a = V×6×104

π×n

a: Total amplitude (μm)

V: Vibration velocity (mm/s)

n: Equipment rotation speed (min-1)

80

60

40

20

10 600 800 1000 1500 2000 3000 4000 6000 8000

100

Total amplitude

(1/1000 mm)

This manual suits for next models

5

Table of contents

Other Teral Water Pump manuals

Teral

Teral SJS User manual

Teral

Teral VFZ Series User manual

Teral

Teral VKN Series User manual

Teral

Teral LP User manual

Teral

Teral Patron SP-10 User manual

Teral

Teral VKN-e Series User manual

Teral

Teral MSU User manual

Teral

Teral NSVM Series Installation instructions

Teral

Teral VKD-e Series User manual

Teral

Teral LVS-e Series User manual